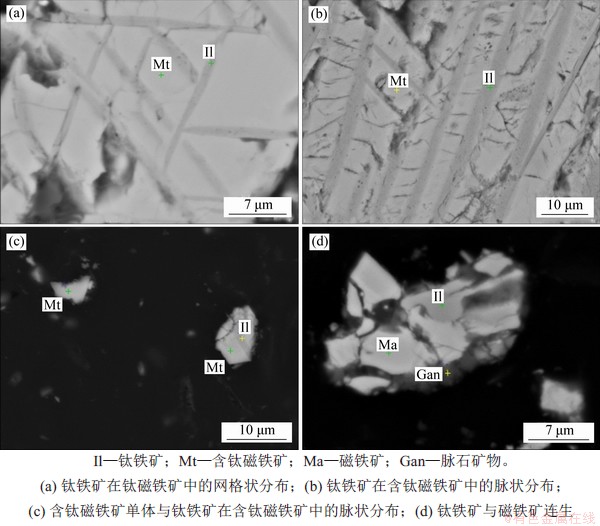

从表6和表7可见:含钛磁铁矿与钛铁矿之间的连生比较多,16.80%的含钛磁铁矿与钛铁矿连生,而钛铁矿中与含钛磁铁矿连生的矿物颗粒占总量的34.36%,这一部分钛铁矿多是以网格状(见图6(a))或者细脉状(见图6(b)和图6(c))生长在含钛磁铁矿中,呈固溶体分解结构,少量与含钛量较少的磁铁矿相邻产出,形成连晶颗粒(见图6(d))。这些与含钛磁铁矿嵌布共生的钛铁矿粒度非常小,一般在10 μm左右,并且网格状与细脉状生长的钛铁矿宽度只有2 μm,与含钛磁铁矿结合十分紧密,在常规磨矿细度下很难将这2种矿物分开,导致磁选精矿铁品位较低、Ti质量分数过高。

表4 铁精矿中主要矿物的粒度分布

Table 4 Grain size distribution of main minerals in iron concentrate

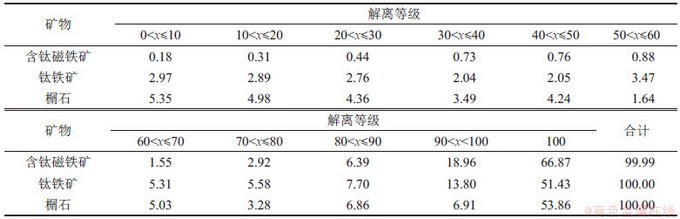

表5 铁精矿中主要矿物的解离度(质量分数)

Table 5 Dissociation degree of main minerals in iron concentrate(mass fraction) %

表6 铁精矿中含钛磁铁矿的连生状态(以质量分数表征)

Table 6 Interlocking status of titaniferous magnetite in iron concentrate %

表7 铁精矿中钛铁矿的连生状态(以质量分数表征)

Table 7 Interlocking status of ilmenite in iron concentrate %

图6 含钛磁铁矿与钛铁矿嵌布关系图

Fig. 6 Dissemination relationship between titaniferous magnetite and ilmenite

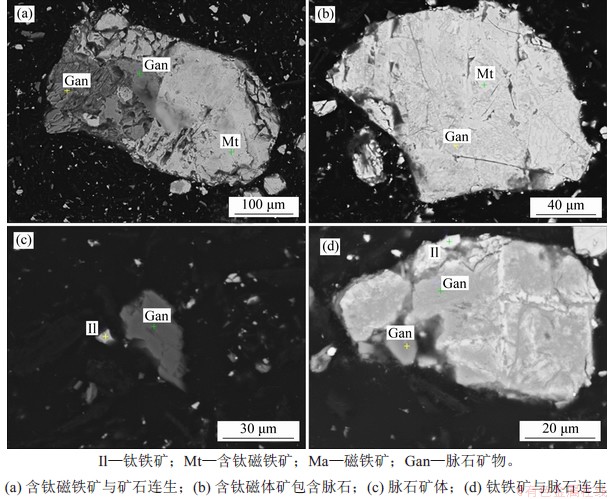

图7 含钛磁铁矿与脉石嵌布关系图

Fig. 7 Dissemination relationship between titaniferous magnetite and gangue mineral

含钛磁铁矿与脉石嵌布关系如图7所示。含钛磁铁矿与脉石的连生同样也较多,约占总量的16%。图7(a)中,矿物颗粒是一个粒度大含钛磁铁矿与辉石的连生体,这一类连生体可以通过细磨使它们解离;而含钛磁铁矿中还含有微细粒脉石矿物包体(见图7(b)),实现二者的单体解离难度较大,该铁精矿中钛铁矿有51.44%是以单体形式存在的。图7(c)中矿物颗粒是粒度小的钛铁矿与解离开的透闪石。钛铁矿与脉石矿物也存在连生现象,与榍石的连生边界十分复杂(见图7(d)),而且在该种矿粒中钛铁矿占较小,分离较困难。

