汽车废催化剂微波加热厚度优化

来源期刊:中国有色金属学报(英文版)2020年第12期

论文作者:何广军 刘鹏 曲雯雯 王仕兴 张利波

文章页码:3417 - 3426

关键词:汽车废催化剂;微波;加热厚度;优化

Key words:spent automobile catalyst; microwave; heating thickness; optimization

摘 要:为了提高汽车废催化剂在微波加热过程中温度场分布的均匀性,开发加热厚度优化的新方法。采用高斯模型和基于介电损耗正切和反射损耗的数值算法计算汽车废催化剂的微波加热平均穿透深度和厚度。结果表明:汽车废催化剂是一种中等损耗物料,从室温到800 °C的过程中平均穿透深度为1.11 m,汽车废催化剂的最优加热厚度约为0.83 m或平均穿透深度的0.75倍。工业化应用分析显示:该最佳厚度能提高温度场的均匀分布、减少能耗。

Abstract: A new method was developed to optimize the microwave heating thickness of the spent automobile catalyst in order to improve the uniform distribution of the temperature field. The average penetration depth and the microwave heating thickness of the spent automobile catalyst were calculated by Gauss model and numerical calculation based on dielectric loss tangent and reflection loss. The results showed that the spent automobile catalyst was a medium loss material. The average penetration depth was 1.11 m from room temperature to 800 °C. The optimum microwave heating thickness of the spent automobile catalyst was about 0.83 m or 0.75 times of the average penetration depth. Industrial application analysis indicated that the optimization of heating thickness could improve the uniform distribution of the temperature field and reduce energy consumption.

Trans. Nonferrous Met. Soc. China 30(2020) 3417-3426

Guang-jun HE1,2,3,4,5, Peng LIU2,3,4,5, Wen-wen QU1,2,3,4, Shi-xing WANG2,3,4,5, Li-bo ZHANG2,3,4,5

1. Faculty of Science, Kunming University of Science and Technology, Kunming 650500, China;

2. State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization, Kunming University of Science and Technology, Kunming 650093, China;

3. Yunnan Provincial Key Laboratory of Intensification Metallurgy, Kuming University of Science and Technology, Kunming 650093, China;

4. National Local Joint Laboratory of Engineering Application of Microwave Energy and Equipment Technology, Kuming University of Science and Technology, Kunming 650093, China;

5. Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming 650093, China

Received 23 December 2019; accepted 19 October 2020

Abstract: A new method was developed to optimize the microwave heating thickness of the spent automobile catalyst in order to improve the uniform distribution of the temperature field. The average penetration depth and the microwave heating thickness of the spent automobile catalyst were calculated by Gauss model and numerical calculation based on dielectric loss tangent and reflection loss. The results showed that the spent automobile catalyst was a medium loss material. The average penetration depth was 1.11 m from room temperature to 800 °C. The optimum microwave heating thickness of the spent automobile catalyst was about 0.83 m or 0.75 times of the average penetration depth. Industrial application analysis indicated that the optimization of heating thickness could improve the uniform distribution of the temperature field and reduce energy consumption.

Key words: spent automobile catalyst; microwave; heating thickness; optimization

1 Introduction

Automobile catalyst is mainly used to convert CO, CHx and NOx into non-toxic CO2, H2O and N2, and it consists of carrier and catalytic active substances. The active substances are mainly platinum group metals (PGM), such as Pt, Pd, and Rh [1,2]. More than 60% of PGM are used in automobile exhaust industry. With the abandonment of a large number of automobiles, lots of the spent automobile catalysts accumulated in many parts of the suburbs. This leads to environmental pollution and waste of scare resources [3]. Therefore, the recovery of PGM from the spent automobile catalyst has attracted a lot of attention.

The recovery methods of PGM from the spent automobile catalyst include pyrometallurgical and hydrometallurgical processes. Especially, micro- wave technology has attracted much attention in the field of recovering precious metals from the spent automobile catalyst in recent years [4-6], because it can improve the leaching efficiency, reduce the roasting temperature and shorten the leaching time [7,8]. However, one of the major problems in microwave heating process is uneven distribution of temperature field [9,10], which causes hot spots and cold centers. The hot spots and cold centers would result in overheating or incomplete reaction, high energy consumption, low energy efficiency, and so on [11]. The uneven distribution of temperature field is caused by non-uniform electromagnetic field inside microwave cavity and uneven absorption of microwave energy by the spent automobile catalyst [12]. Therefore, it is the research focus to realize the uniform distribution of temperature field in microwave heating.

