镁合金表面复合膜的制备及其耐蚀性

尚伟1, 2,陈白珍1,石西昌1,温玉清2,黄安生2

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 桂林理工大学 化学与生物工程学院,广西 桂林,541004)

摘要:利用溶胶凝胶技术在镁合金微弧氧化膜表面制备SiO2溶胶凝胶膜形成复合膜层。通过扫描电镜和能谱测试,分析膜层的表面形貌和成分。采用动电位极化曲线测试研究不同条件下复合膜的电化学性能。研究结果表明:SiO2溶胶凝胶膜的最佳沉积条件为浸涂次数3 次,浸泡时间1 min,干燥温度80~100 ℃,干燥时间8 h,固化温度170 ℃,固化时间1 h。溶胶凝胶膜能够有效地封闭镁合金表面微弧氧化膜的微孔,形成均匀且较为致密的复合膜层。动电位极化曲线结果表明:复合膜比微弧氧化膜和镁合金基体具有更正的腐蚀电位(Ecorr)、更低的腐蚀电流密度(icorr)和更大的线性极化电阻(Rp),说明微弧氧化镁合金沉积溶胶凝胶膜后耐腐蚀性能有显著地提高,复合膜对AZ91D镁合金具有良好的防腐蚀作用。

关键词:镁合金;微弧氧化;SiO2溶胶;复合膜层;耐蚀性

中图分类号:O646 文献标志码:A 文章编号:1672-7207(2011)11-3256-06

Preparation and corrosion resistance of composite coatings on magnesium alloy

SHANG Wei1, 2, CHEN Bai-zhen1, SHI Xi-chang1, WEN Yu-qing2, HUANG An-sheng2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. College of Chemistry and Bioengineering, Guilin University of Technology, Guilin 541004, China)

Abstract: Composite coatings consisted of a MAO layer and a sol-gel layer were obtained on a magnesium alloy by micro-arc oxidation (MAO) and sol-gel technique. The surface morphologies and composition of the MAO coating and the composite coatings were analyzed by scanning electron microscopy (SEM) and energy dispersive spectrometer (EDS). Potentiodynamic polarization curves were used to investigate the electrochemical properties of the composite coatings formed under different conditions. The results show that the optimum conditions are obtained as follows. Coated frequency is 3 times, soak time is 1 min, drying temperature is controlled within 80-100 ℃, drying time is 8 h, curing temperature and curing time are 170 ℃ and 1 h, respectively. SiO2 sol-gel film could effectively seal micropores in the MAO coating. The composite coatings are more uniform and compact than the MAO coating. The polarization result shows that the composite coatings have more positive corrosion potential (Ecorr), lower corrosion current density (icorr), and higher linear polarization resistance (Rp) than the MAO coating and magnesium alloy substrate, indicating that the sol-gel coating formed on the magnesium alloy with MAO coating under the optimum conditions has better corrosion resistance. The composite coatings have good protection to magnesium alloy AZ91D.

Key words: magnesium alloy; micro-arc oxidation; SiO2 sol; composite coatings; corrosion resistance

镁合金是工业应用中最轻的结构金属,纯镁的密度为1.74 g/cm3,是铝的2/3,钢的1/4,具有比强度比刚度高、导热导电性好、阻尼减振、电磁屏蔽、易于加工成型和容易回收等优点,被誉为“21世纪的绿色工程材料”[1-2]。其在汽车、3C产品、航空航天、国防军工等领域具有越来越重要的应用价值和广阔的应用前景[3]。目前其用量以每年15%的速度增长,远远高于铝、铜、锌、镍、钛和钢铁的增长速度。其中AZ系镁合金(即Mg-Al-Zn合金)是目前最具商业应用前景的结构镁合金材料[4],但由于其化学活性高、电极电位低,在潮湿空气、含硫气氛和海洋大气中均会遭受严重腐蚀,严重限制了它们的推广应用[5-6]。目前,人们常用的表面改性方法主要有化学转化处理、阳极氧化处理、微弧氧化处理、激光表面处理和离子注入等[7]。微弧氧化是一种在有色金属表面原位生长陶瓷层的技术,它具有与金属基体结合力强、电绝缘性好、光学性能优良、耐热冲击、耐磨损和耐腐蚀等特性,表面防护效果远远优于传统的表面处理方法,近年来微弧氧化技术成为国内外的研究热点[8]。然而,镁合金的微弧氧化膜存在很多微孔,在腐蚀环境中腐蚀介质可以通过这些微孔渗入到基体而造成基体的腐蚀,使涂层的防腐蚀作用和寿命大大降低,甚至可使涂层龟裂和脱落,造成涂层失效。因此,必须对微弧氧化膜进行封孔处理[9-11]。本文作者主要采用溶胶凝胶法在镁合金微弧氧化处理的基础上进行改进工艺研究。在不同的沉积工艺条件下,于微弧氧化膜上沉积SiO2溶胶凝胶膜制成复合膜层,采用动电位极化曲线、扫描电镜及能谱分析,优化了制备工艺,研究了膜层的耐腐蚀行为,得到了相关的电化学参数。

