文章编号:1004-0609(2013)12-3374-07

凝胶注模坯体的液体干燥

王小锋1, 2,王日初2,彭超群2,王志勇2

(1. 中南大学 冶金科学与工程学院,长沙 410083;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘要:研究凝胶注模坯体的液体干燥,通过质量称量和尺寸测量等手段分析液体干燥剂类型与浓度和坯体固相体积分数与尺寸对坯体质量损失率和收缩率的影响规律。结果表明:在液体干燥过程中,水分在浓度梯度产生扩散的机制和表面张力差产生的置换机制的作用下被排出,同时,在高分子网络协同扩散机制作用下,坯体发生收缩。酮类液体干燥剂的干燥能力优于醇类的,并且在同种类液体干燥剂中,低分子量干燥剂的干燥能力优于高分子量干燥剂的。较合适的液体干燥剂为丙酮和乙醇。液体干燥剂浓度越高,坯体的质量损失率越大,但收缩率越小,因此液体干燥的剂浓度不能过高。坯体的固相体积分数越低、高径比越大,干燥效果越好。

关键词:坯体;液体干燥;凝胶注模;液体干燥剂

中图分类号:TF123 文献标志码:A

Solvent drying of gelcasting green bodies

WANG Xiao-feng1, 2, WANG Ri-chu2, PENG Chao-qun2, WANG Zhi-yong2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Gelcasting green bodies were dried by solvent drying method, and the influences of type and concentration of liquid desiccant, solids loading and size of green body on the mass loss fractions and shrinkage fractions of green bodies were analyzed through measuring the mass and dimension. The results show that water is discharged due to the diffusion mechanism derived from moisture concentration differences on either side of the green body and the replacement mechanism developed from the gradient of osmotic pressure between the two media. The drying capability of ketones solvent is better than that of the alcohol solvent, and the drying capability of the same kind of solvent with low molecular mass is larger than that of the solvent with high molecular. Acetone and ethanol are suitable liquid desiccant. The more concentration of liquid desiccant is, and the more mass loss fraction is, but less shrinkage fraction of the green body is. The drying efficiency of the green body with lower solids loading and higher aspect ratio is better.

Key words: green body; solvent drying; gelcasting; liquid desiccant

干燥是凝胶注模成型中的关键工序之一[1-3]。如果干燥过程控制不当,坯体会发生卷曲、变形甚至开裂等情况而报废,因此,干燥在很大程度上影响陶瓷材料的最终性能。凝胶注模坯体通常在干燥炉中通过加热的方式使水分迁移从而进行干燥。为了避免因干燥速度过快而造成坯体表面开裂等缺陷,在控制干燥炉内(坯体干燥环境)温度的同时还必须控制其湿度[1, 4]。显然,这种干燥方式的效率十分低,特别是对于大尺寸厚壁坯体。HARN等[4-5]的研究表明,采用该方式将坯体完全干燥所需时间为24 h以上。可见,采用加热方式干燥坯体为凝胶注模成型中耗时最长的工序。此外,干燥过程产生的内应力还有可能损毁坯体,甚至使之完全失效[6]。

液体干燥(又称为置换干燥或极性溶剂干燥)一种已有50多年历史的非热力学干燥和脱水方法[7]。该方法的基本原理是将含水物体浸入液体干燥剂中使之干燥,其原理为利用水在液体干燥剂中的渗透压大于水分在含水物体中的渗透压或利用强烈极性干燥剂与水分的置换扩散来将水分排除[2]。最初该方法(置换干燥)主要功能是清洗零件,干燥只是其辅助功能。氟氯化碳(CFC)为早期广泛使用的干燥剂(也称为置换剂)。在20世纪60年代,电子技术的发展带动了当时作为清洁剂使用的CFC的应用,同时带动了置换干燥技术的广泛应用。1980年,欧洲有超过600台基于置换干燥原理的干燥系统在运行[8]。后来,由于CFC会破坏臭氧层而造成环境危害,因此,CFC被氟氢化碳(HCFC)替代。但HCFC昂贵的价格且对人体有害等弊端限制了该技术的发展。直到1997年,杜邦公司研制出Vertrel 溶剂后,置换干燥才重新获得广泛地应用[9]。采用强烈极性溶剂的液体干燥方法(多称为极性溶剂干燥)最初主要用于木材的干燥[10]。

