文章编号:1004-0609(2010)07-1396-06

烧结方式对ZnO-Bi2O3压敏瓷Bi2O3挥发的影响

徐 东1, 2,程晓农1,赵国平1,严学华1,施利毅2

(1. 江苏大学 材料科学与工程学院, 镇江 212013; 2. 上海大学 纳米科学与技术研究中心, 上海 200444)

摘 要:采用裸烧、盖烧和埋烧等不同的烧结方式制备ZnO-Bi2O3压敏瓷,通过XRD和SEM等方法对压敏瓷的物相和显微组织进行研究,探讨烧结方式对氧化锌压敏瓷电性能和显微组织的影响。结果表明:烧结方式和烧结温度对压敏瓷的显微组织和电性能产生明显的影响。对于裸烧、盖烧和埋烧来说,1 100 ℃均为最佳的烧结温度; 1 000 ℃时埋烧得到的压敏瓷的电性能较好,1 100 ℃和1 200 ℃时裸烧得到的压敏瓷的电性能较好;烧结方式对于Bi2O3挥发控制的强弱顺序为埋烧、盖烧、裸烧。

关键词:ZnO-Bi2O3压敏瓷;氧化锌;烧结;挥发

中图分类号:TB34;TN304.93 文献标志码:A

Influence of sintering process on Bi2O3 vaporization of ZnO-Bi2O3 based varistor ceramics

XU Dong1, 2, CHENG Xiao-nong1, ZHAO Guo-ping1, YAN Xue-hua1, SHI Li-yi2

(1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. Research Center of Nano Science and Technology, Shanghai University, Shanghai 200444, China)

Abstract: ZnO-Bi2O3 based varistor ceramics were sintered by using different sintering processes, open sintering, sintering inside a closed crucible and sintering within a powdered bed. The phases and microstructures of the varisotr ceramics were investigated by XRD and SEM. The effects of sintering process on electrical properties and microstructures of ZnO-Bi2O3 based varistor ceramics were discussed. The results show that the sintering process and sintering temperature have obvious effect on the microstructure and electrical properties of the samples. Optimal values for the electrical characteristics of the varistor ceramics by three kinds of sintering processes are obtained when the sintering is conducted at 1 100 ℃. At 1 000 ℃, the samples sintered within a powdered bed show better electrical properties than those subjected to the other two processes, while at 1 100 ℃ or 1 200 ℃, the open sintering samples exhibit better electrical properties. These results also show that Bi2O3 vaporization in three sintering processes is in the order from strong to weak as follows: sintering within a powdered bed, sintering inside a closed crucible, open sintering.

Key words: ZnO-Bi2O3 based varistor ceramics; zinc oxide; sintering; volatilization

氧化锌压敏瓷是以ZnO为主体,添加多种金属氧化物,采用典型的电子陶瓷工艺制成的多晶半导体陶瓷元件。氧化锌压敏瓷具有很高的非线性电流—电压特性,在对瞬态浪涌电压的保护领域有重要的应 用[1-5]。

由于压敏特性形成剂Bi2O3在烧结时大量挥发,造成显微组织不均匀,使其性能极度恶化[6-8]。PEITEADO等[9-10]认为,在烧结ZnO-Bi2O3系压敏瓷时,样品中Bi2O3的挥发量与烧结样品坯体的紧凑相关参数—表面积/体积(A/V)比例有关,研究得出最佳的A/V比例为4.11 cm-1。METZ等[11]认为,在烧结ZnO-Bi2O3系压敏瓷时,样品中Bi2O3的挥发量与烧结样品的烧结板有关。研究表明,利用白金烧结板在密闭方式下进行烧结,样品中Bi2O3的挥发量损失最小。LIN等[12]研究了微波烧结压敏瓷时Bi2O3的挥发,结果表明,微波烧结使Bi2O3的挥发量减小,同时压敏瓷从表层到中心的Bi2O3挥发量较为一致。ONREABROY等[13]进行了压敏瓷配方粉体和氧化铝粉体埋烧ZnO-Bi2O3压敏瓷的对比试验,结果表明,采用压敏瓷配方粉体烧结的压敏瓷的电性能明显优于氧化铝粉体埋烧的压敏瓷的电性能。目前,大多数文献均是基于对压敏瓷烧结过程中Bi2O3挥发的定性研究,而对于控制压敏瓷烧结过程中Bi2O3挥发的研究却并不多见。本文作者在研究裸烧、盖烧和埋烧等不同的烧结方式对压敏瓷电性能的影响的基础上[6],在更宽的温度范围内进一步定量研究不同烧结方式对压敏瓷Bi2O3的挥发性和压敏瓷微观结构的影响;通过优化烧结方式,控制压敏瓷烧制中压敏形成成分的挥发,从而为工业上制备出微观组织均匀、性能优良的ZnO压敏瓷提供基础理论依据。

