文章编号:1004-0609(2011)11-2952-06

硫化铅矿闪速熔炼过程的热力学分析

汪金良1, 2, 张文海3, 张传福2

(1. 江西理工大学 冶金与化学工程学院,赣州 341000;

2. 中南大学 冶金科学与工程学院,长沙 410083;3. 中国瑞林工程技术有限公司,南昌 330002)

摘 要:基于最小吉布斯自由能原理,建立硫化铅矿闪速熔炼过程多相平衡热力学模型,考察熔炼温度(T)、吨矿氧量(VOVPTO)对粗铅含硫量、炉渣含铅量、烟气含铅量及铅在各平衡相中分配比的影响。结果表明:对一定用量和一定成分的硫化铅矿,随着T和VOVPTO的增大,粗铅含硫量可降至0.1%(质量分数)以下,但过高的VOVPTO会使渣含铅量升至60%(质量分数)以上,铅在粗铅中的分配比低于30%(质量分数);烟气中的铅主要以PbS形式存在,其含量随着T的升高及VOVPTO降低而增高。综合考虑铅的直收率及产物处理的难易程度,闪速炉直接炼铅应采取分区分步熔炼方式,先在氧化区制“低硫铅”,然后在还原区造“低铅渣”,且氧化区熔炼温度宜较低。

关键词:铅闪速熔炼;最小吉布斯自由能;多相平衡;热力学

中图分类号:TF 812 文献标志码:A

Thermodynamic analysis of lead sulfide flash smelting process

WANG Jin-liang1, 2, ZHANG Wen-hai3, ZHANG Chuan-fu2

(1. School of Metallurgical and Chemistry Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

3. China Nerin Engineering Co., Ltd, Nanchang 330002, China)

Abstract: Based on the principle of Gibbs free energy minimization, the thermodynamic model of the lead sulfide flash smelting multi-phase equilibrium system was built. Then, the effects of the smelting temperature (T) and the oxygen volume per ton ore (VOVPTO) on the lead distribution rate and the equilibrium compositions of crude lead, slag and gas were studied. The results show that, for the lead sulfide with a certain amount and a certain composition, the sulfur content in the crude lead can be reduced to be less than 0.1% with the rise of T and VOVPTO, but the lead content in the slag exceeds 60% and the lead distribution rate in the crude lead is less than 30% when VOVPTO is excessive. The lead volatile in the gas, mainly in the form of PbS, rises with the rise of T and the decrease of VOVPTO. Therefore, taking into account the recovery rate of lead and the processing difficulty of products, the lead flash direct smelting furnace should be divided into oxidation and reduction zones, and the low-sulfur lead is produced firstly in the oxidation zone, the low-lead slag is produced secondly in the later zone, and the oxidation smelting temperature should be low.

Key words: lead flash smelting; Gibbs free energy minimization; multi-phase equilibrium; thermodynamics

近30年来,冶金工作者试图通过PbS受控氧化途径来实现硫化铅精矿的直接熔炼,以简化生产流程、降低生产成本,利用氧化反应的热能以降低能耗、产出高SO2含量烟气用于制酸、减少环境污染[1-3]。当前,几种硫化铅精矿直接熔炼法,如基夫赛特法、卡尔多法及QSL法等已在一些冶炼厂得到推广和应用[4-6],从而证明了直接炼铅的可行性。

自1949年问世以来,芬兰奥托昆普闪速熔炼技术经过不断改进、完善和发展,已成为当今最具竞争力的强化熔炼技术[7-9]。闪速熔炼具有工艺成熟、自动化程度高、生产能力大、能源消耗低等特点,被认为是标准的清洁冶炼工艺[10]。芬兰奥托昆普公司分别于1965年和1981年进行了两次闪速炼铅半工业试验,取得了预期成效[11],但关于奥托昆普闪速炼铅的理论鲜有报道。因此,开展铅闪速熔炼过程的热力学研究,促进该技术的发展和工业应用,对铅冶炼工业的节能减排具有重要意义。

