文章编号: 1004-0609(2005)01-0024-09

不同钎料对Ti3Al基合金钎焊接头强度及

界面微观组织的影响

何 鹏1, 冯吉才1, 周 恒2

(1. 哈尔滨工业大学 现代焊接技术国家重点实验室, 哈尔滨 150001;

2. 北京矿冶研究总院, 北京 100001)

摘 要: 研究了Ti3Al基合金真空钎焊及接头组织性能; 分析了不同钎料对接头界面组织和剪切强度的影响, 初步优选了钎料, 优化了钎焊连接规范参数; 利用电子探针、 扫描电镜和X射线衍射等方法对接头进行了定性和定量分析。 结果表明: 采用NiCrSiB钎料连接时, 在界面处有金属间化合物TiAl3、 AlNi2Ti和Ni基固溶体生成, TiAl3和AlNi2Ti的生成降低了接头的剪切强度; 采用TiZrNiCu钎料连接时, 在界面处有金属间化合物Ti2Ni、 Ti(Cu,Al)2和Ti基固溶体生成, Ti2Ni和Ti(Cu,Al)2的形成降低了接头的剪切强度; 采用AgCuZn钎料连接时, 在界面处生成TiCu、 Ti(Cu,Al)2和Ag基固溶体, TiCu和Ti(Cu,Al)2 的生成是降低接头剪切强度的主要原因; 采用CuP钎料连接时, 在界面处生成了Cu3P、 TiCu和Cu基固溶体, Cu3P和TiCu使接头的剪切强度降低; 对于NiCrSiB钎料, 当连接温度为1373K, 连接时间为5min时, 接头的剪切强度最高为219.6MPa; 对于TiZrNiCu钎料, 当连接温度为1323K, 连接时间为5min时, 接头的最高剪切强度为259.6MPa; 对于AgCuZn钎料, 当连接温度为1173K, 连接时间为5min时, 接头的最高剪切强度为125.4MPa; 对于CuP钎料, 当连接温度为1223K, 连接时间为5min时, 接头的最高剪切强度为98.6MPa; 采用TiZrNiCu钎料连接Ti3Al可获得最大接头强度。

关键词: Ti3Al基合金; 钎焊; 界面组织; 剪切强度 中图分类号: TG406

文献标识码: A

Microstructure and strength of brazed joints of Ti3Al-base alloy with different filler metals

HE Peng1, FENG Ji-cai1, ZHOU Heng2

(1. State Key Laboratory of Advanced Welding Production Technology,

Harbin Institute of Technology, Harbin 150001, China;

2. Beijing General Research Institute of Mining and Metallurgy, Beijing 100001, China)

Abstract: The interfacial microstructure and properties of brazed joints of Ti3Al-based alloy were investigated. The effects of different brazing fillers on interfacial microstructure and shear strength were studied. And the optimum joining parameters were given. The brazed joints were qualitatively and quantitatively analyzed by means of EPMA, SEM and XRD. The results show that using brazing filler NiCrSiB, TiAl3, AlNi2Ti and Ni[s,s] are formed at the interface of joint, and the formation of Ti3Al and AlNi2Ti decreases the shear strength. Using brazing filler TiZrNiCu, Ti2Ni, Ti(Cu,Al)2 and Ti[s,s] are formed at the interface of joint, the formation of intermetallics Ti2Ni and Ti(Cu,Al)2 decreases the shear strength. Using brazing filler AgCuZn, TiCu, Ti(Cu,Al)2 and Ag[s,s] are formed, the shear strength of the joint is decreased because of the formation of TiCu and Ti(Cu,Al)2. Using brazing filler CuP, Cu3P, TiCu and Cu[s,s] are formed at the interface of the joint, the former two intermetallics decrease the shear strength. The analysis also indicates that using brazing filler NiCrSiB, the optimum brazing parameters for the joint are joining temperature T=1373K, joining time t=5min, and the maximum shear strength is 219.6MPa. To the brazing filler TiZrNiCu, the optimum parameters are temperature T=1323K, joining time t=5min, and the maximum shear strength is 259.6MPa. To the brazing filler AgCuZn, the optimum parameters are joining temperature T=1173K, joining time t=5min, and the maximum shear strength is 125.4MPa. To the brazing filler CuP, the optimum parameters are joining temperature T=1223K, joining time t=5min, and the maximum shear strength is 98.6MPa.

