文章编号:1004-0609(2011)06-1380-09

不掺杂TiO2陶瓷的缺陷化学与气孔形成机理

严继康1, 2, 3,甘国友1, 2, 3,袁 君1, 2, 3,杜景红1, 2, 3,易健宏1, 2, 3

(1. 昆明理工大学 材料学院,昆明 650093;

2. 昆明理工大学 有色及稀贵先进材料教育部重点实验室,昆明 650093;

3. 昆明理工大学 云南省新材料制备与加工重点实验室,昆明 650093)

摘 要:通过应用缺陷化学和材料检测手段对不掺杂TiO2陶瓷气孔形成的机理进行研究。以锐钛矿TiO2粉体为原料,采用传统电子陶瓷工艺制备了不掺杂TiO2陶瓷,应用SEM、EDS和XPS测试在1 300、1 350和1 400 ℃烧结的不掺杂TiO2陶瓷样品的显微结构、化学组成和离子价态;根据不掺杂TiO2陶瓷晶粒的缺陷化学方程式和电中性条件,计算TiO2晶粒的缺陷浓度;基于点缺陷热力学方法,计算不掺杂TiO2陶瓷晶界的氧空位分布。结果表明:随烧结温度的升高,颗粒间的气孔逐渐减小,而晶粒中的气孔则逐渐长大,这是由于氧空位浓度随温度的增加而增加引起的。不掺杂TiO2陶瓷的氧空位在晶界出现偏析行为,并随烧结温度的增加,晶粒中的氧空位浓度和晶界氧空位浓度均随之增加。不掺杂TiO2陶瓷中存在三价钛离子和晶界吸附氧,三价钛离子浓度和晶界吸附氧含量随烧结温度的增加而增加。不掺杂TiO2陶瓷晶粒和晶界中存在较多气孔,主要起源于高温烧结过程中晶格氧的挥发和氧空位在晶界的偏析。

关键词:TiO2陶瓷;缺陷化学;气孔;显微结构

中图分类号:TQ174 文献标志码:A

Defect chemistry and formation mechanism of pores in

undoped TiO2 ceramics

YAN Ji-kang1, 2, 3, GAN Guo-you1, 2, 3, YUAN Jun1, 2, 3, DU Jing-hong1, 2, 3, YI Jian-hong1, 2, 3

(1. School of Materials Science and Engineering, Kunming University of Science and Technology,

Kunming 650093, China;

2. Key Laboratory of Advance Materials in Rare and Precious and Nonferrous Metals,

Ministry of Education, Kunming University of Science and Technology, Kunming 650093, China;

3. Key Laboratory of Advance Materials of Yunnan Province, Kunming University of Science and Technology,

Kunming 650093, China)

Abstract: The formation mechanism of pores in undoped TiO2 ceramics were investigated through defects chemistry and materials testing methods. The undoped TiO2 ceramics samples were prepared from anatase TiO2 powders by traditional solid-state sintering method. The microstructure, chemistry composition and ionic valence of undoped TiO2 ceramics sintered at 1300, 1350 and 1400℃ were tested by SEM, EDS and XPS. According to the defects chemistry formula and electric neutrality conditions of undoped TiO2 grains, the defects concentration in grains were calculated. Based on the point defects thermodynamic method, the oxygen vacancy distribution at the grain boundaries were obtained. The results show that the gas holes among grains reduce in scale while the pores in grain grow up with rising sintering temperature. The oxygen vacancies in undoped TiO2 ceramics segregate at grain boundaries. With increasing the sintering temperature, the oxygen vacancy concentration of both grains and grain boundaries increase. There exist trivalence Ti3+ and grain boundaries absorbed oxygen in undoped TiO2 ceramics samples. Both absorbed oxygen content in grain boundaries and Ti3+ concentration increase with increasing sintering temperature. There are much pores in grains and grain boundaries of undoped TiO2 ceramics samples. The pores are mainly originated from the lattice oxygen volatilization and oxygen vacancies segregation at grain boundaries during high-temperature sintering.

