文章编号:1004-0609(2007)03-0434-07

挤出和退火工艺对AZ31镁合金组织和织构的影响

曲家惠1, 2,李四军1,张正贵1,王 福1,左 良1

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 沈阳理工大学 装备工程学院,沈阳 110168)

摘 要:研究了挤压比、挤压温度及电场退火对AZ31镁合金组织和织构的影响。结果表明:挤压比达到16时动态再结晶基本完成,挤压比为25时形成平均晶粒尺寸为7.3 ?m的均匀组织;随着挤压比由小到大,以 面织构为代表的变形织构由增强到减弱;而

面织构为代表的变形织构由增强到减弱;而 、

、 面的再结晶织构由弱到强;提高挤压温度,有利于合金元素扩散和动态再结晶,阻碍低温析出物Mg17Al12和MnAl的不连续析出,组织趋于均匀,织构组分由低温变形的

面的再结晶织构由弱到强;提高挤压温度,有利于合金元素扩散和动态再结晶,阻碍低温析出物Mg17Al12和MnAl的不连续析出,组织趋于均匀,织构组分由低温变形的 面织构向高温变形的

面织构向高温变形的 面织构转变;电场退火推迟了再结晶进程因而抑制再结晶晶粒长大,增加了退火织构的漫散度。

面织构转变;电场退火推迟了再结晶进程因而抑制再结晶晶粒长大,增加了退火织构的漫散度。

关键词:AZ31镁合金;织构;动态再结晶;挤压比;挤压温度;电场退火

中图分类号:TG 146.22 文献标识码:A

Effect of extrusion and annealing technology on microstructure and texture of AZ31 magnesium alloy

QU Jia-hui1, 2, LI Si-jun1, ZHANG Zheng-gui1, WANG Fu1, ZUO Liang1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. School of Equipment Engineering, Shenyang Ligong University, Shenyang 110168, China)

Abstract: The effect of extrusion ratio, temperature and electric field annealing on microstructure and texture of AZ31 magnesium alloy were investigated. The results show that the dynamic recrystallization is completed when the extrusion ratio reaches 16. When the extrusion ratio is 25, the microstructure of fine and even grains with average dimension of 7.3 μm can be obtained. With increasing extrusion ratio, the deformation textures represented by  surface texture decrease, while the recrystallization textures of

surface texture decrease, while the recrystallization textures of  and

and  increase. With increasing extrusion temperature, high temperature extrusion helps to diffuse alloy elements and produces dynamic recrystallization, which stops a discontinuous precipitation of Mg17A112 and MnA1 from being separated out. The microstructure tends to become even. The main texture components have changed from

increase. With increasing extrusion temperature, high temperature extrusion helps to diffuse alloy elements and produces dynamic recrystallization, which stops a discontinuous precipitation of Mg17A112 and MnA1 from being separated out. The microstructure tends to become even. The main texture components have changed from  surface texture to

surface texture to  ore. For AZ31 magnesium alloy, its annealing in electric field delays the process of recrystallization. As a result, it refrains the recrystallized grains from growing and increases the diffusion of annealing texture.

ore. For AZ31 magnesium alloy, its annealing in electric field delays the process of recrystallization. As a result, it refrains the recrystallized grains from growing and increases the diffusion of annealing texture.

Key words:AZ31 magnesium alloy; texture; dynamic recrystallization; extrusion ratio; extrusion temperature; electric field annealing

镁合金管材、棒材和带材主要采用挤压加工方法。镁及镁合金是密排六方(HCP)结构[1-2],其塑性变形在低于498 K时仅限于基面{0001}< >滑移和锥面

>滑移和锥面 <

< >孪生[3-4],造成镁合金在室温下的变形协调能力低[5-7]。有研究表明,镁合金通过塑性变形和热处理工艺相结合,可获得高强度和优良延展性[8-9]。形变镁合金与铸造镁合金相比,具有热成形后组织均匀和晶粒细化的特点。然而,相同晶粒尺寸、不同形变工艺的样品性能测试显示出很大差异[10-11],这说明织构对热成形镁合金的性能影响很大。镁合金热成形后即使发生动态再结晶也会产生较强的织构[12-13]。近年来,有研究发现电场对物理冶金过程金属内部的微观结构具有一定的影响[14-15],尤其是对再结晶的影响更大。因此,研究织构变化规律,特别研究电场下退火对合金的织构和微观组织的影响,对合金的成形性或如何获得高强度的织构有着重要的实际意义。本文作者研究了不同挤压比、挤压温度及电场退火条件对AZ31镁合金组织和织构的影响。