由于在高温闪速炉反应塔中干燥的细粒物料能在1 s内完成包括造渣反应在内的冶炼反应[12],因此,可以认为闪速熔炼过程是达到或十分接近平衡状态的。许多研究表明,闪速熔炼过程的多相平衡计算结果与生产实践吻合程度非常高[13]。

本文作者基于吉布斯自由能最小原理,建立硫化铅矿闪速熔炼过程的多相平衡数学模型,重点考察熔炼温度、吨矿氧量(即总氧体积与精矿质量的比)对各相平衡组成的影响,从热力学角度分析铅闪速熔炼过程的物质分布规律及存在的问题,并提出可能的解决办法。

1 多相平衡数学模型

1.1 铅闪速熔炼过程分析

CHANDHURI和MELCHER[14]研究了硫化铅精矿在反应塔内的反应情况。结果表明,在高温、高氧强化熔炼条件下,硫化铅精矿颗粒的氧化反应非常迅速,几乎不受动力学控制。SANNIKOV[15]分析了Kivcet反应塔内温度、反应时间及精矿成分的变化,得到了相似的结论。由此可见,铅闪速熔炼过程可认为达到或基本达到平衡状态。

铅闪速熔炼产物共有3相:粗铅相、炉渣相和烟气相。平衡时各相含有如下组分(由于本研究的主要目的是对硫化铅矿闪速熔炼过程进行热力学分析,精矿成分未考虑Zn、Cu和As等微量组分):

1) 粗铅相:Pb、PbS;

2) 炉渣相:PbO、FeO、Fe3O4、FeS、SiO2、CaO;

3) 烟气相:Pb、PbO、PbS、SO2、S2、O2、N2、H2O、H2。

1.2 模型及求解算法

由最小自由能原理可知,在恒温恒压条件下,当体系处于平衡状态时,体系总吉布斯自由能最小。铅闪速熔炼体系总吉布斯自由能可表示为

(1)

(1)

式中:P是体系的总相数;Cp是p相中的组分数;xpc是p相中组分c的摩尔数;γpc 是p相中组分c的活度因子。

将式(1)在X(n)处按泰勒级数二阶展开得多项式Q,然后结合质量守恒定律,引进Lagrange因子,构造出L函数:

(2)

(2)

式中:ace是组分c中e元素的数目;be是元素e的总摩尔数;m是体系中元素个数;λe 是Lagrange因子。

通过式(2)将有约束条件的极值问题转换为无约束条件的极值问题。

将L分别对xpc和λe求偏导可得

(3)

(3)

式中:p=1, …, P; c=1, …, Cp

(4)

(4)

式中:e=1, …, m。

由式(3)和(4)构成的方程组即为多相平衡数学模型,可用Rand算法进行求解,如图1所示。

图1 多相平衡计算流程图

Fig.1 Flowchart of multi-phase equilibrium calculation

1.3 热力学数据

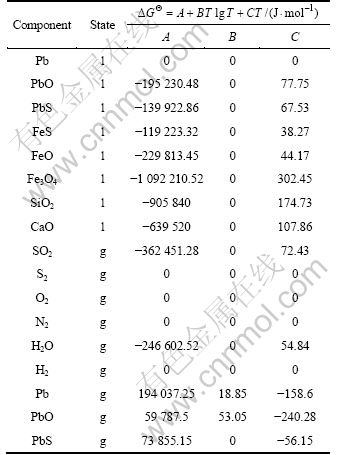

各相各组分的标准生成吉布斯自由能[16-18]和相关活度因子[19-20]分别列于表1和2。

表1 组分的标准生成吉布斯自由能

Table 1 Standard formation Gibbs free energy of components

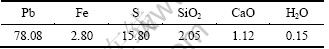

表2 组分的活度因子

Table 2 Activity factors of components

2 模型验证

模拟计算了奥托昆普闪速炼铅半工业状态下的平衡组分,其操作条件为:精矿量1 t,鼓风量 122 m3,富氧浓度 95%,熔炼温度 1 483 K。精矿成分如表3所列,平衡计算结果如表4所列。

表3 硫化铅精矿成分

Table 3 Composition of lead sulfide ore (mass fraction, %)

