文章编号:1004-0609(2013)S1-s0001-06

细晶及超细晶钛合金加工工艺

郭鸿镇,赵 严,赵张龙,姚泽坤,石志峰,彭小娜

(西北工业大学 材料科学与工程学院,西安710072)

摘 要:采用大变形量等温锻造、低温多向锻造、等通道转角挤压(ECAP)、形变热处理及其复合工艺,对TA15近α钛合金进行细晶和超细晶化加工研究。结果表明:高低温复合形变热处理是细化TA15合金显微组织的有效途径,单相区的高温形变热处理可获得细针状马氏体α′和亚稳态β相,两相区较低温度的形变热处理可显著细化由α′马氏体和亚稳β相分解而来的细针状α和β相。ECAP工艺通过强烈的纯剪切变形,虽可使TA15合金等轴α晶粒尺寸细化至3 μm左右,但ECAP形变热处理复合工艺可通过位错墙和孪晶交割等作用进一步获得晶粒尺寸为0.2~0.6 μm的亚微米级等轴超细晶及晶粒尺寸为20~50 nm的部分纳米晶。

关键词:钛合金;锻造;等通道转角挤压;复合形变热处理;位错墙;孪晶交割;超细晶

中图分类号:TG 146.2 文献标志码:A

Processing technology of fine and ultrafine grained titanium alloy

GUO Hong-zhen, ZHAO Yan, ZHAO Zhang-long, YAO Ze-kun, SHI Zhi-feng, PENG Xiao-na

(School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The fine or ultrafine grained near α titanium alloy TA15 was prepared through large deformation isothermal forging, low temperature multi-directional forging, equal channel angular pressing (ECAP), thermomechanical treatment and the ways above combined. The results indicate that high and low temperature thermomechanical treatment is an effective way to refine the microstructure of TA15 alloy. Fine acicular martensite α′ phase and metastable β phase are obtained after high-temperature thermomechanical treatment above β transus, and the needle α and β phases decomposed from martensite α′ and metastable β-phase are significantly refined after thermomechanical treatment at lower temperature in two-phase region. Though the grain size of TA15 alloy can be refined to 2-3 μm under the intense pure shear deformation effect of ECAP process, the microstructures with sub-micron grains of 0.2-0.6 μm and some nano-sized grains of 20-50 nm are obtained under the functions of dislocation walls and twins intersection through multiple processing of ECAP and thermomechanical treatment.

Key words: titanium alloy; forging; equal channel angular pressing; multiple thermomechanical treatment; dislocation walls; twins intersection; ultrafine grains

根据Hell-Petch公式,多晶体合金屈服强度随晶粒尺寸的减小而大大增加,伸长率也明显提高,同时晶粒细化还可以显著提高钛合金的疲劳性能、冲击性能、耐腐蚀性能以及加工超塑性等性能[1-3],因此,晶粒细化或超细化是一种理想的材料强化方式,是提高钛合金综合性能的重要手段之一。研究钛合金晶粒细化的有效方法,实现高质量细晶钛合金的制备和加工,对于提高钛合金的应用水平以及推动航空航天工业的发展具有重要的现实意义。

国内外对钛合金晶粒细化进行了很多研究[4-7],本文作者以TA15近α钛合金为研究对象,在对不同晶粒细化工艺研究的过程中,探索出高低温形变热处理、等通道转角挤压(ECAP)形变热处理复合新工艺,为钛合金细晶化加工技术的进一步开发及工程化应用奠定基础。

1 实验

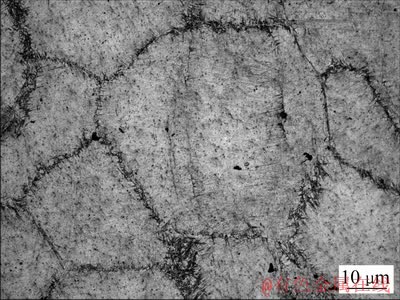

实验用原材料是某厂生产的TA15钛合金改锻棒材,化学成分(质量分数)为:6.8%Al、1.7%Mo、2.2% V、2.0%Zr、0.07%Fe、0.04%Si、其余为Ti,符合技术标准要求。采用金相法测定其β相变温度(tβ)为975 ℃。原材料经700 ℃、1 h退火处理后的显微组织如图1所示。由图1可知,材料主要由等轴初生α相和β相转变组织组成,初生α相含量约为46%,分布较均匀,尺寸有一定差异,较大初生α相尺寸达到10~15 μm,β相转变组织由片状次生α相和残留β相交织分布组成。

