TiC掺杂对热压合成Ti2AlC材料的影响

王 苹1, 2, 梅炳初1, 洪小林1, 朱教群1, 周卫兵1

(1. 武汉理工大学 材料复合新技术国家重点实验室, 武汉 430070;

2. 武汉理工大学 理学院, 武汉 430070)

摘 要: 采用热压工艺合成了Ti2AlC块体材料。 在不同温度时, 通过X射线衍射分析了掺入不同含量TiC混合粉经热压合成试样的物相组成, 并采用SEM观察所合成试样的显微结构。 结果发现: 完全以元素粉为原料不掺TiC的混合粉经1500℃热压60min合成Ti2AlC块体材料, 且产物中含有TiC和Ti3AlC2杂相; 掺入0.5mol或1.0molTiC混合粉经1400℃热压60min后合成不含TiC且只含少量Ti3AlC2的Ti2AlC块体材料。 同时, 探讨了TiC对合成Ti2AlC块体材料的影响机理。

关键词: 热压; 碳化铝钛; 碳化钛 中图分类号: TQ174

文献标识码: A

Effect of TiC addition on synthesis of Ti2AlC by hot pressing

WANG Ping1, 2, MEI Bing-chu1, HONG Xiao-lin1, ZHU Jiao-qun1, ZHOU Wei-bing1

(1. State Key Laboratory of Advanced Technology for Materials Synthesis and Processing,Wuhan University of Technology, Wuhan 430070, China;

2. School of Science, Wuhan University of Technology, Wuhan 430070, China)

Abstract: Ti2AlC bulk materials were synthesized by hot pressing mixture powders with different contents of TiC addition. X-ray diffractrometry was used to detect the phase composition and scanning electron microscopy (SEM) was used to investigate the microstructures of samples synthesized at different temperatures. The results show that Ti2AlC bulk materials can be synthesized by hot pressing elemental mixture powders without TiC addition at 1500℃ for 60min, in which TiC and Ti3AlC2 exist as secondary phases. By adding 0.5mol or 1.0mol TiC into the raw mixtures, Ti2AlC can be fabricated by hot pressing at 1400℃ for 60min, and there exist only a small amount of Ti3AlC2 as secondary phase. At the some time, the effect mechanism of TiC on synthesis of Ti2AlC bulk materials were investigated.

Key words: hot pressing; titanium aluminum carbide; titanium carbide

早在20世纪70年代, Jeitschko和Nowotny报道了Ti2AlC化合物的存在[1]。 直到最近, 人们对Ti2AlC的研究才逐渐增多。 由于人们发现Ti2AlC具有非同寻常的综合性能, 如高断裂韧性[2]和高温塑性[3]。 Ti2AlC的显微结构由层状颗粒组成, 因此它也被称为纳米层状陶瓷[4]。 而与一般脆性陶瓷不同的是, Ti2AlC并不脆, 它像金属一样易于机械加工[5]。 这种性能的优势使Ti2AlC很有可能在许多要求非常复杂形状结构的领域中广泛应用。

但由单相Ti2AlC块体材料的制备非常困难。 Barsoum等[5, 6]以Ti、 Al4C3和石墨为原料, 采用热等静压工艺于1300℃保温30h后获得了比较纯的Ti2AlC材料和热压工艺在1600℃保温4h获得了Ti2AlC多晶块体材料。 由于原料Al4C3具有强烈的吸湿性, 因此, 这两种工艺合成的Ti2AlC材料都含有约4%(体积分数)Al2O3。 同时, 由于Al4C3的反应活性低, 因此以它为原料就要求合成温度很高或者合成时间很长。 近年来, 周延春等[2]以Ti粉、 Al粉和石墨粉等元素粉为原料, 采用一种液固反应合成法制备致密的Ti2AlC材料。 这种方法具有合成时间短和合成温度低的优点。 另外, 有研究表明, TiC是合成Ti2AlC的中间相[7-9], 以TiC取代部分元素粉为原料可以加速反应的进行, 有助于采用自蔓延高温合成工艺合成Ti2AlC粉体[7]。 因此, 本文作者在原料中添加TiC采用热压工艺合成Ti2AlC块体材料, 研究了添加前后的性能差异(使用的碳质原料为活性炭)。

