DOI: 10.11817/j.issn.1672-7207.2018.04.005

轨道交通用7003铝合金型材失效行为分析

胡桂云1, 2,陈康华1, 2, 3,陈送义1, 2,姜慧丽1, 4

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 有色金属先进结构材料与制造协同创新中心,湖南 长沙,410083;

3. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

4. 东风柳州汽车有限公司,广西 柳州,545005)

摘要:采用金相、扫描电镜和透射电镜观察以及慢应变速率拉伸应力腐蚀实验等分析测试方法对轨道交通用7003铝合金型材的失效原因进行分析。研究结果表明:型材失效件的裂纹为沿晶扩展,且有支裂纹向外扩展;失效件断口形貌呈冰糖块状花样特征,断口表面附集着铝、锌的氧化物,还有少量氯化物和硫化物,经分析失效型材的裂纹是由应力腐蚀导致的沿晶脆性断裂。型材试样在30 g/L NaCl+10 mL/L HCl腐蚀溶液中的抗拉强度为181.5 MPa,断裂时间为5.1 h,在空气中的抗拉强度为320.3 MPa,断裂时间为27.7 h,试样的应力腐蚀敏感指数(ISSRT)为0.46。晶界析出相尺寸较小、密度大,且呈链状连续分布,在腐蚀过程中,晶界连续析出相易成为阳极腐蚀通道,是较高的应力腐蚀敏感性的主要原因。

关键词:7003铝合金型材;失效分析;沿晶脆性断裂;应力腐蚀;连续析出相

中图分类号:TG 146.2+1 文献标志码:A 文章编号:1672-7207(2018)04-0802-07

Failure behavior analysis of railway 7003 aluminum alloy extrusions

HU Guiyun1, 2, CHEN Kanghua1, 2, 3, CHEN Songyi1, 2, JIANG Huili1, 4

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center,

Central South University, Changsha 410083, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

4. Dongfeng Liuzhou Automobile Co., Ltd., Liuzhou 545005, China)

Abstract: The failure behavior analysis of rail railway 7003 aluminum alloy extrusions was studied by optical microstructure, scanning electron microscopy(SEM), transmission electron microscopy (TEM) and slow strain rate tensile stress corrosion testing, etc. The results show that the crack of extrusions extends along the grain boundary and bits of branch crack extend outward. Fracture morphology of failure extrusions is sugar lump pattern features, and also the fracture surface is attached to aluminum, zinc oxide and bits of chlorides and sulfides. The intergranular brittle fracture is caused by stress corrosion. The tensile strength and break time of extrusions sample are respectively 181.5 MPa and 5.1 h in 30 g/L NaCl+10 mL/L HCl corrosion solution; The tensile strength and break time of extrusions sample in air are 320.3 MPa and 27.7 h, respectively. Stress corrosion sensitivity index (ISSRT) is 0.46. The small size, high density and continuous chain distribution of grain boundries precipiates which easily become anodic corrosion channel during the corrosion process, are the main causes of high sensitivity to stress corrosion.

Key words: 7003 aluminum alloy; failure behavior analysis; intergranular brittle fracture; stress corrosion; continuous precipiates

中强可焊7003铝合金具有优异的比强度、热加工性及可焊性,是航空航天、高铁动车及车辆等领域的主要结构材料[1-3]。目前,该合金已被广泛用于高铁和动车的车体结构、上侧梁、车顶梁、外板及骨架(型材)等[4-5]。然而,文献[6-9]表明,7003铝合金容易发生应力腐蚀开裂现象。应力腐蚀开裂是指合金或金属在应力(主要是拉应力)和腐蚀介质的共同作用下引起的材料破坏现象。应力腐蚀开裂是一种与时间有关的延迟断裂,在应力的作用下,合金材料在腐蚀环境中经过一段时间将产生微裂纹,微裂纹一旦形成,裂纹会继续扩展且没有任何明显的征兆,因此,应力腐蚀开裂对材料的破坏极大[10-12]。目前,很多学者发现应力腐蚀是导致7×××铝合金结构件服役提前失效的主要原因之一[13-15]。本文作者针对国内某轨道交通用7003铝合金型材在服役中产生的裂纹问题,通过金相、扫描电镜、慢应变速率拉伸应力腐蚀等实验手段分析7003铝合金挤压型材失效原因及机理。