表4 模拟结果与半工业试验数据

Table 4 Simulation results and semi-industrial test data (mass fraction, %)

表4数据表明,本模型所计算的数据与半工业试验数据[11]吻合较好,说明该模型对于模拟硫化铅矿闪速熔炼过程具有较高精度,可以用于闪速炼铅过程的热力学研究。

3 闪速炼铅过程热力学分析

通过改变熔炼温度T和吨矿氧量(VOVPTO)考察平衡各相组成的变化情况。

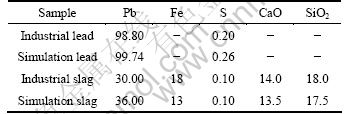

3.1 粗铅含硫量

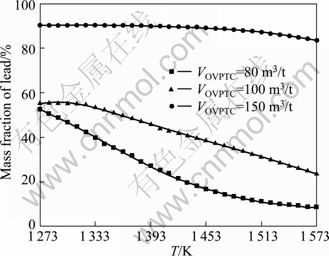

粗铅含硫量随T和VOVPTO的变化如图2所示。

图2数据表明,粗铅含硫量随VOVPTO的增加和T的升高而逐渐下降,当VOVPTO大于100 m3/t、T为 1 573 K时,粗铅中硫含量可降低到0.1%以下。由此可见,升高温度和提高吨矿氧量有利于降低粗铅含硫量,从而得到合格的熔炼产物。

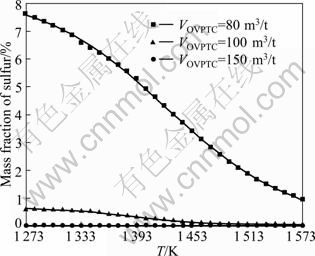

3.2 炉渣含铅量

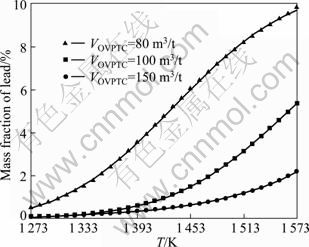

炉渣中铅含量(质量分数)随T和VOVPTO的变化如图3所示。图3表明,当VOVPTO较低时,炉渣中铅含量随T的升高逐渐降低;当VOVPTO大于100 m3/t矿时,炉渣含铅量可达60%以上,甚至90%,且T对其影响不明显。

图2 T和VOVPTO对粗铅含硫量的影响

Fig.2 Effect of T and VOVPTO on sulfur content in crude lead

图3 T和VOVPTO对炉渣含铅量的影响

Fig.3 Effect of T and VOVPTO on lead content in slag

可见,熔炼“低硫铅”必然伴随“高铅渣”的产出。虽然提高VOVPTO有利于降低粗铅的含硫量,但应控制氧化程度,否则可能将铅全部氧化成PbO进入渣中。

3.3 烟气含铅量

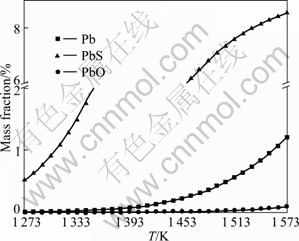

图4所示为烟气的含铅量(包括Pb、PbO和PbS)随T和VOVPTO的变化。图4表明,铅在烟气中的挥发损失总体上随T的升高而增加,随VOVPTO的增大而降低。

图5所示为VOVPTO为80 m3/t时烟气中各种形式铅的含量与T的关系。图5表明,烟气中PbS含量最高,其次是Pb,且都随T的升高而增大。由此可见,铅主要是以PbS的形式挥发进入烟气。