图1 实验用原材料的显微组织

Fig. 1 Microstructure of as-received material

大变形量等温锻造用设备为3 150 kN四柱液压机,等温锻用模具及模具加热装置为自制。TA15合金试件尺寸为30 mm×21 mm×60 mm,锻造温度为930 ℃,变形程度为60%,活动横梁速度为1~2 mm/s,锻后空冷。

低温多向锻造用设备为3 000 kN双盘摩擦压力机。TA15合金试件尺寸为40 mm×50 mm×50 mm,锻造温度为550~700 ℃,对试样进行多火次三向较快速锻造,锻后立即水冷,并进行700 ℃、1 h的退火处理。

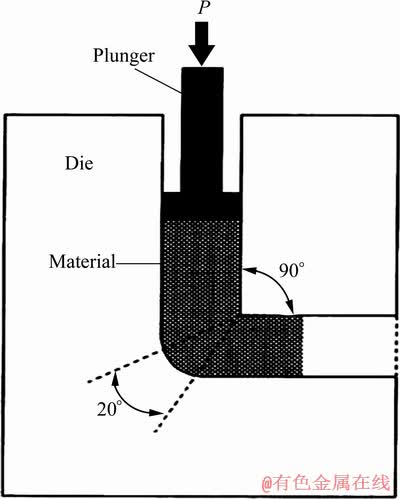

ECAP挤压用设备为3 150 kN四柱液压机,活动横梁速度为1~2 mm/s。实验用等通道转角挤压模具为自制,构造示意图见图2。图2中凹模的内径为16.8 mm,模具转角为90°。模具的加热装置为自制的中频感应加热炉,允许的最大功率为10 kW,最大电流为50 A。试样加热温度为900 ℃,以BC路径(每两次挤压之间试样均沿同一方向旋转90°)进行不同次数的挤压,并进行700 ℃、1 h的退火处理。

TA15合金所采用的高低温复合形变热处理工艺方案如下:预制坯(1 030 ℃,60%变形,WQ+930 ℃, 50%变形,WQ)+等温锻(930 ℃,60%变形,AC)+热处理(810 ℃,1 h,AC),其中预制坯过程包括高、低温两次锻造并采用锻后水冷。

图2 自制等通道转角挤压模具示意图

Fig. 2 Schematic assembly diagram of self-made ECAP dies

TA15合金所采用的ECAP形变热处理复合工艺主要包括两步核心工序:第一,1 000 ℃(β单相区)进行1次ECAP挤压后快速水冷;第二,在900 ℃(α+β两相区)对经第一步工序处理的TA15合金试样进行2次ECAP挤压,挤后水冷,并进行700 ℃、1 h的退火处理。

2 结果与分析

2.1 大变形量等温锻造工艺

TA15钛合金试样经60%等温变形并进行退火处理后,其显微组织如图3所示。由图3可以看出,有较多粗大的初生等轴α相和沿变形方向分布的粗片状α相,说明较高温度下单方向较大变形量的慢速等温锻造未能有效细化原始晶粒组织,组织均匀性也较差。这与高温慢速变形条件下回复作用增强、再结晶形核减少和晶粒容易长大等因素有关。