Key words: Ti3Al-based alloy; brazing; interfacial microstructure; shear strength

近年来, 随着材料科学的发展以及能源危机的冲击, 航空航天工业对高强度、 高弹性模量、 低密度、 耐高温的新型结构材料的需求越来越迫切[1]。 Ti-Al系金属间化合物具有比强度高、 弹性模量大、 高温蠕变强度高和抗氧化性好等优点, 被认为是一种理想的具有广阔应用前景的高温结构材料[2]。 目前Ti3Al基合金多用于制造有限的小型铸锻零部件, 很少用于加工工艺复杂的构件, 其原因之一在于Ti3Al基合金的焊接性问题没有很好地解决, 限制了其应用, 因此解决好Ti3Al基合金的连接问题非常重要。 Ti3Al基合金连接的方法分为固相连接和熔化连接, 主要有扩散焊[3, 4]、 摩擦焊[5, 6]、 氩弧焊[7, 8]等。 国外有关熔焊的研究表明, Ti3Al基合金存在2个较突出的问题: 1) 有焊接热裂趋向; 2) 焊缝区与经过热机械处理等工艺得到的基体组织不同, 表现出较低的力学性能[9, 10]。 因此, 对于Ti3Al基合金用熔焊方法进行连接可焊性较差, 尤其在与异类金属合金的连接时更为突出。 但近些年来, 随着熔焊技术的发展, 采用电子束焊[11]、 激光焊[9, 10]、 氩弧焊[7, 8]技术已成功地实现了Ti3Al基合金的同种合金自体焊接。 如对TiAl24Nb14V3合金进行的电子束焊接, 未发现冷裂纹等缺陷, 焊后焊件接头最高延伸率达10.47%, 首次实现了对实用零件的焊接[11]。 刘博等[12]通过采用预热防止焊接冷裂纹, 而后用焊后热处理改善焊缝组织和性能的方法顺利实现该合金的氩弧焊接, 所得焊件的最终室温抗拉强度接近基体, 拉伸塑性可提高到3.89%, 满足工程要求。 从现有的有限研究结果来看, Ti3Al基合金可以采用固态和熔焊工艺焊接, 只是其焊后性能, 包括室温和高温性能尚未最后确定, 不能肯定所有这些方法都可以应用于关键部件的焊接。 对焊接性能关键控制因素的了解, 依赖于对这些合金物理冶金特点的详细分析, 目前Ti3Al基合金焊接中的主要问题仍然是该材料的冶金学特点研究不够。 对于Ti-Al基合金焊接性具有重要影响的另一方面是间隙元素的影响, 任何熔焊工艺都不可避免地在合金中引入间隙元素, 并且这种间隙元素一般就有有害作用, 这在该类合金的研究中尚未引起注意。 从间隙元素对常规钛合金焊件的影响看, 这一点值得深入研究。 从现有数据来看, Ti3Al基合金的焊接性不存在本质上不可焊的问题, 焊接的主要困难在于需找到某种工艺, 使焊件室温下仍能保持一定的塑性。 本文作者以具有航空发动机应用背景的Ti3Al基合金为对象, 采用真空钎焊方法[13-16], 研究镍基钎料、 钛基钎料、 银基钎料和铜基钎料对Ti3Al基合金的同种合金自体钎焊接头组织及力学性能的影响, 为获得高性能的连接接头提供基础数据。

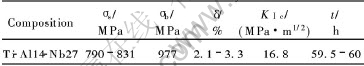

1 实验

实验采用的Ti3Al基合金材料是Ti-14Al-27Nb(摩尔分数, %)轧制板材, 钎料箔片分别为高温钎料Ni-Cr7-Si5-B3-Fe3、 活性钎料Ti-Zr35-Ni15-Cu15、 Ag基钎料Ag-Cu34-Zn16和Cu基钎料Cu-P7.1, Ti3Al基合金材料及应用钎料的成分及性能见表1和表2。

表1 Ti3Al基合金材料的成分及性能

Table 1 Mechanical performances of Ti3Al base alloy

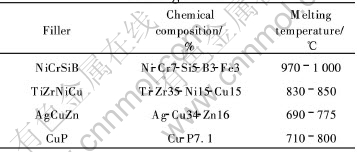

表2 钎料的成分及性能

Table 2 Composition and property of brazing fillers

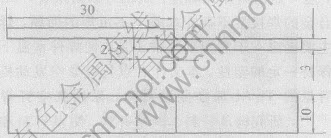

首先将Ti3Al基合金进行焊前处理, 用240#~1000#水砂纸对试件表面磨光, 再用丙酮和无水乙醇冲洗, 晾干。 采用如图1所示搭接方式对试件进行装配, 钎焊在辐射加热真空扩散焊机中进行。 为了防止试件在高温下氧化, 钎焊结束后, 将试件随炉冷却, 当温度冷却到室温时从真空室取出试件。 搭接试件焊后在INSTRON MODEL1186电子 万能试验机上进行拉剪实验, 焊好的试件制成金相试样, 采用GEOLsuperobe733电子探针仪、 S-570扫描电子显微镜等分析方法对钎焊接头的质量进行分析评价。

