DOI: 10.11817/j.ysxb.1004.0609.2021-37828

基于落重试验的离散元多颗粒黏结建模技术

王 晓1, 2,薛玉君1, 2,刘 俊3,杨纪昌3,邹声勇3,Zhiqiang GUAN4,李济顺1, 2

(1. 河南科技大学 机电工程学院,洛阳 471003;

2. 河南省机械设计及传动系统重点实验室(河南科技大学),洛阳 471003;

3. 矿山重型装备国家重点实验室(中信重工机械股份有限公司),洛阳 471003;

4. School of Mechanical and Mining Engineering, University of Queensland, Brisbane 4072, Australia)

摘 要:确定磨矿工艺参数以保证最佳的物料粒度分布是近年来矿物加工研究的热点,而矿物加工过程的物料粒度控制是提高选矿效率的关键。离散元法(DEM)仿真是研究物料破碎过程的有效方法,物料模型的构建对离散元仿真结果有显著影响。本文基于物料落重试验,提出了离散元仿真用多颗粒黏结模型关键参数颗粒组成和颗粒间黏结键参数值的设置方法。应用该方法对单块矿石进行了多颗粒黏结建模,通过离散元仿真冲击破碎过程,得到了单块矿石的破碎粒度分布。离散元仿真结果与落重试验得到的破碎粒度分布具有良好的一致性,表明该建模技术可以表征矿石物料的破碎特性,为破磨过程仿真提供了一种有效的物料建模方法。

关键词:物料破碎;落重试验;颗粒粒度;离散元仿真;多颗粒黏结模型

文章编号:1004-0609(2021)-08-2258-11 中图分类号:TD453;TP391.9 文献标志码:A

引文格式:王 晓, 薛玉君, 刘 俊, 等. 基于落重试验的离散元多颗粒黏结建模技术[J]. 中国有色金属学报, 2021, 31(8): 2258-2268. DOI: 10.11817/j.ysxb.1004.0609.2021-37828

WANG Xiao, XUE Yu-jun, LIU Jun, et al. DEM multi-particle bonding modeling based on drop weight test[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2258-2268. DOI: 10.11817/j.ysxb.1004.0609.2021-37828

物料破磨加工在矿山、冶金、水泥、化工等行业生产中占有重要地位,物料破碎粒度控制是影响产品性能、选矿效率的关键因素。影响物料破碎粒度因素很多,除了机械设备参数如磨机衬板结构和磨介形状、工艺参数如填充率和进料量,物料自身材料特性也是直接影响破碎效果的重要因素[1-4]。

确定物料特性的主要试验方法有落重试验(Drop weight test, DWT)、半自磨机粉碎试验(SAG mill comminution, SMC)试验、摆锤试验等[5-6]。通过试验测定矿石的不同特性参数,如特定尺寸筛下产率、腐蚀系数、硬度、可磨度系数、邦德功指数、粒度分布等,这些参数能够表征矿石在磨矿过程中的破碎难易程度[7-8]。

由于矿石特性复杂多变,不同地区不同批次矿石特性都不同,导致每次更换矿石物料都需要提前测定其特性来制定合适的破磨工艺,步骤较为繁琐,且试验测定仅满足于小尺寸试验机设备,与实际生产设备相差较大。为解决矿石性质多变造成的破磨工艺制定复杂的问题,许多学者开始着手进行针对矿石破碎过程的仿真研究。

物料破碎的离散元法(DEM)仿真是研究物料破碎过程的有效方法,其仿真的有效性取决于矿物物料的离散元建模技术。颗粒破碎建模方法主要有基于颗粒黏结模型(Bonded-particle model, BPM)方法和碎片替换方法(Fragment replacement method, FRM)两种。BPM模型对一定数量及粒度的小颗粒进行黏结构成可破碎的大颗粒,通过黏结键的断裂模拟颗粒破碎行为;FRM则采用一组无黏结的小颗粒替代发生破碎的大颗粒,达到预先设定的颗粒破坏规则后,小颗粒组将直接替换大颗粒。基于BPM的颗粒破碎模拟方法能够反映颗粒强度的尺寸效应,可以很好地再现可碎颗粒集合体的复杂力学响应,缺点在于计算成本高且组成团簇的子颗粒不能进一步破碎[9-10]。此外学者们还提出了多体颗粒破碎的弹簧-四面体单元模型、基于分形维数的破碎形态模型、凝聚颗粒快速生成模型等[11-14]。从上述众多研究可以看出,颗粒破碎建模多集中在针对特定结构物料破碎特性的研究及对破碎效果的评判方面,对于矿石内部多变的力学特性方面考虑较少,如何确定颗粒破碎模型中关键参数如颗粒粒径、黏结键参数如法向刚度、剪切刚度、抗拉强度、剪切强度、黏结键半径等方面的研究更少。由于单颗粒破碎模型与磨矿过程颗粒阶段性破碎关联研究较少,造成了颗粒破碎模型和实际破碎过程有很大差距。

