Trans. Nonferrous Met. Soc. China 22(2012) 1563-1567

Infiltration of A6063 aluminium alloy into SiC-B4C hybrid preforms using vacuum assisted block mould investment casting technique

Alptekin KISASOZ, Kerem Altug GULER, Ahmet KARAASLAN

Department of Metallurgy and Materials Engineering, Yildiz Technical University,

Davutpasa Campus, TR 34210, Esenler, Istanbul, Turkey

Received 9 October 2011; accepted 5 April 2012

Abstract: Production of A6063/SiC-B4C hybrid composite using vacuum assisted block mould investment casting was investigated. Firstly, SiC-B4C hybrid preforms were fabricated in cylindrical shape. The preferred mean particle size of the SiC and B4C powders were 60 μm and 55 μm respectively. In early experiments, single powder ratio of 85% SiC and 15% B4C was selected to produce the tough preforms. Subsequently, the preforms were placed into the cylindrical shape gypsum bonded block investment moulds and A6063 alloy was infiltrated into the preforms using vacuum assisted (-105 Pa) casting machine. Porosity fraction of preforms was determined using Archimedes’ test. The fabricated cast specimens were characterized using hardness tests, image analysis and SEM observations and EDX analysis. The result indicates that, by the vacuum assisted block mould investment casting technique, the infiltration of the preforms by molten metal was successfully realized.

Key words: AlMMC; SiC; B4C; investment casting; hybrid preform

1 Introduction

Metal matrix composites are used in special application areas because of their high specific modulus, strength and wear resistance compared to the conventional alloys. Many studies have examined the effect of reinforced materials on the mechanical properties of metal matrix composites. SiC, Al2O3, TiC and B4C are used as ceramic reinforcement particles that limit the amount of plastic deformation in the matrix and enhance the mechanical properties of the matrix [1-5].

Aluminium metal matrix composites are considered a group of new advanced materials for their low density, high strength, high specific modulus, low coefficient of thermal expansion and good wear resistance properties. The uses of Al matrix composites are limited in very specific applications such as aerospace and military weapon due to high processing cost. Recently, Al matrix composites have been used for the automobile products such as engine piston, cylinder liner and brake disc/drum. Processing techniques for aluminium matrix composites can be classified into liquid state processing, semisolid processing and powder metallurgy. The primary function of the reinforcement in metal matrix composite is to carry most of the applied load, where the matrix binds the reinforcements together, and transmits and distributes the external loads to the individual reinforcement. Good wetting is an essential condition for the generation of a satisfactory bonding between particulate reinforcements and liquid Al matrix during casting composites, to allow transfer and distribution of load from the matrix to the reinforcements without failure [5-10].

The most suitable technique for the production of particle-reinforced aluminium alloy is squeeze casting technique that is commonly used to infiltrate the molten metal into the preforms, which have ceramic particles with a defined geometry and sustain the mechanical loads imposed during processing. The squeeze casting technique can reduce the casting defects, the air entrapment and the metal-starve cavities and therefore improves the wettability between the molten metals and the reinforcements [11,12].

Thus, squeeze infiltration is an effective process for achieving good casting integrity. It is, however, limited in the complexity of castings that can be produced. Investment casting is well known for its ability to produce castings with complex shapes. Thin sections are easily produced by this casting route due to the lower thermal conductivity of the ceramic investment mould as compared to the steel dies used in squeeze casting. In order to overcome the squeeze infiltration limitations and to enhance casting complexity, the hybrid process, based on investment casting, was adopted for the production of metal matrix composites via the liquid metal infiltration route. The process permitted preform infiltration by an aluminium alloy melt without the need to alter the chemical compositions of the constituents as required by the pressureless infiltration processes [13].

In this study, the production of Al/SiC-B4C hybrid composite by vacuum assisted investment flask casting is investigated. The A6063 aluminium alloy is used as matrix material. Moreover, SiC and B4C particulates are used for preform production.

