Trans. Nonferrous Met. Soc. China 28(2018) 1186-1191

Nanosized copper powders prepared by gel-casting method and their application in lubricating oil

Wen-chao CHEN1,2, Ji-gui CHENG1,2, Hui-pei CHEN1,2, Nan-min YE1,2, Bang-zheng WEI1, Lai-ma LUO1,2, Yu-cheng WU1,2

1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Research Centre for Powder Metallurgy Engineering and Technology of Anhui Province, Hefei 230009, China

Received 22 February 2017; accepted 18 September 2017

Abstract: Nanosized copper powders were prepared by a gel-casting method using copper nitrate, acrylamide (AM) and N, N′-methylenebisacrylamide (MBAM) as the main raw materials. The as-prepared copper powders were characterized by X-ray diffractometry and scanning electron microscopy, and then added into a 48# industrial white oil. Dispersion and wear properties of the compounded lubricating oil were tested. The results show that the copper powders prepared are of high purity, fine dispersibility with mean particle size of about 60 nm and with a narrow particle size distribution. The nanosized copper powders can be well dispersed in the lubricating oil. The addition of the copper powders obviously improves the anti-wear properties of the lubricating oil owing to their good self-repairing performance. Compared with 48# industrial white lubricating oil, the friction coefficient of GCr15 steel with the compounded oil containing 0.6% copper powders reduces by 0.07 and nearly no wear chippings are found in the scratches of the friction counter parts.

Key words: nanosized copper powder; gel-casting method; compounded lubricating oil; anti-wear property

1 Introduction

Nanosized copper powders are widely used in electrical and electronic, chemical and mechanical engineering and other applications for their unique physical and chemical properties [1-3]. With the development of high technology, there have raised new requirements for nanosized copper powders with high purity, spherical shape, good dispersibility and narrow particle size distribution [4,5]. Recently, nanosized metal powders, such as Cu, Fe and Ag element powders were added into some lubricating oil to improve the friction and wear behaviors and the self-repairing properties [6-8]. It has shown that ultrafine copper powders have good tribological performances in reducing friction coefficient and enhancing wear resistance because of their low shear strength and fine diffusibility, and the particle size and morphology of the copper powder also have effects on the friction properties [9,10]. However, the wear mechanism still remains to further investigate and overcome.

By now, many methods have been tried to prepare nanosized copper powders, such as the atomization, the mechanical alloying, the chemical reduction and the electrochemical methods [11-15]. However, some drawbacks still remain in these methods, e.g., introducing impurity into the powders, the high production cost and the complicated procedures. Recently, a wet chemical method, namely the gel-casting method has drawn much attention in preparing ultrafine or nanosized powders due to the advantages of preparing powders with narrow particle size distribution, spherical shape and the high collection efficiency. This method has been widely used in preparing ceramic oxide powders [16,17]. Up to now, however, there have less reports about using the gel-casting method to prepare metallic powders.

In this work, copper powders with ultrafine particle size were prepared by the gel-casting process. The as-prepared nanosized copper powders were added into an industrial white oil to evaluate the effects on the friction and wear properties of the oil.

2 Experimental

2.1 Synthesis and characterization of copper powders

An aqueous gel-casting method was employed to synthesize the copper powders in which stoichiometric amount of copper nitrate (Cu(NO3)2) was mixed in water with organic monomer (mixture of acryl amide (AM) and N, N′-methylenebisacrylamide (MBAM), V(AM): V(MBAM)=20:1) by ball milling for 24 h to form a mixed solution. Ammonium persulphate ((NH4)2S2O8) was then added into the solution and wet gel formed by heating the solution to about 80 °C. The wet gel was further heated to about 120 °C to remove the solvent water. The dried gel was then calcined at 500 °C for 3 h, and ultrafine copper powders were finally obtained by reducing the dried precursor powders in H2 at 400 °C for 3 h.