>孪生[3-4],造成镁合金在室温下的变形协调能力低[5-7]。有研究表明,镁合金通过塑性变形和热处理工艺相结合,可获得高强度和优良延展性[8-9]。形变镁合金与铸造镁合金相比,具有热成形后组织均匀和晶粒细化的特点。然而,相同晶粒尺寸、不同形变工艺的样品性能测试显示出很大差异[10-11],这说明织构对热成形镁合金的性能影响很大。镁合金热成形后即使发生动态再结晶也会产生较强的织构[12-13]。近年来,有研究发现电场对物理冶金过程金属内部的微观结构具有一定的影响[14-15],尤其是对再结晶的影响更大。因此,研究织构变化规律,特别研究电场下退火对合金的织构和微观组织的影响,对合金的成形性或如何获得高强度的织构有着重要的实际意义。本文作者研究了不同挤压比、挤压温度及电场退火条件对AZ31镁合金组织和织构的影响。

1 实验

熔铸的AZ31铸棒的直径为d150 mm,其成分(质量分数, %)为:Al 2.56,Zn 0.666,Mn 0.287,余量为 Mg。用台湾源上1650挤压机挤压成d100 mm的圆棒坯料,然后,将d100 mm的坯料挤压出挤压比为2.04~100共9种规格的圆棒。挤压坯料在FCC-550工频感应加热炉(±5 ℃)中预热至200 ℃,然后挤压,挤压筒平均温度为256 ℃。在垂直挤压方向截取样品,挤压比λ的表达式为

为研究挤压温度对组织和织构的影响,本研究特别选择162、258和320 ℃进行挤压,挤压比均为10.4。对挤压比为39.1的样品进行非电场和电场退火,退火温度分别为270、300、350、400和450 ℃,保温时间为1 h,随后出炉空冷。电场退火时通氮气保护。不锈钢电极板接高压电源负极,样品接正极,负极与正极间距5 mm。

金相显微组织观察是在LeicaDM/T-400型光学显微镜、SSX-550扫描电镜和Philips-G20透射电子显微镜上进行。织构测定采用Philip公司的X’Pert PRD型织构测量仪进行织构测定,选用Co Kα靶作为入射光源,管电压为35 kV,管电流为40 mA,按反射法测量 、

、 、

、 、

、 4张不完整极图,测量范围:α在0?~70?间,β在0?~360?间变化,测量步长均为5?,采用LaboTex3.0定量织构分析软件计算晶粒取向分布函数(ODF)。

4张不完整极图,测量范围:α在0?~70?间,β在0?~360?间变化,测量步长均为5?,采用LaboTex3.0定量织构分析软件计算晶粒取向分布函数(ODF)。

2 结果与讨论

2.1 挤压比对挤出组织和织构的影响

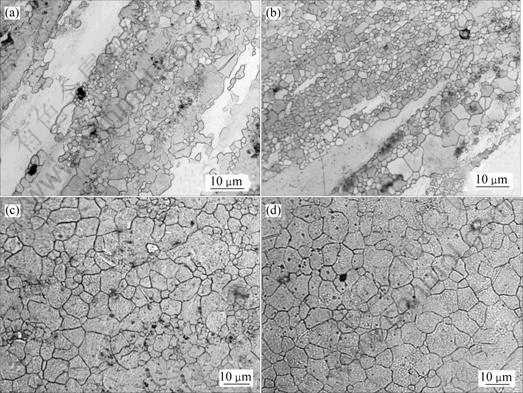

图1所示是在平均挤压温度为256 ℃时,不同挤压比的AZ31镁合金组织。由图1(a)和(b)可知,当形变量较小时,晶粒被拉长,在晶界周围和孪晶界附近有细小的等轴晶粒,它们是在塑性变形时发生动态再结晶的结果,组织不均匀。值得注意的是,低形变量下发生动态再结晶产生的新晶粒极细小,一般新晶粒平均尺寸为2 ?m左右,如图1(b)所示。随着形变量增大,动态再结晶晶粒增多,并长大。当挤压比达到16时,平均晶粒尺寸达到6.8 ?m左右,如图1(c)所示。形变量继续增大,挤压比达到25时,新晶粒长大,组织趋于均匀。平均晶粒尺寸为7.3 ?m,如图1(d) 所示。

