文章编号:1004-0609(2010)10-1982-07

La2O3对WC-MgO复合材料组织和力学性能的影响

张 祎1,马 俊1, 2, 3,狄 平1,朱世根1, 2, 3

(1. 东华大学 机械工程学院,上海 201620;2. 东华大学 纺织装备教育部工程研究中心,上海 201620;

3. 东华大学 材料科学与工程学院,上海 201620)

摘 要:以高能球磨法制备的WC-MgO复合粉末为原料,研究稀土氧化物(La2O3)添加量对WC-MgO复合粉末热压烧结块体的组织和力学性能的影响,采用XRD、SEM和SPM对复合材料的结构特征进行表征,并讨论稀土氧化物(La2O3)对颗粒增韧复合材料热压烧结成形的影响。结果表明:La2O3的加入量为0.1%(质量分数),可抑制烧结过程中出现的脱碳现象、细化烧结组织,提高增韧颗粒分散均匀性和改善颗粒/基体界面形貌,使成形致密度达理论密度的98.56%,维氏硬度和断裂韧性分别为18.02 GPa与12.38 MPa?m1/2;而添加过量La2O3(≥0.25%,质量分数),导致复合材料的成形性能降低。

关键词:WC-MgO;La2O3;热压烧结;显微组织;力学性能

中图分类号:TF124;TF125.3;U214.8+2 文献标志码:A

Effects of La2O3 on microstructures and mechanical properties of hot-pressing sintered WC-MgO composite material

ZHANG Yi1, MA Jun1, 2, 3, DI Ping1, ZHU Shi-gen1, 2, 3

(1. College of Mechanical Engineering, Donghua University, Shanghai 201620, China;

2. Engineering Research Center of Advanced Textile Machinery,

Ministry of Education, Donghua University, Shanghai 201620, China;

3. College of Materials Science and Engineering, Donghua University, Shanghai 201620, China)

Abstract: The WC-MgO composite powder synthesized by high-energy ball milling was used as raw material. A detailed investigation was carried out into the influence of rare earth (RE) oxide (La2O3) contents on the microstructure and mechanical properties of the as-consolidated WC-MgO bulk composites prepared by hot-pressing sintering method (HPS). The effective mechanisms of rare earth material (La2O3) in hot-pressing sintered composite were discussed. The results show that, by addition of 0.1% La2O3, the sintered structure can be refined, the decarburization reaction can be suppressed, the reinforcing particulates can be homogeneously refined, and the particulate and matrix bonding can be improved, leading to a high relative density of 98.56%, while the hardness is 18.02 GPa and the fracture toughness is 12.38 MPa?m1/2. However, an excessive addition of La2O3 (≥0.25%) results in the decrease of the hot-pressing sintering ability.

Key words: WC-MgO; La2O3; hot-pressing sintering; microstructure; mechanical properties

钨基硬质合金因其硬度高、高温抗氧化和耐腐蚀好,成为工业技术领域中不可缺少的工具材料、涂层材料和结构材料[1]。但由于纯WC的抗冲击性能和断裂韧性较低,很难将纯WC用于工业应用。研究表 明[2],Co对WC具有良好的润湿性和粘结性,目前将Co作为粘结剂来改善WC的综合力学性能。

添加Co这类金属粘结剂会直接影响材料的硬度,有部分研究[3]围绕着减少粘结剂添加量,甚至不使用粘结剂来改善WC的性能。新型的复合材料WC-MgO就是其中的一种[4],与微米级粒度和亚微米级粒度的WC-Co相比,WC-MgO可以实现较高硬度和较高断裂韧性的结合[5-6]。

热压烧结是粉末冶金中的一种常用的烧结方法。在烧结过程中,加热与施压同时进行,烧结装置也十分简单。加热过程中,在压力的作用下,粉末活性的提高,可以获得较致密和性能优良的块体材料。

