文章编号:1004-0609(2014)11-2928-07

磷灰石在微生物浸铜体系的溶出特性及对浸铜效率的影响

周闪闪1, 2,林 海1, 2,董颖博1, 2,许晓芳1, 2

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京 100083;

2. 北京科技大学 土木与环境工程学院,北京 100083)

摘 要:为了探明磷灰石在微生物浸出黄铜矿体系中的溶出特性及其对黄铜矿浸出的影响,选择粒径小于43 μm的磷灰石与粒径小于74 μm的黄铜矿以及At.f菌组成矿浆浸出体系,考察不同At.f菌接种量对于磷灰石溶出速率的影响及对黄铜矿浸出效果的影响。结果表明:浸出体系中含低浓度PO43-可以提高铜的浸出效率;当At.f菌接种量为5%时,微生物浸出体系中磷灰石溶出的PO43-浓度最小,为0.62 mg/L,此时黄铜矿的最终浸出率最高,达到57.4%,比PO43-溶液浓度最高时体系的铜浸出率提高近30%。通过对微生物浸出前、后的浸渣进行扫描电镜、能谱分析和XRD分析发现,浸出后磷灰石表面浸蚀不明显,而黄铜矿表面浸蚀明显,同时浸渣中有新物质铵黄铁矾生成;磷灰石对于新生成的沉淀有一定的吸附作用,而且溶出较低浓度的PO43-体系能提高黄铜矿的浸出。

关键词:黄铜矿;磷灰石;微生物浸出;At.f菌

中图分类号:TD925.5 文献标志码:A

Dissolution characteristics of apatite in chalcopyrite bioleaching system and its influence on chalcopyrite leaching efficiency

ZHOU Shan-shan1, 2, LIN Hai1, 2, DONG Ying-bo1, 2, XU Xiao-fang1, 2

(1. Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education,

University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Environmental Engineering,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: To make sure the dissolution characteristics of apatite in the chalcopyrite bioleaching system and the influence on the chalcopyrite leaching efficiency, the apatite with particle size of less than 43 μm, chalcopyrite with 74 μm and Acidithiobacillus ferrooxidans (At.f) were used to prepare a bioleaching system. And the influence of different At.f inoculation amount on the apatite dissolution rate and chalcopyrite leaching effect were studied. The results show that chalcopyrite leaching efficiency can be improved when there exists PO43- with low concentration in the bioleaching system. And PO43- reaches the lowest concentration of 0.62 mg/L in the bioleaching system when the At.f inoculation amount is 5%, and the final chalcopyrite leaching rate reaches the highest of 57.4%, which is 30% higher than that in the bioleaching system with the highest concentration of PO43-. Scanning electron microscope (SEM), energy dispersive spectroscope and X-ray diffraction (XRD) analyses before and after the bioleaching show that, there is not any obvious erosion on the apatite surface after leaching, while obvious erosion exists on the chalcopyrite surface and new compound ammoniojarosite generates in the leaching residue. And the precipitates newly generated can be absorbed by apatite, low concentration PO43- in the bioleaching system can improve the leaching of chalcopyrite.

Key words: chalcopyrite; apatite; bioleaching; Acidithiobacillus ferrooxidans

中国铜资源相当匮乏,为了降低生产成本,有效回收低品位、难回收的铜矿物,微生物浸铜技术在矿物加工中应用研究逐渐增多[1-2]。在铜的生物提取方面,目前采用生物法提取的铜约占世界总铜产量的25%,在美国、加拿大、澳大利亚和智利等20多个国家实现了生物提铜产业化[3-5]。

近年来,关于微生物浸铜技术的理论与实践研究报道较多[6-8],但关于微生物浸铜体系中脉石矿物的溶出规律以及对铜浸出率的影响方面的研究较少。脉石矿物是铜矿中含量最多的矿物,其影响和作用都非常大[9-10]。铜矿中所含有的脉石矿物在微生物浸出铜矿物的体系中不断溶出,其溶出的各种离子不仅对浸矿的微生物有很大的影响,而且对铜的浸出也有显著影响[11]。磷灰石是铜矿中常见的一种脉石矿物,如四川拉拉铜矿尾矿矿物中磷灰石以P2O5计质量分数为0.78%[12]。磷灰石在微生物浸出过程中不断溶出PO43-,而磷又是细菌体内核酸、磷脂和ATP的重要组成成分,是细胞的结构物质,参与高能化合物如ATP和ADP的形成,在能量积累和转换过程中发挥作用,能够活化体内蛋白质,调控细菌体的整个代谢过程,在体内信号转导和生理代谢等方面扮演十分重要的角色[13-14]。故研究磷灰石在微生物浸铜体系中的溶出规律以及对黄铜矿微生物浸出的影响,具有非常重要的意义。