为解决物料建模不准确造成的破碎仿真失真等问题,本文基于落重试验结果,确定多颗粒黏结模型的特征参数,对物料建模关键参数黏结键值及粒度组成的选择方法进行分析及优化。设计多颗粒黏结模型冲击破碎仿真,对比仿真破碎物料粒度分布与落重试验得到的粒度分布,验证多颗粒黏结破碎模型的建模有效性。

1 矿物多颗粒黏结模型

颗粒黏结模型(Bonded-particle model,BPM)是一种通过黏结键黏结一定数量的子颗粒组成团聚体,当子颗粒间的黏结键失效达到一定数目时,颗粒团聚体发生破碎的颗粒破碎模型[15]。

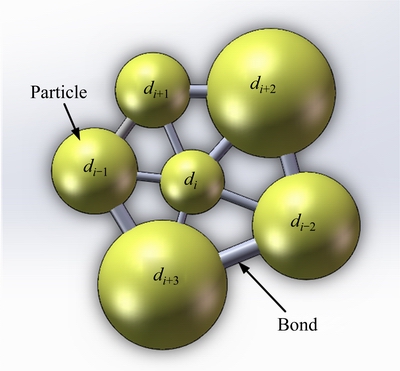

图1 颗粒黏结结构

Fig. 1 Particle bonding structure

BPM模型是一种根据损伤发展和破裂过程来理解岩石力学模型的直接建模方法,它将材料理想化为结构单元的集合或在其接触点黏合在一起的单独颗粒,并利用结构单元或键的断裂来表示损伤,颗粒黏结结构如图1所示。BPM模拟了类似水泥黏结剂连接的一组颗粒的力学行为,其特征是颗粒密度、颗粒形状、颗粒尺寸分布、颗粒堆积和颗粒-黏结剂微观性能。其中颗粒密度不影响准静态行为,颗粒形状为球形,颗粒尺寸分布满足Dmin和Dmax限定的均匀颗粒尺寸分布,颗粒堆积在材料形成过程中获得。颗粒-黏结剂的每个胶结接触基于黏结剂的部分即为黏结键,可视为梁,其力-位移行为由以下五个定义平行黏结的微观参数描述:单位面积的法向刚度Kn、剪切刚度Ks,抗拉强度σc,剪切强度τc,黏结半径乘数λ。仿真中需要确定的黏结键参数如下:法向刚度,剪切刚度,抗拉强度,剪切强度,黏结键半径。

(1)

(1)

(2)

(2)

式中:△Fn、△Fs分别为单位时间内材料所受的轴向力增量和剪切力增量;△Un、△Us分别为单位时间内轴向位移增量和剪切位移增量;A为黏结键横截面积。

当最大拉应力超过抗拉强度(σmax≥σc)或最大剪应力超过剪切强度(τmax≥τc),则黏结键断裂[15]。其中:

≥

≥ (3)

(3)

≥

≥ (4)

(4)

式中:Fn、Fs分别为颗粒所受法向力和剪切力;Mn、Ms分别为颗粒所受的法向力矩和剪切力矩;A为黏结键横截面积;I为黏结键的转动惯量;J为黏结键的极转动惯量。

BPM模型的微观性能包括颗粒粒度和黏结键的刚度、强度和半径。粒径会影响物料的断裂韧性,从而影响破坏过程;而黏结键的形成、结合和破坏过程则表示了微观损伤过程并由此形成宏观断裂;颗粒粒度和颗粒间黏结键是构建BPM模型的两个关键参数[15]。

针对BPM模型中子颗粒不能进一步破碎造成的破碎粒度局限性,优化颗粒黏结模型粒度选取方法,选择多种粒度的小颗粒为基础颗粒组,构成矿石多颗粒黏结破碎模型。根据实际矿石破碎粒度分布,选取若干小粒度颗粒构成基础颗粒组,进而由黏结键黏结构成大颗粒,从而实现不同粒度表征。不同粒度颗粒组合弥补单一颗粒构成物料时造成的孔隙率过大问题,与实际矿石结构更为贴合。

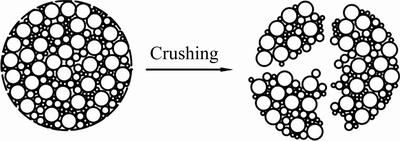

针对实际矿石内部性质不均的问题,将基础颗粒生成方式设计为随机生成。通过施加一定外部压力使其团聚成颗粒集合体,组成矿石的小颗粒之间由黏结键连接,不同颗粒间黏结键变化代表矿石内部力学结构的不均性,同时不同颗粒的随机组合能够一定程度表征矿石内部复杂的晶体结构。多颗粒黏结模型破碎过程如图2所示。

多颗粒黏结破碎模型关键参数包括基础小颗粒粒度和颗粒间黏结键。基础颗粒组即组成矿石的最小颗粒,受BPM模型构建原理的影响,其粒度选取直接代表破碎后最小颗粒粒度;颗粒间黏结键则对破碎难易程度和破碎后粒度分布有决定性影响。

