W-TiC合金的烧结行为及其显微组织演变

张顺,范景莲,成会朝,田家敏,成创功

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:采用粉末冶金方法制备W-TiC合金,研究W-TiC合金的烧结行为,并对合金的显微组织演变进行分析。结果表明:W-TiC合金粉末具有高的烧结活性,合金致密化过程主要发生在1 500~1 800 ℃,经1 800 ℃常压烧结120 min后,合金相对密度即达97.5%;当温度提高至1700℃甚至更高温度后,合金显微组织均匀性明显改善;在高温烧结过程中,添加TiC与W形成(W,Ti)C固溶体以及含W,Ti,C和O元素的复合物粒子相,均匀分布在W基体中,有效地抑制了W晶粒长大,提高了合金性能;在1 950 ℃烧结120 min后,其相对密度为98.1%,显微硬度达最大值HV670.4,相对纯W提高29.3%。

关键词:W-TiC合金;烧结行为;显微组织;显微硬度

中图分类号:TG146.4+11 文献标志码:A 文章编号:1672-7207(2012)08-2938-05

Sintering behavior and microstructure evolution of W-TiC alloy

ZHANG Shun, FAN Jing-lian, CHENG Hui-chao, TIAN Jia-ming, CHENG Chuang-gong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A W-TiC alloy was fabricated by powder metallurgy method, and the sintering densification behavior and microstructure evolution of the alloy were investigated. Experimental results show that the W-TiC alloy has high sintering activity, and the main densification behavior happens during 1 500-1 800 ℃, the relative density of the alloy is 97.5% after being sintered at 1 800 ℃ for 120 min in H2. The microstructure uniformity of the alloy is significantly improved when the sintering temperature exceeds 1 700 ℃. During high temperature sintering process, (W,Ti)C and the particle containing elements W, Ti, C and O form by adding TiC, which can effectively inhabit grain growth and improve the mechanical properties(hardness) of the alloy. The relative density is 98.1%, and the highest microhardness is HV 670.4 after being sintered at 1 950 ℃ for 120 min in H2, which is 29.3% higher in comparison with pure tungsten.

Key words: W-TiC alloy; sintering behavior; microstructure; microhardness

金属钨具有高熔点、高弹性模量、优良的高温强度、良好的耐热冲击性能、良好的导热性以及抗中子辐射能力强等优点,是航空航天和原子核能等尖端领域中一种理想的超高温结构材料[1-6]。但是由于纯钨密度较高,且随着温度的升高强度急剧降低,在1 000 ℃时的强度相对室温下降了60%[6-11],严重限制了其在更高温工作领域中的应用。TiC不仅具有高熔点 (>3 000 ℃)、良好的高温强度和耐腐蚀性能以及低密度(TiC密度为4.9 g/cm3)等优点,而且可以与W形成(Ti,W)C固溶体,具有比TiC更高的硬度和高温强 度[4-6]。因此,国内外研究人员常通过添加TiC颗粒来细化W晶粒,提高W合金的高温强度和降低合金理论密度[4-6,8-10]。Kurishita等[5]采用热等静压法(1 620 K,200 MPa)制备了W-(0-1.5)%TiC合金,并对其高温超塑性变形能力进行研究;Chen等[6]在真空热压条件下(2 000~2 100 ℃和20~30 MPa)制备了W-TiC合金,并研究其烧蚀行为和断裂韧性等性能[6]。上述研究结果表明W-TiC合金具有较好的室温及高温性能,但是即便采用热压或热等静压法,制备的W-TiC合金致密度仍不理想(≤98%),限制了合金性能的进一步提升,同时,合金产品形状尺寸也受到极大的抑制[4-6]。为此,本研究尝试在W-TiC合金制备中引入合金元素进行强化烧结,于常压氢气氛下烧结制备W-TiC合金,研究W-TiC合金的烧结行为,并对其显微组织演变过程进行分析。

1 实验

按W-2%TiC(质量分数)的成分配比分别称取W粉和TiC粉,混合球磨5~20 h。混合粉末在25 t油压机上压制成“工”字型试样,压制压力为350 MPa。然后将压坯试样在氢气中进行预烧,预烧温度为 1 000 ℃,保温2 h。最后,在氢气气氛下进行高温烧结,烧结温度为1 500~2 000 ℃,保温时间为120 min。同时,作为对比试验,在相同球磨及烧结工艺条件下制备了纯W样品。