图1 不同挤压比热挤压AZ31镁合金的显微组织

Fig.1 Microstructures of AZ31 extruded at different extrusion ratios: (a) λ=2.37; (b) λ=4.94; (c) λ=16; (d) λ=25

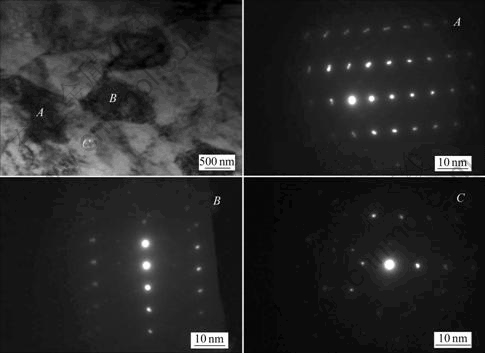

图2所示是d100 mm样品中,3个相邻晶粒的电子衍射花样。晶界取向差用两个相邻晶粒的带轴夹角来表示。得到晶粒A的带轴指数为< >,B晶粒的带轴指数为<

>,B晶粒的带轴指数为< >,晶粒C的带轴指数为<287>。其晶带轴夹角分别为θAC=56?和θBC=51?。从衍射花样来看,再结晶晶粒和原始晶粒的取向差很大,为大角度晶界,这是由于在较高温度下变形,亚晶界微取向扭转形成的。

>,晶粒C的带轴指数为<287>。其晶带轴夹角分别为θAC=56?和θBC=51?。从衍射花样来看,再结晶晶粒和原始晶粒的取向差很大,为大角度晶界,这是由于在较高温度下变形,亚晶界微取向扭转形成的。

图2 d100 mm样品的TEM像及晶粒的电子衍射花样

Fig.2 TEM micrograph(a) and diffraction patterns of grains A(b), B(c) and C(d) for d100 mm extruded sample

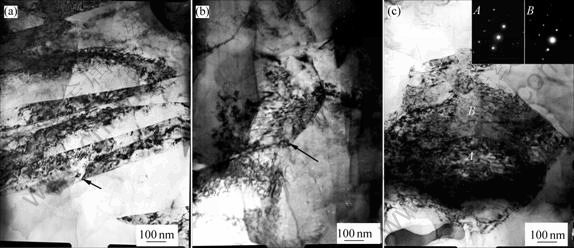

图3所示是挤压比为2.37样品的TEM像及电子衍射花样。随形变量的增大,晶粒内部出现形变带,大量位错在晶界上塞积,位错缠结形成位错胞,在形变带上存在再结晶晶核,如图3(a)所示。图3(b)表明位错在晶界上塞积,晶界周围存在细小的亚晶。在图3(c)中大尺寸晶粒的晶界上有缠结的位错胞,这些细小的位错胞结构通过回复过程转变成亚结构。由图3(c)相邻晶粒的电子衍射花样,计算出相邻亚晶带轴均为< >,这些亚结构的取向基本一致,取向差较小,为小角度晶界。

>,这些亚结构的取向基本一致,取向差较小,为小角度晶界。

图3 挤压比为2.37样品的TEM像

Fig.3 TEM micrographs of extruded sample at λ=2.37: (a) Deformation bands; (b) Low angle grain boundary; (c) Sub-grains and diffraction patterns