1 实验

1.1 基体预处理

实验材料选用AZ91D镁合金,其化学成分(质量分数)为8.8% Al,0.81% Zn,0.21% Mn,其余为Mg。将试样加工成尺寸(长×宽×高)为20 mm×15 mm×3 mm的长方体,前处理工艺为:打磨→抛光→密封→表面除油清洗→微弧氧化→干燥备用。除油液由Na3PO4,NaOH和Na2SiO3组成,60~70 ℃下在该溶液中处理10 min,之后再用热水和冷水分别清洗试样表面,吹干备用。试验过程中用水均采用蒸馏水。微弧氧化电源为HKDA直流脉冲电源,频率选择50 Hz,占空比30%,电解液为铝酸盐体系,pH为12~13。试样作为工作电极,不锈钢板作为对电极进行微弧氧化成膜。

1.2 溶胶凝胶膜制备

以正硅酸乙脂、无水乙醇、蒸馏水为原料,硝酸为催化剂。按一定比例混合后于50 ℃搅拌2 h,控制pH为2~3,即可得到澄清的SiO2溶胶,在室温下静置24 h。采用排液法对试片进行涂覆处理,可重复多次以增加膜层厚度。之后将试片置于高湿度氛围中使溶胶凝胶化。最后将试样于恒温干燥箱中进行干燥和固化。固化结束后试片随炉冷却,即可得到镁合金表面微弧氧化SiO2溶胶凝胶复合膜。具体制备工艺参数如表1所示。

1.3 测试方法

采用JSM-5610LV型扫描电镜观测微弧氧化膜及复合膜的形貌。用电子能谱仪表征膜层表面的化学成分。动电位极化曲线由CHI660B型电化学工作站测试,采用标准三电极体系,参比电极为饱和甘汞电极,辅助电极为铂电极,研究电极为密封后留有1 cm2面积的镁合金样品。腐蚀介质为3.5%的NaCl溶液,试验在室温条件下进行。测试初始延迟若干时间,待开路电位稳定后开始测试,扫描速度为2.5 mV/s。

2 结果与讨论

2.1 不同工艺条件下制备复合膜的极化曲线

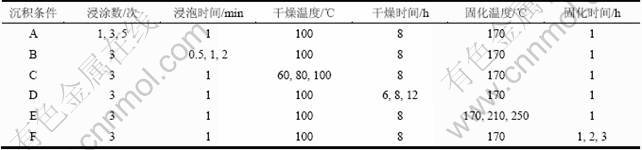

在不同的浸涂次数、浸泡时间、干燥温度、干燥时间、固化温度与固化时间下于镁合金微弧氧化膜上制备了SiO2溶胶凝胶膜,并分别测定其极化曲线,如图1所示,从极化曲线得出腐蚀电位(Ecorr)、腐蚀电流密度(icorr)及线性极化电阻(Rp)参数列于表2。

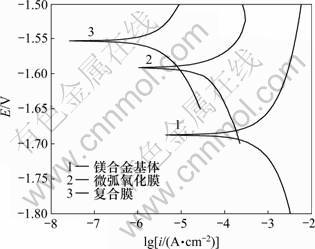

表1 复合膜成膜工艺参数

Table 1 Parameters of composite filming process

图1 不同工艺条件下制备的复合膜的极化曲线

Fig.1 Polarization curves composite coatings under different preparing conditions