X-ray diffraction analysis (X'Pert PRO MPD, Panalytical) was performed on the precursor and the copper powders to identify the phase composition with a scanning range of 10°-90°. Average grain sizes of the powders were calculated by the Debye–Sherrer equation D=kλ/(βcos θ), k=0.89) [18]. A transmission electron microscope (JEM-2100F, JEOL) was used to observe the morphology of the powders.

Anti-oxidation treatment was performed on the prepared copper powders, in which polyvinyl pyrrolidone (PVP) was first dissolved in anhydrous ethanol, then the as-prepared copper powders were added into the solution. Copper powders coated with PVP were obtained by heat the mixes to evaporate the anhydrous ethanol.

2.2 Performance test of compounded lubricating oil containing nanosized copper powders

Different amounts (0-0.8%) of the as-prepared copper powders with and without anti-oxidation treatment were added into 48# industrial white lubricating oil, and by ultrasonic dispersion for 0.5 h, the nanosized copper powders were homogeneously dispersed in the oil. An ultraviolet–visible spectrophotometer (DUV-3700, Shimadzu) equipped with an integrating sphere was used to characterize the absorbance values for ultraviolet and visible light wave lengths with range of 200-800 nm according to the Lambert-Beer law as follows:

(1)

(1)

where A is the absorbance value, I0 is the incident light intensity (cd), I is the transmitted light intensity (cd), ε is the molar absorption coeffcient (L·mol-1·cm-1), b is the optical distance (m) and c is the molarity (mol·L-1).

Friction and wear test with the lubricating oil was performed on a four-ball wear test machine (MMW-1A, Ji’nan Yihua Friction Testing Technology Co., Ltd) with GCr15 steel as the counter parts whose hardness is HRC 64-66 and the diameter is 12.7 mm. Typical experimental conditions are: atmospheric environment, room temperature, step loading of 292 N, rotational velocity of 500 r/min and test time of 30 min. The friction coefficient curves were obtained by the test machine automatic identification. Microstructure of the worn regions on the ball surfaces was observed by scanning electron microscopy (JSM-6490LV, JEOL), and surface elements in worn regions were analyzed by EDS (INCA Energy 250, Oxford Instruments).

3 Results and discussion

3.1 Characterization of copper powders

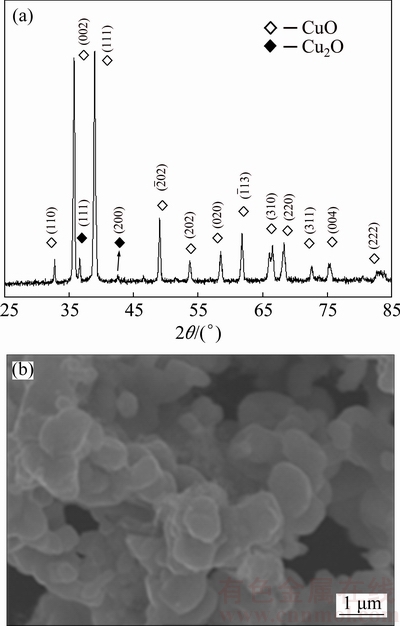

Figure 1 shows XRD pattern and SEM image of the dried precursor powders. The main phases (Fig. 1(a)) in the precursors are copper oxide (CuO) with a small quantity of cuprous oxide (Cu2O), which results from the decomposition of the copper nitrate. Mean particle size of the precursors is about 1 μm (Fig. 1(b)).

