DOI: 10.11817/j.issn.1672-7207.2020.11.002

C/N物质的量比和金属碳化物对TiCN-Ni合金体系润湿行为的影响

张立,肖桥平,刘涛,凌群,罗国凯,吴厚平,崔焱茗

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:采用座滴法分别测量真空条件下Ni熔体与TiC0.4N0.6,TiC0.7N0.3,TiC0.7N0.3-29WC-12TaC和TiC0.7N0.3-29WC-12TaC-2Mo2C基体之间的接触角,采用扫描电镜和能谱分析仪分析润湿性测试后合金体系微观结构与成分变化。对Mo2C显著改善合金体系润湿性的机理、层状结构形成机理、WC和TaC在合金中作用行为等进行分析,提出液相烧结合金体系润湿性的改善方法及其综合评价方法。研究结果表明:该合金体系的初始接触角分别为24.5°,21.2°,19.8°和14.2°,4种基体中均形成了层次分明的富Ni和贫Ni层状结构,合金体系属于扩散和溶解驱动型润湿;在TiC0.4N0.6基体表面出现了Ni熔体显著蒸发及其在基体中扩散和渗透能力显著弱化的独特现象。

关键词:金属陶瓷;黏结金属;润湿性;接触角;层状结构;熔体渗透

中图分类号:TG14 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3007-12

Effects of C/N molar ratios and metal carbides on wetting behaviors of TiCN-Ni alloy system

ZHANG Li, XIAO Qiaoping, LIU Tao, LING Qun, LUO Guokai, WU Houping, CUI Yanming

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The contact angles between Ni melt and TiC0.4N0.6, TiC0.7N0.3, TiC0.7N0.3-29WC-12TaC, TiC0.7N0.3-29WC-12TaC-2Mo2C substrate in vacuum were measured by sessile drop method. The microstructure and composition changes of the alloy systems after the wettability tests were observed and analyzed by scanning electron microscope and energy dispersive spectrometer. The mechanisms of substantially improved wettability of the alloy system by Mo2C and the formation of layered structure, and the behaviors of WC and TaC in the alloy were analyzed. Improvement and comprehensive evaluation methods for the wettability of alloys by liquid phase sintering were proposed. The results show that the initial contact angles of the above alloy systems are 24.5°, 21.2°, 19.8° and 14.2° respectively, driven by a diffusion- and solution-driven wetting mechanism. In the four substrates, a distinct Ni-rich and Ni-deficient layer structure is formed. For the TiC0.4N0.6 substrate, a unique phenomenon of significantly evaporation and significantly weakened diffusion and penetration ability of Ni melt is identified.

Key words: cermet; binder metal; wettability; contact angle; layer microstructure; melt infiltration

在金属矿山粉尘治理、金属材料焊接以及粉末冶金材料等领域,润湿性是一个非常重要的物理参数。王嘉莹等[1]关于南京梅山铁矿采掘面爆破粉尘润湿性的研究结果表明,粒径和真密度是影响粉尘润湿性能的关键因素,粒径与真密度越小,粉尘疏水性越强;尘粒表面的化学特性并不是影响粉尘润湿性的关键因素,与亲水粉尘相比,疏水粉尘表面亲水物相含量更高,表面疏水基团含量更低,其化学属性与其被润湿行为之间存在明显的不一致性。这一现象的发现为疏水粉尘的有效治理提供了新的思路。在金属材料焊接领域,焊接过程中熔体在焊接面的铺展能力(润湿性)、焊接材料之间热膨胀系数匹配性、界面反应产物、界面结构等对焊接强度和焊接材料的耐腐蚀性等均具有显著影响[2-3],因此焊料的选择重在协同设计。在粉末冶金材料领域,液相烧结是制备难熔金属材料、硬质合金、金属陶瓷、陶瓷复合材料等最基本的工艺。合金体系的润湿性对液相烧结粉末冶金材料的致密化行为、合金微观结构均质性和均匀性以及合金性能等均具有重要影响[4-5]。基于研究对象的特殊性,不同行业背景的研究者会从不同的视角开展对润湿性的相关研究。

作为一种对战略性钨资源依赖度较低的硬质材料,相对传统硬质合金,TiCN基金属陶瓷具有摩擦因数低、耐高温性能好、化学稳定性高、质量轻等优势。目前TiCN基金属陶瓷已成功应用于一些金属材料的高速半精加工和精加工[6-8]。虽然TiC和TiCN具有比WC更高的硬度,但TiCN基金属陶瓷相对较低的强度和韧性已成为制约其推广应用的瓶颈。TiCN基金属陶瓷新型黏结金属及其微观结构影响机理的研究是改善其强度和韧性的重要途径。合金体系的润湿性是新型黏结金属的研发中普遍关注的问题[9-10]。通常采用接触角θ评估液相对固相的润湿性,因此接触角又被称为润湿角。目前,粉末冶金材料体系的润湿性研究主要集中在接触角表征、润湿机制以及熔体铺展动力学等方面,涉及接触角以及熔体与基体之间的交互作用对合金微观组织结构影响的研究很少。Ni是TiCN基金属陶瓷黏结金属最基本的组元。本文作者探讨TiCN原料中C/N物质的量比和常见过渡族金属碳化物组元对Ni熔体与基体之间交互作用行为的影响,分析合金体系接触角的量变导致合金微观组织结构突变的现象。研究结果为TiCN基金属陶瓷的材料与工艺设计以及对合金体系润湿性内涵的解析提供了新的视角,是TiCN基金属陶瓷黏结金属间协同作用研究的重要组成部分。

表1 TiCN固溶体粉末的主要技术参数

Table 1 Main technical parameters of titanium carbonitride solid solution powders