The optimization of the microwave heating thickness is an effective method to solve the uneven temperature distribution [13], because too small thickness would cause hot spots and high energy- consumption, and too large thickness would cause cold centers [14]. In literatures, experiments and simulations were wildly used to optimize microwave heating thickness [15-18]. However, the processes are tedious and time-consuming. SHANG et al [19] obtained the multiple values of the optimized thickness for silica. However, they didn’t suitable for the actual production process. Therefore, it is necessary to develop an effective method to optimize the microwave heating thickness based on the material nature.

This work was to develop an optimization method of microwave heating thickness. The dielectric properties of the spent automobile catalyst were measured from room temperature to 800 °C at 2450 MHz. The microwave absorption characteristics were studied by theoretical analysis and heating experiment. Based on the absorption characteristics and dielectric properties, the optimum microwave heating thickness of the spent automobile catalyst was obtained by numerical calculation from room temperature to 800 °C at 2450 MHz.

2 Experimental

2.1 Material

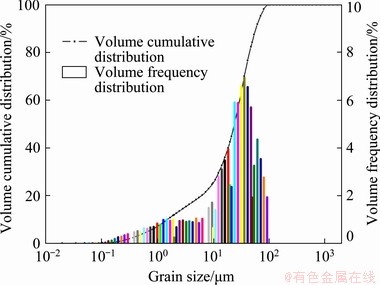

The spent automobile catalyst was crushed and milled into powder using a ball mill. The volume cumulative distribution and volume frequency distribution were examined using a JL-1177A laser particle analyzer. As shown in Fig. 1, the area average particle size and volume average particle size of the powder sample are 3.57 μm and 25.63 μm, respectively.

X-ray diffraction (XRD) pattern of the spent automobile catalyst is shown in Fig. 2. The main components of the spent automobile catalyst were cordierite, γ-Al2O3 and CeO. The chemical composition of the spent automobile catalyst was confirmed by X-ray fluorescence (Axios PW4400/40, Panalytical, Netherlands). The normalized element contents of platinum and rhodium are 0.11 and 0.04 wt.%, respectively (Table 1).

Fig. 1 Volume cumulative distribution and volume frequency distribution of spent automobile catalyst

Fig. 2 XRD pattern of spent automobile catalyst

Table 1 Chemical composition of spent automobile catalyst (wt.%)

2.2 Measurement of dielectric properties

Dielectric properties are the principal parameters that determine how the energy is absorbed and transmitted inside a material. The dielectric properties can be expressed in the followed form [20]: εr=ε′r-jε″r, where relative dielectric constant (ε′r) represents the storing ability of microwave energy, and relative dielectric loss factor (ε″r) represents the dissipating ability of microwave energy inside a material.

The dielectric properties were measured by the cavity perturbation method [21,22]. The measurement system includes induction heating equipment, circulating water cooling equipment, pneumatic equipment, TM0n0 cylindrical cavity, vector network analyzer (Keysight Technologies, Agilent N5230C), computer and test software. The test software is used to calculate and calibrate the date collected from the cavity perturbation. The powder of spent automobile catalyst was dried at 100 °C for 10 h in a drying oven and was put into a quartz tube with length of 500 mm and inside diameter of 28 mm. The measurements were conducted every 50 °C in the range from room temperature to 800 °C. The dielectric properties were measured three times, and the average data were used. The entire measurement process was in an air atmosphere. The mass of sample was weighed by analytical balance. The volume of sample was calculated based on the values of radius and height. The density of spent automobile catalyst could be calculated (1.48 g/cm3). The mass didn’t change before and after the measurement of dielectric properties.

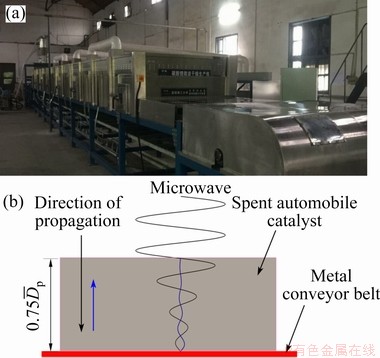

2.3 Microwave heating equipment

The microwave heating equipment in the present work is designed and fabricated in the Key Laboratory of Unconventional Metallurgy of the Ministry of Education, Kunming University of Science and Technology (Fig. 3). The inner dimensions of the microwave cavity are: 420 mm in length, 260 mm in width and 260 mm in height. The thermal insulation material is placed in the microwave cavity to reduce heat loss. The power of the microwave reactor is adjustable from 0 to 4.8 kW at 2.45 GHz. The temperature was measured by a K-type thermocouple connected to the control system and inserted from the top of microwave cavity. The thermocouple is 1000 mm in length and 3 mm in diameter, with the temperature range of 0-1250 °C and the measurement precision of ±0.5 °C. The sample is placed in the alumina crucible, and the thermocouple was inserted into the sample during the heating process.