矿物解离度检测结果进一步表明,造成该铁精矿中含钛磁铁矿质量分数偏低的原因在于含钛磁铁矿的单体解离度不高,一部分钛铁矿和脉石矿物以连生体形式进入铁精矿,并且这部分连生的钛铁矿和脉石矿物与含钛磁铁矿共生关系非常密切,在常规磨矿细度下难以实现分离。但在该铁精矿中存在一部分钛铁矿和脉石矿物呈单体解离状态,从铁精矿中钛铁矿的质量分数(见表2)与钛铁矿的单体解离度(见表7)可以得出,呈单体解离状态的钛铁矿颗粒质量占其总质量的7.72%,通过改进磁选分离工艺,将这些钛铁矿和脉石矿物分离,可以有效提高该铁精矿的Fe品位,降低TiO2质量分数。

4 结论

1) 试验所用铁精矿来自辽宁朝阳地区某选厂两段磁选精矿,最大粒度约为104 μm,平均粒度约为21 μm。该铁精矿TFe质量分数为43.75%,含二氧化钛21.54%,含钒0.91%。

2) 该铁精矿中含钛磁铁矿是主要的含铁矿物,质量分数为63.81%,其中含TiO2质量分数约为10.99%,这部分Ti主要赋存于磁铁矿晶格中,难以通过选矿方法分离。

3) 该铁精矿中钛铁矿的质量分数约为15%,钛铁矿质量分数偏高是导致该铁精矿品位较低、TiO2质量分数过高的主要原因之一,但其中一部分钛铁矿呈单体解离状态,钛铁矿质量分数约为7.72%。通过改进磁选分离工艺,可以将其从铁精矿中分离,从而提高Fe品位,降低TiO2质量分数。

4) 该铁精矿中其他脉石矿物质量分数约为21.19%,其中不仅存在少量粒度相对较大的单体脉石矿物,如石英、透闪石、长石等,而且有与含钛磁铁矿连生不紧密的的细粒脉石,这些脉石矿物可以通过改进分选工艺如细磨后磁选进行分离,从而提高铁精矿品位。但含钛磁铁矿内部存在少量微细粒脉石矿物包体,这类脉石被包裹在磁铁矿内部,很难分离。

5) 含钛磁铁矿内部存在细脉状和棋盘格状钛铁矿,形成固溶体分离结构,嵌布关系密切,这是该铁精矿品位较低、TiO2质量分数过高的另一个原因。由于铁精矿中含钛磁铁矿的粒度很小,粒度小于10 μm的钛磁铁矿质量分数约为37%,通过再磨矿实现含钛磁铁矿和钛铁矿以及其他矿物单体解离,难以达到理想的效果。

参考文献:

[1] CHENG Gongjin, GAO Zixian, LU Mengyang, et al. Coal-bbased reduction and magnetic separation behavior of low-grade vanadium-titanium magnetite pellets[J]. Minerals, 2017, 7(6): 86-99.

[2] 陈露露. 我国钒钛磁铁矿资源利用现状[J]. 中国资源综合利用, 2015, 33(10): 31-33

CHEN Lulu, Current situation of vanadium-titanium magnetite resource utilization[J]. China Resources Comprehensive Utilization. 2015, 33(10): 31-33

[3] 王勋, 韩跃新, 李艳军, 等. 钒钛磁铁矿综合利用研究现状[J]. 金属矿山, 2019(6): 33-37.

WANG Xun, HAN Yuexin, LI Yanjun, et al. Research status on comprehensive development and utilization of vanadium-titanium magnetite[J]. Metal Mine, 2019(6): 33-37.

[4] 刘兴华, 赵礼兵, 袁致涛. 朝阳某钒钛磁铁矿石工艺矿物学特性研究[J]. 现代矿业, 2011, 27(8): 23-25.

Liu Xinghua, Zhao Libing, Yuan Zhitao. Study on technological mineralogy characteristics of a vanadium titanium magnetite in Chaoyang[J]. Express Information of Mining Industry, 2011, 27(8): 23-25.

[5] 许承宝, 张一敏, 刘涛, 等. 辽西某钒钛磁铁矿工艺矿物学研究[J]. 有色金属(选矿部分), 2018(3): 6-10, 46.

XU Chengbao, ZHANG Yimin, LIU Tao, et al. Process mineralogy of vanadium-titanium magnetite ore from western Liaoning[J]. Nonferrous Metals (Mineral Processing Section), 2018(3): 6-10, 46.

[6] 唐志东, 李文博, 高鹏, 等. 朝阳钒钛磁铁矿工艺矿物学研究[J]. 东北大学学报(自然科学版), 2017, 38(12): 1769-1774.

TANG Zhidong, LI Wenbo, GAO Peng, et al. Mineralogical study of vanadium titanium magnetite ore in Chaoyang[J]. Journal of Northeastern University(Natural Science), 2017, 38(12): 1769-1774.

[7] 李亮, 罗建林. 攀枝花地区某钒钛磁铁矿工艺矿物学研究[J]. 金属矿山, 2010(4): 89-92, 109.