因此,较低的熔炼温度和较高的吨矿氧量有利于减少铅在烟气中的挥发损失。

图4 T和VOVPTO对烟气含铅量的影响

Fig.4 Effect of T and VOVPTO on lead content in gas

图5 VOVPTO为80 m3/t时T对烟气中各组分含量的影响

Fig.5 Effect of T on component content in gas at VOVPTO of 80 m3/t

3.4 铅在平衡相中的分配

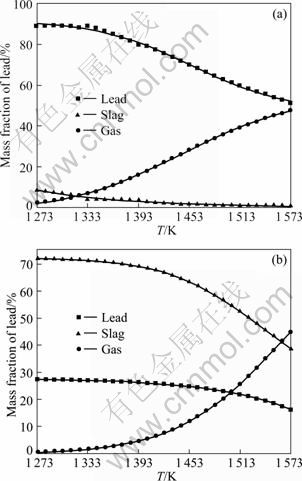

图6所示为VOVPTO分别为80 m3/t和150 m3/t时铅在粗铅、炉渣和烟气平衡相中分配比与T的关系。

图6表明,铅在粗铅和炉渣中分配比随T的升高呈下降趋势,而铅在烟气中的分配比则呈上升趋势。因此,要减少铅的挥发损失,应采取低温熔炼方式。

此外,当VOVPTO为150 m3/t时,铅在炉渣中的损失太大,铅的直收率低于30%。因此,应防止硫化铅的过氧化以提高熔炼直收率。

图6 VOVPTO为80 m3/t和150 m3/t时T对铅在各相中分配比的影响

Fig.6 Effect of T on lead distribution ratio in different phases at different VOVPTO: (a) VOVPTO=80 m3/t; (b) VOVPTO=150 m3/t

4 结论

1) 基于最小吉布斯自由能原理建立了铅闪速熔炼热力学模型。模拟结果表明,该模型能较好地反映硫化铅矿闪速熔炼实际情况,可以用于闪速炼铅过程的热力学分析。

2) 多相平衡分析表明,“低铅渣”必然伴随“高硫铅”和“高挥发”,而“低硫铅”虽然伴随“高铅渣”,但具有“低挥发”的优点。于是,从炼铅目的出发,综合考虑炉渣和烟尘回收处理的难易程度,闪速炉直接炼铅应采取分区分步熔炼方法,即先在氧化区制“低硫铅”,然后在还原区造“低铅渣”。

3) 在“低硫铅”氧化熔炼过程中,应提高氧势,以降低粗铅含硫量,但应避免过氧化,否则大部分铅会被氧化而进入渣中;同时,应适当降低温度,以减少PbS的挥发损失。

REFERENCES

[1] 蒋继穆. 我国铅锌冶炼现状与持续发展[J]. 中国有色金属学报, 2004, 14(S1): 52-62.

JIANG Ji-mu. Status and sustainable development of lead and zinc smelting industry in China[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S1): 52-62.

[2] 张文海, 汪金良. 有色重金属短流程节能冶金产业技术发展方向[J]. 有色金属科学与工程, 2010, 1(1): 11-14.

ZHANG Wen-hai, WANG Jin-liang. Development orientation of industrial technologies for nonferrous heavy metal smelting with short flow [J]. Nonferrous Metals Science and Engineering, 2010, 1(1): 11-14.

[3] 李若贵. 我国铅锌冶炼工艺现状及发展[J]. 中国有色冶金, 2010, 39(6): 13-20.

LI Ruo-gui. Status and development of lead and zinc smelting process in China[J]. China Nonferrous Metallurgy, 2010, 39(6): 13-20.

[4] CHAUDHURI K B, MELCHER G. How KIVCET lead smelting compares with other direct reduction process for lead[J]. Engineering and Ming Journal, 1978, 179(4): 88-91.

[5] 李卫锋, 张晓国, 郭学益, 张传福. 我国铅冶炼的技术现状及进展[J]. 中国有色冶金, 2010, 39(2): 29-33.

LI Wei-feng, ZHANG Xiao-guo, GUO Xue-yi, ZHANG Chuan- fu. Status and progress of lead smelting technology in China[J]. China Nonferrous Metallurgy, 2010, 39(2): 29-33.

[6] 何国才. 白银QSL炼铅工艺实践的回顾与展望[J]. 中国有色冶金, 2004, 33(4): 24-26.

HE Guo-cai. Retrospect of lead smelting with QSL process and its prospects in Baiyin corporation[J]. China Nonferrous Metallurgy, 2004, 33(4): 24-26.