Fig. 3 Photo of microwave heating equipment

2.4 Reflection loss and power penetration depth

Reflection loss is a significant parameter to evaluate microwave absorbing characteristics. According to transmission line theory, microwave irradiates vertically to absorber slab backed by an ideal conductor. The reflection loss (LR) can be summarized by the following equations [23,24]:

(1)

(1)

(2)

(2)

where Zin is the normalized input impedance and Z0 is the impedance of free apace; μr is relative complex permeability and is assumed to be 1 in this study; d is the thickness of absorber slab; c is the speed of light in free space; f is the frequency of microwave; LR is a ratio of the reflection power to the incident power. A lower value of LR stands for a better microwave absorbing characteristics.

The power penetration depth (Dp) is a very important factor in the design and scale-up of a microwave heating system. It is defined as the distance from the surface into material at which the incident wave power density attenuates to e-1 of its surface value, and can be calculated by [25,26]

(3)

(3)

3 Results and discussion

3.1 Dielectric properties of spent automobile catalyst

The influence of temperature on the dielectric properties of the spent automobile catalyst at 2.45 GHz is shown in Fig. 4. The dielectric constant decreased from room temperature to 200 °C and followed by a slight fluctuation as the temperature increased to 800 °C in Fig. 4(a). The greater thermal agitation disturbed the alignment of molecular dipoles with the electromagnetic field as temperature increased and reduced the polarization in the range from room temperature to 200 °C. The value of the dielectric constant varied from 3.3995 at 200 °C to 3.5983 at 800 °C, and its arithmetic mean was 3.476, indicating that spent automobile catalyst was weakly polar. These results suggested that temperature had a little effect on the dielectric constant and polarity of the spent automobile catalyst, which was attributed to insensitivity of its main chemical components to temperature. As shown in Fig. 4(b), the dielectric loss factor decreased slightly from room temperature to 200 °C (its minimum value was 0.0176 at 200 °C), and then increased as temperature increased to 800 °C (its maximum value was 0.1166 at 800 °C). So, the temperature had a significant influence on the dielectric loss factor of the spent automobile catalyst at 2.45 GHz. The dielectric loss factor characterizes the ability of a material to dissipate electromagnetic energy into heat, which results from dipole loss and conduction loss [27,28]. Dipole is an important physical model in the study of dielectric materials. Generally, a polar molecule can be equivalent to a dipole. The dipole loss decreases with the increase of temperature, and the conduction loss increases with the increase of temperature. When one of the two loss mechanism is dominant, the trend of the dielectric loss factor corresponds to this mechanism. The curve of dielectric loss factor may show a valley feature when the contribution of the two loss mechanisms are equal [22]. Figure 4(b) indicated that the dipole loss was dominant from room temperature to 200 °C and the conduction loss was dominant from 250 to 800 °C [29]. Hence, the smaller drop of the dielectric loss factor was attributed to smaller decrease of the dielectric constant from room temperature to 200 °C. The increase of the dielectric loss factor from 250 to 800 °C might be caused by the PGM in spent automobile catalyst, because the outer electrons of PGM became unstable with the increase of temperature. As a consequence, the temperature-dependent electrical conductivity could enhance the temperature- dependent dielectric loss factor of spent automobile catalyst [22].

Fig. 4 Temperature dependence of dielectric properties at 2.45 GHz

3.2 Microwave absorbing characteristics of spent automobile catalyst

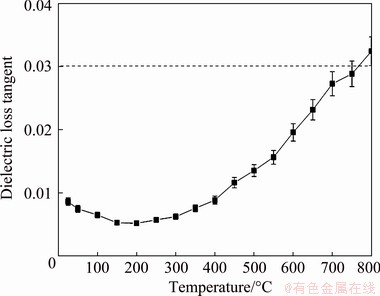

Dielectric loss tangent (tan δ=ε″r/ε′r) is an intuitive parameter to describe the ability of a material to convert microwave energy into heat [30]. In general, the microwave absorbing ability is greater when the dielectric loss tangent is higher. LAYBOURN et al [31] classifies materials by the dielectric loss tangent. The tan δ of the low loss materials is smaller than 3×10-4. The tan δ of the medium loss materials is between 3×10-4 and 3×10-2. The tan δ of the high loss materials is larger than 3×10-2. Figure 5 shows the temperature dependence of tan δ at 2.45 GHz. The dielectric loss tangent of the spent automobile catalyst decreased from room temperature to 200 °C, and then increased with temperature to 800 °C. The minimum value of the tan δ is 0.0052 at 200 °C while the maximum is 0.0324 at 800 °C. Hence, the spent automobile catalyst is medium loss material from room temperature to 750 °C and high loss material from 750 to 800 °C.