热压烧结获得的WC-MgO复合块体与放电等离子体烧结得到的块体相比,粉末的烧结性与块体的致密度均有所降低,这主要是由于增韧颗粒发生团聚的现象。深入研究发现,只要在WC-MgO复合粉末体系中添加少量的稀土氧化物(La2O3),就可以显著提高烧结产物的性能。本研究工作中,考察不同含量La2O3对WC-MgO复合材料的显微组织与力学性能的影响,并讨论稀土元素(La2O3)对颗粒增韧复合材料热压烧结成形的影响。

1 实验

1.1 材料

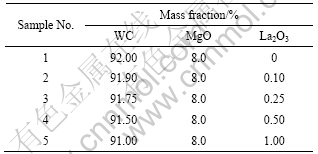

实验材料主要如下:纯度为99.5%的WC粉末,平均粒度为75 μm;纯度为99.5%的MgO粉末,平均粒度为48 μm;纯度为99.5%的La2O3粉末,不规则外形,平均粒度为16 μm。复合粉末采用机械合金化方法制备,将3种粉末按5种不同质量比配置(见表1),并置于QM-1SP4行星式球磨机中合成(氩气保护,球磨介质为硬质合金球,球料比为10:1,转速为350 r/min,球磨时间为50 h)。

1.2 工艺

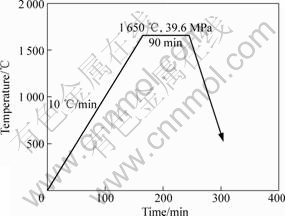

采用ZT-40-20Y型真空热压烧结炉,在真空度

表1 原始粉末组成

Table 1 Primary powder constitution

为0.13 Pa、升温速度为10 ℃/min、烧结温度为 1 650 ℃、压力为39.6 MPa、保温时间为90 min的条件下进行烧结实验(见图1)。

图1 粉末烧结工艺曲线

Fig.1 Sintering cycle curve of powder system

热压烧结使用的模具直径为d15 mm的圆柱形高强度石墨制成。在模具内腔与粉末之间垫有0.2 mm厚的石墨纸。烧结过程采用热电偶和红外仪联用的双控温系统。

1.3 表征

热压烧结试样致密度利用Archimedes定律测算;试样的物相用Rigaku D/Max-2550PC型X射线衍射仪(XRD)分析(CuKα);金相试样腐蚀剂选用含K3[Fe(CN)6](10 g)、KOH(10 g)及蒸馏水(100 mL)的Murakami溶液,腐蚀时间为5 min;试样的显微组织用NanoScope IV型扫描探针显微镜(SPM)和S-4800型场发射扫描电镜(FE-SEM)的二次电子像(SE)和背散射电子像(BSE)来表征;成分组成利用能谱仪(EDS)表征;试样的硬度利用HV-50Z型维氏硬度计测定,载荷为490 N,保压时间为10 s。试样断裂韧性由压痕裂纹长度根据Shetty公式估算[7]。取10次测量结果的均值作为试样的硬度和断裂韧性。

2 结果与分析

2.1 稀土对WC-MgO复合材料力学性能的影响

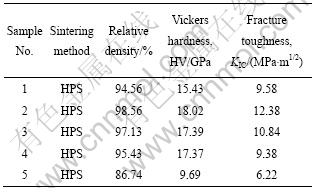

不同La2O3添加量WC-MgO热压烧结试样的力学性能如表2所列。由表2可看出,烧结试样的硬度和断裂韧性受La2O3含量的影响显著。未添加La2O3时,WC-MgO复合块体试样维氏硬度值可达15.43 GPa,断裂韧性为9.58 MPa·m1/2;加入0.1%的La2O3时,不但提高了热压烧结样品的致密度,同时块体的硬度也增加,硬度可达18.02 GPa。同时,根据维氏硬度压痕裂纹(见图2),用Shetty公式[7](KC=8.89×10-2 ,式中:F为硬度测量时载荷,N;

