文章编号:1004-0609(2010)02-0189-06

钟罩浸块铸造法制备的CNTs/AZ31镁基复合材料的力学性能

徐 强,曾效舒,周国华

(南昌大学 机电工程学院,南昌 330031)

摘 要:将Al粉、Zn粉、碳纳米管(CNTs)混合料按照质量比为3?1?X(X=0,0.5,1.0,1.5)压块,并用钟罩压入法将这些预先制备的压块加入到合金熔体中制备AZ31/CNTs复合材料。测试该复合材料的力学性能,利用扫描电子显微镜(SEM)、能谱分析仪(EDS)、X射线衍射仪和光学显微镜对AZ31/CNTs复合材料的金相试样、断口形貌进行表征和分析。结果表明:钟罩压块法可以有效地将碳纳米管分散到镁合金熔体中;CNTs对AZ31镁合金的力学性能有较强的增强效果,与本研究中的铸造AZ31合金相比,AZ31/CNTs复合材料的最大抗拉强度和伸长率分别提高41.3%和119.4%,弹性模量和显微硬度分别提高67.8%和66.9%;CNTs对AZ31镁合金基体晶粒的细化作用显著,与镁基体界面结合较好;复合材料试样断口形貌由韧窝和撕裂棱组成,呈现准解理断裂特征。

关键词:AZ31镁合金;碳纳米管;预制块;复合材料;力学性能

中图分类号:TG146.2+2;TB333 文献标识码:A

Mechanical properties of CNTs/AZ31 composites prepared by adding CNTs block with plunger

XU Qiang, ZENG Xiao-shu, ZHOU Guo-hua

(School of Mechatronics Engineering, Nanchang University, Nanchang 330031, China)

Abstract: Precast blocks were prepared with powders of Al, Zn and carbon nanotubes with mass ratio of 3?1?X(X=0, 0.5, 1.0, 1.5), and then the carbon nanotubes AZ31 composites were produced by immersing the precast block into the alloy melt by adding CNTs block with plunger. The mechanical properties of the as-cast AZ31 alloy based composites (AZ31/CNTs) were tested and their microstructures and fracture morphology were observed by metalloscopy, scanning electron microscopy (SEM), energy depressive spectroscopy (EDS) and X-ray diffractometry. The results show that the CNTs are dispersed effectively by bell jar immersing precast block casting. The maximal tensile strength and the elongation of the AZ31/CNTs composites are enhanced by 41.3% and 119.4%, respectively, and the elastic modulus and micro-hardness are also raised by 67.8% and 66.9%, respectively, when compared with those of the as-cast AZ31 Mg alloys. The CNTs can greatly refine the grains of the composites, playing a good role in reinforcing the matrixes of AZ31 Mg alloy. The fracture sections of the composites mainly consist of dimples and prisms, which demonstrates quasi- cleavage fracture modes.

Key words: AZ31 Mg alloy; carbon nanotubes; precast block; composite; mechanical properties

金属镁及其合金是迄今在工程应用中最轻的结构材料。常规镁合金比铝合金轻30%~50%,比钢铁轻70% 以上,在实际应用中可大幅减轻结构件质量[1]。但镁合金存在绝对强度低、组织较软和高温性能较差等弱点,使得镁合金仅能用来制造壳类等不能承受较大载荷的零件。而镁基复合材料具有更高的比强度、比刚度,同时还可能具有较好的耐磨性和耐高温性能。与镁合金相比,镁基复合材料具有更大的潜在应用前景,在航天航空、军事和汽车等行业中已获得了较广泛的应用,越来越受到人们的关注[2?3]。开发镁基复合材料已被看作是一种能提高镁合金力学性能的有效途径。迄今为止,研究较多的镁基复合材料的增强相材料主要有SiC 颗粒和晶须、Al2O3 颗粒、短纤维、TiC 颗粒和石墨纤维等,但研究发现[4?6], 复合材料中往往存在微米级增强相断裂以及与基体间界面失效等缺点。而相对于微米级的增强相, 碳纳米管拥有更小的密度,更大的长径比,更高的强度、韧性和弹性模量,理论上是改善基体材料力学性能最理想的纳米增强材料[5?7]。 碳纳米管增强金属基复合材料的研究才刚刚起步, 成功制备碳纳米管增强金属基复合材料必须同时解决碳纳米管的分散性以及与熔融金属的界面反应这两大核心问题。研究表明[8?11],碳纳米管在高达 2 700 K 的真空状态和983 K 的铝液条件下的稳定性良好, 并且在基体材料中分散均匀。但在目前镁基复合材料的制备工艺条件下,有关碳纳米管增强镁基复合材料的报道较少[12?14]。