Fig. 5 Temperature dependence of dielectric loss tangent at 2.45 GHz

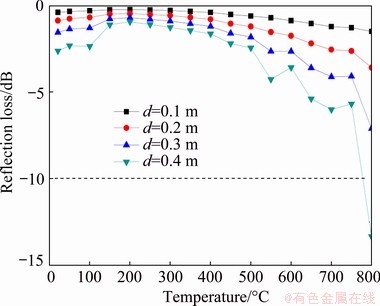

The reflection loss of spent automobile catalyst at different thicknesses and 2.45 GHz is shown in Fig. 6. Generally, LR<-10 dB denotes that 68% amplitude or 90% power of electromagnetic wave is absorbed by material, while LR<-20 dB represents that 90% amplitude or 99% power of electro-magnetic wave is absorbed by material [32,33]. Obviously, the LR of the spent automobile catalyst is temperature dependent and thickness dependent. The LR decreased with the increase of thickness, increased from room temperature to 200 °C and decreased from 250 to 800 °C. The maximum value of LR occurred at 200 °C. Interestingly, the value of LR<-10 dB (-13.33 dB) was obtained only at d=0.4 m and 800 °C, indicating that the spent automobile catalyst was a medium loss material from room temperature to 750 °C. This result is similar to that of dielectric loss tangent. The peak value in Fig. 6 corresponds to the valley value in Fig. 5 at around 200 °C. Hence, the dielectric loss tangent and reflection loss are equivalent parameters to measure the microwave absorbing characteristics.

Fig. 6 Reflection loss of spent automobile catalyst at different thicknesses (d) and 2.45 GHz

Fig. 7 Microwave heating curve of spent automobile catalyst at 2.45 GHz

The heating curve of spent automobile catalyst (50 g) in the microwave heating equipment with power of 1000 W and frequency of 2.45 GHz is shown in Fig. 7. The temperature of spent automobile catalyst increased from 17 to 170 °C in 50 min with a heating rate of 3.06 °C/min. These experiment results showed that the spent automobile catalyst was a medium loss material. On the other hand, the temperature rise curve was gradually away from the tangent of point (4 min, 35 °C) with the increase of time, indicating that the heating rate was decreased. According to the heat conduction equation: ρc( T/

T/ t)=

t)=

[34,35], the heating rate (

[34,35], the heating rate ( T/

T/ t) is proportional to ε″r at low temperatures.

t) is proportional to ε″r at low temperatures.

The decrease of the heating rate was attributed to the decrease of the dielectric loss factor from room temperature to 170 °C, which was consistent with the data of dielectric loss factor in Fig. 4(b). Therefore, microwave heating experiment also verified that the spent automobile catalyst was medium loss material.

3.3 Average penetration depth of spent automobile catalyst

Figure 8 illustrates the effect of temperature on the calculated value and fitting curve of the power penetration depth at 2.45 GHz. The power penetration depth of the spent automobile catalyst could be calculated from Eq. (3). Obviously, the variations of the penetration depth were caused by the variations of the dielectric properties. The dielectric properties were temperature dependent, so the penetration depth was temperature dependent. The penetration depth of the spent automobile catalyst increased when the temperature increased from room temperature to 200 °C, and reached a maximum value of 2.04 m at 200 °C. When the temperature increased from 200 to 800 °C, the penetration depth decreased rapidly to 0.32 m at 800 °C. The penetration depth can be used to describe the absorbing characteristics of materials. For the spent automobile catalyst, the larger the penetration depth was, the weaker the absorbing ability was. The penetration depth is often used to determine the heating thickness of materials. However, it is only suitable for the case that the penetration depth does not change much with the increase of temperature. Hence, the average penetration depth would be employed to determine the microwave heating thickness of the spent automobile catalyst. Firstly, the variation of the penetration depth could be fitted by Gauss model as a function of temperature. The Gauss model can be expressed as exponential form [36]:

(4)

(4)

where T is the temperature; D0, A, w and Tc are constants. The fitting results of the constants were D0=0.3875, A=654.6956, w=334.6203, and Tc=205.3548. The coefficient of correlation (R2) was 0.99, which implied that the fitting curve was in good agreement with the calculated value.

Secondly, the average penetration depth is determined by the following expression:

(5)

(5)

where T0 and Tf are the initial temperature and final temperature, respectively.

Lastly, the average penetration depth of the spent automobile catalyst was  =1.11 m.

=1.11 m.

For microwave heating process, the average penetration depth is an intuitive physical quantity to describe the attenuation of electromagnetic energy in a material. It takes an average of 1.11 m to attenuate the microwave power density to 37% of its surface value from room temperature to 800 °C.

