DOI: 10.11817/j.issn.1672-7207.2020.12.028

基于风洞试验和CFD仿真的350 km/h高速铁路飞砟研究

井国庆1,杜文博1,丁东2,汲生成3

(1. 北京交通大学 土木建筑工程学院,北京,100044;

2. 法国贡比涅技术大学,法国 贡比涅,60200;

3. 中国商飞北京民用飞机技术研究中心,北京,102211)

摘要:研究350 km/h高速列车作用下,有砟道床表面流场和空气动力特性、道床断面形式对飞砟问题的影响以及小粒径单个道砟的风动特性。构造有砟轨道钢轨—轨枕—道床半边模型并进行风洞试验,同时利用k-ω SST双方程湍流模型和不可压缩三维定常雷诺时均方程(RANS)进行CFD仿真分析。研究结果表明:轨枕盒内部风压存在由正变负的现象,降幅约为300 Pa,最大负风压出现在轨枕背风面和端部,约为-400 Pa;道床中心处负风压大、风速高且相对稳定;距离道床表面越远,负压越大;钢轨附近风压波动大,外侧负压小于内测负压;钢轨两侧轨枕盒内风速变化大且产生小幅度空腔涡流和明显后台阶流动效应;负风压随砟肩堆高增加而增大,50 mm的砟肩增高会引起2%~5%的负风压增幅,为在防治飞砟的同时兼顾轨道结构稳定性,砟肩堆高宜选用100 mm;降低道床顶面位置对其表面风场特性无显著改善,但可减少道砟落在轨枕表面的概率;道砟颗粒在风荷载作用下先发生颤动再发生滚动,轨枕表面、轨道中心和砟肩部位道砟更易发生移动,为防治飞砟应及时清理轨枕表面道砟。

关键词:有砟轨道;飞砟;风洞试验;CFD仿真;空气动力学

中图分类号:U213.3 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)12-3546-08

350 km/h high speed railway ballast flight analysis based on wind tunnel test and CFD simulation

JING Guoqing1, DU Wenbo1, DING Dong2, JI Shengcheng3

(1. School of Civil Engineering, Beijing Jiaotong University, Beijing 100044, China;

2. University of Technology of Compiègne, Compiègne 60200, France;

3. Beijing Aeronautical Science & Technology Research Institute, Beijing 102211, China)

Abstract: Wind flow field and aerodynamic characteristics of the ballasted track bed surface at 350 km/h trains running speed were investigated. The influence of track bed geometry and the ballast particle position on the ballast flight was also analyzed. Wind tunnel tests and the CFD simulation analysis were carried out to study the aerodynamics of rail-sleeper-ballast half model. During the CFD simulation, k-ω SST turbulence model and 3-D steady incompressible RANS equations were used to analyze. The results show that wind pressure between sleeper changes from positive to negative, with the decrease of 300 Pa. The maximum negative air pressure occurs on the leeward side and the end of the sleeper, with about -400 Pa. The center of the ballast bed has higher wind speed, and greater negative pressure. Wind pressure near the rail fluctuates greatly, and the external negative pressure is less than the internal pressure. Wind speed on both sides of the rail varies greatly and produces a small cavity vortex. The higher the ballast shoulder, the greater the wind negative pressure. Ballast shoulder height increase with 50 mm can cause wind negative pressure to increase by 2% to 5%; however, considering ballast flight prevention and track structure stability, 100 mm ballast shoulder is appropriate. Reducing the crib height has no significant improvement on aerodynamics characteristics of the track surface, but it can decrease the probability of ballast particles moving onto the sleeper surface. Under wind load, the ballast particles change from vibration to move. The positions of sleeper surface, track center and ballast shoulder easily have ballast movement. Therefore, in order to prevent ballast flight, a regular cleaning measure is necessary.

Key words: ballasted track; ballast flight; wind tunnel test; CFD simulation; aerodynamics

飞砟是指在列车动力和空气动力共同作用下,有砟轨道道床表面道砟发生迁移、跳跃甚至飞离道床,并击打列车车体及转向架的现象,一般发生在列车速度超过300 km/h时[1-2]。飞砟现象危害大、分布广,是目前高速有砟轨道面临的严重问题之一,除限制列车提速外,还会损坏道床和车体结构,威胁列车安全行驶。飞砟现象引起的破坏主要包括:1) 道砟颗粒散落在钢轨踏面上改变车轮-钢轨作用力,引起轨道恶化和车轮扁疤;2) 道砟击打车体和转向架引起损伤;3) 有砟道床断面形式难于保持,承载力不均匀甚至不足[3]。