2 Experimental

2.1 Preform making

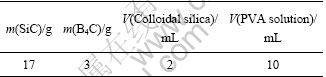

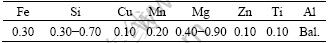

SiC and B4C powders, polyvinyl alcohol (PVA) and colloidal silica were provided as raw materials to produce preforms. Water-based PVA solution was prepared with 20% PVA (mass fraction). The composition of the fabricated preform is shown in Table 1.

Table 1 Composition of fabricated preform

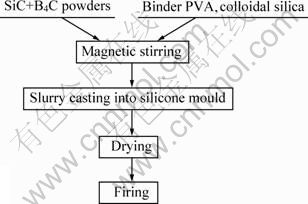

SiC and B4C powders, PVA solution and colloidal silica were mixed to obtain homogeneous slurry and cast into silicone moulds. Hardened preforms were taken out after holding for 24 h. Then, the preforms were dried at 110 ℃ for 1 h and heated gradually up to 750 ℃ and held for 2 h. The flow chart of preform making is given in Fig. 1.

After the sintering process, the SiC-B4C hybrid preforms with 8 mm in height and 17 mm in diameter were obtained as shown in Fig. 2.

Fig. 1 Flow chart of preform making

Fig. 2 Photograph of SiC and B4C hybrid preforms

2.2 Mould making

Pattern wax that was melted at 90 ℃ was cast into plastic mould and the pattern with 21 mm in diameter and 50 mm in height was obtained. This pattern was placed into stainless steel flask with 70 mm in diameter. A castable slurry was obtained by mixing plaster/silica investment with the water to powder ratio of 0.40, then the slurry was filled into the flask under vibration. Also, the slurry was set in 15 min and the mould was held for 2 h in undisturbed conditions.

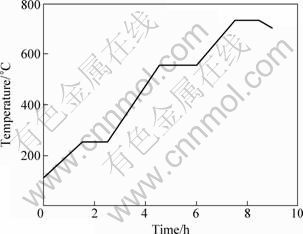

The mould was heated to 110 ℃ for dewaxing to obtain mould cavity. Moreover, the preform was settled into the mould cavity and the mould was fired by heating regime as shown in Fig. 3.

Fig. 3 Firing regime of investment mould

2.3 Casting

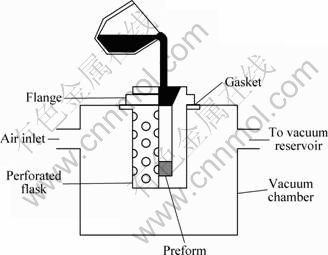

The flash mould was taken out from the furnace at 700 ℃ and was placed into the vacuum casting machine. -105 Pa pressure was applied during the casting process.

A6063 alloy was melted at 830 ℃ in an electric resistance furnace, and then was cast into the mould that was placed into a vacuum assisted casting machine as shown in Fig. 4. The chemical composition of A6063 alloy is given in Table 2.

Table 2 Chemical composition of A6063 alloy (mass fraction, %)

Fig. 4 Schematic illustration of casting process

After solidification, the mould was knocked-out in the water for decomposition and the cast part was taken out.

3 Results and discussion

In the experimental studies, SiC-B4C hybrid composite specimens, with A6063 alloy as a matrix material, were manufactured using the vacuum assisted block investment casting technique. Porosity fraction of the preforms was investigated using Archimedes’ test. Open porosity of the preforms was determined according to the standard ASTM C20-80a. Also, image analysis, SEM observation, EDX analysis and Brinell hardness tests were carried out to characterize the cast composite specimens.