1 实验

1.1 实验矿物

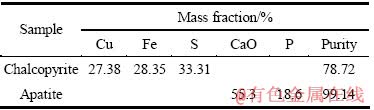

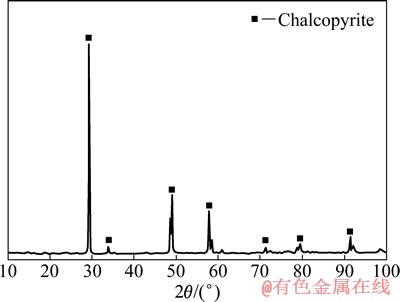

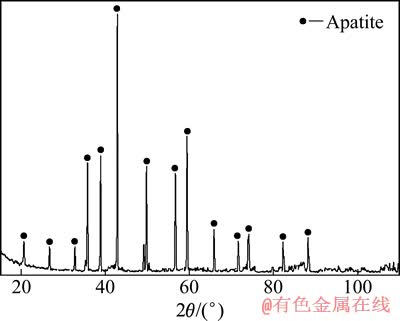

实验采用黄铜矿(黄铁矿型黄铜矿)和磷灰石纯矿物。黄铜矿矿样经手工挑选出单颗粒,用盐酸浸泡以净化硫化矿表面后,用蒸馏水反复浸泡、清洗并采用瓷球磨细磨至粒度小于74 μm。实验用矿物主要元素分析结果见表1,黄铜矿纯度为78.72%,主要是因为黄铜矿和黄铁矿共伴生,且黄铁矿的存在有利于黄铜矿的微生物浸出[15],因此,手工挑选时只是尽量挑选纯黄铜矿,但也存在少量的黄铁矿和黄铜矿连生体。黄铜矿、磷灰石的XRD谱分别如图1和2所示。由图1和2中可看出,实验样品中杂质较少。

表1 矿物中主要元素分析

Table 1 Analytical results of main elements in ore samples

图1 黄铜矿的XRD谱

Fig. 1 XRD pattern of chalcopyrite

图2 磷灰石的XRD谱

Fig. 2 XRD pattern of apatite

1.2 菌种及培养基制备

浸矿菌种经鉴定为嗜酸性氧化亚铁硫杆菌(Acidthiobacillus ferrooxidans,At.f菌),同源度为99.99%,其16SrDNA gene基因库登录序列号为FN811931.。菌种最佳培养条件如下:初始pH值2.0,摇床温度30 ℃,转速160 r/min,采用9 K培养基[16]。

微生物的富集培养采用9 K培养基,其组成为(NH4)2SO4 3.00 g/L,KCl 0.10 g/L,K2HPO4 0.50 g/L,MgSO4·7H2O 0.50 g/L,Ca(NO3)2 0.01 g/L,FeSO4·7H2O 44.20 g/L,pH=2.0。

1.3 试验方法

脉石矿物对黄铜矿微生物浸出的影响试验在250 mL锥形瓶中进行,采用9 K培养基,经LS-B55L型立式压力蒸汽灭菌锅灭菌后,加入黄铜矿2 g和磷灰石3 g(矿浆浓度为5%时黄铜矿的浸出率较高[15],且脉石矿物是铜矿中含量最多的矿物,为了研究脉石矿物溶出规律,确定黄铜矿为2 g,磷灰石为3 g),调节酸平衡至pH=2.0后(用体积分数为10%稀硫酸调节矿浆pH),分别接入不同接种量的菌液(5%、10%和15%),使最终浸出液都为100 mL,将锥形瓶用封口透气膜封上,放入THZ-D型台式恒温振荡器,调节实验温度为30 ℃,转速为160 r/min。考察At.f接种量对磷灰石在微生物-化学作用下溶出特性的影响,间隔一定时间后测定浸出体系的pH和氧化还原电位φ以及PO43-溶出离子浓度,取样损失用相同体积、pH=2.0的稀硫酸补充。试验结束后,过滤浸出液,浸渣经pH=2.0的稀硫酸清洗处理后自然风干、称量,分析残留矿物的量及浸渣的组成、表面化学成分和形貌的变化。

