文章编号:1004-0609(2010)S1-s0847-05

Ti-55钛合金板材的超塑性变形行为

赵子博1,葛敬鲁1, 2,陈志勇1,王清江1,刘建荣1

(1. 中国科学院 金属研究所,沈阳 110016;

2. 沈阳大学 机械工程学院,沈阳 110044)

摘 要:研究Ti-55钛合金板材在890~910 ℃、初始变形速率为4.4×10-4~1.76×10-3 s-1条件下的超塑性变形行为。结果表明:在900 ℃、初始应变速率为8.8×10-4 s-1变形条件下平均晶粒尺寸在4 μm左右细小等轴晶的Ti-55钛合金板材的伸长率可达1 300%,表现出良好的超塑性;在一定成形温度下其超塑伸长率随应变速率的增大呈先增加后降低的趋势,存在最佳应变速率8.8×10-4 s-1,高于或低于8.8×10-4 s-1,板材的超塑变形能力均有明显降低;在高应变速率下,Ti-55板材的最大伸长率向高温区移动;超塑性变形过程中晶粒呈相互聚合长大的现象,应变诱发组织粗化是超塑变形过程中组织粗化的主要因素。

关键词:Ti-55钛合金;超塑性;变形速率;变形温度;显微组织

中图分类号:TG 456.3 文献标志码:A

Superplastic deformation of Ti-55 alloy sheet

ZHAO Zi-bo1, GE Jing-lu1, 2, CHEN Zhi-yong1, WANG Qing-jiang1, LIU Jian-rong1

(1. Institute of Metal Research, The Chinese Academy of Sciences, Shenyang 110016, China;

2. College of Mechanical Engineering, Shenyang University, Shenyang 110044, China)

Abstract: The superplastic tensile tests were performed at various temperatures (890-910 ℃) and initial strain rates (4.4×10-4-1.76×10-3 s-1). The results show that the fine-grained Ti-55 sheet, with an average grain size about 4 μm, exhibits excellent superplasticity. On the optimal superplastic condition of 900 ℃ and initial strain rate 8.8×10-4 s-1, a maximum elongation of 1 300% can be achieved. There exists an optimal strain rate of 8.8×10-4 s-1 for each test temperature to get the highest strain, and the superplastic elongation would be significantly reduced at strain rates higher or lower than the optimum strain rate. The temperature for the best superplasticity of Ti-55 sheet moves to higher temperatures at high strain rates. The influence of the deformation on microstructure is obviously. The strain induce grain growth is one of the most prominent characteristic during superplastic deformation.

Key words: Ti-55 titanium alloy; superplasticity; strain rate; deformation temperature; microstructure

Ti-55钛合金是一种可以在550 ℃下长期服役的一种近α钛合金,在550 ℃以下具有良好的热强性及热稳定性,是一种比较理想的航空航天材料[1],但是由于在材料应用过程和制造形状复杂构件时,存在热加工成形困难和材料利用率较低等问题,严重制约了高温钛合金的发展及应用。而具有成本低,易成型复杂构件和工艺简单等优点的超塑成型技术为解决这一问题提供了有效途径。该技术被认为是钛合金成型有效手段之一而日益引起人们的重视。目前Ti-6Al-4V合金的超塑成型技术已经成熟,日本甚至发明了一种具有良好超塑变形能力的SP700合金,应用于多种行业和领域中[2]。高温钛合金由于具有比Ti-6Al-4V高的应变速率敏感性和流变应力,因此,研究该合金的超塑成型工艺及技术对材料推广应用具有重要意义。

一般情况下,要使材料具有良好的超塑性,须有细小的等轴晶粒组织(一般不超过10 μm),并且要求显微组织在变形期间保持稳定。合适的变形温度、变形速率以及细小的等轴组织是获得良好超塑性变形能力的重要条件[3-6]。本文作者以Ti-55板材为研究对象,研究了变形速率和变形温度对Ti-55板材超塑性的影响以及超塑成形过程中的组织演化规律。