2.2 低温多向锻造工艺

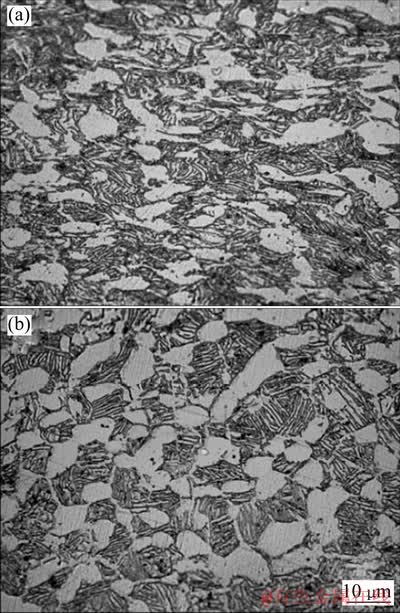

图4(a)和(b)所示分别为TA15合金试样经低温多向锻造后淬火态和退火态的显微组织。由于较低温度多火次的三向锻造引入了较大的变形量,储存了很高的畸变能,再结晶开始温度远远低于理论再结晶温度,因此在变形过程中,随着晶粒反复在各个方向上被压缩和拉长,有一定的动态再结晶发生,但在淬火态的组织中明显保持了变形组织的特征,依然清晰可见晶粒有一定的取向性,并呈多角形状;而在退火态的组织中,由于静态再结晶充分发生,位错缠结消失,残余应力基本消除,晶粒明显球化,尺寸为5~10 μm的等轴α相与在退火过程中析出的次生片状α相形成均匀混合组织。与TA15合金原始组织(图1)相比,经低温多向锻造后的组织表现出明显的细化和均匀化,但由于总变形程度依然有限,细化效果还不是特别理想。

图3 经等温锻造及退火处理后TA15合金试样的显微组织

Fig. 3 Microstructure of TA15 alloy sample processed with isothermal forging and annealing

图4 低温多向锻造后TA15合金试样淬火态和退火态的显微组织

Fig. 4 Microstructures of TA15 alloy sample processed with low temperature multi-directional forging (a) and annealing (b)

2.3 ECAP工艺

图5(a)~(d)所示分别为TA15合金试样以BC路径分别挤压1、2、4和16次并退火的显微组织。从图5中可以看出,试样经1次挤压后,与原始组织(图1)相比,晶粒经历了变形与破碎,发生了部分动态再结晶,有了较明显的细化。随着挤压次数的增加,即变形量的增大,动态再结晶作用大大增强,位错增殖远远大于湮灭的速度,位错密度增大,位错胞大量形成,尺寸变小,最终形成更小的等轴晶粒,经4次挤压后晶粒细化以及等轴组织均匀化程度均达到了最佳水平,有效总应变计算值达到3.628,平均晶粒尺寸为3.4 μm[8]。

从图5还可以看出,随着挤压次数的增多,有效总应变增大,虽然16道次挤压后应变高达14.51,但是晶粒的尺寸并没有继续减小,反而有所增大,均匀化程度变差。这说明大的应变虽然提供了更高的畸变能,使得在大剪切变形过程中的动态再结晶变得更容易,但是当变形量达到一定程度后,位错的增殖和湮灭达到动态平衡,同时随着热能的输入,回复作用逐渐明显,再挤压时晶粒的大小和纵横比基本上不再变化。但在大变形的过程中由于相邻晶粒间的相互作用,晶粒不断发生转动,晶粒间的取向差又趋于减小,有相邻晶粒合并长大的现象发生。

2.4 复合工艺

2.4.1 高低温复合形变热处理工艺

TA15合金经高低温复合形变热处理处理所得的显微组织如图6所示。由图6可以看出,球状初生等轴α相及少量片状α相显著细化,等轴α相尺寸已经细化至5 μm以下,表明单相区与两相区高低温复合形变热处理工艺对TA15近α钛合金的显微组织具有显著的细化效果[9]。

图5 BC路径不同次数挤压后TA15合金的试样退火态的显微组织

Fig. 5 Microstructures of annealed TA15 alloy sample processed using BC route for various passes

图6 高低温复合形变热处理后TA15合金试样的显微组织

Fig. 6 Microstructure of TA15 alloy sample processed with high and low temperature composite thermomechanical treatment

形变热处理工艺中首先采用了1 030 ℃ β单相区大变形、水冷的工序,由于β相在水冷时来不及通过扩散转变成平衡的α相,只能通过β相中原子作集体有规则近程迁移,发生切变相变成α稳定元素过饱和固溶体,即针状α′马氏体,所以其显微组织为α′+亚稳定β组织。第2道工序930 ℃,50%大变形、水冷的目的是在α+β两相区充分破碎锻造加热时从亚稳β相和α′马氏体针分解而来的细针状α+β相。这种组织在锻造变形中极易靠切变机理而破断,并发生充分的动态与静态再结晶,使显微组织得到细化。锻后水冷为进一步细化晶粒储存了一定的应变能。