Key words: TiO2 ceramic; defect chemistry; pores; microstructure

TiO2陶瓷是一种具有多种功能的电子陶瓷,在各个领域有着广泛的应用。电子功能陶瓷常采用干压成型工艺,这是由于干压成型的陶瓷坯体致密度高、成瓷密度高、瓷件内部气孔少和自动化程度高等优点,得到了快速发展。然而,干压成型的陶瓷件表面或内部气孔在生产过程中也时有发生,影响了电子功能陶瓷的质量和稳定性。陶瓷材料的气孔大小、气孔类型、气孔形态、气孔率和气孔聚集态与显微结构、电学性能、磁性性能和力学性能等均有非常密切的关系,是材料的重要性能指标[1-3]。通常采用光学显微镜、电子显微镜来检测、评价陶瓷中的气孔,还采用小角度中子散射和漫辐射传输方法表征孔的形态和孔的微结 构[4-5]。为了更深入地研究气孔的形成机理和规律,提出了在高温烧结过程中气孔形成的数学模型和变化规律[6-7]。景晓宁等[8]采用二维相场模型模拟固相陶瓷烧结后期,晶粒和气孔耦合生长演化过程,研究结果表明:气孔对晶界迁移和晶粒生长均产生钉扎作用。气孔的迁移、生长是与晶粒和晶界等显微结构密切相关。气孔的分布也与显微结构有关,圆形气孔位于两个晶粒之间,非圆形气孔至少位于3个晶粒之间[9],而且气孔会向晶粒内部迁移[10],并直接影响陶瓷的晶粒生长和致密化,最终影响陶瓷的显微结构和物理性能。这些理论与模型的建立为调控陶瓷的结构和性能的研究奠定了坚实的基础。

陶瓷中气孔产生的原因是多方面的[11],主要包括原料粉体的粒度与纯度、粉体的级配方案、造粒工艺、成型工艺和烧结工艺等,而提高原料纯度、减少原料水分、控制有机物添加量、改进造粒、成型与烧结工艺、提高排胶和烧结温度的时间可以有效降低气孔 率,提高陶瓷的物理性能。目前,陶瓷气孔的起源于4种机制:颗粒间隙的空气、添加有机物及杂质的挥发、相变引起的位错和晶界迁移形成的应力。由以上4种机制形成的气孔一般位于晶界、三叉晶界和四叉晶界,并随着烧结温度的增加和烧结时间的延长,气孔数量会减少,并逐渐沿晶界排除达到陶瓷致密化的目的[12]。在烧结初期,气孔和晶粒共同演变以降低总的表面能和晶界能。当原子沿着晶界向气孔扩散时气孔将会收缩。原子从脱离一个晶粒然后又与另一个晶粒结合而使晶粒生长。如果原子沿晶界扩散快,气孔将消失,大多数晶粒生长,通过烧结形成致密小晶粒陶瓷。当晶界迁移较快时,气孔无法维持原状,因此气孔将与晶界分离,最后形成多孔的粗晶粒陶瓷。而位于晶粒内部的气孔只有通过晶格扩散才能消除,但这个过程比晶界迁移要慢得多[10]。本文作者研究发现不掺杂TiO2陶瓷的气孔一般位于晶粒,并且随烧结温度和烧结时间的延长很难消除,这可能是不掺杂TiO2陶瓷在高温烧结过程中形成的点缺陷引起的。

比较常见的TiO2两种结构为锐钛矿型和金红石型,在高温锐钛矿型转变为金红石型。锐钛矿TiO2的点缺陷有这样的规律:在低温高氧分压下Schottky缺陷占优;在高温低氧分压,Frenkel缺陷占优[13]。在金红石TiO2中主要存在以下点缺陷:钛间隙Tii、钛空位VTi、氧间隙Oi和氧空位VO,并且随温度增加,缺陷形成能降低,有利于点缺陷的形成[14-15]。本文作者以锐钛矿TiO2为原料,在高温烧结过程中,锐钛矿转变为更稳定的金红石TiO2。且随着温度的升高,锐钛矿的晶格应力能和八面体位错能增加,锐钛矿的晶格位错有利于向金红石相转变[16]。经高温烧结的TiO2陶瓷中存在很多点缺陷,这些点缺陷对电子结构和电学性能有较为明显的影响,但对气孔的产生与运动是否有关联的研究鲜见相关报道。结果表明:点缺陷,特别是氧空位对于气孔形成具有直接影响。由于晶界原子排列比较疏松,晶界成为氧空位扩散的快速通道,此时,通过压应力和毛细管力的作用,氧空位沿着晶界运动直接导致多个小气孔在晶界的扩散、融合、长大最后形成较大的气孔[6]。本文作者将采用缺陷化学、SEM、EDS和XPS检测手段研究不掺杂TiO2陶瓷的氧空位与气孔形成的关联性,探讨不掺杂TiO2陶瓷气孔的形成机理。

1 实验

以分析纯的锐钛矿TiO2粉体为原料,采用传统电子陶瓷工艺一次烧成法制备TiO2陶瓷样品。将称量好的分析纯锐钛矿TiO2、玛瑙球、无水乙醇和去离子水按照一定比例加入玛瑙罐中,以250 r/min的转速在行星式球磨机研磨8 h,研磨后得到的浆料经烘干和造粒后,在140 MPa下干压成型制备成直径为13 mm,厚度为1.0~1.5 mm的TiO2素坯圆片,在650 ℃排胶后,分别在1 300、1 350和1 400 ℃和大气气氛进行无压烧结4 h得到直径为10 mm左右、厚度为1 mm左右的TiO2陶瓷样品。