本文作者通过钟罩浸块铸造法制备了CNTs/AZ31复合材料,并测试常温下复合材料的铸态力学性能及碳纳米管加入量对复合材料铸态力学性能的影响。利用扫描电子显微镜对CNTs/AZ31复合材料进行铸态断口形貌观察及能谱分析,为开发碳纳米管增强镁基复合材料提供参考。

1 实验

1.1 实验材料

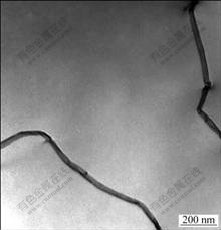

基体材料选用AZ31镁合金,其化学成分如表1所列[4]。实验按表1自行配置AZ31合金,原材料纯度(质量分数)分别如下:镁锭99.6%、铝粉99.99%、锌粉99.96%、锰粒99.9%。增强材料选用CVD法制备的一维多壁碳纳米管(MWCNTs),由南昌大学太阳纳米技术有限公司提供,碳纳米管提纯后的TEM像如图1所示。由图1可知,碳纳米管管壁洁净,直径为10~30 nm,长度为1~5 μm, 纯度≥90%。为了增加碳纳米管的密度和改善碳纳米管的表面润湿性,使其在搅拌过程中能更好地分散在镁基体中,并与镁基体界面结合更紧密,对提纯后的的碳纳米管进行了化学包覆镍处理,其透视电镜形貌如图2所示。

表1 AZ31合金的化学成分[4]

Table 1 Chemical composition of AZ31 alloy(mass fraction, %)[4]

图1 多壁碳纳米管的TEM像

Fig.1 TEM image of pure MWCNTs

图2 镀镍多壁碳纳米管的TEM像

Fig.2 TEM image of nickel plating MWCNTs

1.2 预制块成型工艺

首先配好质量比为3?1?X(X=0,0.5,1.0,1.5)的Al粉、Zn粉和碳纳米管的混合料,加入少量硬脂酸作为粘结剂(硬脂酸的含量在5%~8%),然后将各配比粉末混合后在球磨机内球磨20 min左右取出,在模具内腔温度为76 ℃的环境下热压成形,制成大小为d30 mm×5 mm的不同配比预制块。采用Al粉、Zn粉混合碳纳米管制备预制块,与只用碳纳米管制备预制块相比,由于Al和Zn的密度大于Mg的密度,相当于增加了碳纳米管的含量,使得其能在熔炼过程中,更好地浸入熔体中,达到复合的效果。

1.3 复合材料制备工艺

在氩气保护下采用钟罩浸块法制备碳镁合金/纳米管复合材料,具体工艺过程如下:首先在氩气保护下,在690~700 ℃温度下在5 kg坩埚电阻炉中先把镁锭及锰粒进行熔炼处理,并加入0.5%~1.5%的RJ?2熔剂起精炼和覆盖作用;完全熔为液态后,将烘干好的预制块加入到镁熔体中,并采用钟罩将其压入熔体中,并不断搅拌分散;炉料全部熔清后加入0.5%~0.8%的六氯乙烷对镁熔体进行精炼变质处理,静置后,在650~660℃,采用真空吸铸法制得试样。

1.4 测试方法

在室温条件下,利用CSS?55100型电子万能材料试验机测试复合材料铸态力学性能,拉伸速率为 1 mm/min。试样经磨制、抛光,并用酒精?5%硝酸(质量分数)腐蚀后在XJG?05型金相显微镜下进行组织观察。用HXS?1000AK显微硬度计测试复合材料的显微硬度,载荷为1 N,加载时间为10 s。利用Quanta200环境扫描电子显微镜进行试样断口形貌观察和能谱分析。实验中所有数据都采用5次测试的平均值。

2 结果与讨论

2.1 CNTs加入量对CNTs/AZ31复合材料显微组织的影响

图3所示为AZ31镁合金和AZ31/CNTs复合材料的铸态金相组织。由图3可知,随着CNTs的加入,晶粒明显细化。碳纳米管对基体组织的细化机制主要有以下两点[15]: 1) 碳纳米管作为纳米级增强相的引入, 形成了巨大的微观界面区域,包括增强相与增强相之间、基体与增强相之间的界面, 这些界面提供了较多优先形核的位置, 在材料凝固过程中α-Mg 固溶体在这些界面区域非均质形核, 大幅提高形核率;2) 丝状的碳纳米管相互连接阻碍初生相界面移动, 延迟晶粒长大; 并且随着碳纳米管含量的增加, 形核位置越多, 对相界面的阻力也越大。