1 实验

实验材料取自国内某公司生产的轨道交通用挤压型材失效件,材料为6 mm厚的7003-T5铝合金型材,具体化学成分见表1。采用线切割机将包含裂纹的部位从失效件上取下,经打磨、抛光和超声清洗后制得扫描电镜试样,在Nova NanoSEM230型场发射扫描电镜上观察失效件的断口形貌以及断口腐蚀产物的能谱分析。同时用keller腐蚀试剂(0.5% HF+1.5% HCl+2.5% HNO3+95.5% H2O,体积分数)腐蚀制得金相显微组织试样,在德国莱卡DM4000M智能型显微镜下观察型材的金相组织。

采用慢应变速率拉伸应力腐蚀实验测试材料的应力腐蚀敏感性,试样选取L-T方向。实验在西安力拓慢应变速率腐蚀拉伸机上进行,应变速率为3.34×10-8 s-1,腐蚀介质分别为30 g/L NaCl+10 mL/L HCl溶液和空气。按照HB 5254—83[16]计算应力腐蚀敏感指数(ISSRT)以评价材料的应力腐蚀敏感性。将慢应变速率拉伸断裂后的试样在Nova NanoSEM230型场发射扫描电镜上观察断口形貌。

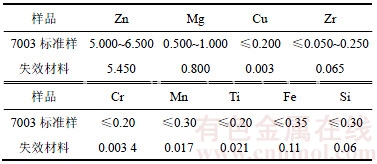

表1 合金的化学成分(质量分数)

Table 1 Chemical composition of alloys %

将型材的焊接接头区域进行打磨、抛光和超声清洗后,采用7501A 涡流导电仪和HV-50维氏硬度计上分别测试焊接区域的电导率和硬度。晶间腐蚀实验按照GB 7998—87[17]标准进行。试样经打磨、抛光和超声清洗后制得晶间腐蚀样品,腐蚀溶液为30 g/L NaCl+10 mL/L HCl,腐蚀时间为6 h,实验温度为35 ℃。

失效件采用电解双喷法(电解液为体积比1:3的硝酸、甲醇混合溶液,电压为20 V,温度为-25 ℃)制备透射电镜试样,采用TECNAIG2 20透射电镜观察晶内晶界析出相分布形态。

2 结果与分析

2.1 裂纹宏观形貌

图1所示为轨道交通用7003铝合金型材失效件裂纹的宏观形貌。裂纹起源于角铝型材边缘,由外向里扩展。裂纹沿垂直于挤压型材的方向扩展,裂纹长度约为70 mm。

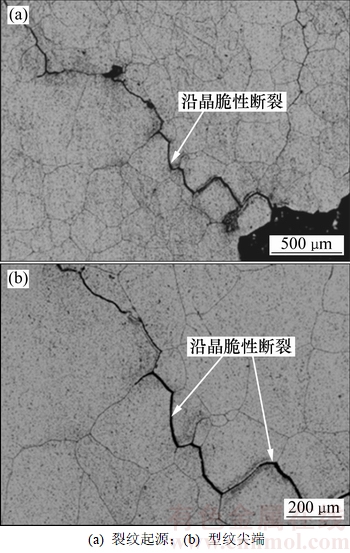

2.2 裂纹扩展金相组织

图2所示为型材失效件的裂纹扩展形态的金相组织,图2(a)所示为裂纹源头,图2(b)所示为裂纹尾端。由图2可知:失效件型材发生完全再结晶,晶粒为粗大的等轴晶,晶粒粒径为100~200 μm,晶粒度为3~5级。裂纹扩展路线是沿着晶界扩展的,主裂纹上还有少量支裂纹向外扩展。因此,可初步判定型材失效件的断裂方式为沿晶脆性断裂。