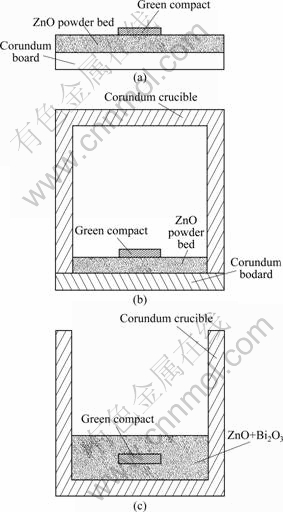

1 实验

氧化锌压敏瓷的成分选定为分析纯化学试剂,其配比(摩尔分数)为96.5% ZnO + 0.7% Bi2O3 + 1.0% Sb2O3 + 0.8% Co2O3 + 0.5% MnO2 + 0.5% Cr2O3。采用氧化锆球、聚乙烯罐,在球磨机中湿磨5 h,转速为500 r/min,球、粉与无水乙醇的质量比为20?1?4,浆料过孔径为63 μm的筛后在70 ℃烘干24 h 成干粉。添加质量分数为2%的PVA,过孔径为150 μm的筛后,在半自动压样机压制成d 12 mm×2.0 mm的生坯。生坯经500 ℃排胶2 h后,采用图1所示的裸烧(OS,open sintering)、盖烧(CS,sintering inside a closed crucible)和埋烧(PS,sintering within a powdered bed)等不同的烧结方式,在1 000~1 300 ℃烧结制备氧化锌压敏瓷,其升温速度为5 ℃/min,保温时间为2 h,随炉冷却。不同烧结温度的氧化锌压敏瓷的编号见表1。样品两面印刷电极银浆,在600 ℃烧结10 min。用压敏电阻直流参数仪(CJ1001,常州创捷防雷电子有限公司)测量样品在1.0和0.1 mA 下的电压,以V1mA作为压敏电压,非线性系数α在0.1~1.0 mA内为1/lg(V1mA/V0.1mA)。在0.75 V1mA下测得漏电流IL,漏电流密度J由公式J = IL/S来计算,S是待测样品的端电极面积。用玛瑙研钵对样品粉碎研磨后,采用电感偶合等离子发射光谱仪ICP-AES(美国Perkin-Eluer),测量计算烧结前后的样品中Bi2O3的挥发量w(Bi2O3)。

图1 不同烧结方式的示意图

Fig.1 Schematic diagram of different sintering processes: (a) OS; (b) CS; (c) PS

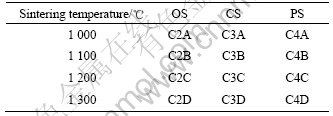

表1 不同烧结方式的样品编号

Table 1 Sintering schedules of samples sintered at different temperatures by different processes

样品仔细打磨后进行相结构分析,压敏瓷的相结构分析是在日本理学Rigaku D/max 2200 X射线衍射仪上进行的。样品用稀释的醋酸腐蚀后,采用扫描电镜(SEM, FEI QUANTA 400)观察压敏瓷的显微组 织[6, 14]。ZnO压敏陶瓷的平均晶粒大小可应用Mendelson的线性截距法直接从电镜照片中测试。根据Mendelson方法,平均晶粒大小由G = 1.56L获得,其中G为平均晶粒大小,L为4 条任意穿越显微照片的直线在晶粒边界上的截距的平均值。