图1 钎焊接头示意图

Fig.1 Sketch of brazed joint (unit: mm)

2 结果与讨论

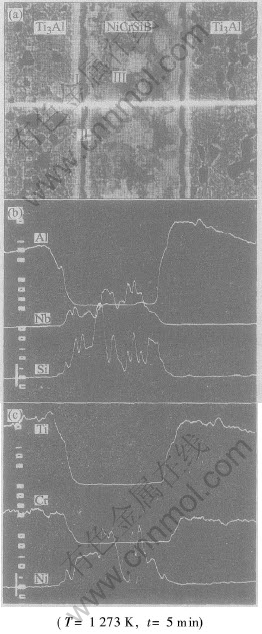

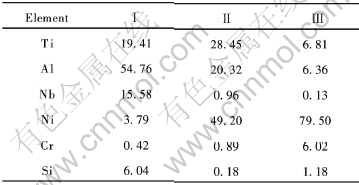

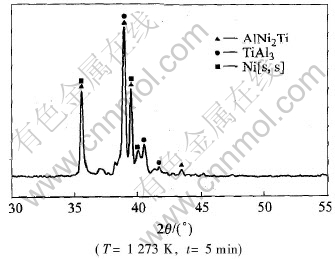

图2所示为采用NiCrSiB钎料连接Ti3Al基合金的接头背散射像及元素线扫描分布, 界面处可以观察到有3个反应层出现, Ⅰ区为靠近母材的白色细条状区域, Ⅱ区为黑色条状区域, Ⅲ区为灰白色区域并分布有大量的黑块。 从元素线扫描照片可以看出, Ti、 Al元素在Ti3Al基合金母材侧含量较高, 在Ti3Al/NiCrSiB/Ti3Al界面处曲线快速下降, 最终在钎料处出现平台; 与Ti、 Al元素的曲线不同, Ni、 Si元素的曲线在界面处上升, 并且在钎料区域出现时高时低的曲线波, 说明钎料中的Ni等元素是分散存在的。 接头的成分分析结果(表3)显示, Ⅰ区和Ⅱ区主要含Ti、 Al和Ni元素; Ni元素在Ⅲ区富集。 由断口X射线衍射谱(图3)可以看出, 界面上反应的产物主要是TiAl3、 AlNi2Ti和Ni[s, s]。