挤压比小于16时,位错在大尺寸晶粒的晶界上塞积,晶界周围能观察到细小的亚晶及亚晶核,说明再结晶还未完成。以上实验结果表明,大尺寸晶粒塑性变形机制主要是滑移机制,变形过程中亚晶最先出现在晶界周围。在再结晶初期还能观察到位错在晶界塞积、缠结,特别是在大尺寸晶粒中间容易产生。这是由于滑移系少的六方金属较易产生孪生,特别是在不利于滑移的位向挤压时,变形一开始就以孪生机制进行。在多晶体变形时由于相邻晶粒间的协调作用,当孪生所产生的畸变较大或滑移受到阻碍时,滑移面上的位错在局部地区因受阻而集中,导致变形不均匀及应力分布不均匀。经过高度变形的金属,由于大量的塑性变形造成金属晶体结构的严重畸变,为再结晶的发生提供了有利的条件,加上挤压热的作用,很容易发生动态再结晶。动态再结晶开始于旧晶界处,新的晶粒又在正在长大的再结晶晶粒边界上形核长大[16]。再结晶时从晶格严重畸变的高能位区域产生大量的晶核,从而使晶粒细化[17]。 在本实验中,AZ31镁合金在256 ℃挤压,挤压比为25时能获得平均晶粒尺寸为7.3 ?m的完全动态再结晶组织,为改善AZ31镁合金塑性变形能力提供了有利的组织条件。

2.2 挤压温度对挤出组织的影响

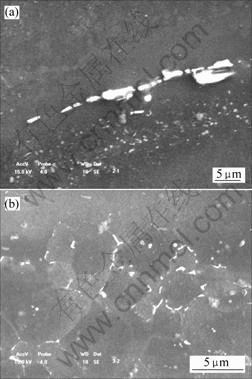

图4所示为挤压比相同时(λ=10.4),挤压温度不同时镁合金的显微组织。由图4 (a)可见,挤压温度低(162 ℃)时,出现长条变形晶粒和细小再结晶晶粒的混晶组织,挤压样品中再结晶程度低,再结晶平均晶粒尺寸为2 μm。258 ℃时,样品中再结晶程度大幅提高,未再结晶的晶粒保持长条状,平均晶粒尺寸为7.46 μm,如图4(b)所示。320℃挤压得到完全再结晶组织,虽然存在一些异常长大的晶粒,但是组织明显比低温挤压的组织均匀,如图4 (c)所示。

图4 挤压温度对AZ31镁合金组织的影响

Fig.4 Effect of extrusion temperature on microstructures of AZ31: (a) 162 ℃; (b) 258 ℃; (c) 320 ℃

图5所示为不同温度挤压镁合金析出相形貌。由图5(a)可见,低温变形产生不连续的条状析出相,由能谱分析得出析出物中Mg、Al、Mn的摩尔比为17?27?15。析出物为(Mg17Al12)和MnAl相。图5(b)所示为258 ℃挤压镁合金显微组织形貌,可见在此温度下变形时,析出相也是不连续的,但与162 ℃低温挤压组织相比,析出物较少。由图可以观察到在晶界上和晶内存在细小的析出相,能谱分析得出析出物中Mg、Al、Zn的摩尔比为78?10?1,根据Mg-Al合金相图分析,析出物应为Mg17Al12。温度较高时变形组织较均匀,晶粒细小,析出物很少几乎没有,表明高温变形有利于合金元素扩散,促进动态再结晶,阻碍析出物的不连续析出。形变量相同时,AZ31镁合金在低温挤压变形时出现被拉长的晶粒和细小再结晶晶粒的混晶组织,容易产生不连续析出的Mg17Al12和MnAl化合物,Mn的含量增加将降低合金的延性;中温挤压变形时,再结晶程度大,Mg17Al12析出相不连续,没有MnAl相析出;在高温下变形时,有利于合金元素扩散,阻碍析出物的不连续析出。

图5 不同挤压温度的析出相分布

Fig.5 Micrographs of precipitation phase at different extrusion temperatures: (a) 162 ℃; (b) 258 ℃

2.3 非电场退火和电场退火对挤出组织的影响

图6(a)和(b)所示为挤压比39.1时样品分别在300 ℃非电场退火1 h与电场退火1 h的显微组织。由图可知,非电场退火样品在大晶粒晶界处出现了大量细小的再结晶晶粒,新晶粒沿着原始晶界形成典型的再结晶链式结构[15];而电场退火样品的晶界没有出现明显的再结晶晶粒,组织形貌与热挤压状态的接近,为等轴晶。显然,电场退火推迟了AZ31镁合金再结晶进程,电场退火样品的再结晶程度明显滞后于非电场退火样品,再结晶晶粒长大受到抑制,与非电场退火样品相比,组织更均匀。电场退火对晶粒产生明显的均匀细化作用,有利于镁合金的塑性变形。