1.4 分析方法

用Mettler320型pH计测量浸出体系的pH值;用BPP-922型台式ORP计实时监测浸出铜体系中的氧化还原电位;用METTLER TOLEDO 326电导率仪测量各试验体系的电导率值;Cu2+和PO43-质量浓度采用全谱多参数水质分析仪进行测定;用SEM-EDS观察分析不同浸出条件下矿物表面的形貌特征;用XRD分析不同浸出条件下矿物成分的变化。

2 结果与分析

2.1 浸出体系中矿物溶出规律

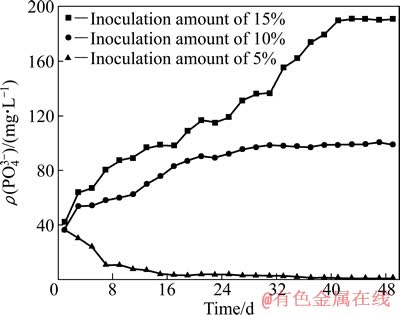

选择粒度小于43 μm的磷灰石,与粒度小于74 μm的黄铜矿构成矿浆浸出体系,考察不同At.f接种量对在微生物浸出黄铜矿体系中磷灰石的溶出特性和对铜浸出率的影响。At.f接种量分别为5%、10%和15%,浸出温度为30 ℃,摇床转速为160 r/min,浸出时间为49 d。

图3所示为不同At.f接种量浸出体系中浸出49 d后PO43-的溶出浓度。从图3可以发现,接种量为5%、10%和15%时,浸出49 d后,对应脉石矿物磷灰石中PO43-浓度分别为190.67、98.91和0.62 mg/L。At.f接种量不同,PO43-溶出浓度相差也比较大。对于At.f接种量为10%和15%的微生物浸出体系,其磷灰石中PO43-的溶出浓度不断增加并逐渐趋于平衡;而At.f接种量为5%的浸出体系中,PO43-的浓度不断降低,最终保持不变。浸出体系中PO43-的浓度不断降低说明在细菌浸出黄铜矿体系中,PO43-不断被细菌利用来维持正常的生命活动[13],而且还生成了部分含磷的沉淀物质(这与EDS能谱分析相吻合),其被利用和生成沉淀物质的速率要明显高于磷灰石中PO43-在酸和细菌作用下的溶出速率。综上所述可以发现,浸出体系中磷灰石的溶解不仅是酸作用下的化学溶出,其中的细菌对于磷灰石在微生物浸出体系中的溶解也有很大的影响。

图3 不同At.f接种量浸出体系中浸出49 d后PO43-的溶出浓度

Fig. 3 Dissolution concentration of PO43– in leaching system with different inoculum amounts of At.f after leaching for 49 d

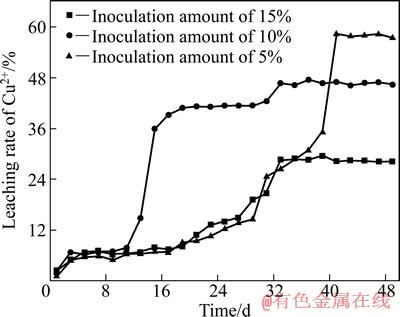

图4所示为浸出体系浸出49 d的Cu2+浸出率变化情况。在浸出初期,接种量对于黄铜矿的浸出影响不大,其浸出率基本一样。在浸出中期,接种量对于黄铜矿的影响比较明显:At.f接种量为10%的浸出体系中黄铜矿浸出率增长较快,但也在较短时间内即趋于平稳;接种量为5%和15%的浸出体系中黄铜矿浸出率在前35 d基本差别不大,35 d后区别较明显,接种量为5%的浸出体系中黄铜矿的浸出率增长迅速。浸出末期,溶液中的铜浸出率变化不大,浸出49 d、接种量为5%、10%和15%时,对应体系中铜的浸出率分别为57.40%、46.33%和28.13%。在At.f接种量为5%的微生物浸出体系中,黄铜矿的最终浸出率最高,为57.40%。其变化规律与浸出体系中PO43-的浓度变化规律相反,体系中PO43-的最终浓度越高,黄铜矿的浸出率越低。张成桂[13]认为低浓度的PO43-能促进细菌的生长,提高细胞分裂速度,使细菌生长平稳期的细菌浓度显著大于正常生长情况下的细菌浓度;只有高浓度的磷酸盐环境才能抑制细菌的生长的观点与本文研究相符。