Li Liang Luo Jianlin. Process mineralogy studies on V-Ti magnetite in Panzhihua region[J]. Metal Mine, 2010(4): 89-92, 109.

[8] 于宏东, 王丽娜, 曲景奎, 等. 中国典型钒钛磁铁矿的工艺矿物学特征与矿石价值[J]. 东北大学学报(自然科学版), 2020, 41(2): 275-281.

YU Hongdong, WANG Lina1 QU Jingkui,et al. Process mineralogical characteristics and ore value of typical vanadium titanium magnetite in China[J]. Journal of Northeastern University(Natural Science), 2020, 41(2): 275-281.

[9] XU Chengbao, ZHANG Yimin, LIU Tao, et al. Characterization and pre-concentration of low-grade vanadium-titanium magnetite ore[J]. Minerals, 2017, 7(8): 137-150.

[10] 王良, 刘长河, 庄立军. 辽西钒钛磁铁矿综合开发利用研究[C]// 第26届全国铁合金学术研讨会论文集: 上册. 北京: 中国金属学会, 2018: 306-308.

WANG Liang, LIU Changhe, ZHUANG Lijun, Research on Comprehensive development and utilization of vanadium titanium magnetite in West Liaoning[C]// Proceedings of the 26th National Ferroalloy Symposium: Volume 1. Beijing: Chinese Metal Society, 2018: 306-308.

[11] 贾木欣, 周俊武, 应平, 等. 工艺矿物学自动测试系统BPMA的研制及应用[J]. 有色冶金设计与研究, 2017, 38(4): 5-16, 20.

JIA Muxin, ZHOU Junwu, YING Ping, et al. Development and application of BGRIMM process mineralogy analyzing system(BPMA)[J]. Nonferrous Metals Engineering & Research, 2017, 38(4): 5-16, 20.

[12] 张文平, 蔡明明, 高腾跃, 等. 某含金矿石的BPMA自动工艺矿物学研究[J]. 有色金属(选矿部分), 2019(1): 14-20.

ZHANG Wenping, CAI Mingmin, GAO Tengyue, et al. Study on the process mineralogy by BPMA of a gold ore[J]. Nonferrous Metals (Mineral Processing Section), 2019(1): 14-20.

[13] SUN Yongsheng, HAN Yuexin, LI Yanfeng, et al. Formation and characterization of metallic iron grains in coal-based reduction of oolitic iron ore[J]. International Journal of Minerals, Metallurgy and Materials, 2017, 24(2): 123-29.

[14] 温利刚, 贾木欣, 王清, 等. 自动矿物学新技术_BPMA技术及在煤中的应用[J]. 中国煤炭地质, 2019, 31(9): 8-17.

WEN Ligang, JIA Muxin, WANG Qing, et al. A new technique in automated process mineralogy: BPMA technology and its application in coal research[J]. Coal Geology of China, 2019, 31(9): 8-17.

[15] 张亚楠. 辽西风化壳型钒钛磁铁矿矿床浅析及其意义[J]. 有色矿冶, 2014, 30(1): 14-16.

ZHANG Yanan. Simple analysis and its meaning on the weathering crust vanadium titanium magnetite deposit of western Liaoning province[J]. Nonferrous Mining and Metallurgy, 2014, 30(1): 14-16.

[16] 李厚民, 王瑞江, 肖克炎, 等. 中国超贫磁铁矿资源的特征、利用现状及勘查开发建议: 以河北和辽宁的超贫磁铁矿资源为例[J]. 地质通报, 2009, 28(1): 85-90.

LI Houmin, WANG Ruijiang, XIAO Keyan, et al. Characteristics and current utilization status of ultra-lowgrade magnetite resource, and suggestion on its exploration and development[J]. Geologcal Bulletin of China, 2009, 28(1): 85-90.

[17] 罗金华, 武昭妤, 吴恩辉, 等. 红格钒钛磁铁矿选铁精矿工艺矿物学特征[J]. 钢铁钒钛, 2015, 36(2): 73-77.

LUO Jinhua, WU Zhaoyu, WU Enhui, et al. Studies on mineralogical characteristics of iron concentrates in Hongge vanadium titano-magnetite[J]. Iron Steel Vanadium Titanium, 2015, 36(2): 73-77.

[18] 刘然, 李超, 吕庆, 等. 承德钒钛磁铁矿粉基础特性及烧结试验研究[J]. 钢铁钒钛, 2014, 35(4): 77-82.

LIU Ran, LI Chao, LU Qing, et al. Study on differential thermal analysis and single burning experiment of vanadium-titanium ore powder[J]. Iron Steel Vanadium Titanium, 2014, 35(4): 77-82.

(编辑 陈灿华)

收稿日期: 2020 -02 -13; 修回日期: 2020 -04 -28

基金项目(Foundation item):国家自然科学基金资助项目(U1908226) (Project(U1908226) supported by the National Natural Science Foundation of China)

通信作者:薛向欣,博士,教授,从事钒钛磁铁矿研究;E-mail:xuexx@mail.neu.cn