图6 AZ31镁合金非电场退火和电场退火后的显微组织

Fig.6 Microstructures of AZ31 after annealed with or without electric field: (a) 300 ℃, 1 h, without electric field; (b) 300 ℃, 1 h, with electric field

2.4 AZ31镁合金微取向流变行为的演变

AZ31镁合金在挤压温度平均为256 ℃经过不同挤压比的挤压,形成绕挤压方向的面织构,其中 面最强,次强为

面最强,次强为 面、

面、 、

、 等晶面。

等晶面。 和

和 面的取向密度f(g)随挤压比λ的变化如图7所示。

面的取向密度f(g)随挤压比λ的变化如图7所示。 面的取向密度f(g),开始随挤压比λ的增加而增加,λ=4.91时,达到最大,f(g)=4.6;随后,挤压比λ进一步增大时,取向密度f(g)反而降低了。

面的取向密度f(g),开始随挤压比λ的增加而增加,λ=4.91时,达到最大,f(g)=4.6;随后,挤压比λ进一步增大时,取向密度f(g)反而降低了。 面随挤压比一直是增加,但是,当λ大于16时,趋于缓慢;在λ<16时,以

面随挤压比一直是增加,但是,当λ大于16时,趋于缓慢;在λ<16时,以 面的纤维织构为主,即

面的纤维织构为主,即 类型织构,这些面的法线方向平行于挤压方向。对于六方晶系,{hkil}晶面的法线方向指数为2/2c2)l>,所以晶体的<

类型织构,这些面的法线方向平行于挤压方向。对于六方晶系,{hkil}晶面的法线方向指数为2/2c2)l>,所以晶体的< >方向与挤压方向相平行;当λ=16时,两种取向近似相等;而λ>16时,与挤压方向相垂直的

>方向与挤压方向相平行;当λ=16时,两种取向近似相等;而λ>16时,与挤压方向相垂直的 面多于

面多于 面。晶体取向的这种变化表明,挤压开始时,由于挤压比小,形变量不大,主要为形变织构,动态再结晶不明显;随挤压比的增加,

面。晶体取向的这种变化表明,挤压开始时,由于挤压比小,形变量不大,主要为形变织构,动态再结晶不明显;随挤压比的增加, 面织构增强,动态再结晶也加剧,晶粒长大;这一相互矛盾的变化,使

面织构增强,动态再结晶也加剧,晶粒长大;这一相互矛盾的变化,使 面织构为代表的变形织构减弱,而再结晶织构

面织构为代表的变形织构减弱,而再结晶织构 、

、 面织构逐渐增强;在λ>25的样品中织构强度最弱,与之相比形变量更大的样品中由于再结晶过程中,具有形核和长大优势的晶粒的长大使再结晶织构增强,而挤压形变织构减弱。162 ℃挤压样品中主要存在

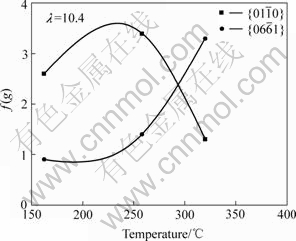

面织构逐渐增强;在λ>25的样品中织构强度最弱,与之相比形变量更大的样品中由于再结晶过程中,具有形核和长大优势的晶粒的长大使再结晶织构增强,而挤压形变织构减弱。162 ℃挤压样品中主要存在 和

和 面织构,其中

面织构,其中 面强度值为2.6;

面强度值为2.6; 面的强度为0.9。320 ℃挤压时与

面的强度为0.9。320 ℃挤压时与 面的f角相差-6?的面强度值最大,强度值为3.3,也形成较强的面纤维织构;而

面的f角相差-6?的面强度值最大,强度值为3.3,也形成较强的面纤维织构;而 面强度仅为1.3。可能是由于在较高温度下变形,有利于更多滑移系开动,同时再结晶更容易进行。挤压比为10.4时,