用Philip ESEM X30扫描电镜测试样品的显微形貌,包括晶粒大小、气孔形态与分布。用EDAX EDS能谱仪测试样品的化学组成,包括晶粒、晶界和三叉晶界的化学组成。用XPS光电子能谱仪检测TiO2陶瓷中O和Ti的电子结构与离子价态,包括Ti3+和Ti4+的相对含量、晶格氧和吸附氧随烧结温度的变化规律。

2 结果与讨论

2.1 显微结构与组成

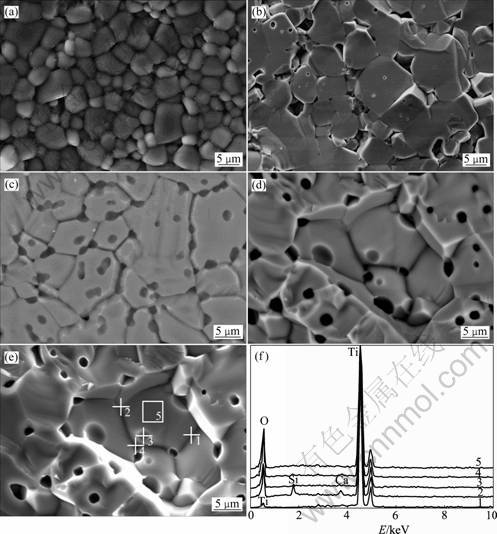

图1和表1所示为不掺杂TiO2样品的显微结构与组成。图1(a)为不掺杂TiO2素坯在650 ℃排胶后的SEM像,可以看出颗粒之间存在明显的气孔。图1(b)所示为在1 300 ℃烧结的不掺杂TiO2的SEM像,可以看出,晶粒明显长大,气孔数量减少,原来存在于颗粒间的气孔在晶粒生长过程中发生迁移、扩散和改变,在晶粒间形成一些较大的气孔。特别注意到,在图1(b)中晶粒存在一些较小的气孔。图1(c)所示为在 1 350 ℃烧结的不掺杂TiO2的SEM像,晶粒间的气孔比较少,但晶粒中的气孔却越来越多。图1(d)所示为在1 400 ℃烧结的不掺杂TiO2样品的SEM像,晶粒和晶界中存在许多气孔,气孔大都为圆形,直径最大为3 μm左右,最小为0.5 μm左右。由图1(a)~(d)可以看出:颗粒间的气孔随着烧结温度和时间的延长,在晶界迁移的带动下,气孔数量会减少,在界面形成较大的气孔,然后逐渐排除实现样品的致密化[14],但随着烧结温度的升高,晶粒中的气孔数量、尺寸和深度都逐渐增加,很明显这不是颗粒间气孔演变而来,这可能是高温烧结过程中肖特基热缺陷大量形成氧空位导致的。且随着烧结温度增加,各种点缺陷的形成能降低,氧空位等点缺陷在晶粒中大量产生[15],这些氧空位在晶界迁移过程中扩散、聚积和融合形成位于晶粒中的气孔。由于晶粒的气孔只有通过晶格扩散才能消除,而晶格扩散比晶界迁移要慢得多,因此晶粒中的气孔很难消除[10]。

图1 不掺杂TiO2样品的显微结构与组成

Fig.1 Microstructures and EDS spectra of undoped TiO2 samples: (a) After binder removal; (b) Sintered at 1 300 ℃; (c) Sintered at 1 350 ℃; (d) Sintered at 1 400 ℃; (e) Schematic diagram of positions; (f) EDS spectra of positions in Fig.(e)

由图1(e)和(f)以及表1可知:不掺杂TiO2样品的晶粒由Ti和O组成,而Si和Ca等杂质聚集在三叉晶界处。晶界和晶粒的能谱分析表明:Ti的相对含量高于面分析的平均组成,特别是点2对应的晶界,其Ti含量远大于平均组成,Ti含量的增加可以认为氧空位浓度较高,导致O的挥发而产生的。

三叉晶界由于SiO2和CaO等氧化物的聚积,其O含量较高,导致Ti与O的组成与平均组成比较接近。同时晶界中存在氧吸附,使得三叉晶界中的氧空位减少,氧含量比晶粒中要高[17],吸附气体与瓷体之间的电子转移即形成化学键。在低温时为物理吸附,而当温度较高时由物理吸附转变为化学吸附,由于晶界是氧扩散的快速通道,因此在晶界发生如式(1)反应,氧聚积在三叉晶界。

(1)

(1)

式中: 为带2个单位正电荷的氧空位的缺陷;