2.4.2 ECAP形变热处理复合工艺

图7所示为TA15合金使用90°转角模具在1 000℃(β单相区)进行1次ECAP挤压后快速水冷的淬火态显微组织。由图7可以看出,显微组织由尺寸为200~500 μm的粗大β晶粒组成。由于元素在β相中的扩散速率要比在α相中的扩散速率快至少两个数量级[10],尽管挤压后水冷的操作速度很快,但在相变温度以上,β晶粒仍然快速长大到200 μm以上。

图7 1 000 ℃(β单相区)ECAP挤压后快速水冷的TA15合金的显微组织

Fig. 7 Microstructure of TA15 alloy pressed at 1 000 ℃ (single phase) and rapidly quenched after ECAP

图8所示为图7中粗大β晶粒内部组织的SEM像。由于在相变温度以上挤压后水冷,即在β相区淬火,在近α型钛合金TA15中,并不能将β相固定下来,而是转变成了针状马氏体α′相。在快速冷却的过程中,针状α′相平行排列呈束状。发生马氏体转变时,由于溶入了过饱和的溶质原子,晶格畸变增大,位错密度也大大增加。

图8 1 000 ℃(β单相区)ECAP挤压并快速水冷后TA15合金粗β晶粒内部针状马氏体α′相的SEM像

Fig. 8 SEM image of acicular martensite α′ phase within coarse β grain of TA15 alloy pressed at 1 000 ℃ (single β phase) and rapidly quenched after ECAP

在上述复合细化工艺的第一步结束之后,形成了由粗大β相、晶界α以及β晶内的针状马氏体α′相组成的组织形态,而与此同时,在第一步的ECAP剧烈剪切变形和快速冷却过程中,大量位错和晶格畸变积累了下来,在变形体内储存了大量的畸变能,为第二步的组织细化提供了充足的结构条件和能量条件。

在第二步900 ℃(α+β两相区) ECAP挤压、水冷的工序中,由于大剪切变形引入高应变量,粗大β晶内滑移系增多,越来越多的位错沿着滑移面进行滑移,位错的增殖和运动引起位错大量缠结,并逐渐在β晶内形成许多位错墙(即位错胞壁),将粗大β晶粒分割为许多具有小角度晶界的亚晶。由于亚晶内的滑移变形以及亚晶间相互作用发生相对转动或晶界滑动,这些亚晶逐步演变为具有大角度晶界的等轴结构。最终,晶粒间位向差的增大促进了大角度晶界的发展,亚结构消失,析出为尺寸很小的亚微米级超细晶(图9(a)),尺寸为0.2~0.6 μm[11]。

作为密排六方结构的针状马氏体α′相内的变形以孪生方式为主。在ECAP形变热处理工艺第二步变形过程中发生了多系统孪生变形,不同的孪晶系相互交割,形成很小的亚晶,并逐渐演变为具有大角度晶界的尺寸为20~50 nm的部分纳米晶(图9(b))。

图9 经ECAP形变热处理复合工艺细化后TA15合金试样的超细晶(a)和纳米晶(b)的TEM像

Fig. 9 TEM images of ultrafine grains (a) and nano grains (b) in TA15 alloy sample processed by ECAP based thermo- mechanical treatment

3 结论

1) 较高温度下大变形量等温锻造未能有效细化原始晶粒组织,这与高温慢速变形条件下回复作用增强、再结晶形核减少及晶粒容易长大等因素有关。

2) 低温多向锻造在变形体内引入了很大的畸变能,使再结晶温度降低,变形温度降低,可明显细化钛合金的显微组织。

3) ECAP工艺通过强烈的纯剪切变形,可有效地细化合金组织,使TA15钛合金α晶粒尺寸细化至3 μm左右。

4) 高低温复合形变热处理可有效细化TA15近α钛合金的显微组织(晶粒尺寸小于5 μm)。单相区的高温形变热处理可获得细针状马氏体α′和亚稳态的β相,两相区较低温度的形变热处理可显著细化由α′马氏体和亚稳β相分解而来的细针状α和β相。