面强度仅为1.3。可能是由于在较高温度下变形,有利于更多滑移系开动,同时再结晶更容易进行。挤压比为10.4时, 和

和 面的取向密度f(g)随挤压温度的变化如图8所示。

面的取向密度f(g)随挤压温度的变化如图8所示。

图7 主要织构组分的取向密度与挤压比的关系

Fig.7 Relationship between orientation densities of main texture components and extrusion ratio

图8 主要织构组分的取向密度与挤压温度的关系

Fig.8 Relationship between orientation densities of main texture components and extrusion temperature at λ=10.4

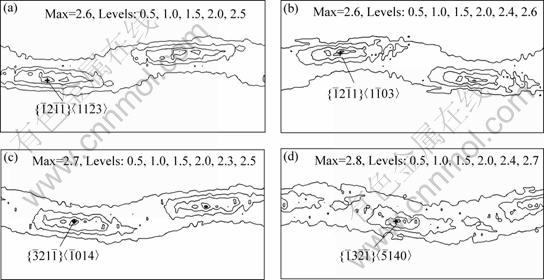

图9(b)所示为300 ℃电场退火样品的ODF截面图,其强点在 <

< >处,强度值为2.6,与非电场退火样品的强点位置(如图9(a)所示)的f角相差34?;取向分布由

>处,强度值为2.6,与非电场退火样品的强点位置(如图9(a)所示)的f角相差34?;取向分布由 向

向 、

、 面漫散。如图9(d)所示,400 ℃电场退火样品中强点在

面漫散。如图9(d)所示,400 ℃电场退火样品中强点在 <

< >,强度值为2.8,与非电场退火样品的强点位置(如图9(c)所示)的f角相差11?。

>,强度值为2.8,与非电场退火样品的强点位置(如图9(c)所示)的f角相差11?。

图9 AZ31镁合金在不同温度下非电场和电场退火样品的ODF截面图

Fig.9 ODF figures of AZ31 Mg alloy after annealing with or without electric field at different temperatures: (f2=0?,f1=0?~360?, f=0?~180?): (a) 300 ℃, 1 h, without electric field; (b) 300 ℃, 1 h, with electric field (E=8 kV/cm); (c) 400 ℃, 1 h, without electric field; (d) 400 ℃, 1 h, with electric field (E=8 kV/cm)

比较非电场和电场退火样品的ODF截面图得知,退火温度对退火织构的影响不明显; 面织构的强度没有明显变化;电场退火对热变形AZ31镁合金再结晶织构的强度和类型没有明显的影响,电场退火增加了退火织构的漫散度。

面织构的强度没有明显变化;电场退火对热变形AZ31镁合金再结晶织构的强度和类型没有明显的影响,电场退火增加了退火织构的漫散度。

3 结论

1) 挤压温度为256 ℃,AZ31镁合金塑性变形时出现孪晶和形变带组织,在孪晶和形变带周围有细小的再结晶晶粒;挤压比达到16时动态再结晶基本完成,挤压比λ=25时,能得到晶粒细小且均匀的组织,平均晶粒尺寸为7.3 ?m,为改善镁合金的塑性变形能力提供有利的组织条件。

2) 形变量相同(挤压比为10.4)时,AZ31镁合金在低温挤压变形时出现长条变形晶粒和细小再结晶晶粒的混晶组织,产生不连续析出的β(Mg17Al12)和MnAl相;在高温挤压变形时,有利于合金元素扩散,阻碍析出物的不连续析出,组织较均匀;温度较低变形的织构组分以 面织构为主,温度较高变形的织构以

面织构为主,温度较高变形的织构以 面织构为主。

面织构为主。

3) 对挤压比为39.1热挤压镁合金进行退火可以细化晶粒,使组织均匀;电场退火推迟热变形AZ31镁合金再结晶进程,抑制再结晶晶粒长大;热挤压AZ31镁合金退火织构主要为{ 2