为带2个单位正电荷的氧空位的缺陷; 为在氧位不带电荷不形成缺陷的氧。

为在氧位不带电荷不形成缺陷的氧。

2.2 缺陷化学

2.2.1 晶粒的缺陷化学

冯少新等[18]研究结果表明:金红石TiO2中Schottky点缺陷为本征缺陷,如式(2)。YANG和WU等[19]研究TiO2 陶瓷烧结动力学发现其烧结过程的传质机制主要依赖于氧空位,金红石相TiO2 在大气环境中高温热平衡状态的主要点缺陷是氧空位,其缺陷反应式如式(3)。随着烧结温度的增加,钛空位浓度会有一定程度增加但非常有限,且随着温度的升高,缺陷反应式(3)会向右进行生成大量氧空位,由式(2)和(3)得知,氧空位浓度的增加会抑制钛空位浓度的增加。在1400℃烧结的样品由于温度过高产生过多氧空位,氧气从晶粒排出而形成气孔导致晶粒中的O含量较低,因此可以认为图2(a)和(b)中的气孔是由于有大量氧挥发而形成的。

null

(2)

(2)

(3)

(3)

式中:null表示完整晶体无缺陷状态; 为带4个单位负电荷钛空位的缺陷;

为带4个单位负电荷钛空位的缺陷; 为三价钛占据钛位带一个单位负电荷的缺陷。

为三价钛占据钛位带一个单位负电荷的缺陷。

根据不掺杂TiO2陶瓷在高温固相烧结的特征,可以认为是属于非化学计量比或组分缺陷TiO2-x。BAK等[20]详细研究了TiO2在不同温度和氧分压下的缺陷浓度。研究结果显示:随氧分压增加,电子n、氧空位 、三价间隙钛离子

、三价间隙钛离子 和四价间隙钛离子

和四价间隙钛离子 的浓度以及组分缺陷TiO2-x中氧的减少量x的值均减少,而空穴p的浓度增加;随烧结温度的增加,各种缺陷浓度和x都增加。这可能是解释不掺杂TiO2晶粒中Ti的相对含量增加而O的相对含量减少的原因之一。氧空位的增加意味着更多的O从晶格中逸出,而与O成化学计量比的Ti随着O的逸出进入TiO2晶格中的间隙位置而保持较高的Ti含量。在O分压较低时,间隙三价Ti离子浓度比间隙四价Ti离子浓度要高,在高氧分压三价间隙钛离子浓度较低,这主要是氧化性增强,使部分三价钛离子被氧化失去一个电子变成四价钛离子。

的浓度以及组分缺陷TiO2-x中氧的减少量x的值均减少,而空穴p的浓度增加;随烧结温度的增加,各种缺陷浓度和x都增加。这可能是解释不掺杂TiO2晶粒中Ti的相对含量增加而O的相对含量减少的原因之一。氧空位的增加意味着更多的O从晶格中逸出,而与O成化学计量比的Ti随着O的逸出进入TiO2晶格中的间隙位置而保持较高的Ti含量。在O分压较低时,间隙三价Ti离子浓度比间隙四价Ti离子浓度要高,在高氧分压三价间隙钛离子浓度较低,这主要是氧化性增强,使部分三价钛离子被氧化失去一个电子变成四价钛离子。

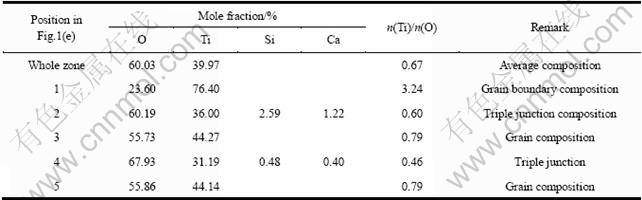

表1 不掺杂TiO2样品化学组成的EDS分析

Table 1 EDS analysis of chemical compositions of undoped TiO2 samples

本文作者制备的TiO2样品是在大气中烧结的,根据BAK等[20]的缺陷方程及其平衡常数考虑,在1.01×105 Pa下,计算了在不同烧结温度不掺杂TiO2样品晶粒的缺陷浓度。不掺杂TiO2的缺陷化学如下:

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

式中: 表示电子带一个单位负电荷;

表示电子带一个单位负电荷; 表示空穴带一个单位正电荷。

表示空穴带一个单位正电荷。

相应平衡常数的表达式如下:

(8)

(8)

(9)

(9)

(10)

(10)

(11)

(11)

式中:K为平衡常数;n为电子浓度;p为空穴浓度。

缺陷化学理论的基础是质量作用定律,因此任何缺陷的形成和消失都可用准化学反应方程式加以描述。化学反应的平衡常数K可表述如下:

(12)

(12)

通常 和

和 都是温度的函数,但在不太十分严格的情况下,可把

都是温度的函数,但在不太十分严格的情况下,可把 和

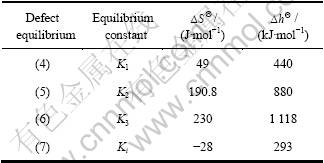

和 视为常数,其取值见表2,根据表2的热力学数据和温度可求解各个准化学反应的平衡常数,计算得到如表3所列的平衡常数。

视为常数,其取值见表2,根据表2的热力学数据和温度可求解各个准化学反应的平衡常数,计算得到如表3所列的平衡常数。

根据缺陷化学平衡方程式(4)~(7)可得到缺陷浓度和电中性条件,如式(13)~(17)。

(13)