Fig. 8 Calculated value and fitting curve of power penetration depth

3.4 Thickness optimization of microwave heating for medium loss materials

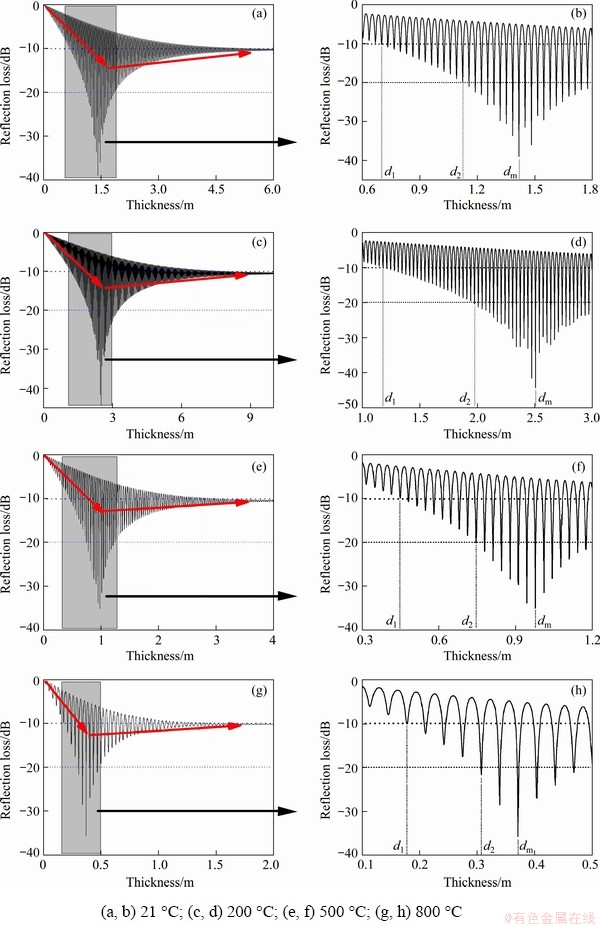

Transmission line theory was employed to optimize the microwave heating thickness of a material in this study. The variation of the reflection loss with material thickness could be obtained using Mathematica 9.0 numerical calculations. Figure 9 shows the effects of the microwave heating thickness on the reflection loss at typical temperature (21, 200, 500 and 800 °C). It can be seen that the reflection loss depends on thickness and temperature. As the thickness increased, the reflection loss decreased firstly, and then increased to a constant less than -10 dB, as shown by the red arrows in Figs. 9(a, c, e, g), indicating that there was an optimum heating thickness at which almost all microwave energy was absorbed by the spent automobile catalyst. It is certainly true that the microwave energy is almost completely absorbed if the heating thickness increases excessively. For example, 90% microwave power would be absorbed by the spent automobile catalyst when the heating thickness is greater than 5 m at 21 °C in Fig. 9(a) and 1.5 m at 800 °C in Fig. 9(g). However, the larger thickness will produce cold centers. Therefore, it is necessary to optimize the micro- wave heating thickness of the spent automobile catalyst.

Fig. 9 Effects of microwave heating thickness on reflection loss

Here, we proposed a novel method to optimize the microwave heating thickness. In Figs. 9(b, d, f, h), d1 is the thickness at the first valley where the reflection loss is less than -10 dB; d2 is the thickness at the first valley where the reflection loss is less than -20 dB; dm is the thickness at the minimum reflection loss. d1, d2 and dm can be obtained by numerical calculation in the heating process. For example, d1=0.67 m, d2=1.24 m and dm=1.42 m in Fig. 9(b); d1=0.45 m, d2=0.75 m and dm=0.98 m in Fig. 9(f). The values of d1, d2 and dm from room temperature to 800 °C can be obtained, and their average values can also be calculated. Values of d1, d2 and dm are given in Table 2. The optimum microwave heating thicknesses are about  for the medium loss materials and

for the medium loss materials and  for the high loss materials.

for the high loss materials.

As discussed in Section 3.2, the spent automobile catalyst is mainly medium loss material in the studied temperature range. We can get  =0.620 m and

=0.620 m and  =1.048 m. Hence, we can draw a conclusion that the optimum microwave heating thickness of the spent automobile catalyst is about 0.83 m, or in form of

=1.048 m. Hence, we can draw a conclusion that the optimum microwave heating thickness of the spent automobile catalyst is about 0.83 m, or in form of  .

.