1 实验

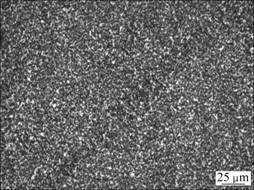

本试验用Ti-55合金板材名义成分(质量分数,%)为Ti-5.2Al-3.5Sn-3.0Zr-1.5Mo-0.4Ta-0.4Nb-0.30Si。板材轧制后退火态原始显微组织见图1,可见由等轴细小的α相以及分布在晶界的β相组成,平均晶粒尺寸在4 μm左右。

图1 试样原始组织

Fig.1 Original structure of specimen

本试验所有超塑性拉伸试验均在日本岛津DCS-25T试验机上进行,选择了以下3个变形温度:890,900和910 ℃,变形时采用恒定夹头速度拉伸。拉伸试样的标距段尺寸为8 mm×4 mm×1.37 mm。每种变形温度下分别采取了3种恒定拉伸速度:0.21,0.42和0.84 mm/min,分别对应初始应变速率为4.4×10-4,8.8×10-4和1.76×10-3 s-1。试样均沿垂直于轧制方向取样。超塑变形完成后的样品,利用ZZeiss Axiovert 200 MAT 金相显微镜观察变形前后显微组织的变化。为降低板材表面氧化,在试样变形部分涂覆了玻璃防护润滑剂[7]。

2 结果与讨论

2.1 拉伸速率对材料超塑性能的影响

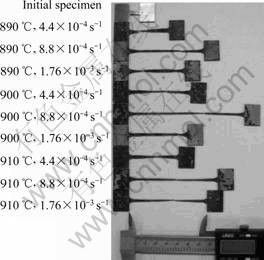

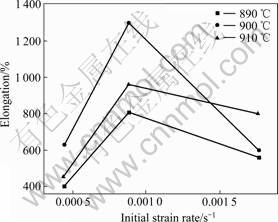

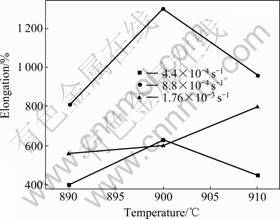

材料的超塑性变形大致可以分为如下3个阶段:均匀变形阶段、准稳定变形阶段和变形失稳阶段。在超塑变形阶段,大伸长率主要在准稳定变形阶段获得的。图2所示为Ti-55试样超塑变形前、后的照片,变形速率对材料超塑伸长率的影响见图3。由图3可知,Ti-55板材在900 ℃,起始应变速率为8.8×10-4 s-1变形条件下超速变形伸长率可达1 300%。同一变形温度下超塑变形伸长率随应变速率的增加存在一峰值,即存在一最佳应变速率(8.8×10-4 s-1),高于或低于这一速率,板材的超塑变形能力将会明显降低。这一现象可由Hart准则得到很好解释。

根据Hart准则,若在变形过程中试样横断面积的减小速率与面积的减少成反比,即 ≤0时,变形

≤0时,变形

处在稳态或准稳态变形阶段,在同一时刻忽略动力学效应的前提下,可以认为试件所有界面上的拉力F及其变化率 都是相同的。由

都是相同的。由

(1)

(1)

(2)

(2)

一般在细颈出现时拉力F值最大,所以:

(3)

(3)

图2 试样变形前、后的照片

Fig.2 Photos of specimens before and after superplastic deformation

图3 伸长率与初始应变速率的关系

Fig.3 Relationship between elongation and initial strain rate

在变形过程中,试样垂直于拉伸方向截面上的拉

力F及其变化率 都相同,所以由式(2)得:

都相同,所以由式(2)得:

(4)

(4)

由式(2)和(3)得:

(5)

(5)

由式(2)~(4)得,

(6)

(6)

由式(5)和(6)得:

(7)

(7)

由Hart准则得在准稳态变性阶段必有:

≥

≥ (8)

(8)