近年来,学者们从空气动力学、轨道动力学和可靠度分析等方面对飞砟问题展开研究[3-7]。研究表明,飞砟现象主要受车体结构、道床结构、列车动力、运营条件和天气的影响。英国伯明翰大学和南安普顿大学在梅德斯通直线段上进行现场试验[3],研究列车底部空气动力学特性和轨道表面的风场特性,并观察到道砟对钢轨轨头的破坏;德国国营铁路公司[7]对ICE3型列车转向架进行风洞试验和CFD仿真,发现转向架空腔位置存在高强度紊流,易引起列车底部风场波动;法国国营铁路公司[8]在应力-强度干涉分析的基础上制定了风险评估方法,可以根据概率分布计算道砟移动的概率,从而评估风险,给出道砟移动阈值。同时,一些学者也对严寒地区冰雪引起的飞砟现象进行了相关研究,发现冰雪路段更易发生飞砟现象[9-10]。但是,目前对道床结构引起列车底部的涡流和风场研究不足,尤其是在空气动力学方面,导致目前在高速铁路有砟轨道设计过程中缺乏降低道床表面风荷载依据。列车动力引起下部道砟颗粒的离散和振动,继而在列车产生的侧向涡流和风压(尤其是负风压)作用下发生飞溅,导致轨道、车体损坏以及道砟分布改变(影响道床阻力)[11]。虽然该问题影响较大,但目前研究仍然不够全面和深入,在运营过程中无法做到有效的预警和防治,在养护维修过程中缺少理论指导,造成人力、物力的大量浪费。为此,本文作者通过有砟轨道风洞试验和空气动力学模拟,研究有砟轨道空气动力学特性,为350 km/h高速铁路标准提供参考,同时为下一步超高速有砟轨道建设与运营奠定理论基础。

1 风洞试验

1.1 试验模型

在充分调研国内外有砟道床结构基础上,根据我国现有高速铁路有砟轨道型式[12-15],制作钢轨-轨枕-道床半边模型,道床模型长为1.52 m,宽为2.4 m,高为0.25 m,边坡坡度为1.00:1.75,砟肩宽度为0.5 m;在模型上方铺设3个方盒模拟Ⅲ型轨枕,并在砟肩和方盒中间铺设特级道砟。

为研究砟肩堆高和道床顶面位置等对有砟轨道流场的影响和小粒径道砟风动特性,制定如下工况及试验内容:砟肩堆高采用150 mm和无砟肩堆高,道床顶面位置采用位于轨枕顶面以下40 mm、道床顶面在轨枕中部与轨枕顶面平齐,同时对22.4~31.5 mm粒径染色道砟进行试验,观察移动情况。

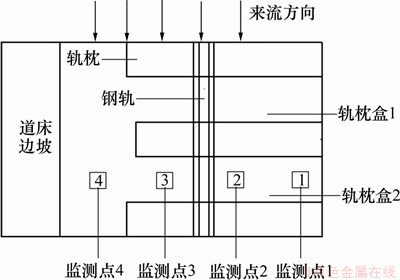

在轨道表面设置监测点,研究不同位置空气动力学特性,监测点布置如图1所示。由于在迎风面风速波动较大,将3个监测点横向布置于轨枕盒内,监测点1位于轨道中心位置;监测点2和监测点3分别位于钢轨内侧和外侧位置(距钢轨底部150 mm处);沿轨道纵向在砟肩顶部设置监测点4。

图1 监测点位置(俯视图)

Fig. 1 Position of pressure detecting points

1.2 试验步骤

根据韩国现场实车试验测试结果,当车速为300 km/h时,轨枕上部风速约为25 m/s,当车速增加到350 km/h时,风速达到30 m/s[6,12,16],因此,本试验将来流风速设定为30 m/s。试验步骤如下。

1) 试验前先将直径为6 mm的塑料管插入监测点作为扫描管通道,之后用标准级配道砟铺设道床、夯实使道砟充分咬合,将60型钢轨放置于木质模型上;

2) 检查测压仪器,无异常后,封闭风洞,打开电源,逐级增加风速,当风速达到10 m/s时开始记录监测点风压,并将风速以3 m/s的增量步逐渐增加到30 m/s,期间记录每级风速所对应风压;

3) 当完成一种工况后停止风机,调整砟肩和轨枕盒道砟结构和厚度,测试下一工况,记录风压;