2 结果与讨论

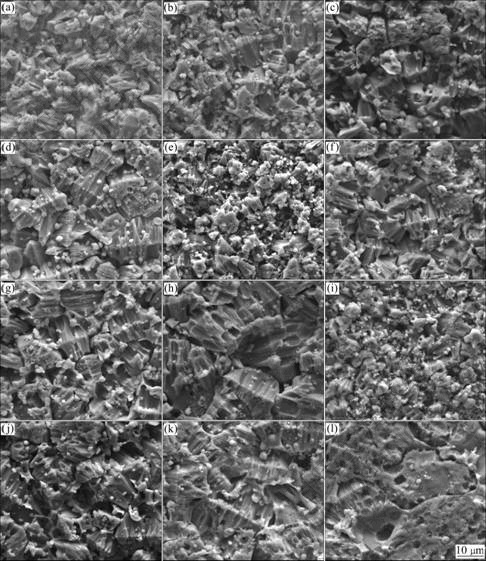

图2所示为不同烧结方式压敏瓷的XRD谱。由图2可知,不同烧结方式没有导致压敏瓷有新相生成,不同烧结方式ZnO-Bi2O3基压敏瓷的显微组织非常相似:均为ZnO相、富Bi2O3的晶间相和尖晶石相。图3所示为不同烧结方式在1 000~1 300 ℃烧结压敏瓷的显微组织。由图3也可得出类似结论。从图3还可以明显看出烧结温度越高,晶粒尺寸越大。1 000 ℃烧结时压敏瓷的晶粒较小,晶粒大小不均匀,晶粒间发育不好[15]且结合不紧密,有明显的孔洞存在。1 100~1 200 ℃烧结时压敏瓷的晶粒尺寸更大、更均匀,气孔较少,其中1 100 ℃烧结的晶粒尺寸最为均匀,这种组织的均匀性非常有利于提高氧化锌压敏瓷的非线性系数。1 300 ℃烧结的压敏瓷的显微组织明显变得更加粗大。上述结果也表明,不同的烧结方式对压敏瓷中Bi2O3的挥发控制有所不同,从而造成压敏瓷显微组织的差异。

图2 不同烧结方式ZnO-Bi2O3压敏瓷的XRD谱

Fig.2 XRD patterns of ZnO-Bi2O3 varistor ceramics sintered by different processes

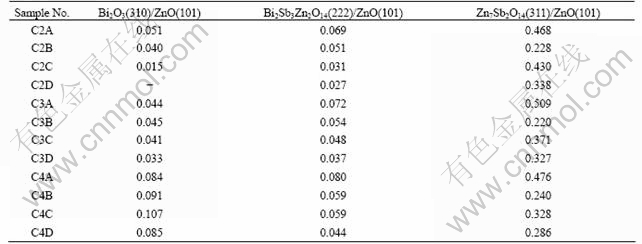

不同烧结方式对压敏瓷各相X射线衍射峰面积比的影响见表2。由表2可以看出采用同一种烧结方式时,随着烧结温度的升高,富Bi相衍射峰的强度及其所围面积逐渐减少,表明压敏瓷中富Bi相的相对含量随着烧结温度的升高而逐渐减少;在烧结温度相同时,不同烧结方式的压敏瓷中富Bi相衍射峰的强度及其所围面积逐渐增大的顺序为OS→CS→PS,表明不同烧结方式的压敏瓷中富Bi相的相对含量增加的顺序为OS→CS→PS,不同烧结方式对Bi2O3挥发控制的强弱顺序为PS→CS→OS。烧结方式对于Bi2O3挥发控制的强弱顺序为埋烧、盖烧、裸烧,裸烧和盖烧得到的压敏瓷中Bi2O3因为挥发而减少,埋烧得到的压敏瓷中Bi2O3因为扩散而增加。从表2还可以看出,由于Bi2O3的挥发,对压敏瓷中焦绿石和尖晶石的含量也产生一定的影响。随着烧结温度的升高,焦绿石的含量逐渐降低,这和高温下Bi2O3的挥发加剧是一致的[16]。同时压敏瓷在1 000~1 200 ℃烧结时,焦绿石的含量减少比较明显,这是由于Bi2O3在1 000 ℃开始明显挥发。随着烧结温度的升高,尖晶石的含量呈现波浪变化,这也进一步证实压敏瓷中部分尖晶石是由于焦绿石的分解而得到的。