表2 b-TiCN基金属陶瓷基体的名义成分

Table 2 Nominal compositions of binderless TiCN substrates

1 实验

1.1 无黏结相TiCN基金属陶瓷基体的制备

采用C/N物质的量比分别为4:6和7:3的2种TiCN固溶体粉末为原料,其主要技术指标见表1。4种无黏结相TiCN基金属陶瓷(b-TiCN)的名义成分见表2。b-TiCN中金属碳化物添加剂WC,TaC和Mo2C原料粉末的费氏粒度(FSSS)分别为1.0,1.0和1.8 μm。采用放电等离子烧结(SPS)技术烧结制备直径为20 mm的b-TiCN基体,设备型号为FCT SPS Systems GmbH,加载压力40 MPa,烧结温度1 800 °C,保温10 min。测试结果表明[11],4种b-TiCN的相对密度≥98.5%,均为fcc-TiCN单相固溶体物相结构。润湿性测试前,对b-TiCN基体表面依次进行研磨、抛光和在无水乙醇中超声波清洗等处理。

1.2 润湿性实验和样品微观结构分析

采用配备金刚石切割刀片的金刚石切割机将高纯Ni金属块体(纯度≥99.99%)切割成长×宽×高为3 mm×3 mm×3 mm的立方体。润湿性测试前,对高纯Ni金属块体表面依次进行研磨、抛光和在无水乙醇中超声波清洗等处理。真空烧结是制备金属陶瓷最常用的工艺。本研究采用座滴法[12-13]测试真空条件下Ni熔体与4种b-TiCN基体之间的接触角。测试设备为KRUSS GmbH高温液滴形状分析仪。基本操作步骤如下:

1) 将b-TiCN基体放置在高纯刚玉材质的样品支撑平台,借助水泡水平仪将其调整至水平;

2) 将金属Ni块置于b-TiCN基体上表面的中央位置;

3) 将样品及其支撑平台推入加热炉的高纯刚玉炉管内;用机械泵对炉体抽真空至≤2 Pa,随后启动分子泵抽真空至9 mPa;

4) 以8 °C/min的加热速率升温至1 500 °C;

5) 根据合金体系的特点,在炉内温度达到1 420 °C时,启用高速CCD相机对Ni的熔化过程进行录像记录,并将此时间定义为润湿性测试初始时刻(t=0 s);

6) 当炉内温度达到1 500 °C时,保温5 min,关闭CCD相机,随炉冷却。采用ADSA(axisymmetric drop shape analysis)接触角分析软件,结合人工描点拟合和Image J软件计算处理,获得接触角。因熔体与基体之间的接触角通常会随温度升高而发生变化,为了便于相对比较,将金属块体完全转变为液相的第一时间相应的温度称为完全熔化温度,金属熔体与固态基体之间形成的接触角定义为初始接触角。

为了分析润湿性测试后样品微观组织结构的变化,采用金刚石切割机沿熔体中心位置将样品分割,随后依次进行镶样、研磨和抛光等处理;观察与分析设备为配备能谱仪(EDS)的FEI Quanta FEG 250场发射环境扫描电镜(SEM)。

2 结果与讨论

2.1 润湿过程

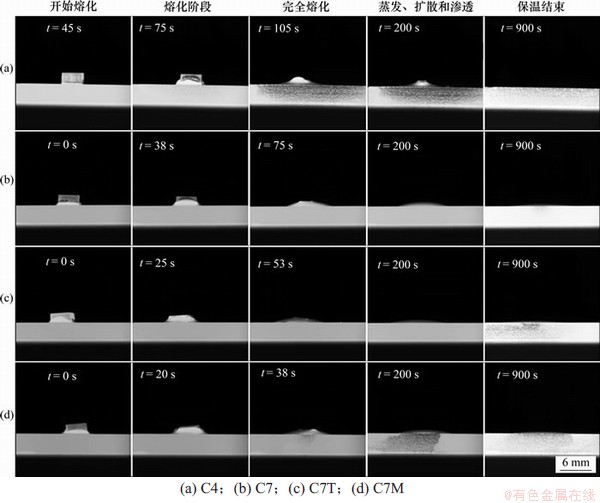

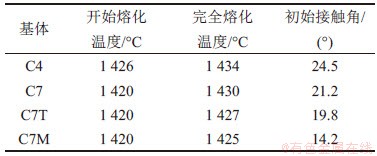

图1所示为金属Ni熔体在4种b-TiCN基体表面的润湿过程中形貌的变化。表3所示为Ni熔体在4种b-TiCN基体表面的润湿过程的开始熔化温度、完全熔化温度和初始接触角。

图1 Ni在4种b-TiCN基体表面的润湿过程(t=0 s时初始温度为1 420 °C)

Fig. 1 Wetting process of Ni on TiCN substrates (initial temperature is 1 420 °C at t=0 s)

表3 Ni熔体在b-TiCN基体表面润湿过程的典型参数

Table 3 Typical parameters of Ni melt on TiCN substrates during wetting process

纯金属Ni的熔点是1 455 °C。由表3可知,高纯金属Ni在4种基体表面的开始熔化温度均低于其熔点,在C4基体表面开始熔化温度为1 426 °C,在其他3种基体表面的开始熔化温度为1 420 °C,基体中的C/N物质的量比是影响Ni开始熔化温度的主要因素。由图1可知,在4种基体表面的金属Ni均从其底部开始熔化。真空条件下,金属Ni块受热方式主要有2种,即热辐射和热传导。显然,真空环境下与基体接触的Ni块底部区域最先开始熔化的现象与热传导所导致的热滞后效应有关。

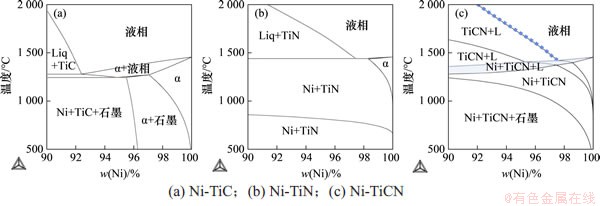

图2所示为Ni-TiC,Ni-TiN和Ni-TiCN合金靠近Ni端的伪二元相图。由图2可知,Ni-TiC合金的共晶温度为1 270 °C[5];Ni-TiN和Ni-TiCN合金未出现共晶反应,其中Ni-TiN合金液相出现的最低温度约为1 426 °C;温度<1 000 °C,TiN中的Ti和N原子在Ni中的固溶度近似为0,而TiC中的Ti和C原子在Ni中依然存在一定的固溶度。由此可以推断,相对其他3种基体,C4基体(TiC0.4N0.6)中相对较低的C/N物质的量比是导致Ni在C4基体表面开始熔化温度增加的主要原因。