4) 完成测压试验后,将小粒径染色道砟置于模型和道砟层表面位置,开动风机,通过影像视频观察不同位置道砟颗粒风动特性。

以正风压表示风压力,负风压表示风吸力。道床模型阻塞率为12.5%。根据相关研究,当模型阻塞比大于5%时,正风压增大系数为1.15~1.25,负风压增大系数为1.45~1.60[17]。本文取正风压折减系数为1.00/1.25,负风压折减系数为1.00/1.60进行修正。

2 CFD数值分析

2.1 数值模拟方法

为与风洞试验结果进行对比,研究350 km/h有砟轨道空气动力学特性,本文建立有砟轨道空气动力学模型,采用计算流体力学软件Fluent进行仿真。

2.2 仿真模型与网格划分

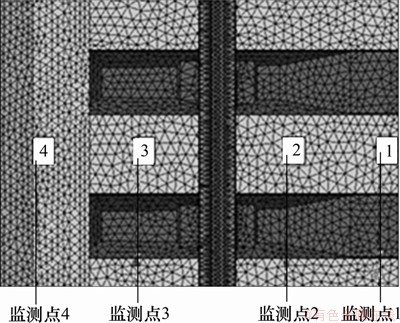

图2所示为有砟轨道空气动力学模型,模型中布置4个监测点,监测点位置与试验时监测点位置相同。该空气动力学模型由10根Ⅲ型轨枕、60型钢轨以及道床组成,道床模型长、宽和高分别为5.72,5.12和0.35 m,砟肩宽度为0.5 m,边坡坡度为1.00:1.75。时速250~300 km/h有砟轨道砟肩堆高为100 mm,同时规定不同速度等级下道床顶面尺寸[15]。根据规范及风洞试验,建模时砟肩堆高分别设为0,50,100和150 mm,道床顶面设为在轨枕顶面下40 mm、道床顶面在轨枕中部与轨枕顶面平齐2种情况。

图2 有砟轨道空气动力学模型

Fig. 2 Ballast bed aerodynamic model

该模型结构对称,因此,沿纵断面取一半进行数值分析,计算域长×宽×高与前述风洞尺寸相同,取3 m×15 m×2 m。模型底面距计算域底面设为0.35 m,模型距风速入口设置为10 m。设定来流风速沿y轴正方向。网格采用“Tetra/Mixed”划分方式。

根据风洞试验监测点布置方法,在轨道模型上相同位置设置监测点。

2.3 模拟参数设定

模型中来流设定为均匀来流。改进的剪应力输运k-ω SST模型在描述近壁面自由流动和约束流动时精确度较高,在列车空气动力学研究中得到认可[18-19]。本文中的空气动力学模型采用该湍流模型及不可压缩三维定常雷诺时均方程RANS方法。扩散项使用二阶中心差分格式,差分离散格式分别使用一阶和二阶迎风格式。控制方程使用耦合压力-速度场和分离式Simple方法求解。

边界条件设定如下:

1) 计算域流动入口处使用速度边界条件。设定入口风速为30 m/s。

2) 计算域流动出口处采用恒压边界条件。压力设定为101.325 kPa。

3) 钢轨、轨枕和有砟道床因材质和施工规范具有不同的粗糙度,影响道床表面流场分布[20]。根据文献[21-22],设定有砟轨道各部分的粗糙度厚度和粗糙度常数。对于粗糙度厚度,道床取4.00 mm,轨枕取2.00 mm,钢轨取0.01 mm;对于粗糙度常数,道床为0.60,轨枕为0.40,钢轨为0.20。

4) 假设边界足够光滑,将计算域表面设置为无摩擦边界。

3 试验与仿真结果

3.1 模型验证

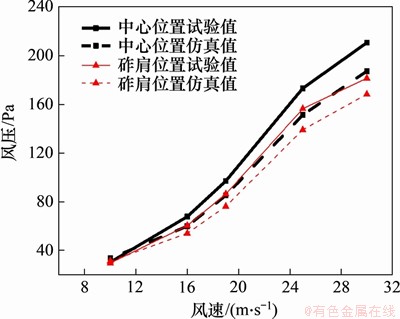

将试验与模拟数据进行对比,结果如表1和图3所示。由表1可知:试验与模拟所得负压相对误差10%左右,处于工程允许误差内[18]。存在误差原因主要有:

1) 数值仿真不能完全模拟道砟层表面不平顺;

2) 试验受设备条件和堵塞率等影响,风场难以产生完全均匀风速;