溶剂后,置换干燥才重新获得广泛地应用[9]。采用强烈极性溶剂的液体干燥方法(多称为极性溶剂干燥)最初主要用于木材的干燥[10]。

JANNEY等[2]提出采用液体干燥方式来干燥凝胶注模坯体。与传统的加热干燥方式相比,采用液体干燥方式干燥凝胶注模坯体具有以下优点[2, 11]:1) 液体干燥方式的干燥能力较强,效率高,短时间内就能去除坯体内20%~30%的水分;2) 液体干燥方式是一种更为均匀的干燥方法,因此,坯体不会发生局部干燥过快而造成的内引力过大,从而导致坯体变形的情况;3) 在液体干燥过程中,坯体是通过浮力支撑的,因此,其发生弯曲、表面褶皱、开裂等现象的情况大为减少,甚至不会出现。ABOLFAZL等[11]采用PEG1000作为液体干燥剂干燥Al2O3凝胶注模坯体,其结果表明坯体内30%的含水量在3 h内就能被除去。但是有关液体干燥剂类型等因素对液体干燥的影响以及凝胶注模坯体的液体干燥过程等方面的研究尚未进行。本文作者研究BeO凝胶注模坯体的液体干燥,分析液体干燥剂类型与浓度和坯体固相体积分数与尺寸对坯体质量损失率和收缩率的影响规律,探讨凝胶注模坯体的液体干燥过程。

1 实验

1.1 实验过程

称取一定量的单体丙烯酰胺AM和交联剂N,N-亚甲基双丙烯酰胺MBAM加入去离子水中,经搅拌均匀直至溶液透明,得到有机水溶液。在单体水溶液中加入分散剂NH4PAA和经过高温煅烧、球磨处理后的高纯BeO粉体(湖南水口山有色金属集团有限公司生产)[12],球磨24h制得不同固相体积分数的BeO粉体悬浮液。将BeO粉体悬浮液真空除气后,在室温(25 ℃)条件下加入引发剂过硫酸铵溶液(APS,质量分数,10%)和催化剂N,N,N′,N′-四甲基乙二胺(TEMED)并注入模具中,使悬浮液凝胶反应固化,脱模干燥得到坯体。除了研究坯体尺寸的影响之外,湿坯的直径均为10 mm,长度均为50 mm。表1所列为实验采用的液体干燥剂。

1.2 测试与表征

研究液体干燥凝胶注模坯体时,将刚脱模的坯体浸入液体干燥剂中,每间隔10 min或30 min取出坯体并用棉纱吸走其表面残留的液体,然后测量其质量和尺寸。采用梅特勒公司生产的电子天平(精度1 mg)和哈尔滨量具厂生产的游标卡尺(精度1 μm)分别测量质量和尺寸。