,式中:F为硬度测量时载荷,N; 为压痕平均裂纹长度,μm;Hv为维氏硬度)。可估算其断裂韧性为12.38 MPa·m1/2。但继续提高La2O3含量,由于烧结试样的致密度下降,则维氏硬度和断裂韧性均有所降低。当提高La2O3含量至1%时,硬度和断裂韧性仅为9.69 GPa和6.22 MPa·m1/2。

为压痕平均裂纹长度,μm;Hv为维氏硬度)。可估算其断裂韧性为12.38 MPa·m1/2。但继续提高La2O3含量,由于烧结试样的致密度下降,则维氏硬度和断裂韧性均有所降低。当提高La2O3含量至1%时,硬度和断裂韧性仅为9.69 GPa和6.22 MPa·m1/2。

表2 不同含量La2O3热压烧结后样品的力学性能

Table 2 Mechanical properties of hot-pressing sintered samples with different La2O3 contents

图2 热压烧结样品2维氏硬度压痕的SEM像

Fig.2 SEM image of Vickers hardness indentation of as-consolidated sample 2

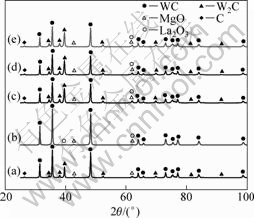

2.2 稀土对WC-MgO复合材料物相的影响

图3所示为不同La2O3含量复合粉末经热压烧结后的XRD谱。从图3可见,WC(六方晶体)和MgO(立方晶体)的衍射峰比较强,热压烧结的主要材料是WC和MgO。没有添加La2O3(见图3(a))和过量添加La2O3 (≥0.25%)(见图3(c)-(e))的样品均出现了C和W2C的衍射峰。出现C和W2C主要是由于WC在烧结过程

图3 不同La2O3含量热压烧结试样的XRD谱

Fig.3 XRD patterns of samples 1(a), 2(b), 3(c), 4(d) and 5(e) after hot-pressing sintering

中出现脱碳现象(见式(1))。另外,由于球磨制备的粉末比表面积比较大,表面吸附作用比较强,导致粉末中吸附与储存的氧含量比较多。这种含氧量比较高的粉末在烧结过程中会发生脱氧反应,同时发生脱碳反应(见式(2)和(3))[8]。研究[9-11]表明,稀土原子的第一电离能很小,吸附于晶界或相界处稀土原子的外层电子容易发生偏移或部分脱离原子核的束缚,造成稀土原子的极化。当适量添加La2O3时,活性稀土元素会吸附残存在粉末中的氧,使氧化脱碳无法进行,因此,也就检测不到C和W2C的衍射峰。但当稀土过量时,极化的稀土元素增多,进入晶体内的极化稀土元素也增多,这些极化稀土元素互相制约,应力场的综合作用增大,形成壁垒阻碍原子进一步扩散,导致稀土元素活性作用下降。在添加了不同质量比的La2O3的样品(见图3(b)~(e))中,还同时发现La2O3衍射峰的存在,但由于只添加微量La2O3,因此其衍射峰不强。

2WC→W2C+C (1)

2C+O2→2CO↑ (2)

2CO+O2→2CO2 ↑ (3)