3) 试验设备和读数等测量误差。

虽然风洞试验与数值模拟存在一定误差,但由图3可知:2种方法所得结果具有一致性且在误差允许范围内。因此,在参考和借鉴相关研究成果基础之上,本文采用CFD数值方法研究有砟道床空气动力学特性。

表1 试验与仿真结果对比

Table 1 Comparison between experiment and simulation

图3 试验与模拟所得不同位置风压-风速曲线

Fig. 3 Wind pressure-wind speed curve at different locations obtained by test and simulation

3.2 风场压力场与流线谱

模型道床顶面设在轨枕中部与轨枕顶面平齐处,砟肩堆高和砟肩宽度分别为100 mm和500 mm,边坡坡度为1.00:1.75[15]。进行仿真分析,研究道床表面风压分布及风速涡流情况。

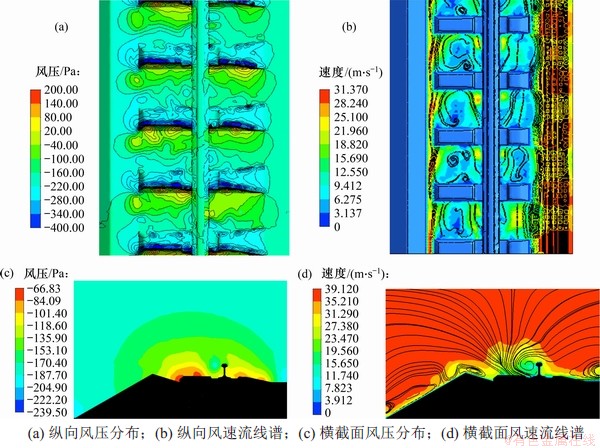

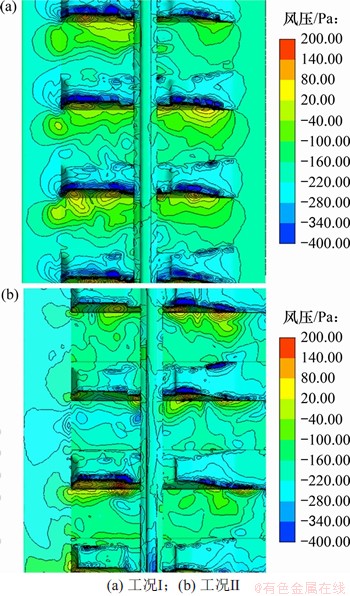

图4(a)和4(b)所示分别为道床顶面纵向风压图和流线谱图,图4(c)和4(d)所示分别为模型中心(y=12.86 m)横截面风压图和流线谱图。

图4 有砟轨道风压和流线谱图

Fig. 4 Pressure contours and velocity streamlines of track

由图4(a)和(b)可知:轨枕盒内风压值沿来流方向由正变负;道床中心负压较大,风速最大,且两者较为稳定;轨枕背风面和端部出现较大负风压;钢轨附近风压波动较大,钢轨两侧轨枕盒内风速变化较大且产生小幅度空腔涡流,有明显后台阶流动效应[12]。

由图4(c)可知:距离道床表面越远,负压越大;钢轨外侧负压小于内侧负压;道床砟肩内外存在约40 Pa风压差。产生该现象的主要原因是在均匀来流条件下,砟肩内侧结构存在不平顺,与工程实际产生差异。由图4(d)可知:钢轨到砟肩范围内风速较低;轨道中心位置处风速较大;在砟肩内侧、钢轨外侧和轨道中心处都产生一定程度空腔涡流。

3.3 砟肩堆高

轨枕横向阻力试验表明,砟肩堆高增加会提高轨道抗变形能力,维持轨道稳定性[23]。然而,在飞砟方面,随着砟肩堆高增加,道砟越靠近车底,更易受列车风影响,增大飞砟概率。当风速为30 m/s时,图1中4号监测点在不同砟肩堆高下的负风压情况如表2所示。

表2 砟肩位置负风压

Table 2 Wind pressure of ballasted shoulder Pa

由表2可知:当风速为30 m/s时,砟肩顶部负风压随砟肩堆高增大而增大,飞砟概率增加。同时,砟肩堆高每增加50 mm,负风压增加2%~5%。综上所述,为防止飞砟,在满足道床稳定性的前提下,砟肩堆高宜选用100 mm,甚至更低。