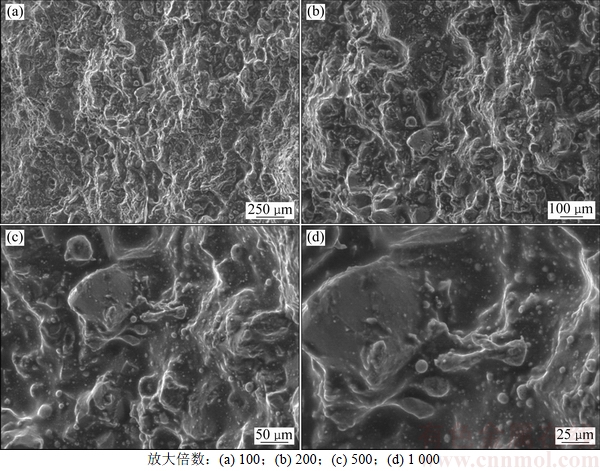

2.3 裂纹断口形貌

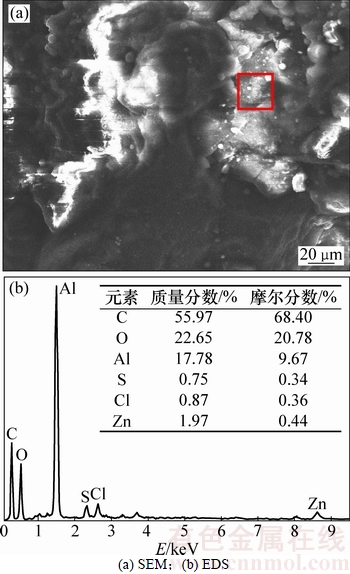

型体裂纹尾端切下之后就自行裂成两半,断口经过清洗之后,两边拼合能够很好地啮合,说明裂纹产生及发展过程中材料没有发生塑性变形,属于脆性断裂。断口表层上有黑色的沉积物,用丙酮溶液经超声清洗之后,黑色沉积物未能清除干净,说明失效件中裂纹已经存在了很长一段时间。图3所示为失效件断口扫描电镜形貌。由图3可知:断口上有类冰糖块状花样特征,高倍数图中出现腐蚀坑,故可判断该断口断裂方式属于沿晶断裂,这与金相组织中观察的裂纹沿晶扩展是一致的。对断口上的黑色沉积物进行能谱分析,如图4所示。从元素成分可以看出:断口上的腐蚀产物主要是铝、锌的氧化物,还有少量氯化物和硫化物。

图1 型材裂纹扩展宏观形貌

Fig. 1 Crack propagation morphology of extrusion

图2 型材裂纹扩展微观组织

Fig. 2 Microstructure crack propagation microstructure of extrusions

从裂纹断口的微观形貌可以判断:型材裂纹属于沿晶脆性断裂;断口表面的腐蚀产物能谱分析反映列车运行过程中经历过无法避免的腐蚀性环境,断口上存在的腐蚀坑也能进一步证实型材金属在裂纹产生前期曾受到局部腐蚀。由于列车在运行过程中,型材存在拉应力,且列车实际服役过程中合金表层有腐蚀介质的存在,考虑到7×××铝合金有较高的应力腐蚀敏感性,结合图2中裂纹扩展组织图可以看出,裂纹具有沿晶扩展、有分支和裂纹由粗到细等特点,该特点基本符合7×××铝合金应力腐蚀开裂的裂纹特征。因此,可初步判断该型材裂纹是应力腐蚀开裂而导致的[18]。

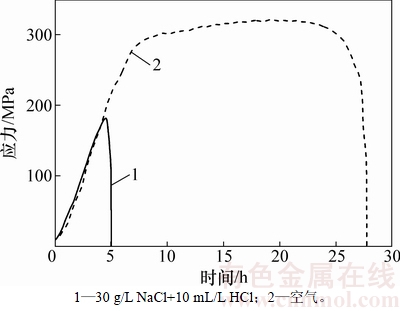

2.4 慢应变速率应力腐蚀实验

慢应变速率拉伸(SSRT)实验具有实验周期较短,能比较快速地评定材料的应力腐蚀敏感性。图5所示为型材在不同腐蚀介质中的慢应变速率拉伸曲线。由图5可知:试样在30 g/L NaCl+10 mL/L HCl腐蚀溶液和空气中的慢拉伸结果差异较大。在30 g/L NaCl+10 mL/L HCl腐蚀溶液中拉伸时,试样的抗拉强度为181.5 MPa,断裂时间为5.1 h。在空气中拉伸时,试样的抗拉强度为320.3 MPa,断裂时间为27.7 h。试样在腐蚀溶液中拉伸时的强度和断裂时间均低于空气中拉伸时的相应指标,故该型材在30 g/L NaCl+10 mL/L HCl腐蚀溶液中存在应力腐蚀敏感性。

根据HB 5254—83[16],慢应变速率拉伸实验得到的各项力学性能指标加以计算所得的应力腐蚀指数(ISSRT),比单一的力学性能指数能更好地反映应力腐蚀开裂敏感性,通常将其作为评价应力腐蚀的重要判据,其计算公式为

(1)

(1)