Table 2 Values of d1, d2 and dm from room temperature to 800 °C

3.5 Industrial application analysis of optimum thickness

Microwave power decays exponentially as a function of distance [12,37]. According to the definition of the power penetration depth, the microwave power decreases to 37% of its surface value at penetration depth, to 14% at twice the penetration depth and to 5% at three times the penetration depth. Hence, the microwave heating thickness with 2-3 times of the penetration depth would seriously arouse the inhomogeneous distribution of temperature field.

We optimized the heating thickness of the large-scale microwave equipment. Figure 10(a) presents the photo of the large-scale microwave equipment manufactured in our laboratory. The magnetron is above the equipment, and the conveyor belt is metal. Microwave irradiates the heated materials from up to bottom. Figure 10(b) shows the schematic diagram of the optimum microwave heating chickness. The optimal thickness of  was obtained when the microwave radiated vertically to the spent automobile catalyst. This indicated that the distance of microwave propagation was

was obtained when the microwave radiated vertically to the spent automobile catalyst. This indicated that the distance of microwave propagation was  inside the spent automobile catalyst. Correspondingly, approximately 80% microwave power was dissipated into the optimum thickness. This conclusion takes into account a balance between the energy consumption and the uniformity of the temperature field. If microwave was oblique, it would lead to greater microwave propagation distance and then more power loss. Certainly, the higher heating rate could be obtained by using a thickness of less than

inside the spent automobile catalyst. Correspondingly, approximately 80% microwave power was dissipated into the optimum thickness. This conclusion takes into account a balance between the energy consumption and the uniformity of the temperature field. If microwave was oblique, it would lead to greater microwave propagation distance and then more power loss. Certainly, the higher heating rate could be obtained by using a thickness of less than  in microwave large-scale production.

in microwave large-scale production.

Fig. 10 Photo of large-scale microwave equipment manufactured in our laboratory (a), and schematic diagram of optimum microwave heating thickness (b)

4 Conclusions

(1) The dielectric properties of spent automobile catalyst were measured from room temperature to 800 °C at 2.45 GHZ. The microwave absorbing characteristics and heating experiment showed that spent automobile catalyst was a medium loss material.

(2) The average penetration depth  calculated by Gauss model was 1.11 m.

calculated by Gauss model was 1.11 m.

(3) For the medium loss characteristics, the optimum microwave heating thickness was about 0.83 m or  .

.

(4) Industrial application analysis showed that approximately 80% of microwave power was dissipated in the optimum thickness. Moreover, the optimized method of microwave heating thickness is also suitable for the medium loss materials.

References

[1] KIM W, KIM B, CHOI D, OKI T, KIM S. Selective recovery of catalyst layer from supporting matrix of ceramic- honeycomb-type automobile catalyst [J]. Journal of Hazardous Materials, 2010, 183: 29-34.

[2] de ABERASTURI D J, PINEDO R, de LARRAMENDI I R, de LARRAMENDI J I R, ROJO T. Recovery by hydrometallurgical extraction of the platinum- group metals from car catalytic converters [J]. Minerals Engineering, 2011, 24: 505-513.

[3] DONG Hai-gang, ZHAO Jia-chun, CHEN Jia-lin, WU Yue-dong, LI Bo-jie. Recovery of platinum group metals from spent catalysts: A review [J]. International Journal of Mineral Processing, 2015, 145: 108-113.

[4] PENG Zhi-wei, HWANG J Y. Microwave-assisted metallurgy [J]. International Materials Reviews, 2014, 60: 30-63.

[5] DUAN Bo-hua, ZHANG Zhao, WANG De-zhi, ZHOU Tao. Microwave sintering of Mo nanopowder and its densification behavior [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 1705-1713.

[6] LI Yan, CHEN Li-li, ZHAO Fang-xian. Highly selective acetone sensor based on ternary Au/Fe2O3-ZnO synthesized via co-precipitation and microwave irradiation [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 137-144.

[7] WANG Shi-xing, CHEN An-ran, ZHANG Ze-biao, PENG Jin-hui. Leaching of palladium and rhodium from spent automobile catalysts by microwave roasting [J]. Environmental Progress & Sustainable Energy, 2014, 33: 913-917.

[8] CHEN An-ran, WANG Shi-xing, ZHANG Li-bo, PENG Jin-hui. Optimization of the microwave roasting extraction of palladium and rhodium from spent automobile catalysts using response surface analysis [J]. International Journal of Mineral Processing, 2015, 143: 18-24.

[9] TSAI Y F, BARNETT L R, TENG H H, KO C C, CHU K R. A study of some inherent causes for non-uniform microwave heating [J]. Physics of Plasmas, 2017, 24: 103301.

[10] MANICKAVASAGAN A, JAYAS D S, WHITE N D G. Non-uniformity of surface temperatures of grain after microwave treatment in an industrial microwave dryer [J]. Drying Technology, 2006, 24: 1559-1567.