(13)

(14)

(14)

(15)

(15)

(16)

(16)

(17)

(17)

将式(13)~(17)联立起来,得到

(18)

(18)

表2 TiO2缺陷平衡的热力学数据[20]

Table 2 Thermodynamic quantities related to defect equilibria in TiO2[20]

表3 不同温度下的缺陷反应平衡常数

Table 3 Equilibrium constant of defect equilibria in TiO2 at different temperatures

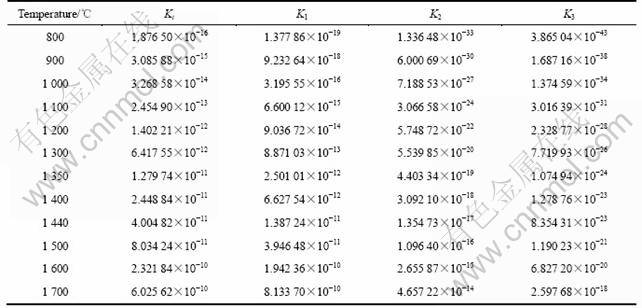

式(18)是一个多项式函数,可利用Excel软件的数值分析方法进行迭代求解,可求出不同温度下的缺陷浓度,计算结果如图2所示。图2表明:随温度增加,所有缺陷浓度均增加,这与BAK等[20]的研究结果是一致的。以上缺陷化学分析表明:三价钛离子浓度是随温度升高而增加,这是由于 TiO2晶格中Ti位上Ti4+获得一个电子被还原成Ti3+;Ti4+则形成点缺陷 ,成为氧空位的补偿方式之一,如式(3)所示。

,成为氧空位的补偿方式之一,如式(3)所示。

图2 不掺杂TiO2陶瓷的缺陷浓度随烧结温度的变化曲线

Fig.2 Various curves of defect concentration of undoped TiO2 vs sintering temperature T

2.2.2 氧空位的晶界分布

点缺陷是电子功能陶瓷的重要研究内容之一,晶粒和晶界中的缺陷分布都是影响显微结构和电学性能的主要因素之一。由以上讨论可知,晶粒中的点缺陷浓度随温度升高而增加,而晶界的点缺陷分布则可根据晶粒内的缺陷化学方程和点缺陷热力学原理得到[21-22]。金红石TiO2中的本征缺陷为Schottky(肖特基)点缺陷,如式(2)所示,体相电中性条件如式(19)所示:

(19)

(19)

根据点缺陷热力学的基本原理和TiO2的肖特基点缺陷,可以得到TiO2陶瓷晶界的点缺陷氧空位和钛空位的浓度表达式[23],如式(20)和(21)。

(20)

(20)

(21)

(21)

式中: 为离开晶界中心x处的钛空位浓度;

为离开晶界中心x处的钛空位浓度; 为离开晶界中心x处的氧空位浓度;

为离开晶界中心x处的氧空位浓度; 为钛空位形成能,eV;

为钛空位形成能,eV; 为氧空位形成能,eV;

为氧空位形成能,eV; 为离开晶界中心x处的静电势;k为波尔兹曼(k=1.38×10-23 J/K);T为烧结温度,K;e为一个电子所带的电荷。

为离开晶界中心x处的静电势;k为波尔兹曼(k=1.38×10-23 J/K);T为烧结温度,K;e为一个电子所带的电荷。

由式(19)~(21)得出体相和边界之间不同的静电势:

=0.05 eV (22)

=0.05 eV (22)

在式(20)和(21)中,x=0时,代表所在位置是晶界中心,x就是距晶界中心的距离;当x=∞时,代表晶粒内部,此时静电势将不再变化,晶界静电势的分布如式(23)。

(23)

(23)

式中:Φ(x)为离开晶界中心x处的静电势;Φ∞为晶界中心电势为0时晶粒内部的静电势;δ为Debye长度,表示静电势的屏蔽能力的大小与屏蔽半径。Debye长度可以由式(24)得到:

(24)

(24)

式中:ε0为真空的介电常数,ε0=8.854×10-12;ε为TiO2的静态相关介电常数,ε=120;Ni为每种离子的浓度,cm-3;Zi为每种离子的有效电荷。

由式(24)可知,晶界静电势主要由晶粒静电势Φ∞和Debye长度δ决定。Φ∞与缺陷形成能、氧分压、掺杂以及温度有直接关系。Debye长度δ随温度T、离子浓度Ni和离子有效电荷Zi变化,而离子浓度和离子电荷也是由缺陷化学、氧分压和掺杂等因素决定的。