2.3 稀土对WC-MgO复合材料显微结构的影响

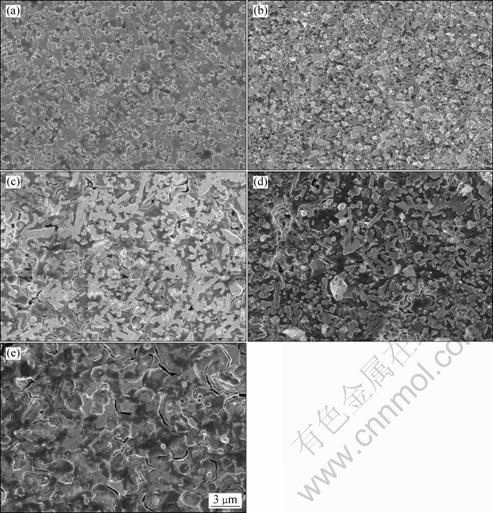

图4所示为不同La2O3含量的试样经过抛光后所得的显微组织。图5所示为La2O3添加量对热压烧结致密度的影响。从EDS能谱分析结果可知,图4中灰色基体组织为WC,而分散的黑色颗粒物质为MgO。对照图4与5可以看出,未添加La2O3时,增韧颗粒粗大(见图4(a)),烧结试样的密度仅为理论密度的94.56%;而添加0.1% La2O3时,增韧颗粒更加细小、均匀弥散地分布在WC的基体之中(见图4(b)),致密

图4 不同热压烧结样品抛光后的SEM像

Fig.4 SEM images of sintered and polished samples 1(a), 2(b), 3(c), 4(d) and 5(e)

图5 热压烧结样品致密度随La2O3含量的变化

Fig.5 Change of relative density of hot-pressing sintered samples with La2O3 content

度也得到改善,增至98.56%;当La2O3的含量增加至0.25%时,颗粒有所增大,但仍然可以保持弥散均匀地分布在基体当中(见图4(c)),此时致密度稍有降低,为97.13%;提高La2O3含量至0.5%时,增韧颗粒出现团聚现象,致密度为95.43%(见图4(d));当La2O3含量增加至1%时,致密度急剧降低至86.74%,烧结组织中出现粗大的空隙和疏松(见图4(e))。这就说明适量的添加La2O3(0.1%)有助于WC和MgO在界面上的结合,从而提高材料的致密度。

La是典型的稀土表面活性元素,有研究表明[12],稀土表面活性元素在晶体各晶面上的吸附量是不同的。稀土元素在某些晶面上吸附,既减小了晶体在这些晶面上的表面自由能,也降低了这些晶面的生长速率,使晶粒长大的驱动力减小[13-15],有效地阻止WC和MgO晶粒间的聚晶长大。这样,随着La2O3的合理添加,能有效地减少晶粒团聚现象、细化晶粒,并最终提高烧结样品的致密度[16-17]。

图6所示为不同La2O3含量下热压烧结试样抛光后的高倍显微组织。从图6可见,MgO增韧颗粒在WC基体中分散的均匀性受La2O3添加量的影响显著。未添加La2O3时,增韧相颗粒形状不规则,且多以2 μm

图6 不同热压烧结试样高倍显微组织

Fig.6 High magnified SEM-BSE images of hot-pressing sintered samples 1(a), 2(b), 3(c), 4(d) and 5(e)

以上的大颗粒团聚形式存在(见图6(a));当La2O3含量为0.1%时,增韧颗粒得到细化,降至0.4 μm左右(见图6(b)),其在基体的分散均匀性得以显著的提高;若La2O3含量增加到0.25%,此时虽然增韧颗粒尺度变化不大,但增韧颗粒分散均匀性受到影响(见图6(c));当La2O3含量增加到0.5%以上(见图6(d)-(e))时,颗粒和基体间产生明显的气孔与疏松。

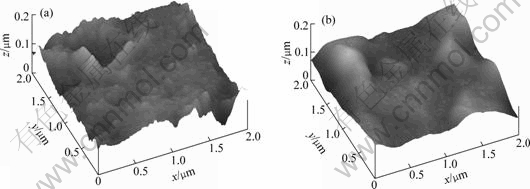

图7所示为不含La2O3和添加0.1% La2O3热压烧结试样中增韧颗粒的三维形貌。比较可以发现,没有添加La2O3时,样品表面参差不齐,布满了棱角与峰面(见图7(a))。添加0.1% La2O3就可以极大地改善原来样品的表面形貌,在样品上观察不到明显的棱角和峰面,其微粒与基体间具有连续相容的界面形貌,且过渡平缓圆滑(见图7(b))。表明添加0.1% La2O3后,增韧颗粒MgO以超细均匀的形态分散于基体中。图8所示为不同La2O3含量下热压烧结的试样腐蚀后的典型显微组织。由图8可见,烧结组织中晶粒生长形态以及增韧颗粒分散状态随La2O3含量的变化有明显差异。未添加时,增韧颗粒团聚严重并且晶粒粗大(见图8(a));当添加0.1% La2O3时,基体晶粒组织显著细化(见图8(b));随着La2O3含量增加到1%时,烧结成型性能恶化,组织中晶粒明显粗化,甚至出现微裂纹(见图8(e))。