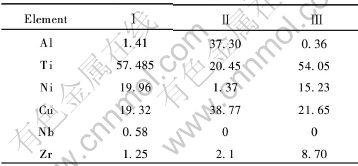

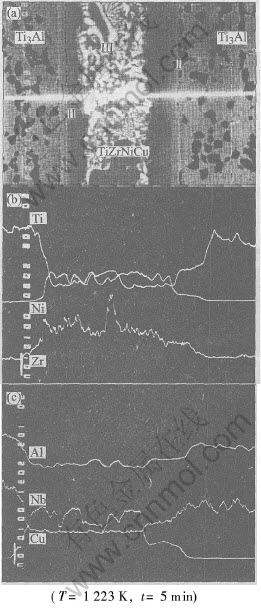

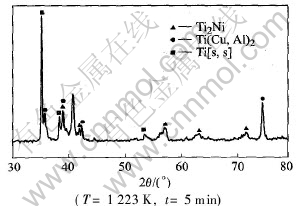

综上所述, 在Ti3Al/NiCrSiB/Ti3Al钎焊接头中靠近母材的Ⅰ区和Ⅱ区主要是由TiAl3和AlNi2Ti组成, 而Ⅲ区主要是Ni基固溶体。 采用TiZrNiCu钎料连接Ti3Al基合金的接头背散射像及元素线扫描分布如图4所示, Ⅰ区为靠近母材的灰白色条状区域; Ⅱ区为深灰色的条状区域, 介于钎料和Ⅰ区之间; Ⅲ区为白色的基体上分布有大量黑块和少量黑白花纹的区域。 从元素线扫描分布可以看出, Ti、 Al元素在Ti3Al基合金母材侧含量较高, 在Ti3Al/TiZrNiCu/Ti3Al界面处曲线快速下降, 在钎料处出现曲线波; Ni、 Cu元素在界面处上升, 并且在钎料区域也出现时高时低的曲线波, 说明钎料中的Ni、 Cu等元素发生了一定规模的扩散。 将线扫描分布和背散射像相对照可以发现: Ⅰ区和Ⅱ区主要含Ti、 Al、 Ni和Cu元素, 在这2个区域有化合物的生成; Ti元素在Ⅲ区富集。 断口的X射线衍射谱(图5)显示, 界面上反应的产物主要是Ti2Ni、 Ti(Cu,Al)2和Ti基固溶体。 由背散射、线扫描、 成分分析(表4)和X射线衍射实验结果可知, 钎料中的Ni元素与母材中扩散的和钎料本身含有的Ti元素发生反应生成了大量的硬度非常高的金属间化合物Ti2Ni, 这种化合物的生成不利于接头的剪切强度; 同时母材中扩散的Al同钎料和母材中扩散的Ti与钎料中扩散的Cu生成了脆性的金属间化合物Ti(Cu,Al)2。 综上所述, 在Ti3Al/TiZrNiCu/Ti3Al钎焊接头中, Ⅰ区主要是Ti2Ni, Ⅱ区和Ⅲ区中的黑块是Cu、 Ti、 Al形成的化合物Ti(Cu,Al)2, Ⅲ区主要是Ti基固溶体。

图2 Ti3Al/NiCrSiB/Ti3Al接头背散射像(a)及元素线扫描分布(b, c)

Fig.2 Backscattered electron image(a) and line scanning distribution of elements(b, c) at Ti3Al/NiCrSiB/Ti3Al interface

表3 Ti3Al/NiCrSiB/Ti3Al接头各部位的成分分析结果

Table 3 Average content of major elements in each reaction layer of Ti3Al/NiCrSiB/Ti3Al (mole fraction, %)

表4 Ti3Al/TiZrNiCu/Ti3Al接头各部位的成分分析结果

Table 4 Average content of major elements in each reaction layer of Ti3Al/TiZrNiCu/Ti3Al (mole fraction, %)

图3 Ti3Al/NiCrSiB/Ti3Al接头断口的X射线衍射谱

Fig.3 XRD pattern of fracture surface of Ti3Al/NiCrSiB/Ti3Al joint

图4 TiZrNiCu钎料接头的背散射电子像(a)及元素线扫描分布(b, c)

Fig.4 Backscattered electron image(a) and line scanning distribution of elements (b, c) at Ti3Al/TiZrNiCu/Ti3Al interface