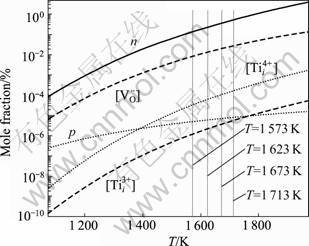

当氧空位形成能 、钛空位形成能

、钛空位形成能 分别为2.2 eV和2.5 eV,Debye长度为80.2 ?时,得到了TiO2陶瓷的晶界静电势分布和晶界缺陷浓度,见图3(a)和(b)。图3(a)所示的静电势Φ(x),当距晶界中心的距离(x)与Debye长度(δ)的比值即x/δ=4.65左右时,Φ(x) 不再增加,这就是体相相对于晶界中心的静电势Φ∞。空间电荷静电势为正,表明晶界中心表面存在过剩的负电荷,为维持整体电中性条件,正电荷

分别为2.2 eV和2.5 eV,Debye长度为80.2 ?时,得到了TiO2陶瓷的晶界静电势分布和晶界缺陷浓度,见图3(a)和(b)。图3(a)所示的静电势Φ(x),当距晶界中心的距离(x)与Debye长度(δ)的比值即x/δ=4.65左右时,Φ(x) 不再增加,这就是体相相对于晶界中心的静电势Φ∞。空间电荷静电势为正,表明晶界中心表面存在过剩的负电荷,为维持整体电中性条件,正电荷 必须在空间电荷层偏析而负电荷

必须在空间电荷层偏析而负电荷 则空间电荷层耗尽,图3(b)表明氧空位在晶界空间电荷层偏析浓度比体相要高,相反地,钛空位在空间电荷层耗尽其浓度比体相低;钛空位

则空间电荷层耗尽,图3(b)表明氧空位在晶界空间电荷层偏析浓度比体相要高,相反地,钛空位在空间电荷层耗尽其浓度比体相低;钛空位 和氧空位

和氧空位 浓度在体相保持电中性。随温度增加,缺陷浓度增加,这是由于Schottky缺陷是热缺陷,温度升高,缺陷形成能降低,缺陷浓度会大幅增加[15]。

浓度在体相保持电中性。随温度增加,缺陷浓度增加,这是由于Schottky缺陷是热缺陷,温度升高,缺陷形成能降低,缺陷浓度会大幅增加[15]。

图3 以Schottky点缺陷为主的TiO2的晶界静电势和晶界缺陷浓度分布

Fig.3 Electrostatic potential(a) and defect concentration distributions at grain boundaries(b) of TiO2 with Schottky disorder

根据晶粒内的缺陷热力学和缺陷化学方程,可以得到晶粒内的平衡缺陷浓度,再联立空间电荷层的表达式,即可得出点缺陷从晶界到晶粒内部的变化趋势。由点缺陷分析可知:随烧结温度增加,晶粒中的氧空位浓度增加,并在晶界偏析聚积,而使气孔生长,这就是随烧结温度增加,气孔率增加的原因。

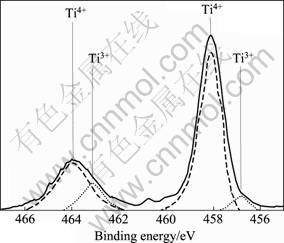

2.3 XPS分析

高温烧结的TiO2样品中的钛离子价态可用XPS来检测,其检测结果如图4所示。图4中四价钛离子的Ti 2p1/2能级的结合能463.85 eV, Ti 2p3/2能级的结合能458.12 eV,三价钛离子的Ti 2p1/2能级的结合能463.12 eV, Ti 2p3/2能级的结合能456.85 eV。三价和四价钛离子Ti 2p的XPS电子能谱的峰值与ATUCHIN等[24]研究Ti离子的XPS结果是一致的。不同价态钛离子的Ti 2p的XPS结合能表明:随价态的增加,其对应的结合能会增加。在高温烧结过程中,大量氧空位的形成释放较多电子,这些电子有可能被TiO2晶粒中Ti位上的结合能较高的四价钛离子Ti4+俘获变成结合能较低的三价钛离子Ti3+。图4所示的Ti2p的XPS光电子能谱表明:高温烧结TiO2陶瓷样品中是存在三价钛离子,这与缺陷化学方程式(3)和(5)是相吻合的。