表1 干燥实验采用的液体干燥剂

Table 1 Liquid desiccant agents for drying experiments

2 实验结果

2.1 液体干燥剂类型的影响

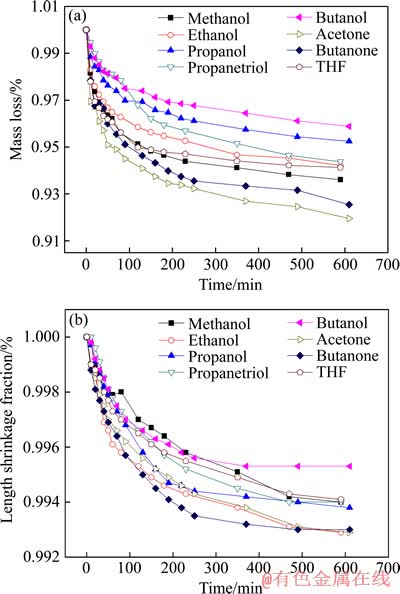

图1所示为采用不同液体干燥剂时坯体的质量损失率及收缩率随时间的变化。由图1(a)可知,液体干燥剂对坯体质量损失率下降程度的影响由大到小的顺序为丙酮、丁酮、甲醇、四氢呋喃、乙醇、丙三醇、丙醇、丁醇。这表明酮类液体干燥剂置换坯体内部水分的能力优于醇类的,并且在同种类液体干燥剂中,低分子量干燥剂的干燥效果优于高分子量干燥剂的。由图1(b)可知,液体干燥剂对坯体收缩程度的影响由大到小的顺序为丁酮、丙酮、乙醇、丙醇、丙三醇、四氢呋喃、甲醇、丁醇。这表明酮类液体干燥剂促进坯体收缩的能力优于醇类的,并且在同种类液体干燥剂中,低分子量干燥剂促进坯体收缩的能力也优于高分子量的。对于坯体的干燥而言,坯体质量损失率越低,收缩率越大,则干燥效果越好。因此,总体来说,采用丙酮作液体干燥剂时,坯体的干燥效果最好,丁酮的次之,接下来是乙醇等,而丁醇的干燥效果最差。

图1 采用不同液体干燥剂时坯体的质量损失率和收缩率

Fig. 1 Mass loss (a) and length shrinkage fractions (b) of gelcasting green body (50%, volume fraction) during drying with different liquid desiccant solvents (Concentrations of liquid desiccant solvent are 100%, respectively)

2.2 液体干燥剂浓度的影响

图2所示为液体干燥剂丙酮浓度对坯体质量损失和收缩的影响。由图2可见,液体干燥剂浓度越高,坯体内的水分越容易排出,坯体在相同时间内的质量损失率越大。但是,坯体的收缩率却随着干燥剂浓度的增加而降低。

图2 液体干燥剂浓度(丙酮)对坯体质量损失和收缩的影响

Fig. 2 Effect of concentration of liquid desiccant on mass loss (a) and length shrinkage fractions (b) of gelcasting green body (Liquid desiccant is acetone and solids loading volume fraction is 50%)

2.3 固相体积分数的影响

图3所示为固相体积分数对丙酮液体干燥的坯体质量损失和收缩变化的影响。由图3可看出,坯体的质量损失率和收缩率随着固相体积分数的增加而降低,并且固相体积分数较低的坯体的质量损失率和收缩率也较高。

图3 固相体积分数对坯体质量损失和收缩的影响

Fig. 3 Effect of solids loading volume fraction on mass loss(a) and length shrinkage fractions(b) of gelcasting green bodies (Concentrations of liquid desiccant acetone is 100% and solids loading volume fraction is 50%)

2.4 坯体尺寸的影响

图4所示为坯体尺寸对丙酮液体干燥的坯体的质量损失和收缩变化的影响。与高径比为1:1的坯体相比,高径比为5:1的坯体的质量损失率和收缩率的变化较大。由图4还可知,在干燥初期,高径比为5:1的坯体的收缩率远大于高径比为1:1的。

图4 坯体尺寸对坯体质量损失和收缩的影响

Fig. 4 Effect of green bodies size on mass loss (a) and length shrinkage fractions (b) of gelcasting green body (Concentration of liquid desiccant acetone is 100% and solids loading volume fraction is 50%)

3 分析与讨论

根据液体干燥(极性溶剂干燥)机理[10],凝胶注模坯体进入液体干燥剂后,坯体中的水在浓度梯度的作用下向液体干燥剂中进行扩散。同时,因为液体干燥剂与坯体中的固态物质(陶瓷粉体和高分子物质)的表面张力低于坯体中的水与固态物质的表面张力,所以液体干燥剂进入坯体中置换出水。因此,在这两种机制的作用下,凝胶注模坯体被干燥。