由图3还可明显观察到CNTs/ AZ31复合材料试样的晶界比AZ31合金的晶界要宽,离异共晶β-Al12Mg17相呈点状分布,黑色二次β-Al12Mg17相增多。在AZ31合金的凝固过程中初生α-Mg相在碳纳米管上形核并长大。随着晶粒继续长大,CNTs被推移到相界面,并与其它长大的晶粒相接触。此时在晶界处残余熔体的铝含量达到共晶成分,当熔体温度达到共晶温度时,发生共晶转变。而在共晶转变过程中处于晶界的CNTs作为共晶相α-Mg的形核基底优先使共晶α-Mg长大,从而造成晶界处离异共晶形成。

图3 AZ31镁合金和CNTs/AZ31复合材料的铸态金相组织

Fig.3 As-cast metallographs of AZ31 Mg alloy and CNTs /AZ31 composites: (a) AZ31 Mg alloy; (b) AZ31-0.5%CNTs composites; (c) AZ31-1.0%CNTs composites; (d) AZ31- 1.5%CNTs composites

图4所示为AZ31及ZA31-1.0%CNTs(质量分数)复合材料的XRD谱。由图4可知,共晶α-Mg长大,β-Al12Mg17相增多,当加入CNTs后,两物相的XRD谱强度也增强。大部分碳纳米管分布在晶界处的离异共晶β-Al12Mg17相和二次β-Al12Mg17相中,对晶界和晶粒之间起相互搭接和强化作用。

图4 AZ31镁合金及AZ31-1.0%CNTs复合材料的XRD谱

Fig.4 XRD patterns of AZ31 Mg alloy (a) and AZ31- 1.0%CNTs composites (b)

当碳纳米管加入量过多时,由于表面效应,会在基体中偏聚,相互缠绕,分散不均匀(见图5),从而导致复合材料的力学性能下降。

图5 AZ31-1.5%CNTs复合材料的抛光表面SEM像

Fig.5 SEM images of surface of AZ31-1.5%CNTs composites after polishing

2.2 CNTs加入量对CNTs/AZ31复合材料铸态力学性能的影响

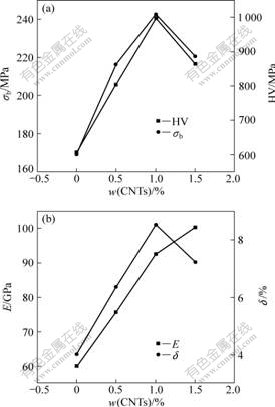

图6(a)所示为CNTs加入量对AZ31镁合金抗拉强度和显微硬度的影响。由图6(a)可知,随着CNTs的加入,相对于基体AZ31镁合金而言,CNTs/AZ31复合材料的抗拉强度显著提高,并在加入量为1.0%时,达到240.56 MPa,相比基体其抗拉强度提高了41.3%;但当加入量为1.5%时,复合材料的抗拉强度有所下降,但仍然高于AZ31镁合金的抗拉强度。抗拉强度的提高是晶粒细化、增强相和界面对位错运动的阻碍作用、强界面结合基础上的载荷转移能力三者综合的结果[15]。由于碳纳米管作为纳米级增强相能较为均匀地分布于基体中,对晶粒和晶界分别起到明显的细化和强化作用,并能抑制位错和晶界的滑移,从而使复合材料的抗拉强度相比于AZ31镁合金得到较大的提高。而经过镀镍处理后的碳纳米管表面润湿性较好,更易与基体形成强界面结合,使镀镍碳纳米管在拉伸变形条件下能较好地发挥载荷转移能力和阻碍晶界滑移的作用,所以复合材料抗拉强度得到显著提高。但是由于碳纳米管的强表面效应,使其有团聚的倾向,从而导致碳纳米管加入量过多时,易在基体中发生偏聚而导致其分布不均匀,从而降低复合材料的抗拉强度。从图6(a)中还可以看出,随着CNTs的加入,复合材料的显微硬度相对AZ31镁合金也显著提高;并在加入量为1.0%时,达到1 008.6HV,相比基体提高了67.8%。但当加入量为1.5%时,复合材料的显微硬度有所下降,这是由于CNTs加入量过多之后会产生偏聚所致,但其硬度仍然高于AZ31镁合金的硬度。由于作为外来形核剂,能细化基体合金的晶粒组织,并跨越晶界,起到强化晶界的作用,使复合材料的显微硬度得到较大提高[16]。但碳纳米管的偏聚会降低其长径比,从而降低复合材料的硬度。