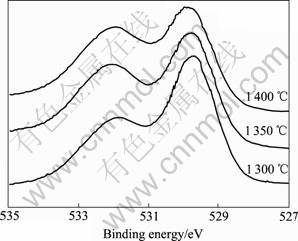

图5所示为不掺杂TiO2陶瓷的O 1s的XPS谱。由图5可以看出,O 光电子谱主要由两个光电子峰组成:一是结合能为529.7 eV的TiO2中的晶格氧,二是结合能为531.8 eV的吸附氧,它与样品中氧空位有关,氧空位浓度越高吸附氧的XPS峰就越明显。由图4可知,随烧结温度的增加吸附氧的含量增加,这与显微结构、缺陷化学和显微组成分析表明随烧结温度增加氧空位增加的结论是一致的。不掺杂TiO2的半导化主要是高温氧空位导致的。在TiO2样品表面主要存在晶格氧和吸附氧,而在体相深处晶粒内部只存在晶格氧。图5表明:不掺杂TiO2陶瓷样品中存在吸附氧,吸附氧来源于高温烧结过程中氧空位形成释放出的晶格氧。

图4 不掺杂TiO2陶瓷Ti 2p的XPS谱

Fig.4 XPS spectra of Ti 2p in undoped TiO2

图5 不掺杂TiO2陶瓷的O 1s的XPS谱

Fig.5 XPS spectra of O 1s in undoped TiO2

以上缺陷化学讨论和XPS检测可以证明存在氧空位,氧空位逐渐演变成气孔。氧空位在晶界扩散、迁移形成气孔的过程中,一部分从晶格挥发的氧会在晶界、三叉晶界或者样品表面成为吸附氧,吸附氧的化学环境与TiO2晶格中的晶格氧的化学环境是不一样的(见图5)。不掺杂TiO2陶瓷的气孔是由于氧空位的偏析、扩散、聚集、融合和迁移的结果。

3 结论

1) 随烧结温度增加,颗粒间的气孔逐渐减少,而不掺杂TiO2陶瓷晶粒中的气孔则逐渐长大,这由于氧空位浓度随温度增加而增加引起的。

2) 不掺杂TiO2陶瓷的氧空位在晶界出现偏析行为,并随烧结温度增加,晶粒中的氧空位浓度和晶界氧空位浓度均增加。

3) 不掺杂TiO2陶瓷中存在三价钛离子和晶界吸附氧,三价钛离子浓度和晶界吸附氧含量随烧结温度增加而增加。不掺杂TiO2陶瓷晶界吸附氧来源于高温烧结过程中氧空位形成释放出的晶格氧。

4) 不掺杂TiO2陶瓷晶粒和晶界中有较多气孔,气孔主要起源于高温烧结过程中氧空位在晶界的偏析和晶格氧的挥发。

REFERENCES

[1] 曹明贺, 孙越魁, 蒋 军, 刘韩星, 袁 俊. 多晶CaB6陶瓷弱铁磁性能与气孔率关系[J]. 无机材料学报, 2006, 21(3): 640-644.

CAO Ming-he, SUN Yue-kui, JIANG Jun, LIU Han-xing, YUAN Jun. Relationship of ferromagnetic property with porosity of polycrystalline CaB6 ceramics[J]. Journal of Inorganic Materials, 2006, 21(3): 640-644.

[2] ZENG Tao, DONG Xian-lin, MAO Chao-liang, ZHOU Zhi-yong, YANG Hong. Effects of pore shape and porosity on the properties of porous PZT 95/5 ceramics[J]. Journal of the European Ceramic Society, 2007(27): 2025-2029.

[3] BOBYLEV S V, MOROZOV A N F, OVID’KO I A. Nucleation of dislocations and the growth of nanosize pores in deformable nanocrystalline ceramics[J]. Doklady Physics, 2009, 54(4): 174-177.

[4] SEN D, PATRA A K, MAZUMDER S, ROMANATHAN S. Pore morphology in sintered ZrO2-8 mol% Y2O3 ceramic: A small-angle neutron scattering investigation[J]. Journal of Alloys and Compounds, 2002, 340: 236-241.

[5] MANARA J, CAPS R, RAETHER F, FRICKE J. Characterization of the pore structure of alumina ceramics by diffuse radiation propagation in the near infrared[J]. Optics Communications, 1999, 168: 237-250.

[6] LU G Q. Evolution of the pore structure of a ceramic powder compact during sintering[J]. Journal of Materials Processing Technology, 1996, 59: 297-302.

[7] SHI J L. Solid state sintering of ceramics: Pore microstructure models, densification equations and applications[J]. Journal of Materials Science, 1999, 34: 3801-3812.

[8] 景晓宁, 赵建华, 何陵辉. 固相烧结后期晶粒和气孔拓扑生长演化的二维相场模拟[J]. 材料科学与工程学报, 2003, 21(2): 170-173.

JING Xiao-ning, ZHAO Jian-hua, HE Ling-hui. 2-D phase field simulation of coupled pore and grain topological evolution during final stage sintering[J]. Journal of Materials Science & Engineering, 2003, 21(2): 170-173.

[9] TOMANDL G, VARKOLY P. Three-dimensional computer modeling of grain growth and pore shrinkage during sintering[J]. Materials Chemistry and Physics, 2001, 67: 12-16.