采用阿基米德排水法测量材料的密度;采用日产3014-2Z型X线衍射仪对样品表面进行物相分析;采用MeF3A型金相显微镜进行显微组织观察;采用捷克NOVA TM NanoSEM230超高分辨率场发射扫描电镜观察样品断口形貌,并利用EDX能谱仪进行选区或定点成分分析;采用HXD-1000T型数字显微硬度测试仪,在50 g加载载荷下测试W-TiC合金及纯钨显微硬度。

2 结果与分析

2.1 物相分析

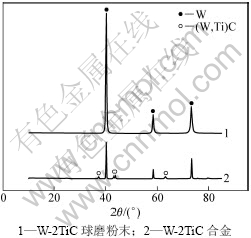

图1所示为W-TiC合金粉末及合金的XRD图谱。由于W-TiC合金粉末添加的TiC含量低(质量分数2%),并且相对于W粉末粒径(3.5 μm),TiC粉末粒径(500 nm)极小,衍射能力弱,因此,在球磨粉末XRD图谱中未出现TiC或(W,Ti)C衍射峰。同时,W-TiC合金中(W,Ti)C衍射峰的晶格点阵常数(0.4235 nm)比原始TiC点阵常数略小,(0.432 7 nm)但仍保持TiC点阵,这是由于W原子半径为0.141 nm,而Ti的原子半径为0.147 nm[12],W扩散到TiC中,置换Ti形成(W,Ti)C,引起点阵常数降低。

对比W-TiC合金粉末,W-TiC合金的W衍射峰向高角度方向发生了微偏移,这是Ti原子扩散进入W晶格形成了(βTi,W);并且衍射峰宽度减小,衍射强度降低。合金粉末衍射峰宽化主要有2方面原因:一方面,由于球磨过程中合金粉末被细化,导致倒易空间发生变化,使衍射峰较宽;另一方面,粉末在球磨过程中受到硬质合金球冲击破碎,晶粒发生晶格畸变,从而引起粉末的衍射峰宽化[13]。而W-TiC合金样品经高温烧结后,W晶粒发生合并长大,并且高温过程中,粉末内应力释放,晶格畸变减少,因此W峰半高宽减小。同时,W-TiC合金的XRD谱中出现了(W,Ti)C峰,说明在高温烧结过程中,W原子扩散进入TiC,与Ti原子发生置换而形成(W,Ti)C固溶体,Ti原子也向W晶体中扩散并形成饱和固溶体,这种互扩散行为破坏了W晶体的完整性,使得参与衍射的W晶体减少而导致峰高降低。

图1 W-2TiC合金烧结前后的XRD谱

Fig.1 XRD patterns of W-TiC alloy before and after sintering

2.2 W-TiC合金的烧结行为

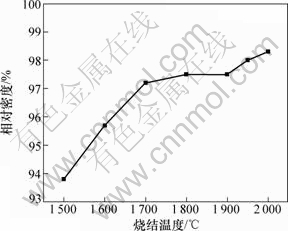

图2所示为烧结温度对W-TiC合金相对密度的影响。随烧结温度升高,W-TiC合金相对密度逐渐提高。W-TiC合金经1 500 ℃烧结后的相对密度为91.5%,在1 700 ℃烧结后,相对密度显著提高至97.2%,在 1 800 ℃烧结后的相对密度为97.5%,随后至2 000 ℃烧结后,合金密度为98.3%,相对密度变化不大,说明W-TiC合金致密化过程主要在1 500~1 800 ℃阶段完成;文献[14]报道:W-1.5%TiC合金在2 100 ℃热压烧结1 h后,相对密度为98%,与之相比,本研究采用常规方法制备的W-TiC合金在达到相同的烧结致密度所需烧结温度降低200 ℃以上。

随烧结温度的升高,混合球磨过程中引入的铁杂质等低熔点金属在局部晶界处形成液相,与非化学计量化合物TiC1-x形成的碳空位共同作用,提高了晶界处发生体积扩散和晶界扩散的能力[9-10];同时,在高温烧结过程中,非化学计量化合物TiC1-x中的Ti原子向W基体发生扩散[9],而β-Ti与W均为bcc结构,且原子尺寸之差为1.5%,依据Hume-Rothery准则,W与Ti可以无限固溶[8],从而使得晶界扩散速度增加、致密化速度大幅度提高;随着烧结温度继续升高,原子扩散及物质迁移能力增强,合金孔隙度进一步降低,密度得到提高,但是增长速度趋于平缓,这与致密化曲线相符合。