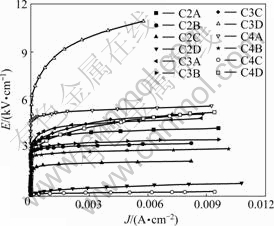

图4所示为不同烧结方式的压敏瓷的E—J(电位梯度—电流密度)特性曲线。E—J曲线测试区域的压敏瓷的电特性可以分为电位梯度—电流密度特性接近于线性的小电流区和电位梯度—电流密度特性呈现为非线性的非线性区。从图4可以看出,这些E—J曲线比较相似,从小电流区到非线性区都有一突变。E—J曲线中曲线弯曲处的曲率半径越小,即E—J曲线的突变处越陡,压敏瓷的非线性越好[2, 6]。从图4还可以看出,样品C4C和C2D突变最为平缓,表明样品C4C和C2D的非线性非常差,这是由于烧结工艺不同造成Bi2O3含量的变化,进而对压敏瓷的电性能产生影响。

由图4还可以看出,采用同一烧结方式时,无论是裸烧还是埋烧,电位梯度随烧结温度的升高而单调递减;对于盖烧,电位梯度随烧结温度的升高却为先减小后增大。随着烧结温度的升高,氧化锌压敏瓷的晶粒尺寸逐渐长大,导致电位梯度降低;而盖烧中电位梯度的增大是由于高温持续时间的延长,晶粒生长发育较完善,使氧化锌和尖晶石的有效活性连接增多而导致压敏瓷的电位梯度增大[15]。由图4可看出,E—J曲线中曲线弯曲处的曲率半径增大的次序,即非线性系数减小的次序为C2B→C4B→C4A→C3B→ C2C→ C2A→C3A→C3C→C3D→C4D→C4C→C2D,电位梯度增大的次序为C4C→C2D→C2C→C4B→ C2B→ C3B→C2A→C3A→C4D→C3C→C4A→C3D。综合考虑,对于裸烧、盖烧和埋烧来说,1 100 ℃均为最佳的烧结温度;对于不同的烧结温度,1 000 ℃时埋烧得到的压敏瓷的电性能较好,1 100和1 200 ℃时裸

图3 不同烧结方式的压敏瓷的SEM像

Fig.3 SEM images of ZnO-Bi2O3 varistor ceramics sintered by different processes: (a) Sample C2A; (b) Sample C2B; (c) Sample C2C; (d) Sample C2D; (e) Sample C3A; (f) Sample C3B; (g) Sample C3C; (h) Sample C3D; (i) Sample C4A; (j) Sample C4B; (k) Sample C4C (l) Sample C4D

表2 烧结方式对压敏瓷各相X射线衍射峰面积比的影响

Table 2 Effects of sintered processes on relative X-ray diffraction peak area ratio of varistor ceramics

图4 不同烧结方式的压敏瓷的E—J曲线

Fig.4 E—J curves of ZnO-Bi2O3 varistor ceramics sintered by different processes.

烧得到的压敏瓷的电性能较好。这些不同与Bi2O3的添加量是否合理有关,也就是说,对于裸烧,氧化锌压敏瓷中Bi2O3的添加量经过烧结时的挥发,在最终产品中剩余的Bi2O3的含量是合适的。对于盖烧和埋烧,由于对Bi2O3的挥发有一定的控制,会造成最终产品中Bi2O3的含量过高,导致压敏瓷的电性能下降;反之,如果减少压敏瓷原始配方中Bi2O3的添加量,不但因节约了贵重金属Bi2O3的使用量而节约了成本,最终还会得到具有合适的Bi2O3含量的压敏瓷,其电性能自然也会较好。

采用欧姆区导电与Schottky热电子发射有关的晶界缺陷模型[2, 6, 17],发射电流密度表达式如下:

J=AT2exp[(bE1/2-ФB)/( kT)] (1)

式中:A为Richardson常数,E为电场强度,k为玻耳兹曼常数,T为绝对温度,β是与势垒高度ФB有关的常数。

(2)

(2)

式中:γ是单位长度晶粒数,e是电子电荷,ε0是真空介电常数,εr是相对介电常数,ω为势垒宽度。

(3)