Fig. 1 XRD pattern (a) and SEM image (b) of precursor powders

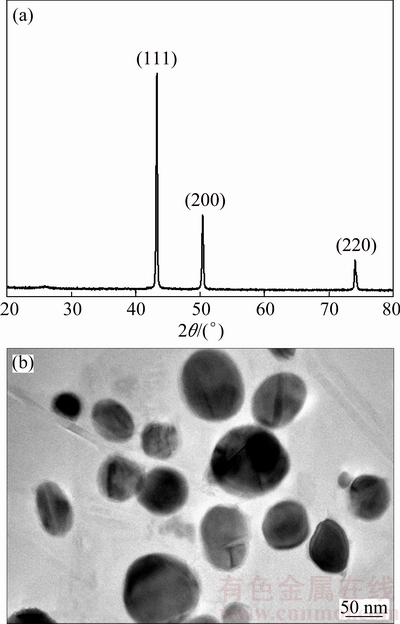

Figure 2 shows XRD pattern and morphology of the copper powders. Only diffraction peaks (111), (200), (220) of pure copper are observed in Fig. 2(a) and the calculated mean grain size of the copper powders is about 21 nm. Figure 2(b) shows that the copper powders have nearly spherical shape with a narrow particle size distribution. According to statistics, average particle size of the copper is about 60 nm. This indicates that the copper powders are polycrystals.

Fig. 2 XRD pattern (a) and TEM image (b) of nanosized copper powders

3.2 Dispersion characteristics of copper powder in lubricating oil

Figure 3 shows the absorbance curves of the compounded lubricating oil containing nanosized copper powders with (a) and without (b) anti-oxidation treatment in the ultraviolet and visible light wavelengths ranging from 200 to 800 nm. The absorbance value of lubricating oil added with nanosized copper powders by anti-oxidation treatment is higher than that without anti-oxidation treatment. Higher absorbance value indicates higher particle concentration in the oil, which means high stability and better dispersibility of the copper particles in the lubricating oil. Comparing curves (a) with (b), it shows clearly that anti-oxidation treatment with PVP can effectively improve the stability of copper powders in lubricating oil.

3.3 Friction and wear properties of lubricating oil

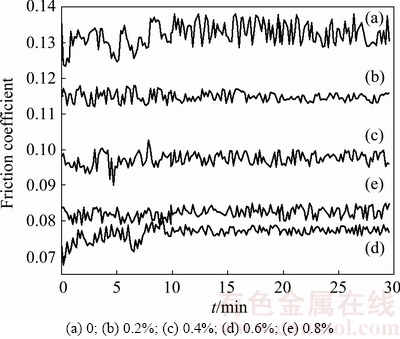

Figure 4 shows friction coefficients of the compounded lubricating oil containing different amounts of copper powders as a function of test time. Curves (a)-(e), represent copper powders with contents of 0, 0.2%, 0.4%, 0.6% and 0.8%, respectively. Dramatic fluctuation of the friction coefficients can be observed at the beginning stage (in 10 min), then the friction coefficients trend to be relatively stable. It can be seen in Fig. 4 that as the addition amount of copper increases in the lubricating oil, the friction coefficient tends to decrease. While the white oil without copper powder addition has friction coefficients of 0.13-0.14, and the friction coefficient of the compounded lubricating oil containing 0.6% copper powder is only 0.07-0.08.

Fig. 3 Absorbance curves of compounded lubricating oil containing nanosized copper powders with (a) and without (b) anti-oxidation treatment

Fig. 4 Friction coefficient of compounded lubricating oils containing different amounts of nanosized copper powders

Figure 5 shows SEM images of the wear chippings on the steel ball surfaces after friction test with 48# white oil and with the compounded lubricating oil containing 0.6% copper powders. Scratches and furrows can be seen on the ball surfaces tested with the white oil containing no copper powders in Fig. 5(a). Compared with Fig. 5(a), Fig. 5(b) shows that the ball surfaces tested with compounded lubricating oil containing 0.6% copper powders are relatively smooth without obvious scratches, and there are only a small amount of short and shallow furrows distributed on the surfaces. This indicates that the addition of nanosized copper powders can effectively improve the lubrication property of 48# white oil and reduces the wear of the balls.

Figure 6 shows EDS analysis results of the wear chippings on the steel ball surfaces. The wear chippings formed with 48# white oil lubrication are composed of Fe, Cr, Mn and C elements in Fig. 6(a). Compared with Fig. 6(a), Fig. 6(b) shows that besides Fe, Cr, Mn and C elements, there has a little Cu in the wear chippings formed with the compounded lubricating oil containing 0.6% copper powders.