图2 烧结温度对W-TiC合金相对密度的影响

Fig.2 Effect of sintering temperature on relative density of W-TiC alloy

2.3 烧结温度对合金硬度的影响

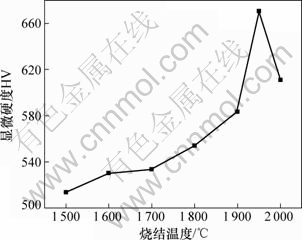

图3所示为W-TiC合金显微硬度随烧结温度的变化曲线。随烧结温度升高,合金显微硬度提高,当烧结温度为1 950 ℃时,合金显微硬度达最大值 HV 670.4,继续升高烧结温度,W-TiC显微硬度又呈下降趋势,而纯钨在2 000 ℃烧结后的显微硬度值仅为HV 518.1,明显低于W-TiC合金。硬度与合金晶粒尺寸和孔隙度有如下关系[15]:

(1)

(1)

式中:H为硬度;d为晶粒尺寸;p为试样孔隙度;K,a和b为常数。

图3 W-TiC合金显微硬度随烧结温度的变化曲线

Fig.3 Vickers microhardness values with various sintering temperatures

从式(1)可知:硬度随孔隙度p减小而增加,而晶粒尺寸d增加会降低其硬度值,合金显微硬度值的变化,是烧结致密化与晶粒长大共同作用的结果。当烧结温度范围为1 500~1 950 ℃时,合金硬度主要受合金致密化过程影响,随烧结温度提高,孔隙度降低,相对密度提高,合金显微硬度增大;当硬度达到最大值后继续升高温度导致硬度值降低,这是受晶粒长大影响的缘故。

2.4 烧结过程中的合金显微组织演变

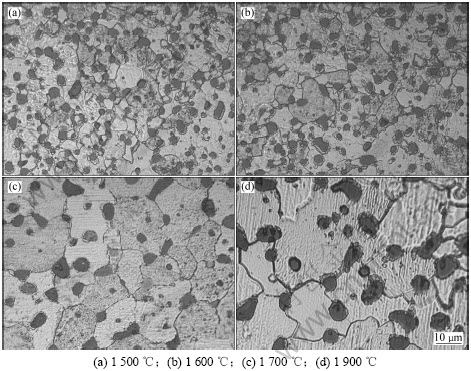

图4所示为W-TiC合金在氢气气氛和不同烧结温度下烧结120 min后的显微组织。当烧结温度为1 500和1 600 ℃时,合金晶粒大小不均匀,晶粒发育不好且结合不紧密,在W晶粒中间存在部分孔洞;随烧结温度提高至1 700 ℃及更高温度后,合金显微组织均匀性显著提高,W晶粒发生长大。

在升温阶段(<1 600 ℃),W晶界处空洞的存在,是导致该温度下烧结合金相对密度较低的原因;当烧结温度高于1 700 ℃时,由于晶粒间的晶界扩散和体积扩散能力加剧,促进了晶粒合并长大,因而合金相对密度得到提高;TiC主要分布在W晶界处,极少数分布在晶内,但是,晶界处的TiC发生长大,这是由于高温烧结过程中,TiC颗粒细小且烧结活化能低而倾向发生团聚并长大;由于TiC熔点高,且为共价键化合物,在低于1 900 ℃时,难以发生致密化,因此在团聚的TiC颗粒区域出现部分微孔洞,影响了合金相对密度的进一步提高。