图2 多颗粒黏结模型破碎过程示意图

Fig. 2 Schematic diagram of crushing process of multi- particle bonding model

2 物料落重试验

2.1 落重试验方法

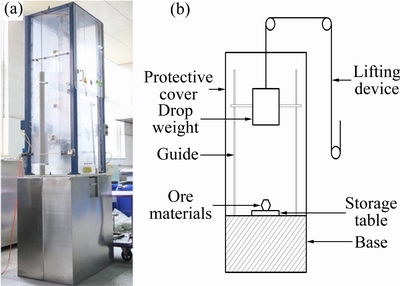

物料特性冲击破碎试验通常采用JKTech落重试验机,试验机及原理如图3所示。落锤从预定高度沿导轨自由落体冲击矿石物料,冲击结束后收集破碎物料进行粒度筛分结果分析。保护罩用于防止冲击碎块飞溅,导轨用于防止落锤冲击后回弹造成二次破碎。

图3 落重试验机及原理示意图

Fig. 3 Drop-weight test machine(a) and schematic diagram(b)

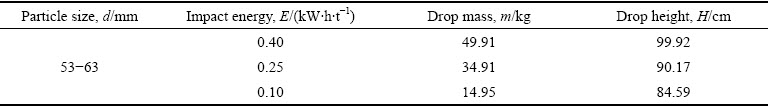

选取粒度范围53~63 mm的单块金矿石作为试验对象,进行10次重复性试验,最终汇总筛分并统计不同粒级产物质量。具体试验参数如表1所示。

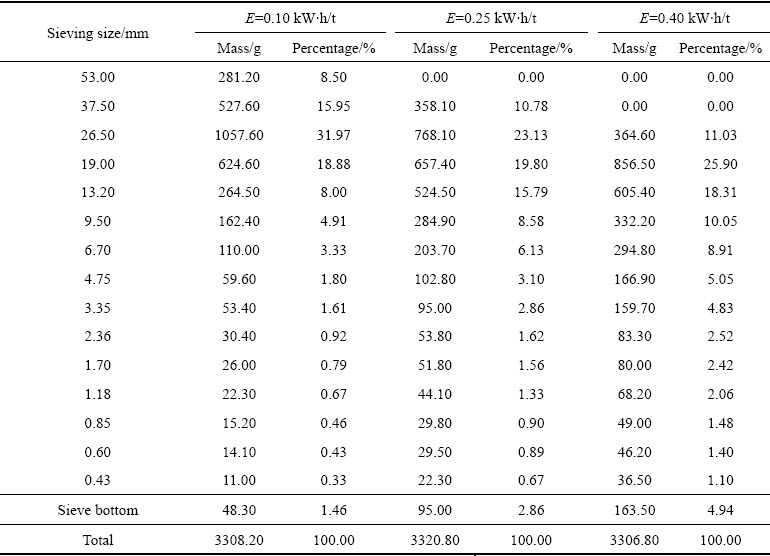

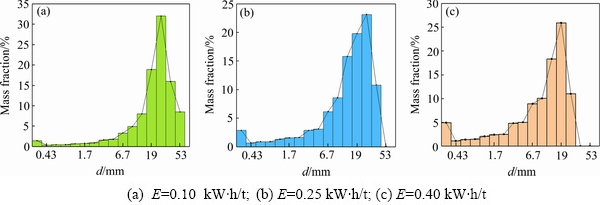

2.2 物料破碎粒度分布

通过3种冲击能量的落重试验,得到的物料筛分粒度及筛余质量如表2所示。从表2可以看出,随冲击能量增大,破碎后最大粒度减小;粒度质量分数随粒度的增大先增加后减小,存在单个峰值。三种冲击能量下破碎的物料粒度质量分布如图4所示。由图4可知,曲线峰值在19~26.5 mm粒级之间,曲线峰值处粒度随冲击能量的增加而减小。除去筛底粉磨质量分数,筛上质量分数大于5%的组份在6.7 mm粒级以上,6.7 mm粒级以下组份质量占比较小;3种冲击能量下6.7 mm粒度以上颗粒总质量分数分别达到91.53%、84.22%和74.20%,破碎结果主要粒度在6.7 mm粒级以上。

表1 不同冲击能量下落重试验参数

Table 1 Drop-weight test parameters under different impact energies

表2 落重试验物料粒度分布

Table 2 Particle size distribution of drop weight test

图4 不同冲击能量下破碎的物料粒度质量分布柱状图

Fig. 4 Histogram of crushed particle size and mass distribution under different impact energies

3 多颗粒黏结破碎模型参数确定

3.1 基础颗粒粒度

3.1.1 基础颗粒粒度确定方法

假设基础颗粒最大直径即过筛直径,当过筛直径与筛分粒级相同时,颗粒恰好可以被该粒级筛分。设粒级编号为m时,物料过筛直径为Dm。

假定破碎后各粒级黏结颗粒由基础颗粒组成,取最小基础颗粒个数为组成条件且基础颗粒粒径不唯一,即存在基础颗粒组。n个基础颗粒的粒径用d1,d2,…,dn表示,则黏结颗粒最大直径与基础颗粒粒径之间满足线性关系,即当粒级编号为m时,单一粒级黏结颗粒最大直径Dm[D1] 满足如下关系式:

(5)

(5)

式中:Dm代表粒级编号为m时黏结颗粒的最大直径,mm;ki代表粒径为di的基础颗粒个数;dn代表粒级为i的基础颗粒直径,mm。

当破碎粒级出现若干组时,基础颗粒组应同时满足所有粒级黏结颗粒最大粒径,即破碎后各粒级黏结颗粒与基础颗粒组满足矩阵方程:

(6)

(6)

式中:kmn为粒级m时粒径为dn的基础小颗粒个数,其余参数与式(5)中一致。

在进行模型构建时,根据不同矿石实际破碎粒度分布选取合适的基础颗粒粒度及数量,可灵活表达各粒级的粒度组成。

3.1.2 基于落重试验的基础颗粒粒度确定

根据物料落重试验中的粒度分布情况选取黏结模型中的基础颗粒粒度。由落重试验数据可知,三种冲击能量下,6.7 mm 粒级以上(含6.7 mm粒级)的总质量分数可达91.53%、84.21%和74.20%;6.7 mm以下粒级粒度变化较小且质量分数较小,对表征破碎后粒度变化影响不大,因此可认为6.7 mm粒级以上即可表征矿石的破碎效果。考虑到建模效率,主要考虑破碎后粒度在6.7 mm以上颗粒的仿真表征。因此,基础颗粒组的颗粒粒径应小于6.7 mm。

落重试验规范规定,6.7 mm以上筛分粒级尺寸为9.5、13.2、19、26.5、37.5和53 mm共六种。为简化建模过程提高建模效率,粒度误差不大于0.5 mm时即认为满足式(6)。

设定基础颗粒组有三种颗粒粒度d1、d2、d3,将选定的基础颗粒组粒径种类数和落重试验粒级代入式(6),得到满足落重试验破碎粒度分布的方程组:

(7)

(7)

该方程组有多组解,根据上文所述在满足落重试验破碎结果的情况下,在6.7 mm粒级和4.75 mm粒级之间,选取了5 mm粒径为基础颗粒最大粒径,其余两种粒径以等差数列的形式选取。这种设定能够使破碎后粒度分布更为平缓和光滑,避免因基础颗粒粒径相差过大而导致破碎后粒度跳跃过大,造成仿真的不准确。即d1=1、d2=3、d3=5为基础粒径组,矩阵k取值如下:

(8)

(8)

满足矩阵方程式(6),即基础颗粒组为1、3和5 mm等三种粒径时,可以满足多颗粒黏结破碎模型构成条件。

这里选取三种基础粒径,主要考虑以下因素:当基础颗粒粒径为单一种类时,只有一种键值,模型缺乏灵活性,破碎仿真得到的粒级分布与落重试验结果存在较大误差;粒径种类过多时,需要设置的粒度组合和键值增多,增加了建模的复杂性,破碎仿真结果与落重试验仍会存在较大差异。综合考虑建模效率和破碎仿真效果选取三种粒径。

3.2 黏结键参数

3.2.1 黏结键参数确定方法

在BPM颗粒黏结模型理论中,当颗粒间距离达到接触半径范围时,颗粒之间生成黏结键。黏结键由黏结键半径和四种材料参数综合表征,分别为单位面积法向刚度、单位面积切向刚度、临界法向应力和临界切应力。物料特性参数随矿石种类等因素变化差异较大,标准材料库参数与实际矿物参数存在差异,目前尚未有明确的方法或理论可以将模型的微观参数值与宏观材料力学特性定量直观连接起来。因此,采用数值试验方法[16-17]对物料模型进行冲击破碎离散元模拟试验来确定符合实际物料的材料参数值。利用物料模型进行落重试验过程模拟,采用破碎后最大颗粒粒度为评判标准,当仿真破碎后最大颗粒粒度与落重试验结果相同时,模型中材料参数值设定合理,符合实际物料特性。

3.2.2 黏结模型中黏结键参数的确定

在标准材料库中,仅有部分矿物基础材料基本参数,无法确定多颗粒黏结模型中的颗粒间黏结键参数,必须依据落重试验数据进行调整。考虑到实际试验中粒度越小破碎越困难、矿石内部不同强度形成多种脆性结合面造成的破碎不均,黏结键参数调整遵循原则如下:1) 相同粒度颗粒之间黏结键随粒度减小而增大;2) 不同粒度颗粒间黏结键随粒度差值增大而减小。

设三种直径颗粒编号分别为p1、p2、p3,dp1=1 mm、dp2=3 mm、dp3=5 mm,不同颗粒间键能[D2]为Emn,其中m、n为颗粒编号。不同直径间颗粒组合与颗粒间组合顺序无关,黏结键参数仅与粒径有关。因此,共需设置6种键能值,分别为E11、E22、E33、E12(E21)、E13(E31)、E23(E32)。刚度参数越大,黏结键越难断裂,物料破碎越困难;应力参数越大,物料破碎后越容易形成颗粒团簇,物料后破碎粒度分级越明显。刚度参数与物料破碎困难程度呈正相关,应力参数与物料破碎形成团簇的困难程度呈负相关,这里采用应力参数为固定值、调整刚度参数的方法调整黏结键参数。