式中:σfA为在惰性介质(如空气)中的断裂强度,MPa;σfw为在腐蚀溶液中的断裂强度,MPa;δfA为在惰性介质中的断裂伸长率,%;δfw为在腐蚀溶液中的断裂伸长率,%。应力腐蚀敏感指数(ISSRT)越大,表示应力腐蚀断裂敏感性越高,即ISSRT越接近1,应力腐蚀断裂敏感性越高,反之越低。

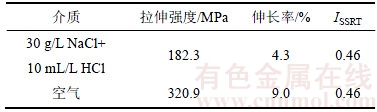

表2所示为失效型材在不同腐蚀介质中的拉伸强度和伸长率,经式(1)计算得出试样的ISSRT为0.46,一般ISSRT大于0.1,即具有较强的应力腐蚀敏感性[18]。因此,当型材在腐蚀环境中受到拉应力时更容易发生应力腐蚀。

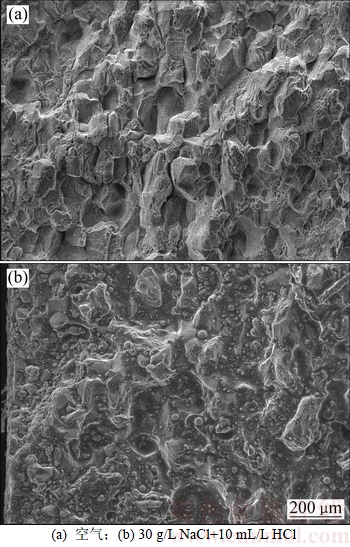

图6所示为失效型材在不同介质中进行慢应变速率拉伸实验后的断口扫描形貌图。由图6可知:试样的拉伸断口呈冰糖块状花样特征,并伴有二次裂纹存在,为明显的沿晶脆性断裂。试样在腐蚀溶液中的拉伸断口形貌(见图6(b))表面附有少量的腐蚀产物,且该形貌图与图3(b)形貌特征相似,故可判断型材的断裂是由于应力腐蚀开裂而导致的。

图3 失效型材断口形貌

Fig. 3 Fracture morphology of failure extrusions

图4 失效型材断口形貌与能谱图

Fig. 4 Fracture morphology and EDS of failure extrusions

图5 柜体型材的慢应变速率拉伸曲线

Fig. 5 Slow strain rate tensile curve of extrusions

表2 失效型材的应力腐蚀敏感指数

Table 2 Stress corrosion sensitivity index of failure extrusions

图6 慢应变速率拉伸断口形貌

Fig. 6 Fracture morphology of slow strain rate tensile

2.5 焊接对型材性能的影响

2.5.1 焊接对型材硬度的影响

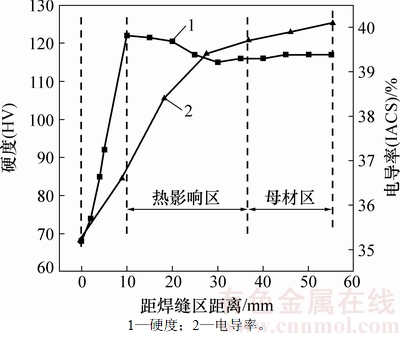

由于该列车7003铝合金型材采用焊接连接,焊接容易导致焊接接头出现软化和耐蚀性变差等问题,且断裂部位位于焊接区域附近[19],因此,对材料焊接接头区域进行性能表征将能更好地分析柜体裂纹产生的原因。图7所示为焊接接头各区域的硬度和电导率分布曲线。由图7可知:合金的焊接接头明显分为熔合区(fusion zone, FZ)、热影响区(heat affected zone, HAZ)和母材区(base material, BM),热影响区又分为固溶区(solid solution zone, SSZ)和过时效区(overaging zone, OZ)。合金的硬度在固溶区最高,过时效区最低,最低值为116(HV),母材区的硬度为118(HV)。其原因是焊接后自然时效显著提高了固溶区的强度,而过时效区强度没有明显影响。电导率随着距焊缝距离增大而增加,且固溶区的电导率增幅最大。固溶区的电导率变化与焊接过程中高温受热而导致溶质原子回溶,引起后续自然时效析出密切相关。