3.4 Analysis of anti-wear mechanism of lubricating oils containing nanosized copper powders

The above results have shown that the addition of nanosized copper powders into the lubricating oils can improve the friction and wear properties during the test, and the best anti-wear properties were obtained with compounded lubricating oil containing 0.6% copper powders. The anti-wear mechanism during lubrication with compounded lubricating oil containing nanosized copper powders is illustrated in Fig. 7. When scratches and furrows form on the surfaces of the counter balls during test, the nanosized copper powders in the lubricating oil will deposit and fill into the cavities, and a solid protective film of copper forms after continuous wear process, achieving a self-repairing effect on the were surfaces [19].

Fig. 5 SEM images of wear chippings on steel ball surfaces with 48# white oil (a) and compounded lubricating oil containing 0.6% copper powders (b)

Fig. 6 SEM images (a, c) and corresponding EDS analysis results (b, d) of wear chippings on steel ball surfaces with 48# white oil (a, b) and compounded lubricating oil containing 0.6% copper powders (c, d)

Fig. 7 Anti-wear mechanism of lubricating oil containing nanosized copper powders

4 Conclusions

1) Nanosized copper powders with particle size of about 60 nm and narrow particle size distribution were prepared by the gel-casting process. The powders are of high purity, fine dispersibility and spherical shape.

2) After anti-oxidation treatment with PVP, the nanosized copper powders can be homogeneously dispersed in the lubricating oil. The compounded lubricating oil containing nanosized copper powders shows high absorbance value for ultraviolet and visible light, indicating high dispersion stability of copper powders in the oil.

3) The addition amount of the Cu powders has an obvious influence on the properties of the lubricating oil. The best friction property is obtained for compounded lubricating oil containing 0.6% copper powders, and the friction coefficient is 0.07. The scratches and furrows forming on the surfaces of the counter steel balls reduce effectively, which can be ascribed to the self-repairing effects of the nanosized copper powders in the compounded lubricating oil.

References

[1] YANG Jian-guang, YANG Sheng-hai, TANG Chao-bo, HE Jing, TANG Mo-tang. Synthesis of ultrafine copper particles by complex- reduction-extraction method [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(S1): s1181-s1185.

[2] SEAKR R. Microstructure and crystallographic characteristics of nanocrystalline copper prepared from acetate solutions by electrodeposition technique [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1423-1430.

[3] MENAPACE C, CIPOLLONI G, HEBDA M. Spark plasma sintering behaviour of copper powders having different particle sizes and oxygen contents [J]. Powder Technology, 2016, 291: 170-177.

[4] UNWIN P J, RUSNACIK M E, KRESTA S M, NELSON A E. Effect of amine and thiol addition on the surface chemistry and agglomeration of fine Cu powders [J]. Colloids & Surfaces A: Physicochemical & Engineering Aspects, 2008, 325(1): 72-80.

[5] CATHARINA W, TALAT A K, MALTE S, CHOI P P, KWON Y S. Homogeneity of mechanically alloyed nano-crystalline Fe-Cu-powders [J]. International Journal of Materials Research, 2008, 99(5): 54-147.

[6] LI Dan, XIE Wen-jie, FANG Wen-jun. Preparation and properties of copper-oil-based nanofluids[J]. Nanoscale Research Letters, 2011, 6(1): 1-7.

[7] YANG Guang-bin, CHAI Shan-tao, XIONG Xiu-juan, ZHANG Sheng-mao, YU Lai-gui, ZHANG Ping-yu. Preparation and tribological properties of surface modified Cu nanoparticles [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 366-372.

[8] ZHANG Yi-dong. Friction reducing antiwear and self-repairing properties of nano-Cu additive in lubricating oil [J]. Journal of Mechanical Engineering, 2010, 46(5): 74-79.

[9] MESHIA L, SAMUHAA S, COHENB S R, LAIKHTMANC A, MOSHKOVICHC A, PERFILYEVC V, LAPSKERC I, RAPOPORTC L. Dislocation structure and hardness of surface layers under friction of copper in different lubricant conditions [J]. Acta Materialia, 2011, 59(1): 342-348.