图4 不同At.f接种量浸出体系中浸出49 d后Cu2+的浸出率

Fig. 4 Leaching rate of Cu2+ in leaching system with different At.f inoculum amounts after leaching for 49 d

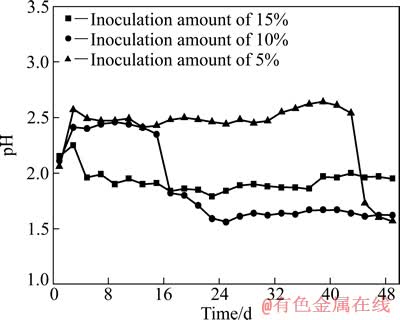

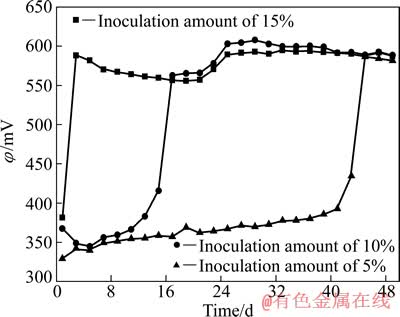

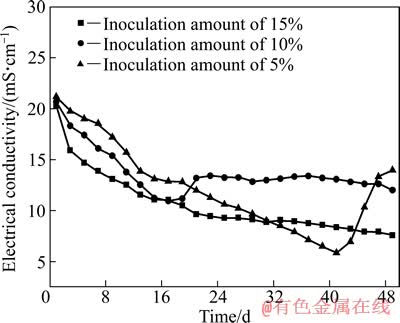

同时,本文作者测定了不同At.f接种量浸出体系的pH、φ和电导率随浸出时间的变化,其结果分别见图5、6和7。

图5 不同At.f接种量浸出体系的pH值

Fig. 5 pH value in leaching system with different inoculum amounts of At.f

图6 不同At.f接种量浸出体系的φ值

Fig. 6 φ value in leaching system with different inoculum amounts of At.f

图7 不同At.f接种量浸出体系的电导率

Fig. 7 Electrical conductivity in the leaching system with different inoculum amount

由图5可以发现,随着时间的延长,其浸出体系的pH呈先上升后下降后趋于稳定的变化趋势,但由于At.f接种量不同,其体系pH的变化程度不同。At.f接种量越大,其pH变化程度越小。浸出体系中能导致pH上升的过程有矿物溶解以及At.f菌氧化Fe2+;反之,pH值下降的过程有At.f菌氧化S的过程、Fe3+水解和生成铁矾类物质的过程。浸出初期,由于浸出体系中含有大量的Fe2+及磷灰石和黄铜矿在酸性溶液中的溶解,所以导致浸出初期溶液pH值呈现上升趋势。随着浸出过程的进行,At.f菌氧化S的过程、Fe3+水解和生成铁矾类物质的过程占据了主导作用,从而使浸出体系的pH值呈现下降的趋势。

由图6可以看出,At.f接种量不同,其体系的氧化还原电位变化也不相同。At.f接种量为15%时,其氧化还原电位增加比较迅速,第3 d时,氧化还原电位就已经达到将近600 mV;而在At.f接种量为10%和5%的浸出体系中,氧化还原电位有一个缓慢的增长期,且接种量越小,浸出体系的氧化还原电位缓慢增长期越长,但最终体系的氧化还原电位相差不大。浸出49 d后,At.f接种量5%、10%和15%的浸出体系的氧化还原电位分别达到581.3、588.2和586.8 mV。

由图7可以发现,随着时间的延长,电导率基本都是呈先逐渐下降后上升最后趋于平稳趋势,但At.f接种量为15%的浸出体系电导率是一直在缓慢下降的。正常情况下,随着矿物的溶解,电导率应该是不断上升的,但该体系电导率呈现下降趋势,应该是由于溶液中开始含有较高的Fe2+,且随着时间的延长,Fe2+不断被氧化为Fe3+并有部分生成沉淀,其速度大于矿物的溶解和微生物浸出速度,导致溶液中整体离子浓度下降,所以使其在一定时期内都是呈现不断下降的趋势。且随着浸出的不断进行,溶液中离子被细菌利用、生成沉淀物的速率小于矿物溶出离子的速率时,其溶液的电导率开始上升,直到两者速率基本相同时,电导率保持基本不变。