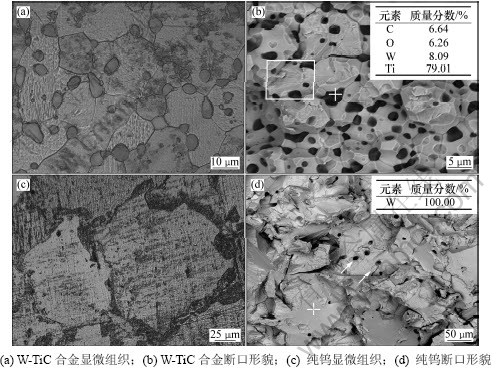

图5所示为W-TiC合金和纯钨在氢气气氛和 1 950 ℃烧结120 min后的显微组织及断口形貌。W-TiC合金组织显示,W晶粒粒径为10~20 μm,晶内分布少量TiC,粒径为1~2 μm,而分布在晶界处的TiC发生了团聚长大,粒径为3~5 μm;相对于1 900 ℃的W-TiC合金显微组织,1 950 ℃烧结后的合金显微组织晶界平直,说明此时W晶粒已得到充分长大。同时,随烧结温度提高,晶界处的TiC团聚粒子发生合并长大而使得孔洞消除,因而在1 950 ℃甚至更高温度烧结后的合金相对密度出现一定提高,这与合金相对密度曲线相符合;而经1 950 ℃烧结的纯W晶粒粒径为100 μm,说明添加的TiC第二相颗粒起到了细化W晶粒的作用。

W-TiC合金(图5(b))主要为脆性穿晶解离和沿晶断裂的混合断裂模式,沿晶区域呈明显冰糖状形貌,穿晶区域有较明显河流状花样(如图5(b)方框白色所示),并且在穿晶W晶粒内部发现TiC粒子,W晶粒平均粒径为10 μm,与W-TiC合金显微组织特征(图5(a))相符;而纯钨断口无明显晶粒形貌,较大平面区域为W晶粒,晶界处呈杂乱无序结构,说明纯钨尚在烧结初级阶段,并发现大量黑色气孔,如图5(d)箭头所示。

图4 W-TiC合金在氢气气氛下、不同烧结温度烧结120 min后的显微组织

Fig.4 Microstructures of polished and etched cross section of W-TiC alloy at different sintering temperatures for 120 min in H2

图5 W-TiC合金和纯钨在1 950 ℃烧结120 min后的微观组织

Fig.5 Microstructures of W-TiC alloy and pure tungsten sintered at 1 950 ℃ for 120 min in H2

在高温烧结阶段,W,Ti以及C原子热激活能量增大,迁移扩散能力变强,扩散系数增大,因而W,Ti和C之间的扩散加剧[9],生成的(βTi,W)和(W,Ti)C固溶体含量增加,提高了W-TiC晶界强度;深色TiC颗粒粒径为2~3 μm,比原始TiC颗粒粗大,并且EDS分析显示部分TiC含有微量氧,这是因为原始TiC颗粒容易产生团聚,高温下TiC颗粒发生反应:TiC+O2→TixOyCz+CO/CO2,(W,Ti)C+O2→(W,Ti)xOyCz+ CO/CO2;形成TixOyCz相或由W,Ti,C及O 4种元素组成的(W,Ti)xOyCz复合物[16],这些粒子与TiC粒子一起分布均匀,共同阻碍晶粒长大,有效地细化了晶粒,并有利于W-TiC合金硬度的提高。

3 结论

(1) 混合球磨提高了合金粉末烧结活性,同时,在高温烧结过程中,由于非化学计量化合物TiC1-x生成的碳空位,提高了W-TiC界面晶界及体积扩散能力,使得W-TiC合金致密化过程主要发生在1 500~1 800 ℃,在1 800 ℃常压烧结120 min后,相对密度达97.5%。

(2) W-TiC合金的显微硬度由烧结致密度和晶粒粒径共同决定,在1 950 ℃达最大为HV 670.4,较纯钨提高了29.3%,随后提高烧结温度,受晶粒尺寸长大影响,显微硬度呈下降趋势;

(3) 碳化物TiC在W基体中的添加,可与W形成(W,Ti)C固溶体,并且部分TiC粒子在高温烧结过程中生成(W,Ti)xOyCz复合物粒子相,抑制W晶粒在烧结过程中的长大,细化晶粒,有利于W-TiC合金性能的提高。

参考文献:

[1] John J P. Creep strength of a tungsten-rhenium-hafnium carbide alloy from 2000 to 2400K[J]. Materials Science and Engineering A, 1999, 265(1/2): 174-178.

[2] ZHANG Tai-quan, WANG Yu-jin, ZHOU Yu, et al. Effect of ZrC particle size on microstructure and room temperature mechanical properties of ZrC/W composites[J]. Materials Science and Engineering A, 2010, 527(1): 4021-4027.