从图1和表2可以看出:随着浸涂次数增加、浸泡时间和干燥时间延长,腐蚀电位(Ecorr)均先正移后负移,腐蚀电流密度(icorr)先减小后增大,线性极化电阻(Rp)则先增大后减小。这可能是由于浸涂次数过少和浸泡时间过短,所制得溶胶凝胶层厚度过薄,耐蚀性较差,但浸涂次数过多和浸泡时间过长会导致微弧氧化镁合金表面附着的SiO2颗粒过多,当试片露出液面后由于溶剂的挥发作用产生的应力,使得膜层极易开裂及脱落。从图1(c)及表2可知:随着干燥温度的变化,腐蚀电位(Ecorr)、腐蚀电流密度(icorr)及线性极化电阻(Rp)变化不大。当干燥温度由60 ℃升高到80 ℃时,腐蚀电流密度(icorr)由13.960下降到8.852 μA/cm2,干燥温度由80 ℃升高到100 ℃时,腐蚀电流密度(icorr)继续下降,由8.852下降到3.911 μA/cm2。考虑到此过程主要为结晶水和有机溶剂的挥发,因此,干燥温度选择80~100 ℃为宜。从图1(e)、(f)及表2发现:随着固化温度的升高和固化时间的延长,腐蚀电流密度(icorr)逐渐增大,线性极化电阻(Rp)逐渐减小,说明较高的固化温度和较长的固化时间可能易造成膜层的烧灼或较大裂纹的产生,以致耐蚀性降低。

表2 从极化曲线图1中得到相关参数

Table 2 Corrosion resistance parameters obtained from polarization curves shown in Fig.1

另外,阳极电流密度(ia)代表了沉积溶胶凝胶膜后微弧氧化镁合金阳极溶解发生的难易程度[12]。从图1可以看出:浸涂次数、浸泡时间、干燥时间和固化时间对阳极电流密度(ia)的影响较大,从而对镁合金表面膜层的耐蚀性影响程度也较大。从图1和表2的分析推断比较适合的沉积条件为:浸涂次数3 次,浸泡时间1 min,干燥温度80~100 ℃,干燥时间8 h,固化温度170 ℃,固化时间1 h。

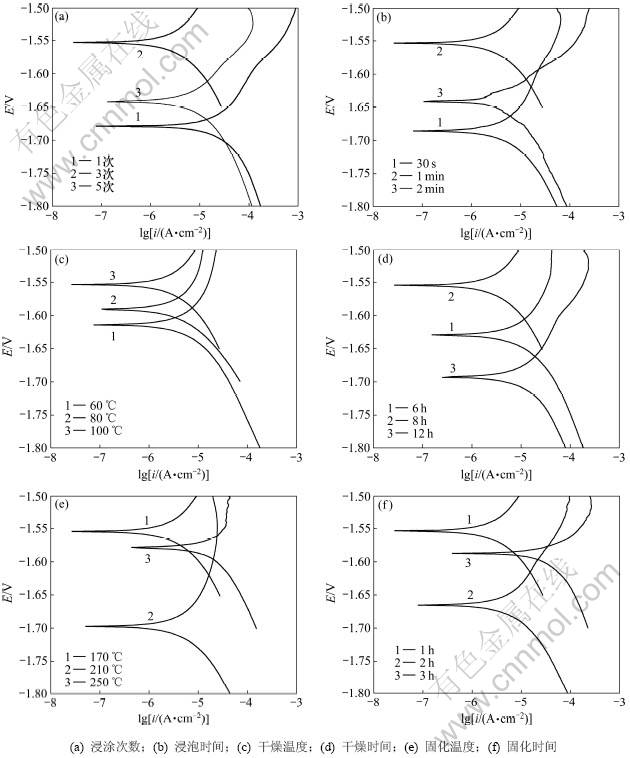

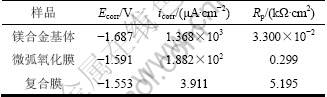

2.2 不同膜层的极化曲线特性

在镁合金表面按照优化的制备工艺制备复合膜层。图2所示为镁合金基体、镁合金表面微弧氧化膜和复合膜的极化曲线。极化曲线分析结果列于表3。由图2和表3可以看出:微弧氧化镁合金上生成SiO2溶胶凝胶膜后明显降低了腐蚀电流密度(icorr),增大了线性极化电阻(Rp),使腐蚀电位(Ecorr)向正方向移动。对于材料的耐腐蚀性来说,腐蚀电流密度(icorr)越小,线性极化电阻(Rp)越大,腐蚀电位(Ecorr)越正,则材料的耐腐蚀性越好[13],说明溶胶凝胶处理明显提高了微弧氧化镁合金的抗腐蚀性能。

涂层样品的腐蚀速度一般是由腐蚀电流密度(icorr)和线性极化电阻(Rp)决定的,他们主要与涂层的微结构有关[14],而涂层样品腐蚀电位(Ecorr)的变化则是由于涂层化学成分不同所致[15]。由表2可以看出:复合膜样品的腐蚀电流密度(icorr)为3.911 μA/cm2,线性极化电阻(Rp)为5.195 kΩ·cm2,比微弧氧化膜样品和镁合金基体都有了较大改变,因而可以推断复合膜层具有更加致密和均匀的微结构。而且,复合膜样品还具有更正的腐蚀电位(Ecorr),这与膜层的元素分析结果一致。因此,复合膜比起单一的微弧氧化膜为镁合金基体提供了更加有效的物理屏障来抵挡腐蚀介质的侵蚀,有助于提高AZ91D镁合金的耐蚀性。