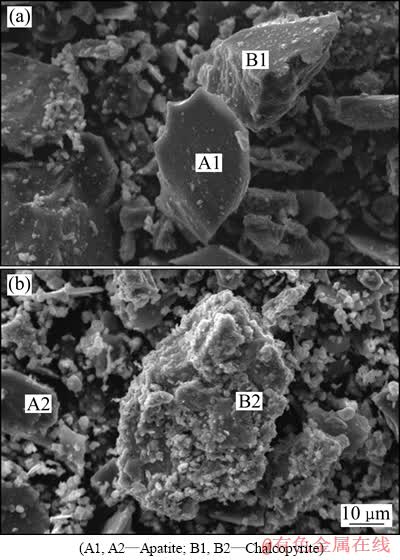

2.2 浸渣的SEM-EDS分析

为了观察经细菌浸出前、后矿石表面微观结构的变化情况,分别对黄铜矿和磷灰石混合矿浸出前后的矿石表面进行扫描电镜分析,其结果如图8所示。由图8可以发现,浸出前、后矿石表面的微观结构发生了明显变化,浸出前黄铜矿和磷灰石矿物表面平整,棱角明显。浸出49 d后,浸渣中各矿物表面形貌相差比较明显,主要是磷灰石表面比较平滑、边缘平整、棱角分明、晶体形状还比较完整,表面上还零星分散一些小颗粒,说明其并没有受到明显浸蚀;黄铜矿颗粒表面由于细菌吸附浸蚀现象明显,出现了许多腐蚀小坑,变得凹凸不平,且有颗粒状物质,结构疏松,受腐蚀部位多出现在矿物缺陷、裂缝、位错等区域,这是由于细菌在矿物表面的附着是有选择性的,起初主要附着在有表面缺陷和位错等能引起表面高电荷的位置[16]。

图8 黄铜矿和磷灰石浸出前后的SEM像

Fig. 8 SEM images of chalcopyrite and apatite before (a) and after (b) bioleaching

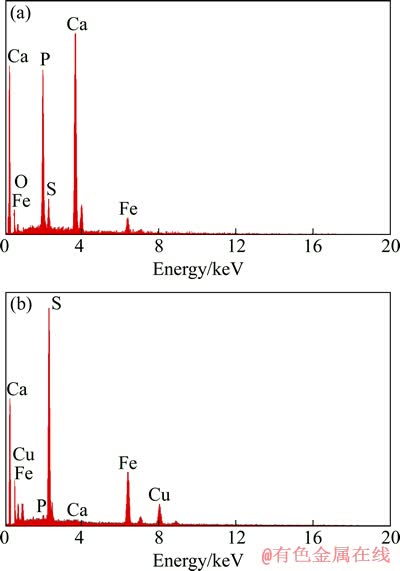

图9 黄铜矿和磷灰石浸出后的EDS能谱分析

Fig. 9 EDS spectra of apatite (a) and chalcopyrite (b) after bioleaching

由各矿物的EDS能谱分析(见图9)可知,在磷灰石的表面除了发现Ca、P和O峰外,还有Fe和S峰,说明磷灰石对于溶液中的离子或反应生成的沉淀(氢氧化铁和元素硫等)产生了吸附作用,这种吸附作用有可能是提高铜浸出率的原因;在黄铜矿表面,Cu峰降低,几乎消失,主要是由于黄铜矿被细菌氧化溶解,Cu离子进入溶液,另外,在黄铜矿表面发现有Ca和P峰,说明磷灰石发生了溶解。同时,在浸出过程中,黄铜矿中的Cu2+在细菌作用下加速溶解形成离子状态,而且脉石矿物磷灰石随着浸出的进行将其含有的主要元素物质释放在浸出液中。