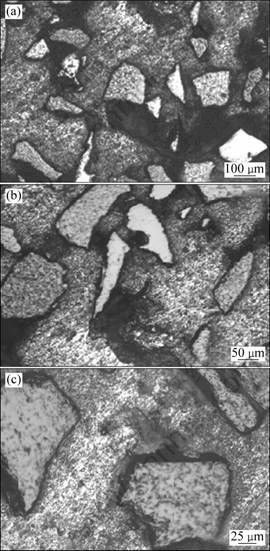

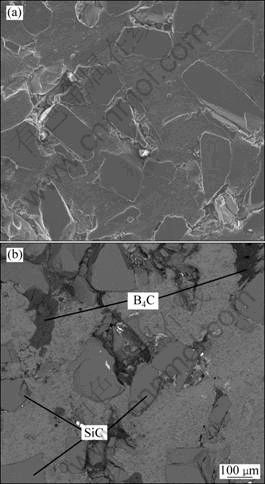

According to Archimedes’ test, the porosity fraction of the preforms was determined as (46%±4%). Figure 5 shows the micrographs of SiC and B4C particulates and matrix structure with different magnifications. Homogenous distribution of SiC and B4C particulates into A6063 matrix is shown in Fig. 5(a). Almost, molten metal was infiltrated into pores under the applied vacuum during the casting process. Plaster bonded investment was designed with high permeability especially for vacuum jewellery castings with fine details and thin sections. As a result of the infiltrated pores with molten metal, A6063 matrix is seen as a network structure among the reinforcement particulates. Figures 5(b) and (c) show the micrographs of composite specimen with higher magnifications. Homogenous distribution of reinforcement particulates into A6063 matrix is seen in Figs. 5(b) and (c). Microstructure observations were supported by SEM (JEOL JSM 5410LV) micrographs also. The secondary electron micrograph and back scattered electron micrographs are given in Figs. 6(a) and (b), respectively. In Fig. 6(b), B4C particulates are seen as dark phases and SiC particulates are seen as grey phases in the A6063 matrix structure. These results were supported by EDX analysis.

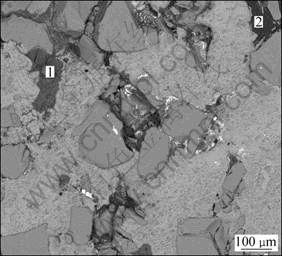

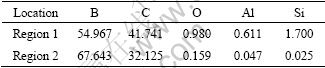

The EDX analysis regions in the microstructure are given in Fig. 7, and the EDX results are given in Table 3. Regions 1 and 2 all consist of B, C, O, Al and Si. According to EDX analysis results, the dark phases are B4C particulates as shown in Fig. 6(b).

The reinforcement particulate fractions of the specimens were computed from micrographs using Leica ICM 1000 image analyzer. The fraction of reinforcement particulates in A6063 matrix was determined as (37%±5%). Particulate content is dependent on various process factors, such as porous preform, preheating of the preform, permeable flash investment mould and applied vacuum during casting.

Fig. 5 Micrographs of SiC and B4C particulates and matrix structure with different magnifications

Fig. 6 SEM micrographs of composite specimen: (a) Secondary electron micrograph; (b) Back scattered micrograph

Fig. 7 Analysis regions in microstructure

Table 3 Results of EDX analysis in Fig. 7 (mass fraction, %)

According to excessive organic content of preform

slurry, preforms have high porosity fraction. Infiltration volume of the molten metal increased with preheating of mould due to the nature of casting procedure. Moreover, vacuum assisted casting is the most effective factor for infiltration of molten metal into preform. Interaction of SiC and B4C particulates and molten metal was increased with applied vacuum.

Effects of the SiC and B4C particulates on the mechanical properties of the specimens were investigated with hardness tests. Brinell hardness tests were carried out using 62.5 kg test load and 2.5 mm diameter indentation tip. Thus, A6063 aluminium alloy hardness value was determined as HB 38.53±3. Also, the average hardness of A6063/(SiC+B4C) composite specimen was determined as HB 166.58±10.

4 Conclusions

SiC+B4C preforms were produced and A6063 matrix composites were fabricated with the investment casting. The properties of the specimens were characterized using hardness tests, SEM, EDX and microstructure analysis. Vacuum assisted investment casting method has a great potential for improving infiltration and wetting ability of reinforcement with molten metal. Especially, fully infiltrated SiC+B4C preforms were obtained using vacuum assisted investment casting. The reinforcement fraction up to (37%±5%) was obtained. In addition, block mould investment casting has been widely used in jewellery and dental prosthesis productions for a long time, so this method is suitable for industrial fabrication of metal matrix composites.