图5 Ti3Al/TiZrNiCu/Ti3Al接头断口的X射线衍射谱

Fig.5 XRD pattern of fracture surface of Ti3Al/TiZrNiCu/Ti3Al joint

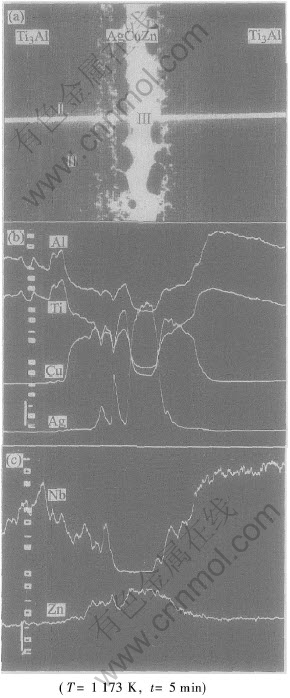

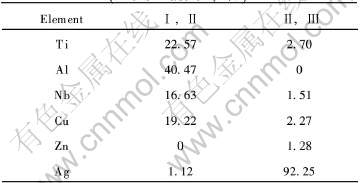

图6所示为采用AgCuZn钎料连接Ti3Al基合金的接头背散射像及元素线扫描分布, Ⅰ区为靠近母材的灰色区域, Ⅱ区为白色条状区域, 均匀分布着细小的黑块, Ⅲ区为白色带状区域并在与Ⅱ区相邻处有大黑块出现。 从元素线扫描分布可以看出:各个元素都发生了一定程度的扩散, 在Ⅰ区和Ⅱ区都含有大量的Ti、 Al和Cu元素; Ag元素在Ⅲ区富集, 并在Ⅱ区中还有一定的固溶。 断口X射线衍射谱(图7)显示, 界面上反应的产物主要是TiCu、 Ti(Cu,Al)2和Ag基固溶体。 由背散射、 线扫描、 成分分析(表5)和X射线衍射结果可知, 母材中的Ti、 Al元素发生了扩散, 在界面处和母材扩散而来的Cu反应形成了金属间化合物TiCu和Ti(Cu,Al)2, 由于钎料内部有大量的Ag元素存在, 因此有Ag基固溶体的生成。 综上所述, 在Ti3Al/AgCuZn/Ti3Al钎焊接头中,靠近母材的Ⅰ区、 Ⅱ区的小黑块和Ⅲ区中的大黑块主要是由TiCu和Ti(Cu,Al)2组成, 而Ⅱ区中的白色区域和Ⅲ区主要是Ag基固溶体。

图6 AgCuZn钎料接头的背散射电子像(a)及元素线扫描分布(b, c)

Fig.6 Backscattered electron image(a) and line scanning distribution of elements (b, c) at Ti3Al/AgCuZn/Ti3Al interface

表5 Ti3Al/AgCuZn/Ti3Al接头各部位的成分分析结果

Table 5 Average content of major elements in each reaction layer of Ti3Al/AgCuZn/Ti3Al (mole fraction, %)

图7 Ti3Al/AgCuZn/Ti3Al接头断口的X射线衍射谱

Fig.7 XRD pattern of fracture surface of Ti3Al/AgCuZn/Ti3Al joint

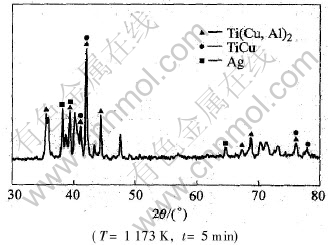

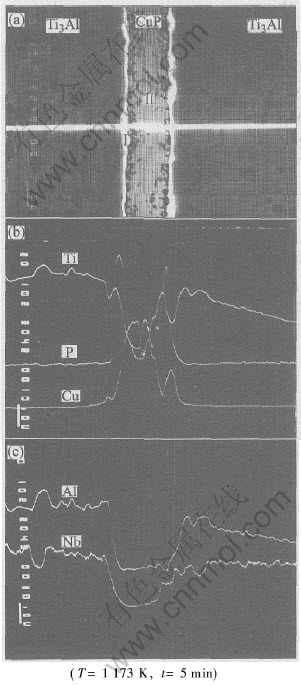

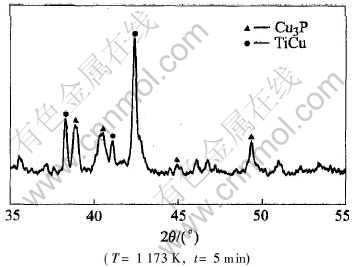

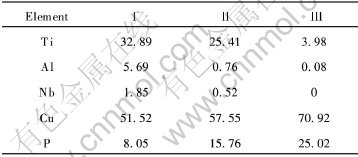

采用CuP钎料连接Ti3Al基合金的接头背散射像及元素线扫描分布如图8所示。 由图可见, Ⅰ区为母材和钎料之间的白色条状区域, Ⅱ区为灰黑色带状区域并在与Ⅰ区相邻处分布有小的黑色絮状物质。 从元素线扫描分布可以看出: 各个元素都发生了一定程度的扩散, 当温度为1173K时, 在Ⅰ区含有大量的Ti元素, Cu、 P元素的曲线在Ⅰ区突然升高, 说明在此区域可能形成了Ti、 Cu和P的化合物; Ⅱ区为钎料区域, 富含Cu、 P。 断口的X射线衍射谱(图9)显示, 界面上反应的产物主要是Cu3P和TiCu。 由背散射、 线扫描、 成分分析(表6)和X射线衍射结果可知, 母材中的Ti元素发生了明显地扩散, 在界面处和母材扩散而来的Cu反应形成了金属间化合物TiCu, Cu元素和P元素反应生成了Cu3P脆性金属间化合物。 由此可知: Ⅰ区和Ⅱ区的小黑块主要是由Cu3P和TiCu组成, 而Ⅱ区中的白色区域为钎料的基体区域。

图8 CuP钎料接头背散射电子像(a)及元素线扫描分布(b, c)

Fig.8 Backscattered electron image(a) and line scanning distribution of elements (b, c) at Ti3Al/CuP/Ti3Al interface