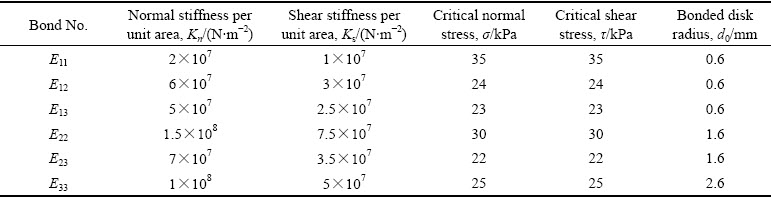

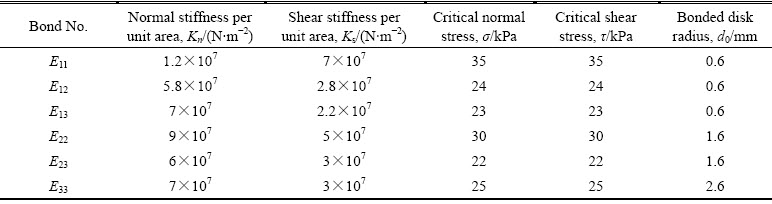

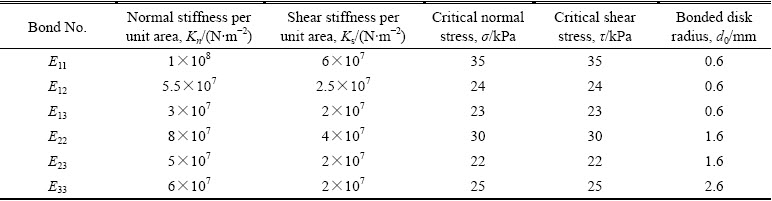

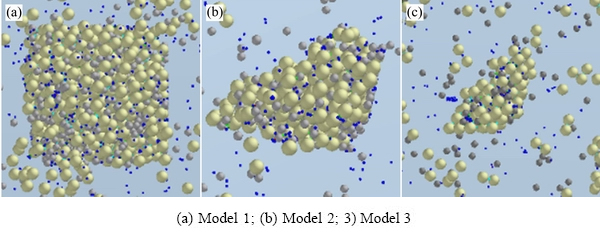

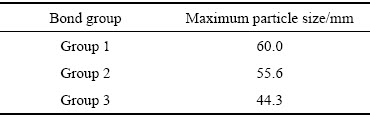

为确定材料参数对破碎仿真结果的影响,分别设置了黏结键参数不同的三种物料模型,具体参数值见表3、4和5。针对表3、4和5中设置的参数构造了物料的离散元多颗粒黏结模型,并应用软件仿真了落重试验,仿真得到的最大粒度如图5所示。从图5中可以看到,随着法向刚度和剪切刚度的减小,破碎后的最大粒度随之减小。破碎后的最大粒度见表6。由于在落重试验中最大破碎粒度在37.5~53 mm之间,采用模型3黏结键参数仿真得到的破碎粒度为44.3 mm,与落重试验的结果一致,该组黏结键参数比较接近实际物料的破碎特性。

表3 模型1的颗粒间黏结键参数

Table 3 Parameters of bonding bond between particles of Model 1

表4 模型2的颗粒间黏结键参数

Table 4 Parameters of bonding bond between particles of Model 2

表5 模型3的颗粒间黏结键参数

Table 5 Parameters of bonding bond between particles of Model 3

图5 三种黏结键参数下模型破碎后的最大粒度

Fig. 5 Maximum particle size after crushing of three sets model of bonding energy parameters

表6 破碎后物料的最大粒度值

Table 6 Maximum particle size after crushing

4 物料冲击破碎过程仿真与分析

4.1 多颗粒黏结物料破碎模型建模

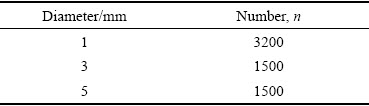

为提高仿真的有效性,建模用的物料形状和实际物料尽可能一致。物料形状选择为四棱柱,物料尺寸为60 mm×60 mm×56 mm。整体物料由基础颗粒填充黏结构成。

由于整体物料形状为四棱柱,基础颗粒为球形颗粒,颗粒填充时存在孔隙率,计算基础颗粒个数时,需引入填充体积分数 。填充体积分数为基础颗粒总体积与其实际物料体积之比;当基础颗粒为单一直径颗粒时,一般经验取填充体积分数

。填充体积分数为基础颗粒总体积与其实际物料体积之比;当基础颗粒为单一直径颗粒时,一般经验取填充体积分数 。孔隙率越大,填充体积分数越小,物料模型结构越松散,模型质量越差。多粒度的基础颗粒组填充可以有效降低孔隙率,提高模型质量。