Acknowledgement

The authors wish to acknowledge Yildiz Technical University and Balkan Center for Advanced Casting Technologies (BCACT) for their financial support and providing research facilities.

References

[1] IPEK R. Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC) [J]. Journal of Materials Processing Technology, 2005, 162-163: 71-75.

[2] TERRY B, JONES G. Metal matrix composites: Current developments and future trends in industrial research and applications [M]. Amsterdam: Elsevier Publishers, 1990.

[3] ROHATGI R. Solidification of metal matrix composites [M]. Indianapolis, 1989.

[4] LINDROOS V K, TALVITIE M J. Recent advances in metal matrix composites [J]. Journal of Materials Processing Technology, 2000, 53: 273-284.

[5] SHOROWORDI K M, LAOUI T, HASEEB A S, CELIS J P, FROYEN L. Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study [J]. Journal of Materials Processing Technology, 2003, 142: 738-743.

[6] SURAPPA M K, ROHATGI R K. Preparation and properties of cast aluminium–ceramic particle composites [J]. Journal of Materials Science, 1981, 16: 983-993.

[7] KOZACK M J, KHATRI S C, ALISON J E, BABER M G. Fundamentals of metal matrix composites [M]. Boston: Butterworth-Heinemann, 1993.

[8] SRIVATSAN T S, IBRAHIM I A, MOHAMED F A, LAVERNIA E J. Processing techniques for particulate-reinforced aluminium metal matrix composites [J]. Journal of Materials Science, 1991, 26: 5965-5978.

[9] RAJAN T P D, PILLAI R M, PAI B C. Review: Reinforcement coatings and interfaces in aluminium metal matrix composites [J]. Journal of Materials Science, 1998, 33: 3491-3503.

[10] DELANNAY F, FROYEN L, DERUYTTERE M. Review: The wetting of solids by molten metals and its relation to the preparation of metal–matrix composites [J]. Journal of Materials Science, 1987, 22: 1-16.

[11] THUNEMANN M, BEFFORT O, KLEINER S, VOGT U. Aluminum matrix composites based on preceramic-polymer-bonded SiC performs [J]. Composites Science and Technology, 2007, 67: 2377-2383.

[12] ZHANG H, LOUKUS J, LOUKUS A. Improvement of the bonding interface in hybrid fiber/particle preform reinforced Al matrix composite [J]. Materials Letters, 2009, 63: 310-312.

[13] INGO G M, RICCUCCI C, CHIOZZINI G. Origin of gas porosity in gold-based alloys cast in calcium sulfate-bonded investment and influence of metal oxide acid–base properties on calcium sulfate thermal stability [J]. Journal of American Ceramic Society, 2004, 84: 1839-1843.

真空辅助熔模铸造制备A6063/SiC-B4C混杂复合材料

Alptekin KISASOZ, Kerem Altug GULER, Ahmet KARAASLAN

Department of Metallurgy and Materials Engineering, Yildiz Technical University,

Davutpasa Campus, TR 34210, Esenler, Istanbul, Turkey

摘 要:采用真空辅助熔模铸造技术制备A6063/SiC-B4C混杂复合材料。首先,采用平均粒径分别为60 μm和55 μm、质量比为85%和15%的SiC和B4C粉末制备圆柱形的SiC-B4C预制块。然后,将预制块放入圆柱形石膏粘结块熔模中,在真空辅助铸造机中将A6063铝熔体浸渗到预制块中。采用阿基米德方法测定预制块中的孔隙度。对制备的复合材料进行硬度测试、图像分析、SEM观察和EDX成分分析。结果表明,采用真空辅助熔模铸造技术,铝熔体能将够成功地浸渗到预制块中。

关键词:铝基复合材料;SiC;B4C;熔模铸造;混杂预制块

(Edited by YUAN Sai-qian)

Corresponding author: Alptekin KISASOZ; Tel: +90-212-3834710; Fax: +90-212-3834665; E-mail: akisasoz@gmail.com

DOI: 10.1016/S1003-6326(11)61356-3