图7 焊接接头的硬度及电导率

Fig. 7 Hardness and conductivity of welded joint

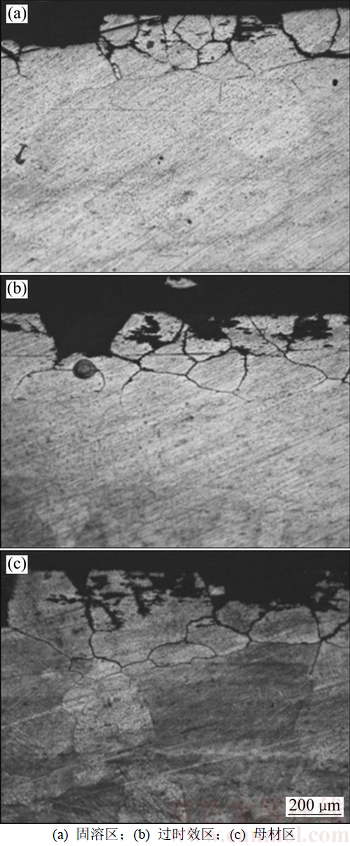

2.5.2 焊接对型材耐蚀性的影响

对7×××系铝合金而言,合金的应力腐蚀性能一定程度上与晶间腐蚀相对应,这源于它们的腐蚀机理都跟晶界析出相有关。图8所示为焊接接头各区域的晶间腐蚀形貌图。由图8可知:合金的焊接接头在晶间腐蚀溶液中的腐蚀深度差别不大,故可间接反映焊接过程对型材晶界析出相的连续性影响不大,且可判断焊接对型材的应力腐蚀敏感性影响也不大。因此,结合图7和图8可判断,焊接不是造成型材出现裂纹的主要原因。

图8 焊接接头各区域的晶间腐蚀

Fig. 8 Intergranular corrosion of welded joint at different areas

3 分析与讨论

从受力方面分析,型材本身承受的载荷并不大,但是作为安装在列车车身上的部件,运行过程中必然会随车身经受交变应力。因此,型材裂纹也可能属于疲劳裂纹。但是,根据疲劳裂纹的典型特征可知,疲劳裂纹的形态通常呈平直化,多属穿晶裂纹,断口宏观形貌平坦,微观上可见条纹花样[8],这与上述系列实验检测结果不符,故该型材的断裂方式不太可能为疲劳断裂。

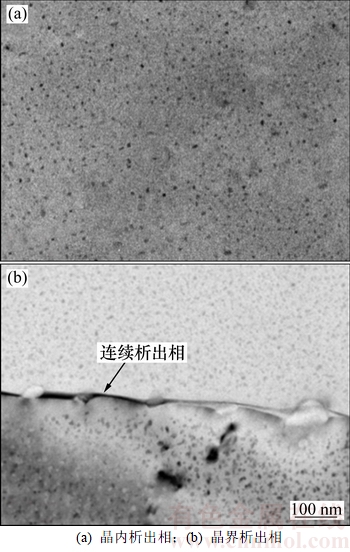

根据失效型材的裂纹金相显微组织和断口形貌分析可初步判断,该失效件的断裂方式为沿晶脆性断裂,导致型材断裂的主要原因为应力腐蚀开裂。通过慢应变速率拉伸实验结果可知:型材存在较强的应力腐蚀开裂敏感性,该材料在腐蚀环境中服役时更容易遭受应力腐蚀(图5)。其次,图9所示为型材失效件的晶内和晶界析出相分布图。由图9可知:合金的晶内析出相呈部分粗大现象,分布不均匀;合金的晶界析出相尺寸较小、密度大,呈链状连续分布。合金在腐蚀过程中,晶界连续析出相与周围的基体易构成电偶腐蚀,晶界连续析出相易成为阳极腐蚀通道。因此,该型材在腐蚀环境中易发生沿晶腐蚀,且连续分布的晶界析出相也增大了合金的应力腐蚀敏感倾向。

合金产生应力腐蚀开裂需具备2个条件[15]:1) 存在拉应力。车体在运行过程中,型材本身承受较小的拉应力。其次,型材产生裂纹的地方位于角铝棱边附近,角铝两侧附近均存在焊缝,焊缝在焊接时纵向收缩会产生残余拉应力,拉应力方向平行于角铝方向,并与裂纹垂直。再者,列车在运行时处于不等振幅的振动状态,此时也会形成交变应力。虽然拉应力、残余应力和交变应力均较小,远远低于7003型材的屈服强度,但是应力腐蚀属于低应力的破坏形式,产生应力腐蚀的门槛应力远低于合金的屈服强度,实际存在的应力只需要大于该合金在一定腐蚀介质中的门槛应力即可。2) 存在易于7×××铝合金发生应力腐蚀的外界环境[20]。列车在实际服役过程中会经历各种不同的外界环境,例如国内南方地区具有潮湿、带有氯离子的海洋性空气、含硫的空气环境以及污染较严重的酸雨环境,列车在这种腐蚀性环境中服役很容易诱发应力腐蚀开裂现象。因此,现役轨道交通7003铝合金型材在国内偏酸性的腐蚀环境运输过程中,由于型材承受着各种应力,且本身抗应力腐蚀性能不足,从而导致在服役过程中出现严重的开裂现象。