图6(b)所示为碳纳米增加量对AZ31/CNTs复合材料弹性模量和伸长率的影响。由图6(b)可知:随着CNTs的加入,复合材料的弹性模量,相对于基体也显著提高,并在加入量为1.5%时,达到100.26 GPa,相比基体提高了66.9%。复合材料的弹性模量大小主要取决于增强相和基体两相弹性模量的加权平均值,由于碳纳米管的弹性模量极高,可达1TPa[17?18]。两者综合效果使得复合材料的弹性模量得到提高。随着CNTs的加入,相对于AZ31镁合金而言,复合材料的伸长率也显著提高,在加入量为1.0%时,达到8.52%,相比AZ镁合金,提高119.4%;当加入量为1.5%时,有所下降,但仍高于AZ31镁合金的伸长率。GOH 等[19]已证明碳纳米管可以激活镁的交滑移系,从而使复合材料具有较多的滑移系,使界面区域的应力集中减少,从而增加复合材料的延展性。

图6 CNTs加入量对铸态CNTs/AZ31复合材料力学性能的影响

Fig.6 Effects of CNTs addition on mechanical properties of as-cast CNTs/AZ31 composites: (a) Tensile strength and microhardness; (b) Elastic modulus and elongation

2.3 CNTs/AZ31复合材料铸态断口分析

图7所示为AZ31-1.0%CNTs复合材料铸态断口SEM像及EDS谱。从图7可以看出,断口形貌表现出准解理断裂的特征。由图7(a)可知,解理面分布较少,并出现较为明显的圆形韧窝和山脉状撕裂棱。由图7(b)能清晰观察到山脊状的撕裂棱的整体形貌,撕裂棱呈山脊状,高高突起,顶部薄而尖锐。由此说明, 复合材料的断裂形式主要是准解理断裂,断口形貌由韧窝和撕裂棱所组成。

图7 AZ31-1.0%CNTs复合材料铸态断口SEM像和EDS 谱

Fig.7 SEM images ((a), (b)) of AZ31-1.0%CNTs composites after abruption and EDS pattern of zone A in (b), ((c))

图7(b)中的须状物(白色箭头所指)搭接于基体组织之间。对图中7(b)所示A点采用EDS分析得知(见图(c)),这些须状物除了富集大量基体元素Mg和Al之外,还含有9.56%的C元素。显然图中的须状物为脱离于基体且其外壁紧密包覆着一层基体合金的碳纳米管,这也表明碳纳米管和基体界面结合紧密。

3 结论

1) 钟罩浸块法能制备出性能较好的CNTs/AZ31镁基复合材料,大部分碳纳米管分布在晶界处的离异共晶β-Al12Mg17相和二次β-Al12Mg17相中,不仅起到细化晶粒作用,还对晶界和晶粒之间起相互搭接和强化作用。

2) CNTs/AZ31镁基复合材料的力学性能基本随着CNTs加入量的增大而提高;在CNTs加入量为1.0%时,其抗拉强度、显微硬度、伸长率分别都达到最大值240.56 MPa、1 008.6HV和8.52%,分别比AZ31基体的抗拉强度、显微硬度、伸长率提高41.3%、67.8%和119.4%在CNTs加入量为1.5%时,其弹性模量达到最大值100.26 GPa,相比AZ31镁合金提高了66.9%。

3) 复合材料的断裂形式主要由准解理断裂、韧窝和撕裂棱所组成,碳纳米管和基体界面结合紧密。

REFERENCES

[1] 肖 盼, 刘天模, 姜 丹. AZ31镁合金的研究进展[J]. 重庆大学学报: 自然科学版, 2006, 29(11): 81?84.

XIAO Pan, LIU Tian-mo, JIANG Dan. Research status and development of AZ31 magnesium alloy[J]. Journal of Chongqing University: Natural Science Edition, 2006, 29(11): 81?84.

[2] WONG W L E, GUPTA M. Using hybrid reinforcement methodology to enhance overall mechanical performance of pure magnesium[J]. Mater Sci, 2005, 40: 2875?2882.