图2 Ni-TiC,Ni-TiN,Ni-TiCN的伪二元相图[5]

Fig. 2 Pseudobinary phase diagrams of Ni-TiC, Ni-TiN and Ni-TiCN[5]

由图1可以看出,在初始接触角形成后,Ni熔体存在体积不断减小现象。Ni在1 500 °C的蒸汽压为0.813 Pa[14-15]。DONG等[16]测量了液态Ni2Cr12Al合金中组元Ni在1 151~1 363 °C的分蒸汽压,结果表明,随温度升高,Ni蒸汽压呈线性增加,1 151 °C和1 363 °C时分别为1.2 mPa和0.12 Pa,明显高于合金组元Cr和Al的分蒸汽压;在NiCrAl合金中,相对合金组元Cr和Al,Ni的分蒸汽压对合金成分的敏感度明显较低。本润湿实验在液相出现后,炉内真空度在3.5~4.7 mPa之间。显然,在此真空条件下存在Ni蒸发现象。基于Ni熔体具有高蒸汽压的特点以及Ni与b-TiCN基体之间的合金化行为,可将合金体系的升温润湿过程分为2个阶段,即以扩散和熔化为主体的阶段和以蒸发、扩散和熔体渗透为主体的阶段。在扩散和熔化阶段,随温度升高,Ni与b-TiCN基体之间的双向扩散加速,界面附近首先出现合金化,从而导致靠近基体的金属Ni首先开始熔化,并向四周铺展,直至完全熔化。C4,C7,C7T和C7M基体表面的金属Ni块体分别在1 434,1 430,1 427和1 425 °C时完全转变为液相(见表3)。显然,完全熔化温度有规律地降低,与基体中合金组元向Ni中的扩散行为和元素间的合金化行为密切相关。由于热滞后效应和液相出现之前原子间扩散相对缓慢,基体对Ni的开始熔化温度和完全熔化温度的影响不显著。

只有在超润湿状态[17]下才出现液体在固体表面完全铺展的状态(接触角为0°或接近0°)。完全熔化时,Ni熔体在b-TiCN基体表面呈圆润状态(呈圆弧状);在完全熔化的第一时间,Ni熔体与C4,C7,C7T,C7M基体之间的初始接触角分别为24.5°,21.2°,19.8°和14.2°(见表3)。在蒸发、扩散和熔体渗透阶段,由于在真空条件下Ni同时存在蒸发以及在基体中的扩散和渗透行为,基体表面的熔体体积会逐渐减小。值得指出的是,上述2个阶段没有明显界限,即使在熔化阶段也存在熔体的蒸发、扩散和渗透行为。

接触角θ<90°是采用液相烧结工艺制备粉末冶金制品的前提条件。合金体系的润湿性对合金的烧结致密化具有重要影响[18-19]。由表3可知,与C7基体相比,Ni熔体在C4基体表面的初始接触角提高幅度为16%,说明高N含量TiCN基金属陶瓷合金体系的润湿性相对较差。ALVAREDO等[5]关于Ni/TiN,Ni/TiC,Fe/TiN,Fe/TiC合金体系润湿性的对比研究结果表明,在1 500 °C、Ar气氛中分别保温200 s和600 s,Ni/TiN体系的接触角由71°减少至55°,Ni/TiC体系的接触角由30°减少至25°;1 550 °C、Ar气氛中分别保温200 s和600 s,Fe/TiN体系的接触角基本维持在93°,而Fe/TiC体系的接触角基本维持在3°。显然,本研究关于高N含量TiCN基金属陶瓷合金体系润湿性变差的结果与上述研究报道[5]具有较好的一致性。由表3可知,与C7基体相比,Ni熔体在C7T和C7M基体表面的接触角分别降低7%和33%,表明添加WC和TaC对合金体系润湿性的改善作用较小,而额外添加2%Mo2C(质量分数)对合金体系润湿性的改善作用显著。Mo2C显著改善TiN-Ni合金体系[19-20]和TiCN-Fe合金体系[18,21]的润湿性已有报道。ALVAREDO等[21]研究了Ar气氛下Fe,Fe-6.6WC 和Fe-5.1Mo2C熔体与TiC0.5N0.5基体间接触角随温度的变化。结果表明,在保温250~300 s时,上述熔体与基体之间的终态接触角分别为100°,70°和38°,Mo2C对润湿性的改善效果明显比WC的优。

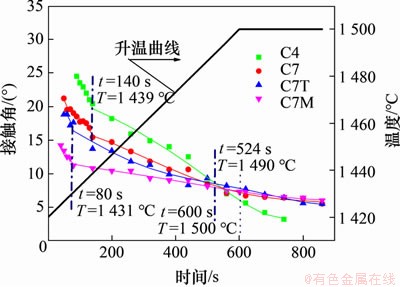

图3所示为连续升温过程中Ni熔体与b-TiCN基体之间的接触角随时间和温度的变化曲线。由图3可以看出,随时间增加,即随温度增加,接触角呈下降趋势,其变化可分为3个阶段,即迅速下降(阶段1)、缓慢下降(阶段2)和趋于稳定阶段(阶段3)。对C4和C7基体,第1阶段的终结时间和温度分别为140 s和1 439 °C;对C7T和C7M基体,第1阶段的终结时间和温度分别为80 s和1 431 °C。在第2阶段,4组基体对应的接触角之间的差异随温度升高逐渐变小;当温度1 490 °C,终结时间524 s时,4组基体对应的接触角非常接近,为8.0°~8.5°。在1 490~1 500 °C以及1 500 °C保温阶段(阶段3),C4基体表面的熔体快速消失,表现出接触角最小化现象;其他3组基体对应的接触角仅呈现微弱下降趋势。1 500 °C保温5 min结束时,除C4基体外的其他3组基体对应的接触角(终态接触角)为5.3°~5.8°。