[11] VADIVAMBAL R, JAYAS D S. Non-uniform temperature distribution during microwave heating of food materials—A review [J]. Food & Bioprocess Technology, 2010, 3: 161-171.

[12] PITCHAI K, BIRLA S L, SUBBIAH J, JONES D, THIPPAREDDI H. Coupled electromagnetic and heat transfer model for microwave heating in domestic ovens [J]. Journal of Food Engineering, 2012, 112: 100-111.

[13] CHANDRASEKARAN S, RAMANATHAN S, BASAK T. Microwave food processing—A review [J]. Food Research International, 2013, 52: 243-261.

[14] SUN Jing, WANG Wen-long, YUE Qin-yan. Review on microwave-matter interaction fundamentals and efficient microwave-associated heating strategies [J]. Materials, 2016, 9: 231.

[15] GIRI S K, PRASAD S. Drying kinetics and rehydration characterisitics of microwave-vacuum and convective hot-air dried mushrooms [J]. Journal of Food Engineering, 2007,78: 512-521.

[16] ZI Wen-hua, ZHANG Xiao-long, PENG Jin-hui, ZHANG Li-bo, LONG Ming-hai, ZUO Jing-jian. Optimization of microwave drying biomass material of stem granules from waste tobacco using response surface methodology [J]. Drying Technology, 2013, 31: 1234-1244.

[17] JIANG Jun, TAN Hong-sing, PAN Bo-chen, DANG Le-ping, WANG Zhan-zhong, WEI Hong-yuan. A novel initial temperature-based methodology to predict the optimal thickness in microwave thin layer drying process [J]. Journal of the Taiwan Insitute of Chemical Engineers, 2018, 84: 67-75.

[18] CAO Hong-wei, FAN Da-ming, JIAO Xi-dong, HUANG Jian-lian, ZHAO Jian-xin, YAN Bo-wen, ZHOU Wen-guo, ZHANG Wen-hai, YE Wei-jian, ZHANG Hao. Importance of thickness in electronmagnetic properties and gel characteristics of surimi during microwave heating [J]. Journal of Food Engineering, 2019, 248: 80-88.

[19] SHANG Xiao-biao, CHEN Jun-ruo, ZHANG Wei-feng, PENG Jin-hui, CHEN Hua, GUO Sheng-hui, CHEN Guo. Dimension optimization for silica sand based on the analysis of dynamic absorption efficiency in microwave drying [J]. Drying Technology, 2014, 32: 1608-1613.

[20] TABRIZI F, PARHIZKAR M, BIDADI H, GHAFOURI M. Dielectric characteristics and nonlinear properties of ZnO–polypyrrole composites [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 1377-1385.

[21] HE Guang-jun, LI Shi-wei, YANG Kun, LIU Jian, LIU Peng, ZHANG Li-bo, PENG Jin-hui. Dielectric properties of zinc sulfide concentrate during the roasting at microwave frequencies [J]. Minerals, 2017, 7: 31.

[22] HE Guang-jun, QU Wen-wen, JU Shao-hua, LIU Chen-hui, LIU Peng, WANG Shi-xing, ZHANG Li-bo. Effects of temperature on relaxation time and electrical conductivity of spent automobile catalyst at microwave frequencies [J]. JOM, 2019, 71: 2353-2359.

[23] TRUONG J T, RIDDELL S Z, MUSCAT R F. Polypyrrole based microwave absorbers [J]. Journal of Materials Science, 1998, 33: 4971-4976.

[24] FENG Wei, WANG Ya-ming, CHEN Jun-chen, WANG Lei, GUO Li-xin, OUYANG Jia-hu, JIA De-chang, ZHOU Yu. Reduced graphene oxide decorated with in-situ growing ZnO nanocrystals: Facile synthesis and enhanced microwave absorption properties [J]. Carbon, 2016, 108: 52-60.

[25] SALEMA A A, YEOW Y K, ISHAQUE K, ANI F N, AFZAL M T, HASSAN A. Dielectric properties and microwave heating of oil palm biomass and biochar [J]. Industrial Crops and Products, 2013, 50: 366-374.

[26] LIU Chen-hui, ZHANG Li-bo, PENG Jin-hui, LIU Bing-guo, XIA Hong-ying, GU Xiao-chun, SHI Yi-feng. Effect of temperature on dielectric property and microwave heating behavior of low grade Panzhihua ilmenite ore [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 3462-3469.

[27] BASARAN-AKGUL N, RASCO B A. Effect of marination in gravy on the radio frequency and microwave processing properties of beef [J]. Journal of Food Science and Technology, 2015, 52: 867-875.