图2 不同样品的极化曲线

Fig.2 polarization curves of different samples

表3 从极化曲线图2中得到相关参数

Table 3 Corrosion resistance parameters obtained from polarization curves shown in Fig.2

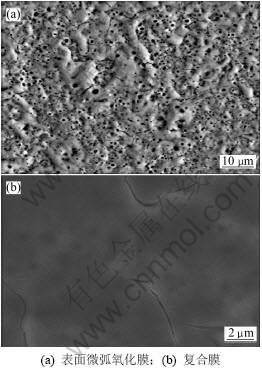

2.3 不同膜层的微观形貌及成分

图3所示为镁合金表面微弧氧化膜和复合膜的表面形貌。由图3可见:微弧氧化膜是由大量的熔融物堆积而成,具有很多分布均匀的微孔,这种多孔结构易使腐蚀介质浸入到镁合金基体表面引起腐蚀。而复合膜则较为平整,几乎完全封闭了微弧氧化膜的微孔,微裂纹较少。致密和均匀的微结构,能够有效阻挡腐蚀溶液的扩散和渗透[16]。因此,复合膜对镁合金基体具有更好的屏蔽效果,验证了极化曲线的分析结果。

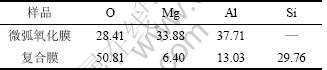

镁合金表面微弧氧化膜和复合膜的成分分析结果列于表4。可以明显看出:除了微弧氧化膜的主要成分Mg,Al和O外,Si元素在复合膜层中具有较高的比重,说明在镁合金表面微弧氧化膜上制备SiO2溶胶凝胶膜的过程中,SiO2粒子可以有效地吸附到膜层 表面。

图3 不同膜层镁合金表面形貌

Fig.3 Surface morphologies of magnesium alloy with different coatings

表4 镁合金表面微弧氧化膜和复合膜的化学成分(质量分数)

Table 4 Composition of MAO coating and composite coatings on magnesium alloy %

3 结论

(1) 镁合金表面微弧氧化SiO2溶胶凝胶膜制备的最佳条件为:浸涂次数3次,浸泡时间1 min,干燥温度80~100 ℃,干燥时间8 h,固化温度170 ℃,固化时间1 h。

(2) 极化曲线结果表明,在最佳条件下生成的复合膜能使腐蚀电位(Ecorr)正移,腐蚀电流密度(icorr)降低,线性极化电阻(Rp)增大。与镁合金基体和微弧氧化膜相比,复合膜的耐蚀性有了较大幅度的提高,对AZ91D镁合金具有良好的防腐蚀作用。

(3) 通过微弧氧化膜和复合膜的表面形貌和成分分析可知,SiO2粒子可以有效地吸附到微弧氧化膜表面,封闭镁合金上微弧氧化膜的微孔。复合膜具有更加致密和均匀的微结构,对镁合金基体具有较好的屏蔽效果,能够有效地抵挡腐蚀介质的侵蚀。

参考文献:

[1] JIN Fan-ya, Chu P K, XU Gui-dong, et al. Structure and mechanical properties of magnesium alloy treated by micro-arc discharge oxidation using direct current and high-frequency bipolar pulsing modes[J]. Mater Sci Eng A, 2006, 435/436: 123-126.

[2] SHANG Wei, CHEN Bai-zhen, SHI Xi-chang, et al. Electrochemical corrosion behavior of composite MAO/sol–gel coatings on magnesium alloy AZ91D using combined micro-arc oxidation and sol–gel technique[J]. J Alloy Compd, 2009, 474(1/2): 541-545

[3] 陈显明, 罗承萍, 刘江文, 等. 镁合金微弧氧化膜层结构[J]. 中南大学学报: 自然科学版, 2006, 37(6): 1065-1069.

CHEN Xian-ming, LUO Cheng-ping, LIU Jiang-wen, et al. Structure of ceramic coating produced by micro-arc oxidation on Mg alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(6): 1065-1069.

[4] 李凌杰, 姚志明, 雷惊雷, 等. 十二烷基苯磺酸钠在AZ31镁合金表面的吸附及其缓蚀作用[J]. 物理化学学报, 2009, 25(7): 1332-1336.