。孔隙率越大,填充体积分数越小,物料模型结构越松散,模型质量越差。多粒度的基础颗粒组填充可以有效降低孔隙率,提高模型质量。

设直径1 mm基础颗粒体积为V1,3 mm基础颗粒为V3,5 mm基础颗粒为V5。当基础颗粒全部为直径5 mm颗粒时,填充体积分数 ,计算得到直径5 mm颗粒个数为1850个。为保证模型内部各直径颗粒分布均匀且满足粒度关系式(5),3 mm和5 mm直径的基础颗粒个数不宜相差过大,1 mm直径颗粒体积较小,个数适当增加用以填充大颗粒间的孔隙,保证模型内部结构紧凑。根据各基础颗粒之间体积比将部分5 mm颗粒替换为1 mm和3 mm颗粒,经计算调整,最终体积填充分数提升至

,计算得到直径5 mm颗粒个数为1850个。为保证模型内部各直径颗粒分布均匀且满足粒度关系式(5),3 mm和5 mm直径的基础颗粒个数不宜相差过大,1 mm直径颗粒体积较小,个数适当增加用以填充大颗粒间的孔隙,保证模型内部结构紧凑。根据各基础颗粒之间体积比将部分5 mm颗粒替换为1 mm和3 mm颗粒,经计算调整,最终体积填充分数提升至 ,得到基础颗粒组中各颗粒个数见表7。

,得到基础颗粒组中各颗粒个数见表7。

利用离散元方法建立的物料多颗粒黏结模型如图6所示。其中该黏结模型中,桃红色球为1 mm颗粒,灰色球为3 mm颗粒,褐色球为5 mm颗粒。红色线段为1 mm颗粒间黏结键,蓝色线段为3 mm颗粒间黏结键,灰色线段为5 mm颗粒间黏结键,深红色线段为1 mm与3 mm颗粒间黏结键,深绿色线段为1 mm与5 mm颗粒间黏结键,绿色线段为3 mm与5 mm颗粒间黏结键。

表7 矿石模型基础颗粒组成及个数

Table 7 Basic particle composition and number of ore model

图6 多颗粒黏结模型

Fig.6 Multi-particle bonding model

4.2 物料破碎过程的离散元仿真

根据落重试验参数设置仿真参数。落锤为圆柱体,材质为铅。多颗粒黏结模型基础颗粒为1 mm、3 mm和5 mm;黏结键能按照第3组键能参数设置。仿真的冲击能量分别为0.10 kW·h/t、0.25 kW·h/t和0.40 kW·h/t,与落重试验一致。

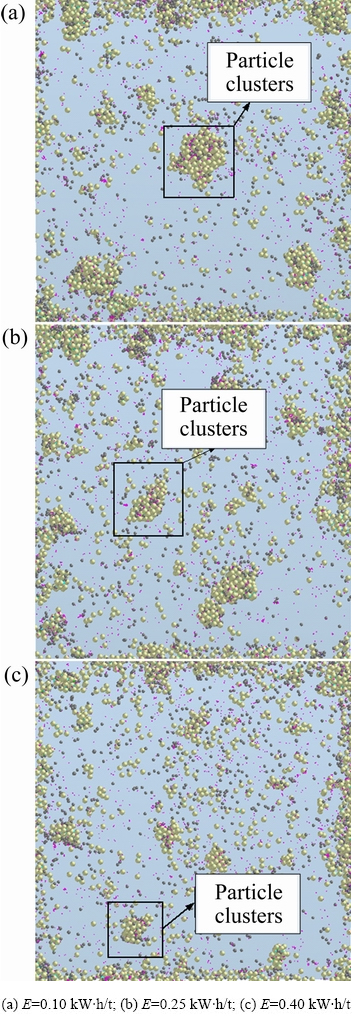

物料落重破碎仿真结果如图7所示。由图7可以看出,破碎后颗粒间键断裂并不完全,在大颗粒破碎后,一部分基础颗粒直接分离,另一部分基础颗粒仍然呈团簇状,形成不同粒度的颗粒团簇。同时,可明显看出,破碎后的物料最大粒度随冲击能量的增大而变小。