图3 Ni熔体在不同基体表面润湿过程中接触角随时间和温度的变化曲线

Fig. 3 Evolution of contact angles of liquid Ni in contact with b-TiCN substrates with time and temperature

由图2(c)可知,除出现液相和在冷却阶段从Ni基黏结相中析出石墨相以外,合金体系没有其他新相形成。因此,可以预测TiCN-Ni基合金体系的润湿属于扩散和溶解驱动型润湿。KONYASHIN等[22]发现,长期以来关于WC-Co合金体系θ=0的认识存在误区,在出现渗碳相的条件下,黏结相模型合金WC-65Co-2C熔体与WC基体之间的接触角约为15°(真空测试条件)。GREN等[23]采用密度泛函理论论证了KONYASHIN等[22]关于WC-Co合金体系的接触角受合金总碳含量影响的正确性。KONYASHIN等[22]的研究结果表明,WC-Co合金微区中总碳含量变化所导致的接触角的差异化是导致合金体系黏结相呈梯度变化的主要机制。因此,除影响合金体系的烧结致密化行为以外,接触角随温度的变化规律也会影响合金的微观均质性。初始接触角是影响液相烧结阶段合金烧结致密化动力学的一个重要参数。初始接触角越小,毛细力越大,越有利于液相渗入两固相之间,越有利于液相沿固相晶界扩散,越有利于阻止固相晶粒之间的并合生长,从而有利于合金组织结构的均匀化。

2.2 熔体与基体间的交互作用以及合金体系润湿性的影响机理

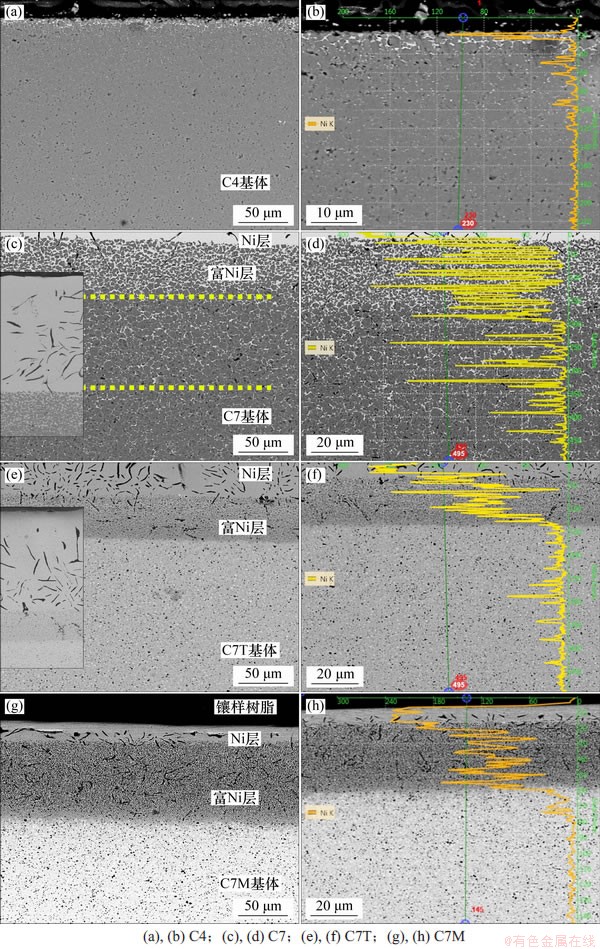

聚焦Ni熔体凝固层和基体微观结构整体特征的典型观察与分析结果见图4,其中,图4(c)和4(e)中带外框的叠加图片补充展示了Ni熔体凝固层全貌。由于不同区域合金组元的加权平均原子序数不同,在背散射模式下可观察到不同颜色衬度(Z-衬度)的组织。对C4和C7样品,由于Ni的原子序数大于基体中Ti,C,N合金组元的加权平均原子序数,因此相应微观组织中Ni基组元(Ni相)呈亮色。对C7T和C7M样品,由于基体中存在高原子序数的W,Ta和Mo(C7M中),基体中Ni相颜色偏暗。由图4(a)和4(b)可知,因Ni熔体对C4基体的润湿性相对较差,Ni熔体向基体中的扩散和渗透量极少,蒸发现象非常显著,因此未能观察到Ni熔体凝固层。图4(c)~4(h)中,从上至下依次存在Ni熔体凝固层(简称Ni层)、Ni扩散和渗透至基体所形成的Ni富集层(简称富Ni层)和贫Ni层。因Z-衬度差异明显的优势,在C7基体中可观察到2种不同贫乏程度的贫Ni层(见图4(c)中水平虚线标识)。结果表明,Ni蒸发以及Ni扩散和渗透至基体的动力学过程受制于基体的化学成分属性。

图4 润湿性测试后样品抛光截面低倍微观结构的SEM照片和Ni分布线扫描分析结果

Fig. 4 SEM images and element Ni EDS line scan analysis results of cross sectional microstructure at low magnification after wettability test

由图4(a)和4(b)可知,C4基体中富Ni层平均厚度<10 μm,贫Ni层平均厚度<20 μm。从微观组织结构分析结果可以推断,随温度升高,位于C4基体表面Ni熔体蒸发不断加剧,因此图3中温度>1 490 °C时C4基体对应的接触角测量数据已不具参考价值。由图4(c)~4(h)可知,C7与C7T和C7M基体的微观组织结构存在明显区别,W和Ta的添加改变了Ni在基体中的合金化行为。对C7,C7T和C7M基体对应的合金体系,分别选取相应的3个典型视场,测量基体中富Ni层厚度和Ni熔体凝固层厚度。C7,C7T和C7M基体合金体系的平均厚度分别为58,49和89 μm,其Ni熔体凝固层厚度平均厚度分别为178,155和18 μm。显然,Mo2C可显著加速Ni在基体中的扩散与渗透。