(3)

式中:ND为施主浓度,NS为界面态密度。

(4)

(4)

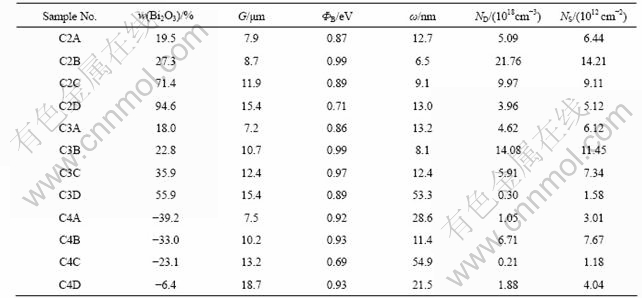

根据式(1)~(4)计算氧化锌压敏瓷的势垒高度ФB、势垒宽度ω、施主浓度ND和界面态密度NS,计算结果如表3所示。从表3可以看出,烧结温度越高,裸烧和盖烧的压敏瓷中Bi2O3的挥发越明显;对于埋烧的压敏瓷而言,其中的Bi2O3的含量不但没有减少反而有一定程度的增加,烧结温度越低,Bi2O3的含量增加越多,这是在压敏瓷埋烧的局部气氛中,填埋物中Bi2O3的浓度高于压敏瓷中Bi2O3的浓度而造成的。同时,温度越高,压敏瓷晶粒尺寸越大;Bi2O3挥发越严重,不同烧结方式的压敏瓷的晶粒尺寸越小,且烧结温度越高,这种现象越明显。1 300 ℃烧结的压敏瓷, 一般来说其ФB、ND、NS最小,ω最大,这还是与高温下Bi2O3的严重挥发有关。

表3 不同烧结方式的压敏瓷的Bi2O3挥发量w(Bi2O3)和晶界特性参数

Table 3 Bi2O3vaporization loss and boundary characteristic parameters of ZnO-Bi2O3 varistor ceramics sintered by different processes

3 结论

1) 不同的烧结方式对ZnO-Bi2O3压敏瓷的组织和性能产生不同的影响。对于裸烧、盖烧和埋烧来说, 1 100 ℃均为最佳的烧结温度;对于不同的烧结温度而言,1 000 ℃埋烧时得到的压敏瓷的电性能较好,1 100和1 200 ℃裸烧时得到的压敏瓷的电性能较好。

2) 烧结方式对于Bi2O3挥发控制的强弱顺序为埋烧、盖烧、裸烧,裸烧和盖烧得到的压敏瓷中Bi2O3的含量因为挥发而减少,埋烧得到的压敏瓷中Bi2O3的含量因为扩散而增加。

3) 在工业生产中可以结合不同的烧结方式,调整压敏瓷原始配方中Bi2O3的添加量,使压敏瓷的性能表现为最佳。

REFERENCES

[1] BUENO P R, VARELA J A, LONGO E. SnO2, ZnO and related polycrystalline compound semiconductors: An overview and review on the voltage-dependent resistance (non-ohmic) feature [J]. Journal of the European Ceramic Society, 2008, 28(3): 505-529.

[2] NAHM C W. The preparation of a ZnO varistor doped with and its properties [J]. Solid State Communications, 2009, 149(19/20): 795-798.

[3] 卢振亚, 黄 欢, 吴建青. SnO2-Sb2O3基压敏陶瓷致密化及脉冲电流耐受特性[J]. 无机材料学报, 2009, 24(4): 841-844.

LU Zhen-ya, HUANG Huan, WU Jian-qing. Densification and surge current performance of SnO2-Sb2O3 based varistor ceramics [J]. Journal of Inorganic Materials, 2009, 24(4): 841-844.

[4] 赵 鸣, 王卫民, 高 峰, 田长生. ZnVSb基压敏陶瓷中尖晶石相形成机理的研究[J]. 无机化学学报, 2007, 23(7): 1242-1246.

ZHAO Ming, WANG Wei-min, GAO Feng, TIAN Chang-sheng. Formation mechanism of spinel in ZnVSb based varistor ceramic [J]. Chinese Journal of Inorganic Chemistry, 2007, 23(7): 1242-1246.