图9 失效型材晶内和晶界析出相分布

Fig. 9 Distribution of precipitates in matrix and grain boundries of failure extrusions

4 结论

1) 7003铝合金型材失效件的金相组织呈完全再结晶态,晶粒为粗大的等轴晶,晶粒度为3~5级,断裂裂纹沿着晶界扩展,断口形貌呈冰糖块状花样特征,断裂方式为沿晶脆性断裂。

2) 该7003铝合金型材具有较高的应力腐蚀敏感性,应力腐蚀指数(ISSRT)为0.46;其慢应变速率拉伸断口呈冰糖块状花样特征,并伴有二次裂纹存在,合金在腐蚀溶液中的断口形貌表面附有少量的腐蚀产物,故试样的断裂属于典型的应力腐蚀开裂。

3) 焊接过程对合金的焊接接头强度没有明显的降低,接头各区域的晶间腐蚀深度差别也不大。焊接过程不是造成该型材出现裂纹的主要原因。

4) 合金的晶界析出相呈链状连续分布。合金在腐蚀过程中,晶界连续析出相与周围的无沉淀析出带构成电偶腐蚀,易成为阳极腐蚀通道,是引起合金的应力腐蚀敏感性倾向较大的主要原因。

参考文献:

[1] STALEY J T, LIU J, HUNT JR W H. Aluminum alloys for aerostructures[J]. Advanced Materials and Processes, 1997, 152(4): 17-20.

[2] DAVID A L, RAY M H. Strong aluminum alloy shaves airframe weight[J]. Advanced Materials and Processes, 1991, 140(4): 46-49.

[3] LUDTKA G M, LAUGHLIN D E. The influence of microstructure and strength on the fracture mode and toughness of 7xxx series aluminum alloys[J]. Metallurgical Transactions A, 1982, 13(3): 411-425.

[4] 戴静敏. 铝合金在高速列车上的应用前景[J]. 铁道车辆, 1993, 1(6): 14-18.

DAI Jingmin. Aluminum alloy applications in high speed trains[J]. Railway Vehicles, 1993, 1(6): 14-18.

[5] 江超, 陈辉, 王晓敏, 等. 高速列车车体铝合金抗应力腐蚀性能[J]. 西南交通大学学报, 2013, 48(3): 500-506.

JIANG Chao, CHEN Hui, WANG Xiaomin, et al. Stress corrosion behavior of car-body aluminum alloy for high speed train[J]. Journal of Southwest Jiaotong University, 2013, 48(3): 500-506.

[6] BAYOUMI M R. The mechanics and mechanisms of fracture in stress corrosion cracking of aluminium alloys[J]. Engineering Fracture Mechanics, 1996, 54(6): 879-889.

[7] KANNAN M B, RAJA V S. Enhancing stress corrosion cracking resistance in Al-Zn-Mg-Cu-Zr alloy through inhibiting recrystallization[J]. Engineering Fracture Mechanics, 2010, 77(2): 249-256.

[8] 王荣, 鄢国强, 李光福, 等. 7020铝合金列车车钩梁开裂原因与机理[J]. 中国腐蚀与防护学报, 2008, 28(4): 240-245.

WANG Rong, YAN Guoqiang, LI Guangfu, et al. Failure analysis of cracking coupler beam of 7020 aluminum alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2008, 28(4): 240-245.

[9] LIN J C, LIAO H L, JEHNG W D, et al. Effect of heat treatments on the tensile strength and SCC-resistance of AA7050 in an alkaline saline solution[J]. Corrosion Science, 2006, 48(10): 3139-3156.

[10] 刘继华, 李荻, 朱国伟, 等. 7075铝合金应力腐蚀敏感性的SSRT和电化学测试研究[J]. 腐蚀与防护, 2005, 26(1): 6-9.