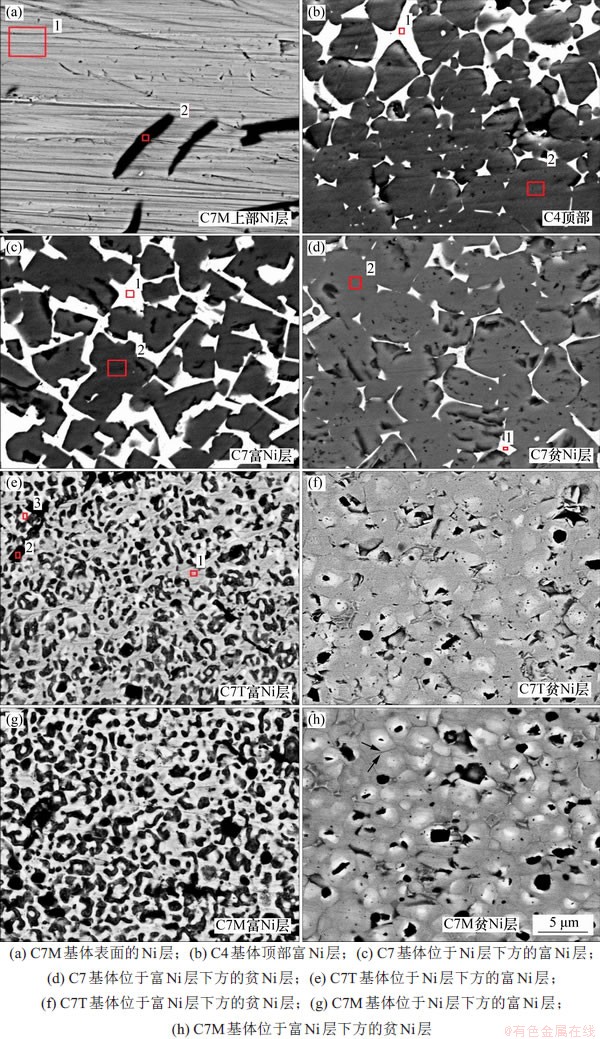

为了探讨基体中合金组元向Ni熔体中的扩散及其合金化行为,以及基体中合金组元对Ni熔体在基体中扩散和渗透及其合金化行为的影响,对润湿性测试后样品抛光截面的微观组织结构及其成分特征在高倍率条件下进行了观察与分析。图5和表4所示分别为典型的微观组织结构及其成分分析结果。图5中贫Ni层选取位置靠近富Ni层区域。

图5 润湿性测试后样品抛光截面微观结构的SEM照片

Fig. 5 SEM images of cross sectional microstructure after wettability test

表4 图5中典型微区的EDS分析结果(质量分数)

Table 4 EDS analysis results of typical micro zones shown in Fig.5 %

由图5可见:位于C7,C7T和C7M基体上部的Ni层具有类似的微观结构特征,除N不能在Ni中固溶以外,包括C在内的基体中其他合金组元均能通过扩散在Ni中固溶;与此同时,由于高温和室温条件下C在Ni中的固溶度差异明显,Ni基固溶体中存在不规则形状的石墨析出相(见图5(a)C7M基体)。这一现象可用Ni-TiCN伪二元相图(图2(c))中存在Ni+TiCN+石墨的3相区来解释。在放大10 000倍的条件下,随机选取C7,C7T和C7M基体上部Ni层中的典型视场进行EDS分析。结果表明,在C7,C7T和C7M基体上部Ni层中Ni质量分数分别为80.9%,84.2%和81.2%,C质量分数分别为16.8%,12.1%和10.1%,固溶金属元素总质量分数分别为2.3%,3.7%和8.7%;其中Ti质量分数分别为2.3%,1.6%和1.3%;W和Ta质量分数分别为1.6%和1.0%(C7T),2.1%和4.9%(C7M)。由此可推断,Mo可促进W和Ta向Ni中扩散与固溶。Ni层中高C含量特征和石墨析出相的存在,表明C在Ni熔体中存在快速扩散行为。由表4可知,图5(a)中石墨相中标识微区(微区2)的EDS分析结果中存在除C以外的其他元素,类似情况在C7和C7T基体上部的Ni层中同样存在。出现这种情况可能与石墨析出相径向尺寸小,不可避免存在Ni基体对EDS分析结果的影响有关,但不排除C与其他合金元素之间存在合金化行为的可能。

经计算可知,TiC0.7N0.3-29WC-12TaC(C7T基体)中单元素Ti,W,Ta,C,N的质量分数分别为46.7%,27.2%,11.3%,10.7%和4.1%;TiC0.7N0.3-29WC-12TaC-2Mo2C(C7M基体)中单元素Ti,W,Ta,Mo,C,N的质量分数分别为45.1%,27.2%,11.2%,2.0%,10.5%和4.0%。对比Ni熔体中和基体中Ti,W,Ta的原始比例可知,各金属组元向Ni中扩散与固溶的能力从强到弱依次为Ta,W和Ti。分别位于C7,C7T和C7M基体上部Ni层中的其他典型视场的分析结果证实了Ti,W和Ta在Ni中扩散与固溶能力的上述排序结果。N,Ti,W和Ta的电负性参数分别为3.04,1.54,2.36和1.50,因此,N与Ti和Ta之间的结合力差距较小。基于基体中合金组元已形成单相固溶体,因此难以从单一的原子间结合能力解析上述金属组元向Ni中扩散与固溶能力的排序结果。