2

}面和{01

}面和{01 0}柱面织构。电场退火对热挤压AZ31镁合金退火织构的类型和强度没有明显的影响。电场退火增加了热变形AZ31镁合金退火织构的漫散度。

0}柱面织构。电场退火对热挤压AZ31镁合金退火织构的类型和强度没有明显的影响。电场退火增加了热变形AZ31镁合金退火织构的漫散度。

4) AZ31镁合金初始变形时,产生典型的< >方向平行于挤压方向的变形织构。随着形变量增大,动态再结晶程度增大,变形织构

>方向平行于挤压方向的变形织构。随着形变量增大,动态再结晶程度增大,变形织构 面织构和再结晶织构

面织构和再结晶织构 、

、 均不能得到充分发展。最终经过大形变量热变形的镁合金中变形织构

均不能得到充分发展。最终经过大形变量热变形的镁合金中变形织构 和再结晶织构

和再结晶织构 、

、 的强度相近且较弱。有利于改善镁合金力学性能的各向异性。

的强度相近且较弱。有利于改善镁合金力学性能的各向异性。

REFERENCES

[1] Somekawa H, Hosokawa H, Watanabe H. Diffusion bonding in superplastic magnesium alloys [J]. Mater Sci Eng A, 2003, A339: 328-333.

[2] Kitazono K, Sato E, Kuribayashi K. Internal stress superplasticity in polycrystalline AZ31 magnesium alloy[J]. Scripta Mater, 2001, 44: 2695-2702.

[3] Agnew S R, Yoo M H, Tom C N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y [J]. Acta Mater, 2001, 49: 4277-4289.

[4] Barnett M R, Keshavarz Z, Beer A G, et a1. Influence of grain size on the compressive deformation of wrought Mg-3A1-1Zn[J]. Acta Mater, 2004, 52: 5093-5103.

[5] Koike J, Kobayashi T, Mukai T. The activity of non-basal slip systems and dynamic recovery at room temperature in fine grained AZ31B magnesium alloys [J]. Acta Mater, 2003, 51: 2055-2065.

[6] Watanabe H, Tsutsui H, Mukai T, et al. Deformation mechanism in a coarsed-grained Mg-Al-Zn alloy at elevated temperatures[J]. Int J Plasticity, 2001, 17: 387-397.

[7] Doege E, Droder K. Sheet metal forming of magnesium wrought alloys-formability and process technology[J]. Journal of Materials Processing Technology, 2001, 115(1): 14-19.

[8] Mordike M L, Ebert T. Magnesium properties applications potential[J]. Mater Sci Technol A, 2001, A302: 37-45.

[9] 余 琨, 黎文献, 王日初, 等. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2002, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, et al. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[10] Mukai T, Yamanoi M, Watanabe H, et al. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure[J]. Scripta Mater, 2001, 45: 89-94.

[11] Chino Y, Mabuchi M. Influences of grain size on mechanical properties of extruded AZ91 alloy after different extrusion processes[J]. Advanced Engineering Materials, 2001, 3: 981-983.

[12] Philippe M J. Texture formation in hexagonal materials [J]. Mater Sci Forum, 1994, 157/162: 1337-1350.

[13] Prez-Prado M T, Ruano O A. Texture evolution during annealing of magnesium AZ31 alloy[J]. Scripta Mater, 2002, 46: 149-155.

[14] Conrad H, Cao W D, Sprecher A F. Effect of electric field on recovery and recoverystallization of Al and Cu [J]. Sciripta Metall Mater, 1989, 23(6): 821-824.

[15] Koch C C. Experimental evidence for magnetic or electric field effects on phase transformations [J]. Mater Sci Eng A, 2000, A278: 213-221.

[16] 张 娅, 马春江, 卢 晨. 变形镁合金的塑性变形机制与动态再结晶[J]. 轻合金加工技术, 2003, 31(7): 35-39.

ZHANG Ya, MA Chun-jiang, LU Chen. Plastic strain mechanism and dynamic recrystallization of magnesium alloy[J]. Light Alloy Fabrication Technology, 2003, 31(7): 35-39.

[17] 汪凌云,黄光胜,范永隔,等. 变形AZ31镁合金的晶粒细化[J]. 中国有色金属学报,2003, 13(3): 594-598.

WANG Ling-yun, HUANG Guang-sheng, FAN Yong-ge, et a1. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594-598.

基金项目:国家高技术研究发展计划资助项目(2003AA331080)

收稿日期:2006-07-25;修订日期:2006-12-18

通讯作者:曲家惠,副教授,博士研究生;电话:024-83681676;传真:024-24681243;E-mail:qjh915@163.com

(编辑 龙怀中)