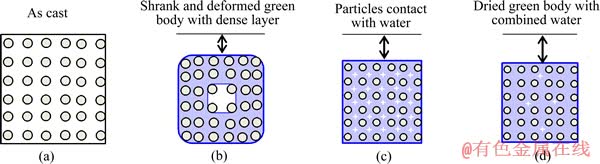

但是,对凝胶注模坯体进行液体干燥时,其实际过程是比较复杂的。关于水凝胶的研究表明[13],在凝胶干燥时,其表面产生的高分子链收缩层会抑制水的排出,因此,坯体干燥时,其表面必然产生一个由高分子网络与陶瓷粉体颗粒组成的密实层,该密实层同样会抑制水的排出。这就是采用加热方式干燥凝胶注模坯体效率低下的主要原因。此外,坯体中的三维网络结构高分子链会影响坯体的收缩,因此,其对干燥过程也必然会有影响。

图5 典型的液体干燥质量损失曲线

Fig. 5 Typical mass loss curves of wetting green body dried by liquid desiccant method (Liquid desiccant is ethanol. Green body with ratio of height to diameter of 1 is prepared by beryllina suspensions with solids loading volume fraction of 50%)

图6 典型的液体干燥收缩曲线

Fig. 6 Typical dring shrinkage curves of wetting green body dried by liquid desiccant method (Liquid desiccant is ethanol. Green body with ratio of height to diameter of 1 is prepared by beryllina suspensions with solids loading volume fraction of 50%)

为了进一步研究凝胶注模坯体的液体干燥过程,采用乙醇为液体干燥剂干燥BeO凝胶注模坯体,典型的坯体质量及干燥速率的变化曲线和长度收缩及收缩速率的变化曲线分别如图5和6所示。由图5和6可见,随着时间的延长,凝胶注模坯体的质量逐渐减少。根据干燥速率的变化(见图5(b)),凝胶注模坯体的干燥过程可分为3个阶段:初期的快降速干燥阶段、中期的慢降速干燥阶段和末期的近匀速干燥阶段。值得注意的是,3个阶段并没有明确的划分标准。在快降速干燥阶段,坯体中的自由水和液体干燥剂在浓度差与表面张力差的作用下快速互换,因此,坯体干燥速度较快。随着干燥的进行,浓度差降低并在坯体表面形成厚度逐渐增加的密实层,因此,干燥速度又迅速下降。在此阶段,坯体的收缩和收缩速率最大(见图6)。在慢降速干燥阶段,坯体干燥速度较慢且缓慢降低。在此阶段,坯体表面已经形成较厚的不含水的密实层,抑制从坯体内部出来的水和从坯体外部进来的液体干燥溶剂通过,因此,坯体收缩和水的排出受到抑制。随后,在逐渐累积的压力、浓度差和表面张力差等的作用下,坯体内部的水被缓慢排出至接近表层,然后与缓慢加入的液体干燥剂互换,因此干燥速度较低。同时,坯体表面密实层的厚度逐渐增加,使得干燥速度缓慢降低。此阶段坯体收缩速率较低(见图6),这也进一步证实上述分析。此外,坯体内压力还会导致坯体发生变形甚至产生表面起泡等现象。因此,该阶段为液体干燥最重要的阶段。当慢降速干燥阶段结束后,坯体中的自由水几乎全部被排除,颗粒互相接触,并且在其堆积间隙存在较多的束缚水。在近匀速干燥阶段,坯体内剩余的水分在更低的浓度差和表面张力差的作用下被进一步排除,干燥速度和收缩速度均很低。图7所示为液体干燥过程中3个阶段的坯体结构转变示意图。

另外,三维网络结构的高分子链对坯体收缩有很大影响。关于水凝胶退胀的研究表明[13],如果从凝胶中放出的水量与时间的1/2次方成正比,那么其收缩变化受高分子网络的协同扩散控制。图8所示为液体干燥过程中坯体排水量与时间的1/2次方的关系。由图8可见,在快降速干燥阶段,坯体排水量与时间的1/2次方之间为线性关系,表明在此阶段坯体收缩机制主要为高分子网络的协同扩散机制。而在其他阶段,坯体排水量与时间的1/2次方之间为非线性关系,表明该机制的作用下降。