基于N不能在Ni中溶解、Ti原子向Ni熔体中的扩散量相对较少等事实,可以推断,真空条件下,Ni熔体中合金组元及其含量的变化以及熔体与基体之间接触角的改变能导致Ni熔体蒸发量及其在基体中扩散和渗透量的突变。因此,在满足液相烧结致密化对接触角的基本要求条件下(小于90°),难以从初始接触角和终态接触角,对合金体系的润湿性进行明确的等级区分(超润湿状态除外)。因4组基体对应的终态接触角非常接近,而合金体系之间的润湿行为存在明显差别,可以推断,终态接触角仅能用作合金体系润湿性评价的次要参数。

由表4可知,C4,C7,C7T和C7M基体中富Ni层中(5(b),5(c),5(e)和5(g))Ni的质量分数分别为10.8%,28.0%,39.5%和38.9%。从富Ni层中Ni质量分数可以解释C7和C7T合金基体表面Ni熔体凝固层的平均厚度(分别为178 μm和155 μm)与基体中富Ni层平均厚度(分别为58 μm和49 μm)之间的不一致现象。从微观组织结构及其成分特征可以判断,4种基体中富Ni层均具有典型的硬质相+Ni基固溶体黏结相的2相结构,但其中的硬质相形貌存在明显差别。在高Ni质量分数以及液、固之间充分接触的条件下,C7基体TiCN硬质相中Ti和C在Ni中的快速溶解和快速析出的动态循环行为导致了Ni基熔体表面张力和液固界面能的迅速变化,从而使硬质相与黏结相的界面大部分呈现平直化,同时使硬质相形貌的不规则性明显增加。这种高黏结相中硬质相晶粒形貌的不规则性明显增加并伴随硬质相结晶完整性明显降低的现象在文献[24]中已有报道。由图5(c)中微区1的EDS分析结果可知,通过Ni熔体向基体中扩散和渗透以及TiC0.7N0.3硬质相中Ti,C在Ni中固溶形成的Ni基黏结相中,C和Ti的质量分数分别为3.3%和4.2%,Ni基黏结相中Ti质量分数明显比位于其上部Ni层的高。由于基体中C优先向位于其表面的Ni熔体中扩散,N不能固溶于Ni中,因此C7基体上部的TiCN硬质相中C/N物质的量比明显比原始成分低(见表4)。

由于C7T和C7M基体中Ni基黏结相与(Ti,M)CN硬质相(M为W,Ta,Mo)外层(环部)中元素的加权平均原子序数比较接近,没有形成明显的Z-衬度效应,在其富Ni层中难以通过视觉分辨Ni基黏结相,因而也难以识别硬质相的形貌特征。相对Ti,W和Ta更容易在液态Ni中发生溶解与析出,因此C7T和C7M富Ni层中(Ti, M)CN硬质相的芯环结构特征更加明显,其芯部以低加权平均原子序数的Ti,C和N为主体,环部以高加权平均原子序数的W,Ta,(Mo)和C为主体。C7T和C7M基体中W/Ta质量比均为2.4,但C7T和C7M基体中富Ni层中W/Ta质量比分别为0.97和0.60(图5(f)和5(g)),这一结果证实了通过对基体上部残留Ni层分析所得出的结论,即Ti,W和Ta等3种元素中,Ta在Ni中固溶更具优势,高温下Ta在基体中能快速扩散。

在C7T和C7M基体的贫Ni层中(图5(f)和5(h))分别检测到了质量分数为1.7%和1.9%的Ni。综合分析Ni含量和微观组织结构特征可以初步判断,在贫Ni层中,Ni基黏结相主要以纳米膜的形式存在于两硬质相之间(如图5(h)中箭头处)。对比图5(f)和5(h)可以推断,少量Mo2C的添加有利于合金体系初始接触角的改善,从而有利于改善Ni基黏结相在合金中分布均匀性。因此黏结金属熔体在基体中的扩散和渗透能力与合金微观组织结构的均质性密切相关。

接触角θ与固/气、固/液、液/气的表面张力/界面能γSV,γSL和γLV之间具有以下关系:cosθ=(γSV–γSL)/γLV。

降低γLV或γSL,或增加γSV均有利于接触角的降低。θ=0°和θ=180°分别对应完全润湿和完全不润湿,θ>90°时为不润湿。SAUERLAND等[25]的研究结果表明,在温度1 500 °C下,纯Ni的表面张力为1 860 mN/m,当掺入10% Ti(原子数分数)时,熔体的表面张力下降至1 522 mN/m。图3中接触角迅速下降阶段(第1阶段)应该与高温下基体中合金组元向Ni熔体中快速扩散从而导致其表面张力迅速下降有关。

在温度为T时,熔体的表面张力 的计算公式为[26]

的计算公式为[26]

(1)

(1)

式中:T0和TB分别为参考温度和沸点; 为蒸发热;α为线膨胀系数;cV为比热容。KOU等[26]的计算和实测结果表明,对包括液态金属在内的绝大部分液态材料,其表面张力随温度升高呈线性下降。因此,图3中接触角变化的第2和第3阶段与熔体表面张力随温度升高而降低相关,熔体的合金化行为是在相同温度下熔体之间表面张力和固液界面能出现差异化的重要原因。

为蒸发热;α为线膨胀系数;cV为比热容。KOU等[26]的计算和实测结果表明,对包括液态金属在内的绝大部分液态材料,其表面张力随温度升高呈线性下降。因此,图3中接触角变化的第2和第3阶段与熔体表面张力随温度升高而降低相关,熔体的合金化行为是在相同温度下熔体之间表面张力和固液界面能出现差异化的重要原因。