1 实验

实验所采用的原料为TiC粉、 Ti粉、 Al粉和活性炭, 其质量分数分别为99.8%、 99.0%、 99.8%和99.0%, 平均粒径分别为4.5、 10.6、 12.8和13.2μm。 所有原料都从中国有色金属研究院购得。 按2.0Ti/1.0Al/1.0C、 0.5TiC/1.5Ti/1.0Al/0.5C和1.0TiC/1.0Ti/1.0Al(摩尔比)配比称取质量后在塑料混料瓶中混合24h。 再将混合粉放入直径为20mm的石墨模具中, 然后在热压烧结炉中按设定的工艺过程进行材料合成: 以5℃/min升温到300℃之后直接以60℃/min升温到热压温度, 在设定温度下保温60min。 其中2.0Ti/1.0Al/1.0C 混合粉的热压温度分别为1400、 1500和1600℃。 0.5TiC/1.5Ti/1.0Al/0.5C和1.0TiC/1.0Ti/1.0Al混合粉的热压温度都分别为1300、 1400和1500℃, 热压压力均为30MPa, 最后自然冷却至室温。 升降温过程中均采用流动氩气保护。 所得圆片试样的厚度为4~6mm。

所合成试样首先除去表面反应层, 然后用转靶X射线衍射仪(D/MAX-RB, RIGAKU Corporation, Japan)分析其物相组成, 用扫描电镜(JSM-5610LV, JEOL Ltd., Japan)观察试样的显微结构。

2 结果与讨论

2.1 添加不同量TiC合成Ti2AlC

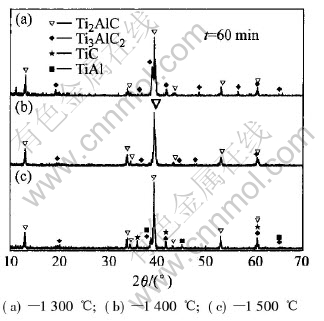

图1~3所示分别为2.0Ti/1.0Al/1.0C、

图1 2.0Ti/1.0Al/1.0C混合粉经不同温度热压后试样的X射线衍射谱

Fig.2 XRD patterns of samples synthesized by hot pressing 2.0Ti/1.0Al/1.0C mixture powders at different temperatures

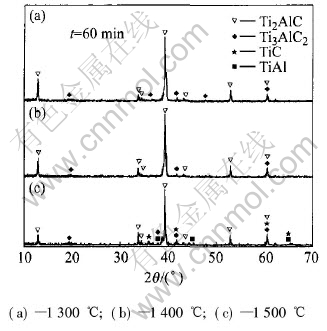

图2 0.5TiC/1.5Ti/1.0Al/0.5C混合粉经不同温度热压后试样的X射线衍射谱

Fig.1 XRD patterns of samples synthesized by hot pressing 0.5TiC/1.5Ti/1.0Al/0.5C mixture powders at different temperatures

0.5TiC/1.5Ti/1.0Al/0.5C和1.0TiC/1.0Ti/1.0Al3种混合粉在不同温度热压60min后所制备试样的X射线衍射谱。

从图1可以看出, 以元素粉为原料不掺TiC的混合物于1400℃下热压后的主晶相为Ti2AlC, 同时含有比较多的金属间化合物TiAl、 Ti3Al、 Ti3AlC2和TiC。 当热压温度升高到1500℃后, TiAl金属间化合物的特征峰消失, Ti2AlC的峰强

图3 1.0TiC/1.0Ti/1.0Al混合粉末经不同温度热压后试样的X射线衍射谱

Fig.3 XRD patterns of samples synthesized by hot pressing 1.0TiC/1.0Ti/1.0Al mixture powders at different temperatures

增加, 表明Ti2AlC的含量增大。 此时, 试样中仍然含有少量TiC和Ti3AlC2。 继续升高热压温度至1600℃后, 试样的主晶相转变为Ti3AlC2, 同时还出现了非常多的TiC和其它未知相的特征峰。 完全以元素粉为原料不掺TiC合成Ti2AlC的较佳温度为1500℃, 此时所合成试样中还含有杂相TiC和Ti3AlC2。

从图2可以看出, 原料中掺入0.5molTiC后于1300℃下热压60min所合成的试样以Ti2AlC为主晶相, 另外还含有大量TiC、 TiAl金属间化合物和Ti3AlC2。 当温度升高到1400℃后, 只观察到Ti2AlC和极少量Ti3AlC2的特征峰, 其余相的特征峰消失; 于1500℃热压60min后, 所合成试样的X射线衍射谱与1400℃的基本相同, 只是Ti3AlC2的含量明显增大。 图2所示为掺0.5molTiC后能够在1400℃合成仅含有少量第二相Ti3AlC2的Ti2AlC材料。 由图2和3可看出, 两者的变化规律完全相同。