[3] YE H Z, LIU X Y. Review of recent studies in magnesium matrix composites[J]. Mater Sci, 2004, 39: 6153?6171.

[4] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及其应用[M]. 北京: 机械工业出版社, 2002.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Application and rationale of magnuminium lightweight alloy[M]. Beijing: China Machine Press, 2002.

[5] 胡茂良, 吉泽升, 宋润宾, 郑小平. 镁基复合材料国内外研究现状及展望[J]. 轻合金加工技术, 2004, 32(11): 10?15.

HU Mao-liang, JI Ze-sheng, SONG Run-bin, ZHENG Xiao-ping. Review and prospect on the process of magnesium matrix composites[J]. Light Alloy Fabrication Technology, 2004, 32(11): 10?15.

[6] 张修庆, 腾新营, 王浩伟. 镁基复合材料的制备工艺[J]. 热加工工艺, 2004(3): 58?61.

ZHANG Xiu-qing, TENG Xin-ying, WANG Hao-wei. Preparation technics of magnesium matrix composites materials[J]. Hot Working Technology, 2004(3): 58?61.

[7] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature, 1991, 354(6348): 56?58.

[8] BAUGHMAN R H, ZAKHIDOV A A, HEER W A. Carbon nanotubes-the route toward applications[J]. Science, 2002, 297(5582): 787?792.

[9] DENG C F, WANG D Z, ZHANG X X, LI A B. Processing and properties of carbon nanotubes reinforced aluminum composites[J]. Mater Sci Eng A, 2007, 444: 138?145.

[10] KUZUMAKI T, MIYAZAWA K, ICHINOSE H, ITO K. Processing of carbon nanotube reinforced aluminum composite[J]. J Mater Res, 1998, 13(9): 2445?2449.

[11] KYUNG T K, SEUNG I C, SEONG H H, SOON H H. Microstructures and tensile behavior of carbon nanotube reinforced Cu matrix nanocomposites[J]. Mater Sci Eng A, 2006, 430: 27?33.

[12] MORISADA Y, FUJII H, NAGAOKA T, FUKUSUMI M. MWCNTs/AZ31 surface composites fabricated by friction stir processing[J]. Mater Sci Eng A, 2006, 419: 344?348.

[13] YANG J, SCHALLER R. Mechanical spectroscopy of Mg reinforced with Al2O3 short fibers and C nanotubes[J]. Mater Sci Eng A, 2004, 370: 512?515.

[14] WANG F X, GAO X P, LU Z W, YE S H, QU J Q, WU F, YUAN H T, SONG D Y. Electrochemical properties of Mg-based alloys containing carbon nanotubes[J]. Journal of Alloys and Compounds, 2004, 370(1/2): 326?330.

[15] XI Y L, CHAI D L, ZHANG W X, ZHOU J E. Titanium alloy reinforced magnesium matrix composite with improved mechanical properties[J]. Scripta Materialia, 2006, 54(1): 19?23.

[16] 戚道华, 曾效舒, 姚孝寒. 碳纳米管/ZM5镁合金复合材料的制备与力学性能研究[J]. 铸造技术, 2007, 28(5): 676?682.

QI Dao-hua, ZENG Xiao-shu, YAO Xiao-han. Fabrication and mechanical properties of carbon nanotubes/ZM5 composites[J]. Foundry Technology, 2007, 28(5): 676?682.

[17] 杨晓华, 兑卫真. 纳米碳管及其复合材料的机械性能[J]. 有色金属, 2004, 56(2): 43?47.

YANG Xiao-hua, DUI Wei-zhen. Mechanical properties of carbon nanotubes and its composite materials[J]. Nonferrous Metals, 2004, 56(2): 43?47.

[18] BAUGHMAN R H, ZAKHIDOV A A, HEER W A. Carbon nanotubes-the route toward applications[J]. Science, 2002, 297(5582): 787?792.

[19] GOH C S, WEI J, LEE L C, GUPTA M. Simultaneous enhancement in strength and ductility by reinforcing magnesium with carbon nanotubes[J]. Mater Sci Eng A, 2006, 423: 153?156.

基金项目:江西省科技厅攻关项目(z02727)

收稿日期:2009-03-06;修订日期:2009-09-10

通信作者:曾效舒,教授,博士;电话:13979138023;E-mail:zengxiaoshu@21cn.com

(编辑 龙怀中)