[10] LI Jing-fu, ZHANG Lei, XIAO Jin-kun, ZHOU Ke-chao. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3354-3362.

[11] CHU Zhi-qiang, GUO Xue-yi, LIU Dong-hua, TAN Yan-xian, LI Dong, TIAN Qing-hua. Application of pre-alloyed powders for diamond tools by ultrahigh pressure water atomization [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(10): 2665-2671.

[12] MADAVALI B, LEE J H, JIN K L, CHO KY, CHALLAPALLI S. Effects of atmosphere and milling time on the coarsening of copper powders during mechanical milling [J]. Powder Technology, 2014, 256(2): 251-256.

[13] WANG Fu-xiang, GAI Guo-sheng, YANG Yu-fen. Sphericizing metal powders by mechanical means [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S2): s705-s707.

[14] PARFENYUK V I, TESAKOVA M V. Electrochemical synthesis of ultradispersed copper-containing powders obtained from solutions of copper nitrates in aqueous propan-2-ol [J]. Protection of Metals, 2008, 44(44): 253-256.

[15] WANG Ming-yong, WANG Zhi, GUO Zhan-cheng. Preparation of electrolytic copper powders with high current efficiency enhanced by super gravity field and its mechanism [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(6): 1154-1160.

[16] TULLIANI J M, LOMBARDI M, PALMERO P, FORNABAIO M, GIBSON LJ. Development and mechanical characterization of novel ceramic foams fabricated by gel-casting [J]. Journal of the European Ceramic Society, 2013, 33(9): 1567-1576.

[17] JIANG Qiu-mei, CHENG Ji-gui, WANG Rui, FAN Yu-meng, GAO Jian-feng. Novel triple-phase composite cathode materials for proton-conducting solid oxide fuel cells [J]. Journal of Power Sources, 2012, 206(1): 47-52.

[18] MONSHI A, FOROUGHI M R, MONSHI M R. Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD [J]. World Journal of Nano Science & Engineering, 2012, 2(2): 154-160.

[19] ZHOU Jing-fang, WU Zhi-shen, ZHANG Zhi-jun, LIU Wei-min, XUE Qun-ji. Tribological behavior and lubricating mechanism of Cu nanoparticles in oil [J]. Tribology Letters, 2000, 8(4): 213-218.

凝胶浇注法制备纳米铜粉及其在润滑油中的应用

陈闻超1,2,程继贵1,2,陈会培1,2,叶楠敏1,2,魏邦争1,罗来马1,2,吴玉程1,2

1. 合肥工业大学 材料科学与工程学院,合肥 230009;

2. 安徽省粉末冶金工程技术研究中心,合肥 230009

摘 要:以硝酸铜、丙烯酰胺和N, N′-亚甲基双丙烯酰胺为原料,采用凝胶浇注法制备纳米铜粉。使用X射线衍射仪和扫描电子显微镜对制备的纳米铜粉进行表征。以纳米铜粉为添加剂加入48#工业白油中,考察其分散性和对润滑性能的影响。结果表明:采用凝胶浇注法可制备纯度高、分散性良好、粒度分布范围窄且平均粒度约为60 nm的铜粉。该法制备的纳米铜粉在工业白油中分散良好,能有效提高其抗磨损性能,并在摩擦件表面发生自修复作用。相比于原润滑油,使用加入0.6%纳米铜粉的复合润滑油可以使材质为GCr15钢的磨球摩擦因数降低至0.07,且对磨件表面基本没有磨痕。

关键词:纳米铜粉;凝胶浇注法;复合润滑油;抗磨损性能

(Edited by Xiang-qun LI)

Foundation item: Project (51674095) supported by the National Natural Science Foundation of China

Corresponding author: Ji-gui CHENG; Tel: +86-551-62901793; E-mail: jgcheng63@sina.com

DOI: 10.1016/S1003-6326(18)64756-9