[3] Faleschini M, Kreuzer H, Kiner D, et al. Fracture toughness investigations of tungsten alloys and SPD tungsten alloys[J]. Journal of Nuclear Materials, 2007, 367-370(1): 800-805.

[4] 宋桂明, 周玉, 王玉金, 等. TiC/W复合材料的制备工艺与力学性能[J]. 稀有金属材料与工程, 1999, 28(3): 171-172.

SONG Gui-ming, ZHOU Yu, WANG Yu-jin, et al. Pocessing and mechanical properties of 30vol% TiC/W composite[J]. Rare Metal Materials and Engineering, 1999, 28(3): 171-172.

[5] Kurishita H, Matsuo S, Arakawa H, et al. High temperature tensile properties and their application to toughness enhancement in ultra-fine grained W-(0-1.5)wt% TiC[J]. Journal of Nuclear Materials, 2009, 386/388(1): 579-582.

[6] CHEN Yong, WU Yu-cheng, YU Fu-wen, et al. Effect of rare La2O3 on the microstructure and mechanical properties of TiC/W composites[J]. Rare metals, 2008, 27(6): 632-636.

[7] Aguirre M V, Martin A, Pastor J Y, et al. Mechanical behavior of W-Y2O3 and W-Ti alloys from 25 ℃ to 1000 ℃[J]. Metallurgical and Materials Transactions A, 2009, 40(1/2): 2283-2285.

[8] Wang Q X, Wang X H, Yang Y, et al. Preparation of W-15% Ti prealloyed powders[J]. Journal of Refractory Metals Hard Materials, 2009, 27(1/2): 847-850.

[9] Genc A, Coskun S, Ovecoglu M L. Decarburization of TiC in Ni activated sinterd W-xTiC(x=0.5.10.15wt%)composites and the effects of heat treatment on the microstructural and physical properties[J]. Journal of Refractory Metals Hard Materials, 2010, 28(1/2): 451-458.

[10] Wang X G, Guo W M, Kan Y M, et al. Densification behavior and properties of hot-pressed ZrC ceramics with Zr and graphite additives[J]. Journal of the European Ceramic Society, 2011, 31: 1103--1111.

[11] Song G M, Wang Y J, Zhou Y. Thermomechanical properties of TiC particle-reinforced tungsten composites for high temperature applications[J]. Journal of Refractory Metals Hard Materials, 2003, 21(1/2): 1-12.

[12] Mas-Guindal M J, Contreras L, Turrillas X. Self-propagating high temperature synthesis of TiC-WC composite materials[J]. Journal of Alloys and Compounds, 2006(419): 227-233.

[13] Gaffet E, Abdellaoui M, Malhouroux G N. Formation of nanostructural materials induced by mechanical processing[J]. Material Transactions, 1995, 36(2): 198-209.

[14] 种法力, 于福文, 陈俊凌. W-TiC合金面对等离子体材料及其电子书热负荷试验研究[J]. 稀有金属材料与工程, 2010, 39(4): 750-752.

ZHONG Fa-li, YU Fu-wen, CHEN Jun-ling. W-TiC alloy plasma facing materials and heat flux performance test under electron beam facility[J]. Rare Metal Materials and Engineering, 2010, 39(4): 750-752.

[15] 胡双. 球磨时间对W-30Cu复合粉末中W晶粒度及烧结致密化行为的影响[J]. 金属材料与冶金工程, 2008, 36(4): 6-10.

HU Shuang. The influence of high energy ball milling time on the grain size and sintering densification behavior of W-30Cu composite powder[J]. Metal Materials and Metallurgy Engineering, 2008, 36(4): 6-10.

[16] 卢明园, 范景莲, 成会朝, 等. TiC的添加对Mo-Ti合金性能与组织结构的影响[J]. 稀有金属材料与工程, 2010, 36(6): 985-988.

LU Ming-yuan, FAN Jing-lian, CHENG Hui-chao, et al. Influence of TiC addition on properties and microstructure of M0-Ti alloy[J]. Rare Metal Materials and Engineering, 2010, 36(6): 985-988.

(编辑 何运斌)

收稿日期:2011-09-29;修回日期:2011-12-20

基金项目:国家杰出青年科学基金资助项目(50925416)

通信作者:范景莲(1967-),女,湖南澧县人,教授,博士生导师,从事难熔合金方面的研究;电话:0731-88836652,E-mail:fjl@csu.edu.cn