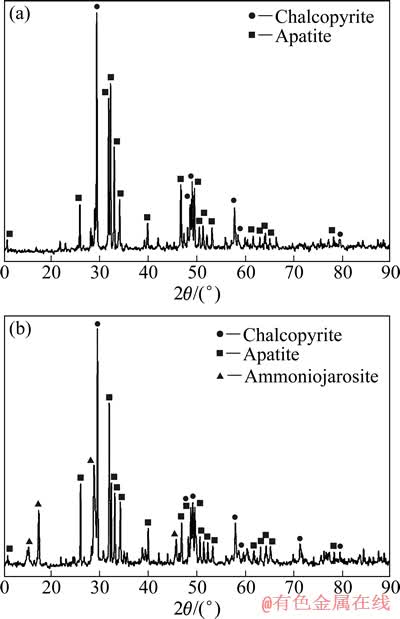

2.3 浸渣XRD分析

对比磷灰石和黄铜矿微生物浸出前后的XRD分析结果(见图10)可以发现,浸渣中主要含有黄铜矿、磷灰石、铵黄铁矾[(NH4)2Fe6(SO4)4(OH)12],与原矿相比新生成的物质是铵黄铁矾。由于培养基中含有(NH4)2SO4浓度为3.0 g/L,而且浸出时采用的是9 K培养基,其中含Fe较多,在浸出的过程中pH值较低,有利于生成铵黄铁矾。铵黄铁矾覆盖在黄铜矿表面,对其浸出有一定的阻碍作用,但是铵黄铁矾的峰较弱,说明钝化物较少,从而解释了在存在脉石矿物磷灰石的黄铜矿微生物浸出体系中,当磷灰石溶出的PO43-浓度较低时可以促进Cu浸出的原因。

图10 磷灰石和黄铜矿微生物浸出前后的XRD谱

Fig. 10 XRD patterns of chalcopyrite and apatite before (a) and after bioleaching (b)

3 结论

1) 以At.f作为浸矿菌种,采用9 K培养基,浸出以黄铜矿和磷灰石组成混合矿,浸出49 d后,由于细菌接种量不同,PO43-溶出浓度相差也比较大。在At.f接种量为10%和15%的微生物浸出体系中,磷灰石中PO43-的溶出浓度不断增加并逐渐趋于平衡;而At.f接种量为5%的浸出体系中,PO43-的浓度在不断降低,最终保持不变。At.f接种量为15%的浸出体系中,PO43-浓度最高,达到190.67 mg/L。

2) 微生物浸出体系中,Cu浸出率随时间不断增加,浸出体系中的PO43-的浓度越低,黄铜矿的浸出率越高;浸出49 d后,接种量为5%,PO43-的最低浓度为0.62 mg/L,黄铜矿浸出率达到最高,为57.40%,比PO43-溶液浓度最高体系的铜浸出率高了近30%。

3) 浸出49 d后,浸渣中各矿物表面形貌相差比较明显,主要是磷灰石表面比较平滑,没有受到明显浸蚀;黄铜矿颗粒表面由于细菌吸附浸蚀现象明显。

4) 磷灰石对于溶液中的离子或反应生成的沉淀产生了吸附作用,这种吸附作用有可能是提高Cu浸出率的原因;在黄铜矿表面,Cu峰降低,几乎消失,主要是由于黄铜矿被细菌氧化溶解,Cu离子进入溶液,另外,在黄铜矿表面发现有Ca和P峰,说明磷灰石发生了溶解。铵黄铁矾是浸渣中的主要新生成物质,覆盖于黄铜矿的表面对微生物浸出Cu有一定的阻碍作用。

REFERENCES

[1] BRIERLEY J A,BRIERLEY C L. Present and future commercial applications of biohydrometallurgy[J]. Hydrometallurgy, 2001, 59: 233-236.

[2] WALRLING H R. The bioleaching of sulphide minerals with emphasis on copper sulphides: A review[J]. Hydrometallurgy, 2006, 84: 81-108.

[3] 曾 涛. 投资海外铜矿的经验和教训[J]. 中国金属通报, 2009, 25: 32-33.

ZENG Tao. Experience and lessons of investment overseas copper[J]. China Metal Bulletin, 2009, 25: 32-33.

[4] 郑永兴, 文书明, 刘 健, 邓永帅. 难处理氧化铜矿强化浸出的研究概况[J]. 矿产综合利用, 2011(2): 33-36.

ZHENG Yong-xing, WEN Shu-ming, LIU Jian, DENG Yong-shuai. Study of refractory oxidized copper leaching[J]. Multipurpose Utilization of Mineral Resources, 2011(2): 33-36.

[5] EDGARDO R D, WOLFGANG S. Microbial processing of metal sulfides[M] . Netherland: Springer Verlag, 2007: 1-33.