LI Ling-jie, YAO Zhi-ming, LEI Jing-lei, et al. Adsorption and corrosion inhibition behavior of sodium dodecylbenzenesulfonate on AZ31 magnesium alloy[J]. J Acta Phys-Chim Sin, 2009, 25(7): 1332-1336.

[5] Phani A R, Gammel F J, Hack T. Structural, mechanical and corrosion resistance properties of Al2O3-CeO2 nanocomposites in silica matrix on Mg alloys by a sol–gel dip coating technique[J]. Surf Coat Technol, 2006, 201(6): 3299-3306.

[6] Lamaka S V, Montemor M F, Galio A F, et al. Novel hybrid sol–gel coatings for corrosion protection of AZ31B magnesium alloy[J]. Electrochim Acta, 2008, 53(14): 4773-4783.

[7] 蒋奎胜, 唐聿明, 赵旭辉, 等. 电流密度对AZ91D镁合金阳极氧化膜表面形貌及粘接性能的影响[J]. 材料研究学报, 2010, 24(3): 305-310.

JIANG Kui-sheng, TANG Yu-ming, ZHAO Xu-hui, et al. Influences of the current density on surface morphology and adhesion of anodic films of AZ91D magnesium alloy[J]. Chin J Mater Res, 2010, 24(3): 305-310.

[8] GUO Hong-fei, AN Mao-zhong. Growth of ceramic coatings on AZ91D magnesium alloys by micro-arc oxidation in aluminate-fluoride solutions and evaluation of corrosion resistance[J]. Appl Surf Sci, 2005, 246(1/3): 229-238.

[9] HU Jun-ying, LI Qing, ZHONG Xian-kang, et al. Novel anti-corrosion silicon dioxide coating prepared by sol–gel method for AZ91D magnesium alloy[J]. Prog Org Coatings , 2008, 63(1): 13-17.

[10] Tamar Y, Mandler D. Corrosion inhibition of magnesium by combined zirconia silica sol–gel films[J]. Electrochim Acta, 2008, 53(16): 5118-5127.

[11] DUAN Hong-ping, DU Ke-qin, YAN Chuan-wei, et al. Electrochemical corrosion behavior of composite coatings of sealed MAO film on magnesium alloy AZ91D[J]. Electrochim Acta, 2006, 51(14): 2898-2908.

[12] 余会成, 陈白珍, 石西昌, 等. 6063铝合金三价铬化学转化膜的制备与电化学性能[J]. 物理化学学报, 2008, 24(8): 1465-1470.

YU Hui-cheng, CHEN Bai-zhen, SHI Xi-chang, et al. Preparation and electrochemical properties of trivalent chromium coating on 6063 aluminium alloy[J]. J Acta Phys-Chim Sin, 2008, 24(8): 1465-1470.

[13] 尚伟, 陈白珍, 石西昌, 等. 添加剂对AZ91D镁合金微弧氧化膜的影响[J]. 稀有金属材料与工程, 2009, 38(2): 335-338.

SHANG Wei, CHEN Bai-zhen, SHI Xi-chang, et al. Effects of electrolyte additives on the performance of micro-arc oxide films on AZ91D magnesium alloy[J]. Rare Met Mater Eng, 2009, 38(2): 335-338.

[14] LIANG Jun, HU Li-tian, HAO Jing-cheng. Improvement of corrosion properties of microarc oxidation coating on magnesium alloy by optimizing current density parameters[J]. Appl Surf Sci, 2007, 253(16): 6939-6945.

[15] YAO Zhong-ping, JIANG Zhao-hua, SUN Xue-tong, et al. Influence of the frequency on the structure and corrosion resistance of ceramic coatings on Ti-6Al-4V alloy produced by micro-plasma oxidation[J]. Mater Chem Phys, 2005, 92(2/3): 408-412.

[16] 林玉华, 杜荣归, 胡融刚, 等. 不锈钢钝化膜耐蚀性与半导体特性的关联研究[J]. 物理化学学报, 2005, 21(7): 740-745.

LIN Yu-hua, DU Rong-gui, HU Rong-gang, et al. A correlation study of corrosion resistance and semiconductor properties for the electrochemically modified passive film of stainless steel[J]. J Acta Phys-Chim Sin, 2005, 21(7): 740-745.

(编辑 陈爱华)

收稿日期:2011-02-20;修回日期:2011-04-18

基金项目:国家科技支撑计划项目(2006BAB09B04);广西教育厅资助项目(200911MS110)

通信作者:尚伟(1978-),女,河南洛阳人,博士研究生,讲师,从事轻质合金表面处理的研究;电话:15077303983;E-mail: shangw13@163.com