5) ECAP形变热处理复合工艺获得了比普通ECAP工艺更进一步的细化效果,得到了晶粒尺寸为0.2~0.6 μm的亚微米级等轴超细晶及尺寸为20~50 nm的部分纳米晶。

REFERENCES

[1] GUITAR A, VIGNA G, LUPPO M I. Microstructure and tensile properties after thermohydrogen processing of Ti-6Al-4V [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2009, 2(2): 156-163.

[2] MURRA L E, ESQUIVELA E V, QUINONESB S A. Microstructures and mechanical properties of electron beam- rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V [J]. Materials Characterization, 2009, 60(2): 96-105.

[3] CHEN Y Y, LI B H, KONG F T. Microstructural refinement and mechanical properties of Y-bearing TiAl alloy [J]. Journal of Alloys and Compounds, 2008, 457(1/2): 265-269.

[4] TABACHNIKOVA E D, BENGUS V Z, PODOLSKIY A V, SMIRNOV S N, CSACH K, MISKUF J, SAITOVAL L R, SEMENOVA I P, VALIEV R Z. Low temperature mechanical properties and failure peculiarities of the Ti-6Al-4V ELI ultra-fine grained alloy [J]. Reviews on Advanced Materials Science, 2008, 18: 604-607.

[5] ZHILYAEV A P, LANGDON T G. Microstructure and microtexture evolution in pure metals after ultra-high straining [J]. Journal of Materials Science, 2012, 47: 7888-7893.

[6] DANNO A, WONG C C, TONG S, JARFORS A, NISHINO K, FURUTA T. Effect of cold severe deformation by multi directional forging on elastic modulus of multi functional Ti+25 mol% (Ta, Nb, V) plus (Zr, Hr, O) alloy [J]. Materials and Design, 2010, 31: 61-65.

[7] 苏祖武, 孟国文, 郭鸿镇, 刘建超, 姚泽坤, 杨昭苏, 胡宗式. TC11钛合金棒材显微组织等轴细晶化工艺研究[J]. 金属学报, 1991, 27(5): 299-302

SU Zu-wu, MENG Guo-wen, GUO Hong-zhen, LIU Jian-chao, YAO Ze-kun, YANG Zhao-su, HU Zong-shi. Technological studies on equiaxed grain refinement in TC11 Ti alloy bar [J]. Acta Metallurgical Sinica, 1991, 27(5): 299-302.

[8] ZHAO Y, GUO H Z, ZHANG Y Q, YAO Z K, SHI Z F. Influence of ECAP processing parameters on microstructure of TA15 titanium alloy [J]. Steel Research International, 2010, 81(9): 466-469.

[9] 王 斌, 郭鸿镇, 姚泽坤, 赵 静, 赵张龙, 张明渊. 复合形变热处理对TA15近α钛合金组织和性能的影响[J]. 材料热处理学报, 2006, 27(5): 70-72.

WANG Bin, GUO Hong-zhen,YAO Ze-kun, ZHAO Jing, ZHAO Zhang-long, ZHANG Ming-yuan. Effect of multiple thermomechanical heat treatment on microstructure and mechanical property of near-alpha TA15 titanium alloy [J]. Transactions of Materials and Heat Treatment, 2006, 27(50): 70-72.

[10] BORISOVA E A. 钛合金金相学[M]. 陈石卿, 译. 北京: 国防工业出版社, 1980.

BORISOVA E A. Metallography of titanium alloy [M]. CHEN Shi-qing, transl. Beijing: National Defence Industry Press, 1980.

[11] ZHAO Y, GUO H Z, FU M W. NING Y Q, YAO Z K. Fabrication of bulk ultrafine grained titanium alloy via equal channel angular pressing based thermomechanical treatment [J]. Materials and Design, 2013, 46: 889-894.

(编辑 陈卫萍)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:郭鸿镇,教授;电话: 029-88492642; E-mail: hzguo@nwpu.edu.cn