4.3 仿真结果与试验数据对比

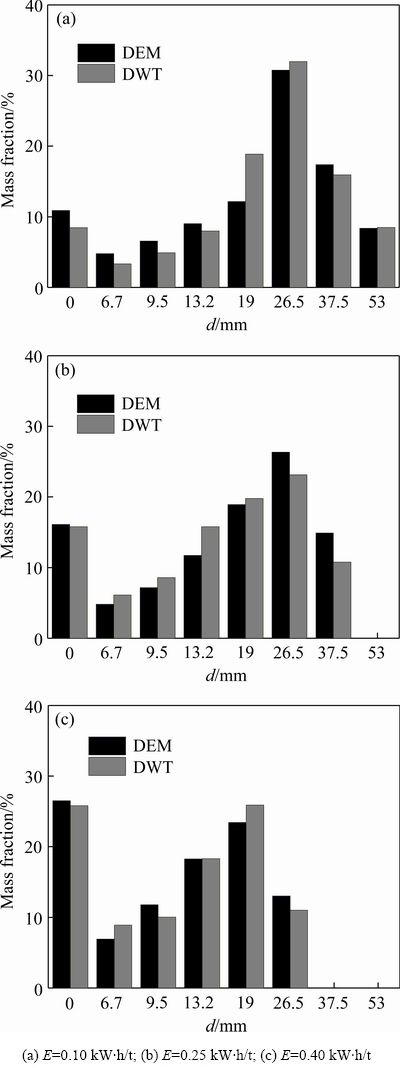

为与通过落重试验得到的物料粒度分布做对比,对仿真得到的物料颗粒的质量分数进行统计,统计结果见表8。落重试验(DWT)和落重仿真(DEM)得到的颗粒粒度质量分数对比结果如图8所示。

由图8可知,仿真结果与试验结果峰值分布粒度区间相同,3组质量分数差值分别为2.01%、1.91%、1.12%,粒度分布具有良好的一致性。

图7 不同冲击能量下的破碎颗粒团簇

Fig. 7 Particle clusters under different impact energies

表8 仿真粒度分布质量分数

Table 8 Mass fractions of simulated particle size distribution

图8 不同粒度质量分数对比

Fig. 8 Mass fraction comparison of different particle sizes

5 结论

1) 提出了一种基于落重试验的多颗粒黏结模型关键参数的确定方法,利用该模型得到的仿真结果与落重破碎试验结果更加吻合,提高了模型精度与准确性。为利用仿真技术对矿物破碎过程进行精准建模提供了研究基础,具有实际应用价值。

2) 给出了基于落重试验筛分粒级粒度分布的基础颗粒种类和粒度的确定方法。选取合适的基础颗粒种类可以避免模型的复杂性,并兼顾模型的灵活性。

3) 给出了黏结键参数设置的原则和验证方法。参考物料强度参数设置黏结键参数,根据建模仿真和落重试验得到的物料破碎粒度分布对比结果调整黏结键参数的大小,可以得到理想的物料破碎键参数表征。

REFERENCES

[1] RASOUL P, KIANOUSH B. The effect of ball size distribution on power draw, charge motion and breakage mechanism of tumbling ball mill by discrete element method (DEM) simulation[J]. Physicochemical Problems of Mineral Processing, 2018, 54(2): 258-269.

[2] 刘 磊, 曹进成, 吕 良, 等. 不同破碎方式下磨矿技术效率[J]. 中国有色金属学报, 2015, 25(9): 2565-2574.

LIU Lei, CAO Jin-cheng, Lü Liang, et al. Grinding technical efficiencies in various comminution modes[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2565-2574.

[3] DELANEY G W, MORRISON R D, SINNOTT M D, et al. DEM modeling of non-spherical particle breakage and flow in an industrial scale cone crusher[J]. Minerals Engineering, 2015, 74: 112-122.

[4] SHI D D, ZHENG L, XUE J F, et al. DEM modeling of particle breakage in silica sands under one-dimensional compression[J]. Acta Mechanica Solida Sinica, 2016, 29(1): 78-94.

[5] 蔡改贫, 余世科, 姚子茂, 等. 落锤冲击破碎能耗试验分析[J]. 矿山机械, 2015(2): 65-68.

CAI Gai-pin, YU Shi-ke, YAO Zi-mao, et al. Analysis on test for impact crushing energy consumption of drop weight[J]. Mining & Processing Equipment, 2015(2): 65-68.

[6] 姚壮壮, 武文宾, 林府进, 等. 基于冲击破碎实验的煤体冲击破碎功研究[J]. 煤炭技术, 2019, 38(10): 73-75.

YAO Zhuang-zhuang, WU Wen-bin, LIN Fu-jin, et al. Study on impact crushing energy of coal body based on impact crushing experiment[J]. Coal Technology, 2019, 38(10): 73-75.

[7] ZHOU W T, HAN Y X, SUN Y S, et al. Multi-scale impact crushing characteristics of polymetallic sulphide ores[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(9): 1929-1938.

[8] 周文涛, 韩跃新, 李艳军, 等. 冲击破碎粒度分布模型建立与预测[J]. 中国有色金属学报, 2019, 29(6): 1316-1323.

ZHOU Wen-tao, HAN Yue-xin, LI Yan-jun, et al. Establishment and prediction of impact crushing particle size distribution model[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1316-1323.

[9] 徐 可, 黄文雄, 王建敏, 等. 岩质颗粒破碎数值模拟研究进展[J]. 科学技术与工程, 2019, 19(21): 8-14.

XU Ke, HUANG Wen-xiong, WANG Jian-min, et al. Progress in numerical simulation study of rock particle crushing[J]. Science Technology and Engineering, 2019, 19(21): 8-14

[10] 徐 琨, 周 伟, 马 刚, 等. 基于离散元法的颗粒破碎模拟研究进展[J]. 岩土工程学报, 2018, 40(5): 880-889.