实验结果表明,La2O3添加量存在最佳值(0.1%)。添加La2O3不可过量,若过量反而导致增韧颗粒团聚且晶粒组织粗化,甚至出现气孔和疏松组织。当La2O3微量适宜时(0.1%),少数极化的稀土原子通过空位扩散机制进入晶体内,造成晶格畸变,使材料的强度得到提高。若过量添加La2O3,则使晶格畸变增多,畸变的晶格造成局部能量增加,使其稳定性降低,并造成晶粒粗大与团聚[15, 18]。因此,只有当烧结体系中稀土含量微量适宜时,其活性作用才能充分发挥,对热压烧结成形材料的改善效果才能最大化,并最终提高材料的力学性能。

图7 热压烧结试样1和2增韧颗粒的三维形貌

Fig.7 SPM images of samples 1 and 2 showing 3-dimensional morphology of reinforcing particulates

图8 不同热压烧结试样腐蚀后的SEM像

Fig.8 SEM images of samples 1(a), 2(b), 3(c), 4(d) and 5(e) after HPS and etching

3 结论

1) 优化La2O3添加量(0.1%)可提高WC-MgO复合材料的综合力学性能。经过热压烧结,其烧结致密度度可达98.56%,硬度可达18.02 GPa,断裂韧性可达12.38 MPa·m1/2。

2) 当La2O3添加量为0.1%时,可阻碍WC基体烧结过程中的脱碳反应,细化烧结组织,提高增韧颗粒分散均匀性,改善颗粒/基体界面形貌。

3) 过量添加La2O3(≥0.25%),会因稀土元素的极化效应导致其活跃性下降,热压烧结成型性能降低。

REFERENCES

[1] 高 勇, 唐振方, 黄景清, 郑家概. 纳米WC-Co复合材料制备及其烧结过程[J]. 硬质合金, 2000, 17(1): 18-20.

GAO Yong, TANG Zheng-fang, HUANG Jing-qing, ZHENG Jia-gai. The preparation and sintering course of nanosize WC-Co composites[J]. Cemented Carbide, 2000, 17(1): 18-20.

[2] SUN J F, ZHANG F, SHEN J. Characterizations of ball-milled nanocrystalline WC-Co composite powders and subsequently rapid hot pressing sintered cermets[J]. Materials Letter, 2003, 57: 3140-3148.

[3] FANG Z, MAHESHWARI P, WANG X, SOHO H Y, GRIFFO A, RILEY R. An experimental study of the sintering of nano-crystalline WC-Co powders[J]. International Journal of Refractory Metals & Hard Materials, 2005, 23(4/6): 249-257.

[4] 吴彩霞, 朱世根, 马 俊, 张梅琳. 高能球磨制备纳米WC-MgO粉末反应模式及判据[J]. 中国有色金属学报, 2009, 19(3): 411-417.

WU Cai-xia, ZHU Shi-gen, MA Jun, ZHANG Mei-lin. Reaction mode and its criterion in synthesis of nanocomposite WC-MgO powders by high-energy ball milling[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 411-417.

[5] EL-ESKANDARANY M S. Fabrication of nanocrystalline WC and nanocomposite WC-MgO refractory materials at room temperature[J]. Journal of Alloys and Compounds, 2000, 296: 175-182.