[28] FRANCO A P, YAMAMOTO L Y, TADINI C C, GUT J A W. Dielectric properties of green coconut water relevant to microwave processing: Effect of temperature and field frequency [J]. Journal of Food Engineering, 2015, 155: 69-78.

[29] LUAN Dong-lei, TANG Ju-ming, LIU Fang, TANG Zhong-wei, LI Feng, LIN Hui-min, STEWART B. Dielectric properties of bentonite water pastes used for stable loads in microwave thermal processing systems [J]. Journal of Food Engineering, 2015, 161: 40-47.

[30] ZHONG Xin, ZHANG Chen, CHEN Fang-xu, TANG Zhu-ming, JIAN Gang. Dielectric properties and relaxor ferroelectric behavior of (1-y)Ba(Zr0.1Ti0.9)O3- yBa(Zn1/3Nb2/3)O3 ceramics [J]. Transactions of Nonferrous Metals Society of China, 2020, 30: 756-764.

[31] LAYBOURN A, KATRIB J, PALADE P A, EASUN T L, CHAMPNESS N R, SCHRODER M, KINGMAN S W. Understanding the electromagnetic interaction of metal organic framework reactants in aqueous solution at microwave frequencies [J]. Physical Chemistry Chemical Physics, 2016, 18: 5419-5431.

[32] IDRIS F M, HASHIM M, ABBAS Z, ISMAIL I, NAZLAN R, IBRAHIM I R. Recent developments of smart electromagnetic absorbers based polymer-composites at gigahertz frequencies [J]. Journal of Magnetism and Magnetic Materials, 2016, 405: 197-208.

[33] LIU Xiang-xuan, ZHANG Ze-yang, WU You-peng. Absorption properties of carbon black/silicon carbide microwave absorbers [J]. Composites Part B: Engineering, 2011, 42: 326-329.

[34] CASTILLEJO N, MARTINEZ-HERNANDEZ G B, LOZANO-GUERRERO A J, PEDRENO-MOLINA J L, GOMEZ P A, AGUAYO E, ARTES F, ARTES- HERNANDEZ F. Microwave heating modelling of a green smoothie: Effects on glucoraphanin, sulforaphane and S-methyl cysteine sulfoxide changes during storage [J]. Journal of the Science of Food and Agriculture, 2018, 98: 1863-1872.

[35] ZHU Han-kun, LI Dong, LI Shu-jun, WANG Shao-jin. A novel method to improve heating uniformity in mid-high moisture potato starch with radio frequency assisted treatment [J]. Journal of Food Engineering, 2017, 206: 23-36.

[36] MOTASEMI F, AFZAL M T, SALEMA A A. Microwave dielectric characterization of hay during pyrolysis [J]. Industrial Crops and Products, 2014, 61: 492-498.

[37] AYAPPA K G, DAVIS H T, CRAPISTE G, DAVIS E A, GORDON J. Microwave heating: An evaluation of power formulations [J]. Chemical Engineering Science, 1991, 46: 1005-1016.

何广军1,2,3,4,5,刘 鹏2,3,4,5,曲雯雯1,2,3,4,王仕兴2,3,4,5,张利波2,3,4,5

1. 昆明理工大学 理学院,昆明 650500;

2. 昆明理工大学 省部共建复杂有色金属资源清洁利用国家重点实验室,昆明 650093;

3. 昆明理工大学 云南省特种冶金重点实验室,昆明 650093;

4. 昆明理工大学 微波能工程应用及装备技术国家地方联合工程实验室,昆明 650093;

5. 昆明理工大学 冶金与能源工程学院,昆明 650093

摘 要:为了提高汽车废催化剂在微波加热过程中温度场分布的均匀性,开发加热厚度优化的新方法。采用高斯模型和基于介电损耗正切和反射损耗的数值算法计算汽车废催化剂的微波加热平均穿透深度和厚度。结果表明:汽车废催化剂是一种中等损耗物料,从室温到800 °C的过程中平均穿透深度为1.11 m,汽车废催化剂的最优加热厚度约为0.83 m或平均穿透深度的0.75倍。工业化应用分析显示:该最佳厚度能提高温度场的均匀分布、减少能耗。

关键词:汽车废催化剂;微波;加热厚度;优化

(Edited by Bing YANG)

Foundation item: Project (51664037) supported by the National Natural Science Foundation of China

Corresponding author: Shi-xing WANG, Tel: +86-13529204964, E-mail: wsxkm@kmust.edu.cn;

Li-bo ZHANG, Tel: +86-13888310177, Email: zhanglibopaper@126.com

DOI: 10.1016/S1003-6326(20)65472-3