从图1~3中可得如下规律: 在热压时间相同(60min)的情况下, 完全以元素粉为原料不掺TiC只能在1500℃获得含有TiC和Ti3AlC2的Ti2AlC材料, 掺入0.5molTiC后在1400℃就能获得不含TiC, 只含有少量第二相Ti3AlC2的Ti2AlC材料。 继续掺入1.0molTiC后并不能获得更好的效果。 也就是说, 原料中不掺TiC时产物中含有TiC, 且Ti2AlC的合成温度更高; 掺入一定量TiC后可以在更低的温度以更快的速度合成不含TiC的Ti2AlC。 掺一定量TiC既增大了反应速度也提高了产物纯度, 对这种现象可以从动力学角度进行解释。 TiC是生成Ti2AlC的关键中间物质[2, 7-9], 它直接参与了生成Ti2AlC的反应。

当原料中未加TiC时, Ti和C之间需要通过反应先合成TiC后再反应才能合成Ti2AlC, 而TiC的生成量相对于要反应生成Ti2AlC所需的TiC量滞后。 当加入TiC时, 反应体系中有较多的TiC, 只要达到反应温度就可以直接合成Ti2AlC。 随着TiC掺入量的增多, 反应生成Ti2AlC的速度越快, 单位时间内生成Ti2AlC的量就越多。 但是, 当TiC的掺入量达到某一个值使得坯体中预掺的TiC和原位生成的TiC能够满足生成Ti2AlC所需TiC的消耗速度时, 继续增加TiC, 掺量显得多余, 不大可能明显进一步提高Ti2AlC的生成速度, 且这个值在0.5mol附近(低于0.5mol)。

其次, Ti与C之间属于强放热反应[10-11], 反应放热使坯体温度超过热压温度。 而Ti-Al-C三元系统中Al的蒸汽压非常高[12], 在高温下很容易挥发损失。 未加TiC时, 原料中的Ti粉与C粉反应生成TiC的同时放出大量的热使坯体温度升高, Al的损失非常严重。 随着TiC掺入量的增加, 可以反应的Ti粉和C粉减少, 反应放热减少, 坯体温度降低, Al的挥发损失也就减小了。 Al的缺失必然使产物中缺Al化合物增多。 这就是掺TiC后产物中TiC杂相反而消失、 Ti2AlC的纯度得到提高(见图1(b)、 图2(c)和图3(c))的原因。

由图1~3可看出, 随着温度的升高, Ti-Al金属间化合物出现了从无到有再到无的变化过程, 这表明Ti-Al金属间化合物是合成Ti2AlC的另一种中间产物。 当然, 这种Ti-Al金属间化合物的组成并不是固定不变的。 以元素粉为原料不掺TiC时的金属间化合物除TiAl外还包括含Al量更低的Ti3Al(见图1), 而掺入TiC后, 金属间化合物为TiAl(见图2和3)。 这也从另外一个方面证实了以元素粉为原料时Al的缺失更严重。

2.2 Ti2AlC的显微结构

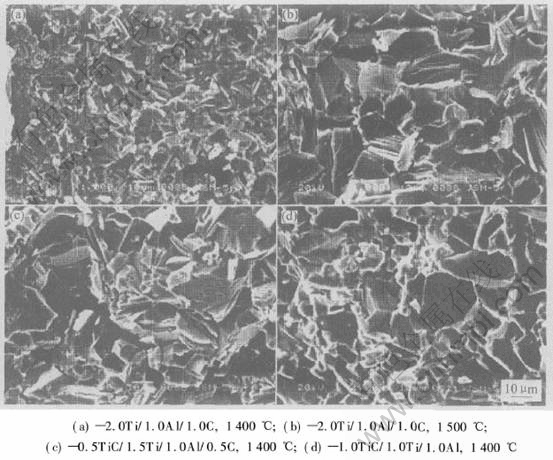

图4所示为添加不同TiC合成试样的SEM像。 由图4可见, 所有合成产物基本上都由层状颗粒组成, 结合X射线衍射谱可知, 这些层状颗粒基本上都为Ti2AlC[13]。 未添加TiC时于1400℃热压60min合成试样中的Ti2AlC平均颗粒尺寸约为10μm(见图4(a))。 经1500℃热压后, 层状结构更明

图4 不同试样的SEM像

Fig.4 SEM images of samples

显, 而且颗粒长大, 尺寸为15~20μm(见图4(b))。 添加0.5mol和1.0molTiC后于1400℃所合成试样的颗粒尺寸基本相同, 都约为15μm(见图4(c)和(d)), 都比不添加TiC在同一温度下热压相同时间合成试样的颗粒尺寸更大。 由此说明, TiC是合成Ti2AlC的中间产物, 添加TiC有助于提高Ti2AlC的合成速度, 添加0.5molTiC能使其合成速度达到最大。