基体中Ni含量跨越式的变化(呈现典型的层状结构)应该与接触角出现3个阶段的明显变化密切相关。第1阶段接触角的迅速下降应该是高温下熔体与基体之间的快速交互作用所导致。在此阶段,除N以外的基体中的合金组元快速溶入Ni熔体,表面张力快速下降的熔体在熔体与基体间Ni浓度差和重力的双重驱动下,快速扩散和渗透至基体并使基体中的硬质相分离,最大限度地占据硬质相的部分原始空间,通过硬质相组元在其中的溶解与析出达到动平衡,从而导致富Ni层的形成,并在富Ni层中通过短程扩散达到浓度平衡。在由温度升高为主因驱动的接触角缓慢下降阶段,Ni熔体进入基体中的量呈缓慢下降趋势,Ni主要靠扩散进入基体。对比Ni熔体分别与C7,C7T和C7M基体之间的初始接触角(分别为21.2°,19.8°和14.2°)以及基体表面Ni熔体凝固层的平均厚度(分别为178,155和18 μm)可知,Ni熔体与C7和C7T基体之间的润湿性差异并不显著。对C7T基体,由于硬质相成分多元化和硬质相中金属组元在Ni熔体中的溶解度差异明显,通过与Ni熔体间的交互作用,在C7T基体中形成明显的(Ti,M)CN硬质相芯环结构。这一现象表明,与C7相比,Ni熔体进入C7T之后两者之间的交互作用明显增强,Ni熔体在基体中扩散与渗透的阻力增加,从而导致了C7T基体中富Ni层平均厚度较C7基体中富Ni层平均厚度更低的现象(分别为49 μm和58 μm)。由于润湿性的显著改善,Ni熔体进入C7M之后两者之间的交互作用对富Ni层形成的阻力明显降低,其富Ni层平均厚度明显增加(为89 μm)。由图5(c)和5(d)可以看出,富Ni层中硬质相的平均晶粒度明显小于贫Ni层中硬质相的平均晶粒度。因液相迁移的驱动力源于液相迁移压或毛细力[22,24,27],而液相迁移压随硬质相的晶粒增大而降低,因此硬质相具有较小晶粒度的富Ni层的热力学稳定性增强。与此同时,扩散时间不充分也是导致Ni熔体凝固层、富Ni层和贫Ni层协同共存的另一重要原因。根据扩散诱导质量传输的基本特点[28-29]和4种合金体系的成分与微观组织结构特征,可以进一步证实本研究的合金体系属于典型的扩散和溶解驱动型润湿。

3 结论

1) 真空条件下,金属Ni熔体在TiC0.4N0.6,TiC0.7N0.3,TiC0.7N0.3-29WC-12TaC和TiC0.7N0.3-29WC-12TaC-2Mo2C基体表面的润湿属于扩散和溶解驱动型润湿,初始接触角分别为24.5°,21.2°,19.8°和14.2°。Ni熔体能分离基体中的硬质相晶粒,在基体中形成富Ni层和贫Ni层。在贫Ni层,Ni能以纳米级薄膜形式存在。

2) 当TiCN基体中C/N物质的量比低于4:6时,会抑制Ti在Ni中的扩散和溶解以及Ni熔体在基体中的扩散和渗透,会导致Ni熔体在真空条件下的显著蒸发,从而显著降低合金体系的润湿性。

3) TiCN基体中金属组元向Ni中扩散与固溶的能力从强到弱依次为Ta,W,Ti。Mo2C可显著促进W和Ta向Ni中扩散与固溶,可显著促进Ni熔体在基体中的扩散和渗透,从而显著改善合金体系的润湿性。WC和TaC对合金体系润湿性的改善作用不显著,但可改变硬质相的微观结构和黏结相的成分属性以及硬质相与黏结相的界面结构。

4) 合金体系的润湿性是初始接触角、金属熔体在基体中的扩散与渗透深度以及熔体金属在基体物相之间形成纳米膜能力的综合反映。硬质复合材料中黏结金属熔体在基体中的扩散和渗透能力与合金微观组织结构的均质性密切相关。改善合金体系润湿性的添加剂应具备以下特性:在黏结金属熔体中具有一定的溶解度,能显著促进其他合金组元在黏结金属中的溶解;与其他合金组元协同作用,具有显著降低黏结金属熔体表面张力,显著抑制黏结金属蒸发以及显著促进黏结金属熔体在基体中扩散和渗透的能力。

参考文献:

[1] 王嘉莹, 金龙哲, 郭敬中, 等. 梅山铁矿爆破粉尘润湿性能关键影响因素[J]. 中南大学学报(自然科学版), 2019, 50(10): 2527-2535.

WANG Jiaying, JIN Longzhe, GUO Jingzhong, et al. Key influencing factors on wettability of blasting dust in Meishan Iron Mine[J]. Journal of Central South University(Science and Technology), 2019, 50(10): 2527-2535.

[2] XUE Junyu, LI Yuanxing, CHEN Hui, et al. Wettability, microstructure and properties of 6061 aluminum alloy/304 stainless steel butt joint achieved by laser-metal inert-gas hybrid welding-brazing[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(10): 1938-1946.

[3] HUANG Li, SHENG Guangmin, LI Jia, et al. Partial transient-liquid-phase bonding of TiC cermet to stainless steel using impulse pressuring with Ti/Cu/Nb interlayer[J]. Journal of Central South University, 2018, 25(5): 1025-1032.

[4] GIURANNO D, BRUZDA G, POLKOWSKA A, et al. Design of refractory SiC/ZrSi2 composites: wettability and spreading behavior of liquid Si-10Zr alloy in contact with SiC at high temperatures[J]. Journal of the European Ceramic Society, 2020, 40(4): 953-960.

[5] ALVAREDO P, DIOS M, FERRARI B, et al. Understanding of wetting and solubility behavior of Fe binder on Ti(C, N) cermets[J]. Journal of Alloys and Compounds, 2019, 770: 17-25.

[6] XIAO Ya, XIONG Ji, GUO Zhixing, et al. Microstructures and properties of PVD TiAlN coating deposited on cermets with different Ti(C, N) grain size[J]. Journal of Central South University, 2020, 27(3): 721-735.

[7] LENGAUER W, SCAGNETTO F. Ti(C, N)-based cermets: critical review of achievements and recent developments[J]. Solid State Phenomena, 2018, 274: 53-100.