XU Kun, ZHOU Wei, MA Gang, et al. Review of particle breakage simulation based on DEM[J]. Journal of Geotechnical Engineering, 2018, 40(5): 880-889.

[11] 洪 俊, 李建兴, 沈 月, 等. 颗粒破碎过程的离散元精细化建模[J]. 天津大学学报(自然科学与工程技术版), 2018, 51(12): 1253-1259.

HONG Jun, LI Jian-xing, SHEN Yue, et al. Particle fracture model based on the discrete element method[J]. Journal of Tianjin University (Science and Technology), 2018, 51(12): 1253-1259

[12] RAISIANZADEH J, MOHAMMADI S, MIRGHASEMI A. Micromechanical study of particle breakage in 2D angular rock fill media using combined DEM and XFEM[J]. Granular Matter, 2019, 21(3): 48.1-48.27.

[13] SUN Y, NIMBALKAR S, CHEN C. Particle breakage of granular materials during sample preparation[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2019, 11(2): 203-208.

[14] 周 健, 张艳伟, 周韵鸿, 等. 考虑粒间法向接触力作用的粗粒土颗粒破碎试验研究[J]. 岩土工程学报, 2018, 40(7): 7-14.

ZHOU Jian, ZHANG Yan-wei, ZHOU Yun-hong, et al. Experimental study on particle breakage of coarse-grained soil considering normal contact force[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(7): 7-14.

[15] CUNDALL P A, POTYONDY D O. A bonded-particle model for rock[J]. International Journal of Rock Mechanics & Mining Sciences, 2004, 41(8): 1329-1364.

[16] 姜胜强, 谭援强, 李 才, 等. 单晶硅力学性能及尺寸效应的离散元模拟[J]. 中国机械工程, 2010, 21(5): 589-594.

JIANG Sheng-qiang, TAN Yuan-qiang, LI Cai, et al. Study on mechanics properties and size effect of monocrystalle silicon using discrete element method[J]. China Mechanical Engineering, 2010, 21(5): 589-594.

[17] 毛亚郎, 孙 毅, 计时鸣, 等. 落球冲击破碎下的非限制料层夹持形态[J]. 中国机械工程, 2016, 27(2): 168-172.

MAO Ya-lang, SUN Yi, JI Shi-ming, et al. Nipped configuration of unconfined particle beds under falling ball impact test[J]. China Mechanical Engineering, 2016, 27(2): 168-172.

DEM multi-particle bonding modeling based on drop weight test

WANG Xiao1, 2, XUE Yu-jun1, 2, LIU Jun3, YANG Ji-chang3, ZOU Sheng-yong3,Zhiqiang GUAN4, LI Ji-shun1, 2

(1. School of Mechatronics Engineering, Henan University of Science and Technology, Luoyang 471003, China;

2. Henan Key Laboratory for Machinery Design and Transmission System, Henan University of Science and Technology, Luoyang 471003, China;

3. State Key Laboratory of Mining Heavy Equipment, CITIC Heavy Industries CO., LTD., Luoyang 471003, China;

4. School of Mechanical and Mining Engineering, University of Queensland, Brisbane 4072, Australia)

Abstract: In recent years, research has been focused on the proper parameter selection of ore grinding technology to achieve an optimal distribution of particle size. The control of particle size in mineral processing plays a significant role in improving mineral separation efficiency. Discrete element method (DEM) has been approved to be an effective numerical simulation to study the process of mineral crushing. However, the accuracy of the DEM simulation is highly depended on the mathematical models used. In this paper, methodologies of predicting particle sizes and inter-particle bond energy were proposed based on the drop weight test carried in the laboratory. Particle sizes and inter-particle bond energy are the key parameters for multi-particle bonding model used in discrete element simulation. The predicted results were applied to construct the multi-particle bonding model for a single block of ore, and its particle size distribution was obtained by simulating the impact crushing process with discrete elements method. The particle size distributions from both the DEM simulation and the falling weight test are in good agreement, which indicates that the modeling technique proposed in this paper can represent the crushing characteristics of ore materials.

Key words: particle breakage; drop weight test; particle size; discrete element simulation; multi-particle bonding model

Foundation item: Project(2012CB724306) supported by the National Key Research Development Program of China; Projects(201200210500, 181200211500-2) supported by the Special Project of Industrial Cluster in National Innovation Demonstration Zone, China; Project(1901016A) supported by the Science and Technology Program of Luoyang, China

Received date: 2020-08-07; Accepted date: 2021-05-06

Corresponding author: LI Ji-shun; Tel: +86-13608657695; E-mail: li_jishun@163.com

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2012CB724306);郑洛新国家自创区创新引领型产业集群专项(201200210500,181200211500-2);洛阳市科技发展计划资助项目(1901016A)

收稿日期:2020-08-07;修订日期:2021-05-06

通信作者:李济顺,教授,博士;电话:13608657695;E-mail:li_jishun@163.com