[10] YU H H, SUO Z. An axisymmetric model of pore-grain boundary separation[J]. Journal of the Mechanics and Physics of Solids, 1999, 47: 1131-1155.

[11] 张光明, 张本清. 干压成型陶瓷气孔成因探析[J]. 真空电子技术, 2007(4): 85-86.

ZHANG Guang-ming, ZHANG Ben-qing. Formation mechanism of pores in ceramics by dry pressing forming[J]. Vacuum Electronics, 2007(4): 85-86.

[12] YANG C C T, WEI W C J. Reaction kinetics and mechanisms between La0.65Sr0.3MnO3 and 8 mol% yttria-stabilized zirconia[J]. J Am Ceram Soc, 2004, 87(6): 1110-1116.

[13] WEIBEL A, BOUCHET R, KNAUTH P. Electrical properties and defect chemistry of anatase (TiO2)[J]. Solid State Ionics, 2006, 177: 229-236.

[14] PENG Hao-wei. First-principles study of native defects in rutile TiO2[J]. Physics Letters A, 2008, 372: 1527-1530.

[15] LI X, FINNIS M W, HE J, BEHERA R K, PHILLPOT S R, SINNOTT S B, DICKEY E C. Energetics of charged point defects in rutile TiO2 by density functional theory[J]. Acta Materialia, 2009, 57: 5882-5891.

[16] 郑遗凡, 李国华, 田 伟, 马淳安. 纳米锐钛矿相变的原位XRD研究[J]. 无机化学学报, 2007, 23(6): 1121-1125.

ZHENG Yi-fan, LI Guo-hua, TIAN Wei, MA Chun-an. In situ XRD study on the phase transformation of nanoanatase[J]. Chinese Journal of Inorganic Chemistry, 2007, 23(6): 1121-1125.

[17] 黎步银, 周东祥, 姜胜林, 吕文中, 龚树萍. TiO2高温电导及缺陷化学分析[J]. 压电与声光, 2001, 23(6): 473-477.

LI Bu-yin, ZHOU Dong-xiang, JIANG Sheng-lin, L? Wen-zhong, GONG Shu-ping. High temperature conductivity and defect chemistry of TiO2[J]. Piezoelectrics & Acoustooptics, 2001, 23(6): 473-477.

[18] 冯少新, 李宝会, 金庆华, 郭振亚, 丁大同. 金红石结构TiO2晶体点缺陷形成能的经验途径计算[J]. 物理学报, 2000, 49(7): 1307-1311.

FENG Shao-xin, LI Bao-hui, JIN Qing-hua, GUO Zhen-ya, DING Da-tong. Em pirlcal calculatlons of the formatlon energles of point defects in rutile TiO2[J]. Acta Physica Sinica, 2000, 49(7): 1307-1311.

[19] YANG Seng-lu, WU Jenn-ming. Effects of Nb2O5 in (Ba, Bi, Nb)-added TiO2 ceramic resistors[J]. J Mater Res, 1995, 10(2): 345-352.

[20] BAK T, NOWOTNY J, REKAS M, SORRELL C C. Defect chemistry and semiconducting properties of titanium dioxide (Ⅱ): Defect diagrams[J]. Journal of Physics and Chemistry of Solids, 2003, 64: 1057-1067.

[21] 周志刚, 唐子龙. 高技术陶瓷材料点缺陷化学和物理[J]. 无机材料学报, 2009, 24(3): 417-426.

ZHOU Zhi-gang, TANG Zi-long. Chemistry and physics of point defects in advanced ceramics[J]. Journal of Inorganic Materials, 2009, 24(3): 417-426.

[22] BATAILLE A, ADDAD A, COURTOIS C, DUHOO T, CRAMPON J. Solute and defect segregation at the space charge layers of Fe-doped fine-grained Al2O3: Effect on the creep rate[J]. Journal of the European Ceramic Society, 2008, 28: 1129-1134.

[23] WANG Qing-lei, LIAN Guo-da, DICKEY E C. Grain boundary segregation in yttrium-doped polycrystalline TiO2[J]. Acta Materialia, 2004, 52: 809-820.

[24] ATUCHIN V V, KESLER V G, PERVUKHINA N V, ZHANG Zhao-ming. Ti2p and O1s core levels and chemical bonding in titanium-bearing oxides[J]. Journal of Electron Spectroscopy and Related Phenomena, 2006, 152: 18-24.

(编辑 李艳红)

基金项目:云南省自然科学基金资助项目(2008ZC014M);昆明理工大学科研基金资助项目(2010-08);昆明理工大学分析测试基金资助项目(2009-013, 2009-016, 2009-030, 2009-031)

收稿日期:2010-06-28;修订日期:2010-09-20

通信作者:严继康,副教授,博士;电话:0871-2902311;E-mail: scyjk@sina.com