[6] EL-ESKANDARANY M S. Synthesizing of nanocomposite WC-MgO powders by mechanical solid-state reduction and subsequent plasma-activated sintering[J]. Metallurgical and Materials Transactions A, 2001, 32: 157-164.

[7] SHETTY D K, WRIGHT I G, MINCER P N, CLAUER A H. Indentation fracture of WC-Co cermets[J]. Journal of Materials Science, 1985, 20: 1873-1882.

[8] KEAR B H, SKANDAN G, SADANGI R K. Factors controlling decarburization in HVOF sprayed nano-WC-Co hard coatings[J]. Scripta Materialia, 2001, 44: 1703-1707.

[9] 赵高敏, 王昆林, 刘家浚. La2O3对激光熔覆铁基合金层硬度及其分布的影响[J]. 金属学报, 2004, 40(10): 1115-1120.

ZHAO Gao-min, WANG Kun-lin, LIU Jia-jun. Effect of La2O3 on hardness distributions of laser clad ferrite-based alloy coatings[J]. Acta Metallurgica Sinica, 2004, 40(10): 1115-1120.

[10] 吉泽升. 稀土对硼铝共渗渗层相组成的影响[J]. 中国稀土学报, 2000, 18(1): 27-30.

JI Ze-sheng. Effect of Re-B-Al on composition of permeation layer[J]. Journal of Chinese Rare Earths Society, 2000, 18(1): 27-30.

[11] 冀晓鹃, 宫声凯, 徐惠彬, 刘福顺. 添加稀土元素对热障涂层YSZ陶瓷层晶格畸变的影响[J]. 航空学报, 2007, 28(1): 196-200.

JI Xiao-juan, GONG Sheng-kai, XU Hui-bin, LIU Fu-shun. Influence of rare earth elements additions in YSZ ceramic coatings of thermal barrier coatings on lattice distortion[J]. Acta Aeronautica Et Astronautica Sinica, 2007, 28(1): 196-200.

[12] GU D D, SHEN Y F, ZHAO L, XIAO J, WU P. Effect of rare earth oxide addition on microstructures of ultra-fine WC-Co particulate reinforced Cu matrix composites prepared by direct laser sintering[J]. Materials Science and Engineering A, 2007, 445/446: 316-322.

[13] JANG B K, ENOK M, KISHI T, OH H K. Effect of second phase on mechanical properties and toughening of Al2O3 based ceramic composites[J]. Composite Engineering, 1995, 5: 1275-1286.

[14] MURRAY J L. Phase diagrams of binary alloys[M]. Metals Park, 1987: 345.

[15] YANG Q H, ZENG Z J, XU J, DING J. Effect of La2O3 on microstructure and transmittance of transparent alumina ceramics[J]. Journal of Rare Earths, 2006, 24: 72-75.

[16] 种法力, 陈 勇, 吴玉程, 陈俊凌. La2O3弥散增强钨合金面对等离子体材料及其高热负荷性能[J]. 材料科学与工程学报, 2009, 27(3): 415-417.

CHONG Fa-li, CHEN Yong, WU Yu-cheng, CHEN Jun-ling. Tungsten alloys strengthened with dispersed La2O3 and its heat flux performance[J]. Journal of Materials Science & Engineering, 2009, 27(3): 415-417.

[17] JANG J S C, FWUA J C, CHANGA L J, CHENA G J, HSUB C T. Study on the solid-phase sintering of the nano-structured heavy tungsten alloy powder[J]. Journal of Alloys and Compounds, 2007, 434/435: 367-370.

[18] ZHANG X H, LIU C X, LI M S, ZHANG J H. Research on toughening mechanisms of alumina matrix ceramic composite materials improved by rare earth additive[J]. Journal of Rare Earths, 2008, 26: 367-370.

(编辑 李艳红)

基金项目:上海市重点学科建设资助项目(B062)

收稿日期:2009-10-21;修订日期:2010-04-02

通信作者:朱世根,教授,博士;电话:021-67792813;E-mail:sgzhu@dhu.edu.cn