图7 液体干燥过程中的坯体结构转变示意图

Fig. 7 Schematic diagrams of structure change in green body during drying by liquid desiccant method

图8 液体干燥过程中坯体排水量与时间平方根的关系

Fig. 8 Relationship between water discharge fraction and square root of time during solvent drying

综上所述,在凝胶注模坯体的液体干燥过程中,坯体中的水在浓度梯度的作用下向液体干燥剂中进行扩散(水分扩散机制),而液体干燥剂也在表面张力降低的驱动下进入坯体中将水分置换出来(液体干燥剂置换机制),同时,坯体在高分子网络协同扩散机制的作用下发生收缩。

显然,在整个液体干燥的过程中,坯体的质量损失率和收缩率受到液体干燥剂类型与浓度的影响。根据液体干燥剂置换机制,液体干燥剂通过扩散进入坯体置换出水分,而低分子量的液体干燥剂的分子链较短,其在坯体内的扩散系数较大,同时根据水分扩散机制,水分子在黏度高的液体干燥剂中的运动较慢,因此,低分子量液体干燥剂的干燥效果优于高分子量的(见图1)。这与TRUNEC[14]的研究结果正好相反,其主要原因是由液体干燥机制不同造成的。TRUNEC[14]采用的液体干燥剂为聚乙二醇,干燥机制主要是通过单纯的依靠水分向聚乙二醇液体的扩散迁移实现干燥。高分子量聚乙二醇液体干燥剂“吸收”水分的能力优于低分子量的,所以前者的干燥效果要优于后者的。对于液体干燥剂浓度的影响,同样由水分扩散机制可知,当液体干燥剂浓度较高时,坯体内外的水分浓度梯度较大,因此坯体质量损失率下降速度较快,下降程度较大。当液体干燥剂浓度较低时,干燥速率较低,坯体有较长的时间进行高分子网络的协同扩散(高分子网络协同扩散机制),从而逐渐收缩,因此其收缩率较大(见图2)。ABOLFAZL等[11]采用液体干燥剂聚乙二醇(PEG1000)干燥Al2O3凝胶注模坯体的研究也得到了类似的结构,并且他们还认为液体干燥剂浓度的差异会造成渗透压差,从而导致溶剂扩散速率的差异。

此外,坯体的质量损失率和收缩率也受坯体固相体积分数与尺寸的影响。固相体积分数较低的坯体的含水率较高,因此,根据水分扩散机制,坯体内的水分在浓度梯度的作用下,容易被排出,因此,坯体质量损失率下降速度和程度均较快(见图3)。相应地,坯体的收缩速度和程度也较高。高径比为5:1的坯体与液体干燥剂的接触面积较多,水分被液体干燥剂置换速度较快,置换的数量也较多,因此,其质量损失率和收缩率的变化较大(见图4)。BARATI等[15]的研究也得到了相同的结果。

4 结论

1) 液体干燥为凝胶注模坯体的一种有效的干燥方法。在干燥过程中,水分在浓度梯度产生的扩散机制和表面张力差产生的置换机制的作用下被排出,同时,在高分子网络协同扩散机制作用下,坯体发生收缩。

2) 酮类液体干燥剂的干燥能力优于醇类的,并且在同种类液体干燥剂中,低分子量干燥剂的干燥能力优于高分子量干燥剂的。较合适的液体干燥剂为丙酮和乙醇。液体干燥剂浓度越高,坯体的质量损失率越大,但收缩率越小,因此,液体干燥剂浓度不能过高。坯体的固相体积分数越低、高径比越大,干燥效果越好。

REFERENCES

[1] OMATETE O O, STREHLOW R A, WALLS C A. Drying of gel-cast ceramics[J]. Ceramic Transactions, 1991, 26: 101-107.