[5] 羊新胜, 赵 勇. 铁磁性锰氧化物掺杂的ZnO压敏电阻性能研究[J]. 物理学报, 2008, 57(5): 3188-3192.

YANG Xin-sheng, ZHAO Yong. Study of ZnO varistor doped with ferromagnetic manganese oxide [J]. Acta Physica Sinica, 2008, 57(5): 3188-3192.

[6] XU D, SHI L, WU Z, ZHONG Q, WU X. Microstructure and electrical properties of ZnO-Bi2O3-based varistor ceramics by different sintering processes [J]. Journal of the European Ceramic Society, 2009, 29(9): 1789-1794.

[7] LAO Y W, KUO S T, TUAN W H. Effect of powder bed on the microstructure and electrical properties of Bi2O3-and Sb2O3-doped ZnO [J]. Journal of Materials Science-Materials in Electronics, 2009, 20(3): 234-241.

[8] XU Dong, CHENG Xiao-nong, YAN Xue-hua, XU Hong-xing, SHI Li-yi. Sintering process as a relevant parameter for Bi2O3 vaporization from ZnO-Bi2O3-based varistor ceramics [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(6): 1526-1532.

[9] de la RUBIA M A, PEITEADO M, FERNANDEZ J F, CABALLERO A C. Compact shape as a relevant parameter for sintering ZnO-Bi2O3 based varistors [J]. Journal of the European Ceramic Society, 2004, 24(6): 1209-1212.

[10] PEITEADO M, de la RUBIA M A, VELASCO M J, VALLE F J, CABALLERO A C. Bi2O3 vaporization from ZnO-based varistors [J]. Journal of the European Ceramic Society, 2005, 25(9): 1675-1680.

[11] METZ R, DELALU H, VIGNALOU J R, ACHARD N, ELKHATIB M. Electrical properties of varistors in relation to their true bismuth composition after sintering [J]. Materials Chemistry and Physics, 2000, 63(2): 157-162.

[12] LIN C, XU Z, PENG H, SUN D F. Bi2O3 vaporization in microwave-sintered ZnO varistors [J]. Journal of the American Ceramic Society, 2007, 90(9): 2791-2794.

[13] ONREABROY W, TUNKASIRI T, SIRIKULRAT N. Effects of alumina surrounding in sintering process on ZnO-Bi2O3 varistors doped with CoO [J]. Materials Letters, 2005, 59(2/3): 283-288.

[14] XU D, CHENG X N, WANG M S, SHI L Y. Microstructure and electrical properties of La2O3-doped ZnO-Bi2O3-based varistor ceramics [J]. Advanced Materials Research, 2009, 79/82: 2007-2010.

[15] ZHANG J, CAO S, ZHANG R, YU L, JING C. Effect of fabrication conditions on I-V properties for ZnO varistor with high concentration additives by sol-gel technique [J]. Current Applied Physics, 2005, 5(4): 381-386.

[16] 林 枞, 徐 政, 彭 虎, 孙丹峰. 微波烧结氧化锌压敏电阻的致密化和晶粒生长[J]. 无机材料学报, 2007, 22(5): 917-921.

LIN Cong, XU Zheng, PENG Hu, SUN Dan-feng. Densification and grain growth of microwave sintered ZnO varistors [J]. Journal of Inorganic Materials, 2007, 22(5): 917-921.

[17] 成鹏飞, 李盛涛, 李建英. ZnO-Bi2O3系压敏陶瓷的晶界电子结构[J]. 物理学报, 2010, 59(1): 560-565.

CHENG Peng-fei, LI Sheng-tao, LI Jian-ying. Grainboundary electronic structure of ZnO-Bi2O3 based varistor ceramics [J]. Acta Physica Sinica, 2010, 59(1): 560-565.

(编辑 何学锋)

基金项目:上海市教育委员会重点学科建设资助项目(J5012);中国博士后科学基金资助项目(20100471380);江苏省普通高校自然科学研究资助项目(10KJB430002)

收稿日期:2010-01-11;修订日期:2010-05-20

通信作者:程晓农,教授,博士;电话:0511-88797633;E-mail: frank@ujs.edu.cn