式中:A为试件的横截面积; 为应变速率。

为应变速率。 表示应力不均匀程度的对数可以用它来表示应力的不均匀性,则

表示应力不均匀程度的对数可以用它来表示应力的不均匀性,则 可以表示应力不均匀性的发展速率。在材料的准稳态变形阶段,细颈不断的产生,细颈出现以后其内部应变速率发生起伏,在细颈发生的截面上应变速率

可以表示应力不均匀性的发展速率。在材料的准稳态变形阶段,细颈不断的产生,细颈出现以后其内部应变速率发生起伏,在细颈发生的截面上应变速率 增加,使其强化速率大于松弛速率从而变形减慢,未发生细颈的部分应变速率

增加,使其强化速率大于松弛速率从而变形减慢,未发生细颈的部分应变速率 较慢,松弛速率大于强化速率,变形抗力小,促进其变形,这样在二者的相互作用下细颈得以转移和扩散,不均匀性得到抑制,使变形可以继续进行。

较慢,松弛速率大于强化速率,变形抗力小,促进其变形,这样在二者的相互作用下细颈得以转移和扩散,不均匀性得到抑制,使变形可以继续进行。

由式(8)可知,只有当应变速率不低于试件应力不均匀性的发展速率时,细颈才能扩散和转移。如果应变速率低于某一临界值,则在变形过程中,细颈出现以后,应力不均匀性的发展速率很容易超过应变速率,即 ≤

≤ ,Hart准则被破坏,这时在细颈出现以后细颈部分获得某种程度的强化,但由于未出现细颈的部分应力水平太低,松弛速率太小,没有来得及软化,造成细颈无法转移。最终导致拉伸失稳,材料断裂。而如果应变速率过大,材料内部变形的协调过程不能及时进行导致空洞增加,实际承载面积A减小,同样导致

,Hart准则被破坏,这时在细颈出现以后细颈部分获得某种程度的强化,但由于未出现细颈的部分应力水平太低,松弛速率太小,没有来得及软化,造成细颈无法转移。最终导致拉伸失稳,材料断裂。而如果应变速率过大,材料内部变形的协调过程不能及时进行导致空洞增加,实际承载面积A减小,同样导致 突然增大,破坏Hart准则[8]。

突然增大,破坏Hart准则[8]。

2.2 变形温度对Ti-55板材超塑变形能力及组织演变的影响

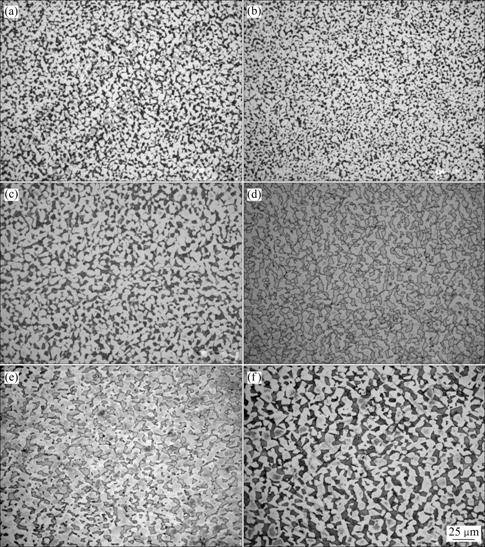

超塑变形温度对伸长率及显微组织的影响如图4和5所示。可见,在低应变速率时材料的伸长率随温度的升高呈先增加后降低的趋势。这是由于变形温度的升高,提高了原子活动的能量,增强了原子的扩散能力以及在变形过程中晶界的协调变形能力,使材料伸长率显著增加。材料在最佳变形温度变形时伸长率(δ)显著提高。超塑性变形主要是一种晶界行为[9],高密度且平坦的晶界有利于超塑性变形,晶粒的粗化将导致伸长率下降,所以当温度继续升高时,在变形过程中晶粒在热效应以及应变诱发条件下发生晶粒粗化聚合[10-12](如图5所示),又会大幅度降低材料超塑性变形能力,导致伸长率(δ)下降。随着变形温度增加,