[2] JANNEY M A, KIGGANS J O. Method of drying articles[P]. US Patent 5885493, 1999-03-23.

[3] JANNEY M A, WALLS C A H. Gelcasting compositions having improved drying characteristics and machinability[P]. US Patent 6228299, 2001-05-08.

[4] HARN Y P, GHOSAL S, ARAL G, EMAMI-NAEINI A, DRASKOVICH B, MAXEY C. Real-time model-based control system design and automation for gelcast drying process[C]// Proceedings of the 1997 IEEE International Conference on Control Applications. Sunnyvale, CA: Syst Inc,1997: 271-276.

[5] GHOSAL S, EMAMI-NAEINI A, HARN Y P, DRASKOVICH B S, POLLINGER J P. A physical model for the drying of gelcast ceramics[J]. Journal of the American Ceramic Society, 1999, 82(3): 513-520.

[6] 曾令可, 税安泽, 等. 陶瓷工业实用干燥技术与实例[M]. 北京: 化学工业出版社, 2008: 44-45.

ZENG Ling-ke, SHUI An-zhe, et al. Practical drying technologies and illustrations for ceramic industry[M]. Beijing: Chemical Industry Press, 2008: 44-45.

[7] 潘永康, 王喜忠, 刘相东. 现代干燥技术[M]. 2版. 北京: 化学工业出版社, 2006: 878-884.

PAN Yong-kang, WANG Xi-zhong, LIU Xiang-dong. Modern drying technology[M]. 2nd ed. Beijing: Chemical Industry Press, 2006: 878-884.

[8] DAVID M. Exploratory study of effect of superheated steam drying on properties of paper[D]. Montreal: McGill University, 1987.

[9] 库 德T, 牟久大A S. 先进干燥技术[M]. 李占勇, 译. 北京: 化学工业出版社, 2005: 176-180.

KUDRA T, MUJUMDAR A S. Advanced drying technologies[M]. LI Zhan-yong, transl. Beijing: Chemical Industry Press, 2005: 176-180.

[10] SALIN J G. Solvent drying of wood-some results[M]. MUJUMDAR A S, FILKOVA I. Amsterdam: Elsevier, 1991: 529-534.

[11] ABOLFAZL B, MEHRDAD K, MOHAMMAD H N F. Drying of gelcast ceramic parts via the liquid desiccant method[J]. Journal of the European Ceramic Society, 2003, 23: 2265-2272.

[12] 罗玉林, 王小锋, 彭超群, 王日初, 李婷婷, 刘 兵. 煅烧预处理对胶态成型用BeO粉体性能的影响[J]. 粉末冶金科学与工程, 2010, 15(2): 151-156.

LUO Yu-lin, WANG Xiao-feng, PENG Chao-qun, WANG Ri-chu, LI Ting-ting, LIU Bing. Effects of calcination pretreatment on properties of BeO powder for colloidal processing[J]. Materials science and engineering of powder metallurgy, 2010, 15(2): 151-156.

[13] 顾雪蓉, 朱育平. 凝胶化学[M]. 北京: 化学工业出版社, 2004: 57-117.

GU Xue-rong, ZHU Yu-ping. Gel chemistry[M]. Beijing: Chemical Industry Press, 2005: 57-117.

[14] TRUNEC M. Osmotic drying of gelcast bodies in liquid desiccant[J]. Journal of the European Ceramic Society, 2011, 31(14): 2519-2524.

[15] BARATI A, NOROUZI H R, KHALEGHI R S, SHARAFODDINZADEH S. Model development and experimental verification of liquid desiccant drying of gelcast- alumina ceramic objects[J]. Industrial & Engineering Chemistry Research, 2011, 50(12): 7504-7512.

(编辑 龙怀中)

基金项目:国家青年自然科学基金资助项目(51202296);中南大学博士后基金资助项目

收稿日期:2012-09-20;修订日期:2013-10-20

通信作者:王日初,教授,博士;电话:0731-8836638;E-mail: wrc@csu.edu.cn