[8] XU Qingzhong, ZHAO Jun, AI Xing. Fabrication and cutting performance of Ti(C, N)-based cermet tools used for machining of high-strength steels[J]. Ceramics International, 2017, 43(8): 6286-6294.

[9] DE NICOLAS M, BESHARATLOO H, ALVAREDO P, et al. Design of alternative binders for hard materials[J]. International Journal of Refractory Metals and Hard Materials, 2020, 87: 105089.

[10] KUBARSEPP J, JUHANI K. Cermets with Fe-alloy binder: a review[J]. International Journal of Refractory Metals and Hard Materials, 2020, 92: 105290.

[11] 肖桥平, 张立, 罗国凯, 等. 无金属粘结相TiCN基金属陶瓷在NaOH溶液中的电化学腐蚀行为[J]. 粉末冶金材料科学与工程, 2019, 24(2): 120-128.

XIAO Qiaoping, ZHANG Li, LUO Guokai, et al. Electrochemical corrosion behavior of binderless TiCN-based cermets in NaOH solution[J]. Materials Science and Engineering of Powder Metallurgy, 2019, 24(2): 120-128.

[12] 杨媛, 王婷婷, 朱定一, 等. Au-30%Si合金熔体与石墨的润湿性及铺展动力学[J]. 中国有色金属学报, 2016, 26(6): 1175-1181.

YANG Yuan, WANG Tingting, ZHU Dingyi, et al. Wettability and spreading dynamics of melting Au-30%Si alloys with graphite[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(6): 1175-1181.

[13] ZHANG Xiangzhao, WU Xiaolang, LIU Guiwu, et al. Wetting of molten Sn-3.5Ag-0.5Cu on Ni-P(-SiC) coatings deposited on high volume faction SiC/Al composite[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(9): 1784-1792.

[14] YAWS C L. Handbook of vapor pressure: inorganic compounds and elements[M]. Houston: Gulf Publishing Company, 1994: 202.

[15] LIN Qiaoli, SUI Ran. Wetting of carbide ceramics (B4C, SiC, TiC and ZrC) by molten Ni at 1 753 K[J]. Journal of Alloys and Compounds, 2015, 649: 505-514.

[16] DONG Z H, SERGEEV D, KOBERTZ D, et al. Vaporization of ni, Al and Cr in Ni-base alloys and its influence on surface defect formation during manufacturing of single-crystal components[J]. Metallurgical and Materials Transactions A, 2020, 51(1): 309-322.

[17] LIU Mingjie, WANG Shutao, JIANG Lei. Nature-inspired superwettability systems[J]. Nature Reviews Materials, 2(7): 17036.

[18] GUO Zhixing, XIONG Ji, YANG Mei, et al. Microstructure and properties of Ti(C, N)-Mo2C-Fe cermets[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(4): 781-783.

[19] PARK J K, PARK S T. Densification of TiN-Ni cermets by improving wettability of liquid nickel on TiN grain surface with addition of Mo2C[J]. International Journal of Refractory Metals and Hard Materials, 1999, 17(4): 295-298.

[20] 刘红卫, 陈康华, 吕海波. Ti(C, N)基硬质合金中的润湿性研究[J]. 粉末冶金技术, 2000, 18(3): 167-171.

LIU Hongwei, CHEN Kanghua, LU Haibo. Wettability of Ti(C, N)-based cermets[J]. Powder Metallurgy Technology, 2000, 18(3): 167-171.

[21] ALVAREDO P, ROA J J, JIMENEZ-PIQUE E, et al. Characterization of interfaces between TiCN and iron-base binders[J]. International Journal of Refractory Metals and Hard Materials, 2017, 63: 32-37.

[22] KONYASHIN I, ZAITSEV A A, SIDORENKO D, et al. Wettability of tungsten carbide by liquid binders in WC-Co cemented carbides: is it complete for all carbon contents?[J]. International Journal of Refractory Metals and Hard Materials, 2017, 62: 134-148.

[23] GREN M A, WAHNSTROM G. Wetting of surfaces and grain boundaries in cemented carbides and the effect from local chemistry[J]. Materialia, 2019, 8: 100470.

[24] ZHANG Li, XIE Mingwei, NAN Qing, et al. Transformation of cobalt gradient structure after resintering of DP cemented carbide[J]. International Journal of Refractory Metals and Hard Materials, 2013, 38: 118-123.

[25] SAUERLAND S, LOHOFER G, EGRY I. Surface tension measurements on levitated liquid metal drops[J]. Journal of Non-Crystalline Solids, 1993, 156/157/158: 833-836.

[26] KOU Haibo, LI Weiguo, ZHANG Xuyao, et al. Temperature-dependent coefficient of surface tension prediction model without arbitrary parameters[J]. Fluid Phase Equilibria, 2019, 484: 53-59.

[27] FAN P, FANG Z Z, GUO J. A review of liquid phase migration and methods for fabrication of functionally graded cemented tungsten carbide[J]. International Journal of Refractory Metals and Hard Materials, 2013, 36: 2-9.

[28] CHENG Kaiming, ZHOU Jixue, XU Huixia, et al. Reviews on modeling of diffusion-induced mass transportation in functionally graded cemented carbides[J]. Diffusion Foundations, 2018, 15: 65-96.

[29] ZHANG Weibin, PENG Yingbiao, ZHOU Peng, et al. Experimental investigation and computer simulation of gradient zone formation in WC-Ti(C, N)-TaC-NbC-Co cemented carbides[J]. Journal of Phase Equilibria and Diffusion, 2013, 34(3): 202-210.

(编辑 赵俊)

收稿日期: 2020 -08 -20; 修回日期: 2020 -09 -14

基金项目(Foundation item):国家自然科学基金资助项目(51574292);湖南省自然科学基金资助项目(2019JJ40373) (Project(51574292) supported by the National Natural Science Foundation of China; Project(2019JJ40373) supported by the Natural Science Foundation of Hunan Province)

通信作者:张立,博士,教授,从事硬质材料科学与工程研究;E-mail: zhangli@csu.edu.cn