[6] ZHAO Xing-qing, WANG Ru-cheng, LU Xian-cai, LU Jian-jun, LI Cheng-xiang, LI Juan. Bioleaching of chalcopyrite by Acidithiobacillus ferrooxidans[J]. Minerals Engineering, 2013, 53: 184-192.

[7] DENISE B, HEIDI L, PATRICIA H S, OSWALDO G Jr, ASSIS V B, JAAKKO A P, OLLI H T. Effect of Na-chloride on the bioleaching of a chalcopyrite concentrate in shake flasks and stirred tank bioreactors[J]. Hydrometallurgy, 2013, 138(6): 1-13.

[8] DONG Ying-bo, LIN Hai, XU Xiao-fang, ZHANG Yue, GAO Yue-jiao, ZHOU Shan-shan. Comparative study on the bioleaching, biosorption and passivation of copper sulfide minerals[J]. International Biodeterioration & Biodegradation, 2013, 84: 29-34.

[9] 莫晓兰, 林 海, 傅开彬, 董颖博, 徐承焱. 绢云母对黄铜矿微生物浸出的影响[J]. 中国有色金属学报, 2012, 22(5): 1475-1481.

MO Xiao-lan, LIN Hai, FU Kai-bin, DONG Ying-bo, XU Cheng-yan. Effect of sericite on bioleaching of chalcopyrite[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1475-1481.

[10] DONG Ying-bo, LIN Hai, ZHOU Shan-shan, XU Xiao-fang, ZHANG Yue. Effects of quartz addition on chalcopyrite bioleaching in shaking flasks[J]. Minerals Engineering, 2013, 46/47: 177-179.

[11] YU Run-lan, LIU Jing, CHEN An, ZHONG Dai-li, LI Qian, QIN Wen-qing, QIU Guan-zhou, GU Guo-hua. Interaction mechanism of Cu2+, Fe3+ ions and extracellular polymeric substances during bioleaching chalcopyrite by Acidithiobacillus ferrooxidans ATCC2370[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 231-236.

[12] 罗仙平, 邱廷省, 胡玖林, 郝志伟, 成先雄. 综合回收拉拉厂铜矿尾矿中磷资源的实验研究[J]. 矿冶, 2002, 11(增刊): 247-249.

LUO Xian-ping, QIU Ting-sheng, HU Jiu-lin, HAO Zhi-wei, CHENG Xian-xiong. Experimental research of comprehensive recovery phosphorus resources from LALA copper mine tailings[J]. Mining & Metallurgy, 2002, 11(Supplementary Issue): 247-249.

[13] 张成桂. 嗜酸氧化亚铁硫杆菌适应与活化元素硫的分子机制研究[D]. 长沙: 中南大学, 2008.

ZHANG Cheng-gui. The study on molecular mechanism of cellular sulfur acclimation and sulfur activation by Acidithiobacillus ferrooxidans[D]. Changsha: Central South University, 2008.

[14] HE Zhi-guo, ZHONG Hui, HU Yue-hua, XIAO Sheng-mu, LIU Jiar-she, XU Jin, LI Gui-yuen. Analysis of differential expressed proteins of Acidithiobacillus ferrooxidans grown under phosphate starvation[J]. Journal of Biochemistry and Molecular Biology, 2005, 38: 545-549.

[15] 董颖博. 含铜尾矿微生物浸矿菌种的选育和浸出规律研究[D]. 北京: 北京科技大学, 2011.

DONG Ying-bo. Study on the breeding of bacteria for bioleaching of copper-containing tailings and the leaching rules[D]. Beijing: University of Science and Technology Beijing, 2011.

[16] DONG Ying-bo, LIN Hai, WANG Han, MO Xiao-lan, FU Kai-bin, WEN Hong-wei. Effects of ultraviolet irradiation on bacteria mutation and bioleaching of low-grade copper tailings[J]. Minerals Engineering, 2011, 24(8): 870-875.

(编辑 龙怀中)

基金项目:国家自然科学基金青年基金资助项目(51204011);中国博士后科学基金第六批特别资助项目(2013T60063);北京市优秀博士学位论文指导教师科技项目(20121000803)

收稿日期:2014-02-20;修订日期:2014-07-15

通信作者:董颖博,副教授,博士;电话:010-62333603;E-mail:gaia1983@163.com