LIU Jihua, LI Di, ZHU Guowei, et al. Stress corrosion susceptibility of 7050 aluminum alloy studied by SSRT and electrochemical tests[J]. Corrosion and Protection, 2005, 26(1): 6-9.

[11] WANG D, MA Z Y. Effect of pre-strain on microstructure and stress corrosion cracking of over-aged 7050 aluminum alloy[J]. Journal of Alloys and Compounds, 2009, 469(1): 445-450.

[12] 陈文敬. 高强铝合金应力条件下的腐蚀行为及其电化学行为研究[D]. 长沙: 中南大学材料科学与工程学院, 2008: 44-53.

CHEN Wenjing. Study on high strength aluminum corrosion and electrochemical behavior under stress conditions[D]. Changsha: Central South University. School of Materials and Engineering, 2008: 44-53.

[13] 刘继华, 李荻, 郭宝兰. 7xxx系列Al合金应力腐蚀开裂的研究[J]. 腐蚀科学与防护技术, 2001, 13(4): 218-222.

LIU Jihua, LI Di, GUO Baolan. Investigation of stress corrosion cracking of 7xxx series aluminum alloys[J]. Corrosion Science and Protection Technology, 2001, 13(4): 218-222.

[14] 张志野, 潘清林, 李波, 等. 含Sc的Al-Zn-Mg-Zr合金应力腐蚀开裂敏感性研究[J]. 轻合金加工技术, 2012, 40(12): 44-48.

ZHANG Zhiye, PAN Qinglin, LI Bo, et al. Study on stress corrosion cracking sensitivity of Al-Zn-Mg-Zr alloy containing Sc[J]. Light Alloy Fabrication Technology, 2012, 40(12): 44-48.

[15] 王荣, 陈冰川, 李光福. 7020铝合金应力腐蚀开裂特征[J]. 腐蚀与防护, 2010, 31(9): 688-693.

WANG Rong, CHEN Bingchuan, LI Guangfu. Stress corrosion cracking of 7020 aluminum alloy[J]. Corrosion and Protection, 2010, 31(9): 688-693.

[16] HB 5254—83. 变形铝合金拉伸应力腐蚀试验方法[S].

HB 5254—83. Deformation aluminum alloy tensile stress corrosion test method[S].

[17] GB 7998—87. 铝合金晶间腐蚀测定方法[S].

GB 7998—87. The method for determining the intergranular corrosion of aluminum alloy[S].

[18] 章淑芳, 王晓敏, 陈辉, 等. 7003 铝合金动车柜体的应力腐蚀开裂[J]. 材料工程, 2015, 43(7): 105-112.

ZHANG Shufang, WANG Xiaomin, CHEN Hui, et al. Stress corrosion cracking of cabinet of 7003 aluminum alloy[J]. Journal of Materials Engineering, 2015, 43(7): 105-112.

[19] 彭小燕, 曹晓武, 段雨露, 等. 7020铝合金MIG焊焊接接头的组织与性能[J]. 中国有色金属学报, 2014, 24(4): 912-918.

PENG Xiaoyan, CAO Xiaowu, DUAN Yulu, et al. Microstructures and properties of MIG welded joint of 7020 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 912-918.

[20] 赵军静, 王晓敏, 陈辉. 车体铝合金腐蚀失效分析[J]. 电焊机, 2011, 41(3): 87-90.

ZHAO Junjing, WANG Xiaomin, CHEN Hui. Corrosion failure analysis of carbody aluminum alloy[J]. Electric Welding Machine, 2011, 41(3): 87-90.

(编辑 杨幼平)

收稿日期:2017-04-16;修回日期:2017-06-13

基金项目(Foundation item):国家重点研发计划(2016YFB0300801);国家重点基础研究计划(973计划)项目(2012CB619502);国家自然科学基金资助项目(51201186);国家重大科研仪器设备研制专项(51327902);研究生自主探索创新项目(2016zzts317)(Project(2016YFB0300801) supported by the National Key Research and Development Program of China; Project(2012CB619502) supported by the National Basic Research Program (973 Program) of China; Project(51201186) supported by the National Natural Science Foundation of China; Project(51327902) supported by the Major Research Equipment Development Projects of National Natural Science Foundation of China; Project(2016zzts317) supported by the Graduate Students Explore Innovation Project)

通信作者:陈送义,博士,从事高性能铝合金研究;E-mail:sychen08@csu.edu.cn