图9 Ti3Al/CuP/Ti3Al接头断口的X射线衍射谱

Fig.9 XRD pattern of fracture surface of

Ti3Al/CuP/Ti3Al joint (mole fraction, %)

表6 Ti3Al/CuP/Ti3Al接头各部位的成分分析结果

Table 6 Average contents of major elements in each reaction layer of Ti3Al/CuP/Ti3Al (mole fraction, %)

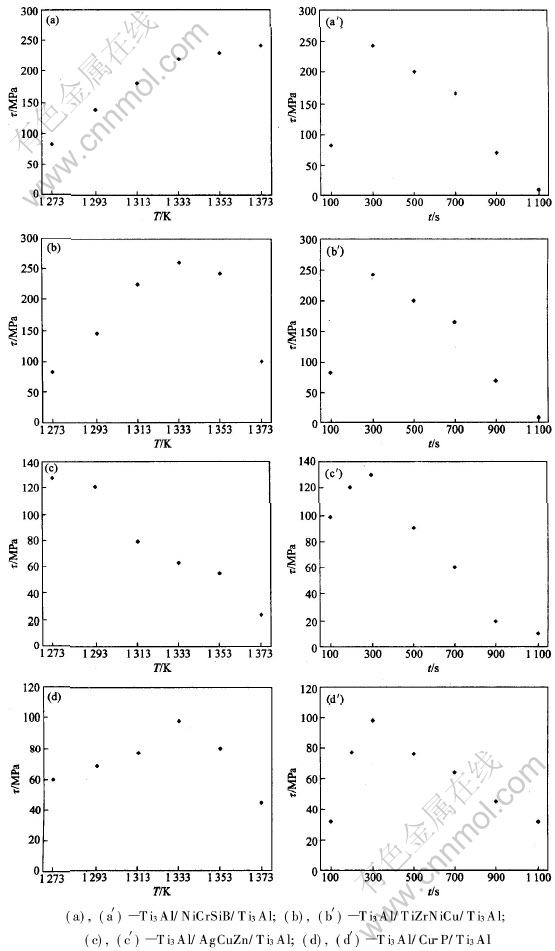

综上所述, 采用不同钎料对Ti3Al基合金钎焊, 其接头的界面微观组织是不同的。 而连接界面组织结构是影响连接性能的关键因素, 不同的界面组织结构及生成相所决定的接合强度不同。 图10所示为采用不同钎料连接Ti3Al基合金所得到的搭接接头的剪切强度随温度和时间的变化规律。 由图可以看出, 采用NiCrSiB钎料对Ti3Al基合金进行钎焊, 当连接时间保持在5min的条件下, 连接温度升高时, 接头的剪切强度也逐渐升高, 在连接温度为1373K时, 接头的剪切强度最大为219.6MPa。 若连接温度保持在1373K时, 当连接时间增加, 接头的剪切强度先增加后逐渐降低, 在连接时间为5min时出现峰值, 当连接时间大于5min时, 接头的剪切强度逐渐降低。 这主要是由于采用NiCrSiB钎料对Ti3Al基合金进行钎焊, 在界面处和钎料内部有[Ti3Al+AlNi2Ti]反应物出现, 并在钎料内部有Ni基固溶体的出现, 随着连接温度的增加, Ti3Al和AlNi2Ti增多, Ni基固溶体减少, 但温度升至1373K时, [Ti3Al+AlNi2Ti]弥散于Ni基固溶体上, 强化接头。 随着连接时间的增加, Ti、 Al的扩散更加充分, 金属间化合物的量增加, Ni基固溶体减少, 接头强度下降。

图10 连接工艺参数对接头剪切强度的影响

Fig.10 Effect of brazing parameter on shear strength with different filler metals

当采用TiZrNiCu钎料对Ti3Al基合金进行钎焊时, 当连接时间保持在5min的条件下, 连接温度升高时, 接头的剪切强度也逐渐升高, 在连接温度为1323K时, 接头的剪切强度最大为253.6MPa。 若连接温度保持在1323K时, 当连接时间增加, 接头的剪切强度先增加后逐渐降低, 在连接时间为5min时出现峰值, 当连接时间大于5min时, 接头的剪切强度逐渐降低。 这主要是由于采用TiZrNiCu钎料对Ti3Al基合金进行钎焊, 在钎料与母材界面处和钎料内部有黑白交替区域出现, 分别是金属间化合物[Ti2Ni+Ti (Cu,Al)2]和Ti基固溶体, 而且随着连接温度的增加, [Ti2Ni+Ti(Cu,Al)2]增加, Ti基固溶体减少, 但温度升至1323K时, [Ti2Ni+Ti (Cu,Al)2]弥散于Ti基固溶体上, 对接头起到强化作用。 随着连接时间的增加, 各元素扩散反应更加充分, 金属间化合物增加, Ti基固溶体相应减少。