[7] 张文海. 闪速熔炼在中国的进展与研究—冷风技术及“非接触冶金”[J]. 中国有色金属学报, 2004, 14(S1): 63-71.

ZHANG Wen-hai. Process and research of flash smelting in China—Cold air technology and “non-contact” metallurgy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S1): 63-71.

[8] 汪金良, 卢 宏, 曾青云, 张传福. 基于遗传算法的铜闪速熔炼过程控制优化[J]. 中国有色金属学报, 2007, 17(1): 156-160.

WANG Jin-liang, LU Hong, ZENG Qing-yun, ZHANG Chuan-fu. Control optimization of copper flash smelting process based on genetic algorithms[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 156-160.

[9] 李卫民. 奥托昆普粗铜闪速熔炼工艺[J]. 中国有色冶金, 2010, 39(3): 1-6.

LI Wei-min. Outokumpu blister flash smelting processes[J]. China Nonferrous Metallurgy, 2010, 39(3): 1-6.

[10] KOJO I V, JOKILAAKSO A, HANNIALA P. Flash smelting and converting furnaces: A 50 year retrospect[J]. Journal of Metals, 2000, 52(2): 57-61.

[11] NERMES E O, TALONEN T T. Flash smelting of lead concentrates[J]. Journal of Metals, 1982, 34(11): 55-59.

[12] 凌 玲, 沈剑韵, 陆金忠, 李 光. 镍闪速熔炼过程的平衡计算[J]. 有色金属, 2000, 52(4): 71-73.

LING Ling, SHEN Jian-yun, LU Jin-zhong, LI Guang. Equilibrium calculation for process of nickel flash smelting[J]. Nonferrous Metals, 2000, 52(4): 71-73.

[13] GUI Wei-hua, WANG Ling-yun, YANG Chun-hua, XIE Yong-fang, PENG Xiao-bo. Intelligent prediction model of matte grade in copper flash smelting process[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(5): 1075-1081.

[14] CHANDHURI K B, MELCHER G. Comparative view on the metallurgy of the Kivcet CS and other direct lead smelting processes[J]. Canadian Mining and Metallurgical Bulletin, 1978, 71: 126-130.

[15] SANNIKOV Y I, LIAMINA M A, SHUMSKIJ V A, GRININ Y A, RADASHIN MV. A physical and chemical description of the Kivcet lead flash smelting process[J]. Canadian Mining and Metallurgical Bulletin, 1998, 91: 76-81.

[16] TAN Peng-fu. Thermodynamic modeling of lead blast furnace[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(1): 160-164.

[17] 梁英教, 车荫昌. 无机物热力学数据手册[M]. 沈阳: 东北大学出版社, 1993: 458.

LIANG Ying-jiao, CHE Yin-chang. Inorganic thermodynamic data manual[M]. Shenyang: Northeastern University Press, 1993: 458.

[18] TAN Peng-fu, ZHANG Chuan-fu. Thermodynamic modeling for direct lead processes[C]//MISHRA B. Proceedings of the EPD Congress 1998. San Antonio: The Minerals, Metals and Materials Society (TMS), 1998: 815-820.

[19] 谭鹏夫, 张传福, 张瑞瑛. QSL炼铅过程的计算机模型[J]. 中南工业大学学报: 自然科学版, 1996, 27(5): 543-546.

TAN Peng-fu, ZHAGN Chuan-fu, ZHANG Rui-ying. A computer model of QSL lead smelting process[J]. Journal of Central South University of Technology: Science and Technology, 1996, 27(5): 543-546.

[20] NOBUMASA K. The application of equilibrium calculations to a copper flash smelting furnace [J]. Journal of the Mining and Materials Processing Institute of Japan, 1987, 103(5): 315-323.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(50904027);国家高技术研究发展计划资助项目(2009AA064603);云南省重点产业创新工程项目(20081A004)

收稿日期:2010-10-26;修订日期:2011-02-30

通信作者:汪金良,副教授,博士;电话:0797-8312204;E-mail:simwjl@163.com