图4 伸长率与变形温度的关系

Fig.4 Relationship between elongation and temperature

图5 变形与未变形后的显微组织

Fig.5 Microstructure of tensiled specimen: (a) Chuck part of specimen, 890 ℃, 4.4×10-4 s-1; (b) Chuck part of specimen, 890 ℃, 8.8×10-4 s-1; (c) Chuck part of specimen, 910 ℃, 4.4×10-4 s-1; (d) Fracture part of specimen, 890 ℃, 4.4×10-4 s-1; (e) Fracture part of specimen, 890 ℃, 8.8×10-4 s-1; (f) Fracture part of specimen, 910 ℃, 4.4×10-4 s-1

材料内部的协调变形能力进一步增强,所以在较高初始应变速率(1.76×10-3 s-1)条件下,Ti-55板材的最大伸长率出现的位置向高温区移动。在890 ℃、4.4×10-4 s-1,890 ℃、8.8×10-4 s-1条件下样品夹持部位与标距段的显微组织分别见图5(a), (d)和5(b), (e)。可见,夹持端在长时间(约4 h)保温后,晶粒较图1所示的原始组织明显粗化[13-15],其平均晶粒尺寸长大到8 μm左右。在应变速率较快(保温时间较短)的条件下,夹持端晶粒明显比应变速率较慢(保温时间较长)时的细。这一晶粒长大过程采用经典晶粒长大模型中大晶粒吞噬小晶粒理论可得到很好解释。随着变形温度的升高,即在910 ℃、4.4×10-4 s-1变形条件下,试样夹持端显微组织中初生α相含量略有减少,表明试验温度已完全进入α+β两相区,材料的再结晶程度提高,晶粒粗化也更加显著,见图5(c)。在超塑成形过程中由于晶界的滑动、晶粒的转动以及高密度缺陷的生成,使合金元素扩散速率加快,使标距段晶粒长大程度较单纯退火组织显著增加。分别比较图5(a)和(d),5(b)和(e)可见,尽管因加热时间不同导致夹持端晶粒尺寸不同,但工作段晶粒尺寸基本相当。表明在超塑性变形过程中晶粒长大不是单纯由热效应所引起的,应变诱导晶粒长大是超塑性晶粒粗化的另一重要原因。

3 结论

1) 具有细小等轴晶的Ti-55板材在890~910 ℃具有良好的超塑变形能力,在900 ℃初始变形速率为8.8×10-4 s-1变形条件下伸长率(δ)达1 300%。

2) 在相同变形温度下,材料的变形能力存在着一最佳应变速率,高于或低于这一应变速率板材的超塑变形能力将会明显降低。在高应变速率条件下材料的超塑变形能力最大值向高温区移动。

3) 在超塑性变形过程中,同相晶粒(α晶粒或β晶粒)不断地聚合长大,与未变形组织相比应变诱发的晶粒长大是超塑性变形过程中组织粗化的重要原因。

REFERENCES

[1] 闫 伟, 张海龙, 刘建荣, 王清江, 陈志勇, 李玉兰, 孙凤久. Ti-55钛合金板激光焊接[J]. 稀有金属材料与工程, 2008, 37(3): 310-313.

YAN Wei, ZHANG Hai-long, LIU Jiang-rong, WANG Qing-jiang, CHEN Zhi-yong, LI Yu-lan, SUN Feng-jiu. Last beam welding of Ti-55 titanium alloy sheet[J]. Rare Metal Materials and Engineering, 2008, 37(3): 310-313.

[2] 蔡建明, 许 超, 郝孟一, 黄 旭, 马济民, 曹春晓. SP700和Ti-6Al-4V钛合金细晶组织的疲劳裂纹扩展特征[J]. 航空材料学报, 2006, 26(3): 71-74.