3 结论

1) TiC和Ti-Al金属间化合物是合成Ti2AlC的中间产物。 在元素粉原料中添加TiC能够加速反应的进行, 使反应在更低的温度下以相同的时间完成。 掺TiC还能减少所合成Ti2AlC试样中的杂相, 提高Ti2AlC的含量。

2) 以元素粉为原料不掺TiC时, Ti2AlC的合成温度为1500℃, 且产物中含有TiC和Ti3AlC2两种杂质相, 掺入0.5molTiC后合成Ti2AlC的温度为1400℃, 且产物中基本不含TiC, 只含有Ti3AlC2一种杂质相; 继续增加TiC的掺量并不能取得更好的合成效果。

REFERENCES

[1]Jeitschko W, Nowotny H, Benesovsky F. Carbon containing ternary compounds (H-phase)[J]. Monatsh Chem, 1963, 94: 672-676.

[2]Wang X H, Zhou Y C. Solid-liquid reaction synthesis and simultaneous densification of polycrystalline Ti2AlC[J]. Z Metallkd, 2002, 93(1): 66-71.

[3]Zhou Y C, Wang X H. Deformation of polycrystalline Ti2AlC under compression[J]. Materials Research Innovation, 2001, 5: 87-93.

[4]Barsoum M W. The Mn+1AXn phases: a new class of solids; thermodynamically stable nanolaminates[J]. Progress in Solid State Chemistry, 2000, 28: 201-281.

[5]Barsoum M W, Ali M, El-Raghy T. Processing and characterization of Ti2AlC, Ti2AlN, and Ti2AlC0.5-N0.5[J]. Metallurgical and Materials Transactions A, 2000, 31A(7): 1857-1865.

[6]Barsoum M W, Brodkin D T, El-Raghy T. Layered machinable ceramics for high temperature applications[J]. Scripta Mater, 1997, 36(5): 535-541.

[7]郭俊明, 陈克新, 葛振斌, 等. 添加TiC对燃烧合成Ti2AlC粉体的影响[J]. 金属学报, 2003, 39(3): 315-319.

GUO Jun-ming, CHEN Ke-xin, GE Zhen-bin, et al. Effects of TiC addition on combustion synthesis of Ti2AlC powders[J]. Acta Metallurgica Sinica, 2003, 39(3): 315-319.

[8]郭俊明, 陈克新, 葛振斌, 等. 燃烧合成三元碳化合物Ti2AlC1-x[J]. 稀有金属材料与工程, 2003, 32(12): 1029-1032.

GUO Jun-ming, CHEN Ke-xin, GE Zhen-bin, et al. Combustion synthesis ternary carbide Ti2AlC1-x[J]. Rare Metal Materials and Engineering, 2003, 32(12): 1029-1032.

[9]Tomoshige R, Matsushita T. Production of titanium-aluminum-carbide ternary composites with dispersed fine TiC particles by combustion synthesis and their microstructure observation[J]. Journal of the Ceramic Society of Japan, 1996, 104(1206): 94-100.

[10]孙晓冬, 梅炳初, 袁润章, 等. TiC-Al体系的燃烧反应合成[J]. 武汉工业大学学报, 1997, 19(1): 8-11.

SUN Xiao-dong, MEI Bing-chu, YUAN Run-zhang, et al. Combustion synthesis of TiC-Al system[J]. Journal of Wuhan University of Technology, 1997, 19(1): 8-11.

[11]洪小林, 梅炳初, 朱教群, 等. 放电等离子烧结制备Ti2AlC材料的研究[J]. 硅酸盐学报, 2003, 31(10): 991-993.

HONG Xiao-lin, MEI Bing-chu, ZHU Jiao-qun, et al. Study on the fabrication of Ti2AlC by spark plasma sintering elemental powders[J]. Journal of the Chinese Ceramic Society, 2003, 31(10): 991-993.

[12]苏彦庆, 郭景杰, 贾均, 等. 真空熔炼TiAl金属间化合物过程中合金元素的挥发行为[J]. 铸造, 1999, 3: 1-4.

SU Yan-qing, GUO Jing-jie, JIA Jun, et al. The evaporation of alloying element during vacuum melting of TiAl intermetallics[J]. Cast, 1999, 3: 1-4.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50172037); 教育部重点科技资助项目(02052)

收稿日期: 2005-03-07; 修订日期: 2005-05-31

作者简介: 王 苹(1970-), 女, 副教授, 博士研究生

通讯作者: 梅炳初, 教授; 电话: 027-87651837-8406; E-mail: bcmei@mail.whut.edu.cn