当采用AgCuZn钎料对Ti3Al基合金进行钎焊时, 连接时间保持在5min的条件下, 连接温度升高时, 接头剪切强度先增加后逐渐下降, 在连接温度为1173K时, 接头的剪切强度最大为125.4MPa。 若连接温度保持在1173K时, 当连接时间增加, 接头的剪切强度先增加后逐渐降低, 在连接时间为5min时出现峰值, 当连接时间大于5min时, 接头的剪切强度逐渐降低。 这主要是由于当采用AgCuZn钎料对Ti3Al基合金进行钎焊时, 在界面处出现了明显的反应层: TiCu和Ti(Cu,Al)2金属间化合物层和Ag基固溶体层, 随着连接温度的增加, TiCu和Ti(Cu,Al)2增多, Ag基固溶体减少。 随着连接时间的增加, Ti、 Al的扩散反应更加充分, 金属间化合物[TiCu+Ti(Cu,Al)2]的量增加, Ag基固溶体进一步减少。

当采用CuP钎料对Ti3Al基合金进行钎焊时, 连接时间保持在5min的条件下, 连接温度升高时, 接头的剪切强度也逐渐升高, 在连接温度为1223K时, 接头的剪切强度最大为98.6MPa。 若连接温度保持在1223K时, 当连接时间增加, 接头的剪切强度先增加后逐渐降低, 在连接时间为5min时出现峰值, 当连接时间大于5min时, 接头的剪切强度逐渐降低。 这主要是由于采用CuP钎料对Ti3Al基合金进行钎焊时, 界面上生成了Cu3P和TiCu, 钎料中心有Cu基固溶体出现, 随着连接温度的增加, Cu3P和TiCu增加, Cu基固溶体减少。 随着连接时间的增加, 各元素扩散反应更加充分, 在界面上形成很厚的金属间化合物层。

3 结论

1) 采用NiCrSiB钎料对Ti3Al基合金进行钎焊, 在界面处和钎料内部有[Ti3Al+AlNi2Ti]反应物出现, 并在钎料内部有Ni基固溶体的出现, 随着连接温度的增加, Ti3Al和AlNi2Ti增多, Ni基固溶体减少, 但温度升至1373K时, [Ti3Al+AlNi2Ti]弥散于Ni基固溶体上, 强化接头。 随着连接时间的增加, Ti、 Al的扩散更加充分, 金属间化合物的量增加, Ni基固溶体减少, 接头强度下降。 在连接温度为1373K时, 接头的剪切强度最大为219.6MPa。

2) 采用TiZrNiCu钎料对Ti3Al基合金进行钎焊时, 在钎料与母材界面处和钎料内部有黑白交替区域出现, 分别是金属间化合物[Ti2Ni+Ti(Cu,Al)2]和Ti基固溶体, 而且随着连接温度的增加, [Ti2Ni+Ti(Cu,Al)2]增加, Ti基固溶体减少, 当温度升至1323K时, [Ti2Ni+Ti (Cu,Al)2]弥散分布于Ti基固溶体上, 对接头起到强化作用。 随着连接时间的增加, 各元素扩散反应更加充分, 金属间化合物增加, Ti基固溶体相应减少。 在连接温度为1323K时, 接头的剪切强度最大为253.6MPa。

3) 采用AgCuZn钎料对Ti3Al基合金进行钎焊, 在界面处出现了明显的反应层: TiCu和Ti(Cu,Al)2金属间化合物层和Ag基固溶体层, 随着连接温度的增加, TiCu和Ti(Cu,Al)2增多, Ag基固溶体减少。 随着连接时间的增加, Ti、 Al的扩散反应更加充分, 金属间化合物[TiCu+Ti(Cu,Al)2]的量增加, Ag基固溶体进一步减少。 在连接温度为1173K时, 接头的剪切强度最大为125.4MPa。

4) 采用CuP钎料对Ti3Al基合金进行钎焊, 界面上生成了Cu3P和TiCu, 钎料中心有Cu基固溶体出现, 随着连接温度的增加, Cu3P和TiCu增加, Cu基固溶体减少。 随着连接时间的增加, 各元素扩散反应更加充分, 在界面上形成很厚的金属间化合物层。 在连接温度为1223K时, 接头的剪切强度最大为98.6MPa。

REFERENCES

[1]张蕾蕾, 陈达, 林栋梁. TiAl金属间化合物研究现状及发展趋势[J]. 材料开发与应用, 1995(10): 44-47.