CAI Jian-ming, XU Chao, HAO Meng-yi, HUANG Xu, MA Ji-min, CAO Chun-xiao. Fatigue crack growth characteristics of fine structures of SP700 and Ti-6Al-4V titanium alloys[J]. Journal of Aeronautical Materials, 2006, 26(3): 71-74.

[3] 何鸿博. 细晶TC4钛合金超塑性变形机制[M]. 大连: 大连理工大学, 2008: 5-40.

HE Hong-bo. The superplastic deformation mechanism and behavior of fine-grained TC4 titanium alloy[D]. Dalian: Dalian University of Technology, 2008: 5-40.

[4] IMAYEV R M, KAIBYSHEV O A, SALISHCHEV G A. Mechanical behavior of fine grained TiAl intermetallic compound-Ⅱ. Ductile-brittle transition[J]. Acta Metallurgica et Materialia, 1992, 40(3): 589-595.

[5] SHAGIEV M R, SENKOV O N, SALLSHCHEV G A, FROES F H. High temperature mechanical properties of a submicrocrystalline Ti-47Al-3Cr alloy produced by mechanical alloying and hot isostatic pressing[J]. Alloys and Compounds, 2000, 313(1/2): 201-208.

[6] NIEH T G, HSIUNG L M, WADSWORTH J. Superplastic behavior of a powder metallurgy TiAl alloy with a metastable microstructure[J]. Intermetallics, 1999, 7(2): 163-170.

[7] 崔 丽, 粟卓新, 魏 琦. 高温氧化对钛合金超塑性能的影响[J]. 钛工业进展, 2006, 23(2): 21-24.

CUI Li, LI Zhuo-xin, WEI Qi. Influence of high temperature oxidation on the superplastic ability of Ti-6Al-4V alloy[J]. Titanium Industry Progress, 2005, 23(2): 21-24.

[8] 吴诗惇. 金属超塑性变形理论[M]. 北京: 国防工业出版社, 2007: 12-32.

WU Shi-dun. The theory of superplastic deformation of metal[M]. Beijing: National Defense Industrial Press, 2007: 12-32.

[9] 陈浦泉. 组织超塑性[M]. 哈尔滨: 哈尔滨工业大学出版社, 1988: 110-114.

CHEN Pu-quan. Microstructure superplasticity[M]. Harbin: Harbin Institute of Technology Press, 1988: 110-114.

[10] 张志清. TC6钛合金的超塑性研究[D]. 西安: 西北工业大学, 2002: 3-9.

ZHANG Zhi-qing. The superplastic deformation behavior of TC6[D]. Xi’an: Northwestern Polytechnical University, 2002: 3-9.

[11] 赵文娟, 丁 桦, 曹富荣, 侯洪亮, 李志强. Ti-6Al-4V合金超塑性变形过程中的组织演变[J]. 中国有色金属学报, 2007, 17(12): 1973-1980.

ZHAO Wei-juan, DING Hua, CAO Fu-rong, HOU Hong-ling, LI Zhi-qing. Microstructural evolution during superplastic deformation of Ti-6Al-4V alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1973-1980.

[12] ZELIN M. Grain growth during superplastic deformation[J]. Interface Science, 2002, 10: 37-42.

[13] RICHTER S, HAMILTON C H. Deformation enhanced grain growth in a two phase titanium alloy[J]. Materials Science Forum, 1993, 113/115: 195-200.

[14] CAMPENNI V D, C?CERES C H. Strain enhanced grain growth at large strains in a superplastic Zn-Al alloy[J]. Scripta Metallurgica, 1988, 22(3): 359-364.

[15] 崔建忠, 吴庆龄, 马龙翔. 晶粒长大对超塑性的影响[J]. 东北工学院学报, 1988, 54(1): 6-10.

CUI Jian-zhong, WU Qing-ling, MA Long-xiang. Effect of grain growth on superplasticity[J]. Journal of Northeast University of Technology, 1988, 54(1): 6-10.

(编辑 杨幼平)

通信作者:王清江,研究员;电话:024-83978830;E-mail: qjwang@imr.ac.cn