ZHANG Lei-lei, CHEN Da, LIN Dong-liang. Research and development of TiAl intermetallics compounds[J]. Development and Application of Materials, 1995(10): 44-47.

[2]Westbrook J H, Fleischer R L. Ti3Al and its alloys, intermetallics compounds, principles and practice[J]. Joining & Welding. 1995(2): 91-131.

[3]邹敦叙, 李世琼, 仲增墉. 航天航空理想新材料Ti3Al和TiAl金属间化合物合金研究开发进展[J]. 钢铁研究学报, 1997, 9(suppl.1): 32-37.

ZOU Dun-xu, LI Shi-qiong, ZHONG Zeng-yong. Research and development of TiAl and Ti3Al intermetallics compounds[J]. Journal of Iron and Steel Research, 1997, 9(suppl.1): 32-37.

[4]Ridley N, Livesey D W, Salehi M T. Superplastic behavior and diffusion bonding of a titanium aluminide alloy[A]. Proceedings International Conference on High Temperature Intermetallics[C]. London: Oxford University, 1991. 198-200.

[5]Cox A, Baeslack W A Ⅲ, Zorko S, et al. Resistance diffusion bonding of a titanium aluminide. Proceedings Conference on Diffusion Bonding[C]. Cranfield: Osaka University, 1990. 395-398.

[6]Baeslack W A Ⅲ, Mascorella T J, Kelly T J. Weld ability of a titanium aluminide[J]. Welding Journal Research Supplement, 1989. 483s-498s.

[7]Baeslack W A Ⅲ, Threadgill P L, Nicholas E D. Linear friction welding of α2 titanium aluminides[R]. TWI Research Report, 1995. 143-156.

[8]Gould J E, Stotler T V. Application of flash welding to a titanium aluminide alloy-micro structural evaluations[A]. ASME Technical Paper[C]. Germany, 1991. 123-124.

[9]Baeslack W A Ⅲ, Cielack M J, Headley T J. Structure, properties and fracture of pulsed Nd:YAG laser welded Ti-14.8wt%Al-21.3wt%Nb titanium aluminide[J]. Scripta Met, 1988, 22(7): 1155-1160.

[10]Baeslack W A Ⅲ. Joining of α2 titanium aluminides, proceedings symposium weldability of materials[A]. ASM Fall Meeting[C], Detroit: Detroit University, 1990. 247-258.

[11]Strychor R, Williams J C, Soffa W A. Phase transformations and modulated microstructures in Ti-Al-Nb alloys[J]. Met Trans A, 1988, 19A: 225-229.

[12]刘博, 崔约贤. Ti3Al-Nb基合金的焊接性研究进展[J]. 宇航材料工艺, 1997(5): 1-6.

LIU Bo, CUI Yue-xian. Weldability development of Ti3Al-Nb based alloy[J]. Space Materials Technics, 1997(5): 1-6.

[13]吴斌. Ag-Cu-Ti钎料活性钎焊Si3N4陶瓷的研究[J]. 华东船舶工业学院学报, 1998, 12(2): 74-79.

WU Bin. Active brazing Si3N4 with Ag-Cu-Ti filler metal[J]. Journal of East China Shipbuilding Institute, 1998, 12(2): 74-79.

[14]Bank. Interfacial reaction between alumina and Cu-Ti filler metal during reaction metal brazing[J]. Weld J, 1994, 73(3): 54-57.

[15]Lee S J, Wu S K. Infrared joining strength and interfacial microstructures of Ti-48Al-2Nb-2Cr intermetallics using Ti-15Cu-15Ni foil[J]. Intermetallics, 1999, 7: 11-21.

[16]Toshimitsu T. Effects of brazing filler on properties of brazing joints between TiAl and metallic materials[J]. Intermetallics, 2001, 9: 253-260.

收稿日期: 2004-06-12; 修订日期: 2004-10-10

作者简介: 何 鹏(1972-), 男, 博士.

通讯作者: 何 鹏, 博士; 电话: 0451-86418146; E-mail: hepeng@hope.hit.edu.cn

(编辑李向群)