3.4 道床顶面位置

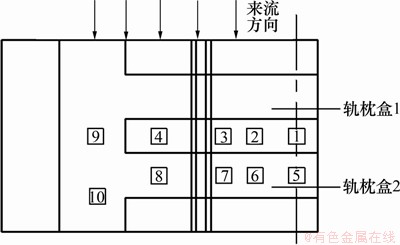

文献[15]中对不同速度等级下有砟轨道道床顶面进行详细要求。本文选取道床顶面在轨枕中部与轨枕顶面平齐(工况Ⅰ)、道床顶面位于轨枕以下40 mm(工况Ⅱ)2种工况,结果如表3所示。

表3 道床顶面位置负压

Table 3 Negative wind pressure on the surface of ballast bed Pa

图5 道床表面风压分布

Fig. 5 Distribution of wind pressure on the surface of ballast bed

由表3可知:2种工况在轨道中心处负压相差不大;但在钢轨内、外侧工况Ⅱ的负压明显较工况Ⅰ的负压大,最大达26 Pa。由图5所示,工况Ⅰ道床表面风压变化较为稳定,工况Ⅱ风压较紊乱;相同位置处工况Ⅱ的负压较大,即降低道床顶面位置对道床表面风场特性并无显著改善。虽然道床顶面位置降低可能会引起轨枕盒内道床顶部负压变大,但将减少道砟落在轨枕表面的概率。

因此,可提出2种防治飞砟的方法:1) 可在确保道床稳定性的前提下,降低道床顶面高度;2) 可在不改变道床高度的前提下,提高轨枕高度。

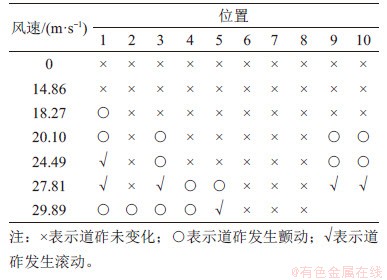

3.5 道砟颗粒风动特性

为研究道砟在风荷载作用下的运动规律,本试验在道床表面设置10个点放置道砟,如图6所示,轨枕上设4个点,依次分别为轨枕中心处、轨道中心处、钢轨内侧和轨枕端部,分别记为1,2,3和4号点;在轨枕盒内设置4个与轨枕上点相对应的点,记为5,6,7和8号;同时,在道床砟肩顶部设置9和10号点。

图6 小粒径道砟摆放位置

Fig. 6 Placement position of small size ballast

将粒径为22.4~31.5 mm的小颗粒辉绿岩道砟放置在上述位置,进行风洞试验,采用视频影像观察上述位置道砟的移动情况,并进行统计,如表4所示。

表4 小粒径道砟不同风速移动情况

Table 4 Movement of small size ballast at different wind speeds

由表4可知:当风速为0~15 m/s时,轨枕盒、道床砟肩顶部和轨枕上的道砟无明显移动现象;增加风速至20 m/s,在轨枕上部轨枕中心处(1号点)、轨枕上部钢轨内侧(3号点),道床砟肩顶部(9和10号点)的道砟出现颤动,可能发生移动;当风速增加至28 m/s时,在轨枕上部轨枕中心处(1号点)、轨枕上部钢轨内侧(3号点),道床砟肩顶部(9和10号点)的道砟发生滚动,同时,轨枕上部钢轨外侧(4号点)和轨枕盒内部轨枕中心处(5号点)的道砟发生颤动;当风速达30 m/s时,轨枕表面道砟发生颤动,轨枕盒内中心处道砟向前发生滚动,其余位置道砟无明显位移变化。以上试验表明,轨道中心、轨枕表面以及砟肩部位道砟更容易在风荷载作用下发生移动。

4 结论

1) 轨枕盒内风压存在由正变负的现象,降幅约为300 Pa,轨枕背风面和端部负风压较大,约为-400 Pa。

2) 道床中心负风压较大,风速高,并相对平稳;钢轨附近风压波动较大,钢轨两侧轨枕盒内风速变化较大且产生空腔涡流。

3) 砟肩负风压随着砟肩堆高增加而增大,每增加50 mm,负风压增加2%~5%。将飞砟问题和轨道结构稳定性结合考虑,砟肩堆高宜选用100 mm。

4) 降低道床顶面位置对其表面风场特性无显著改善,但可减少道砟落在轨枕表面的概率。

5) 道砟颗粒在风荷载作用下先发生颤动再发生滚动,轨道中心、轨枕表面以及砟肩部位道砟更易移动。应注意清理轨枕表面道砟。

参考文献:

[1] JING Guoqing, DING Dong, LIU Xiang. High-speed railway ballast flight mechanism analysis and risk management: a literature review[J]. Construction and Building Materials, 2019, 223: 629-642.

[2] 何华武. 无碴轨道技术[M]. 北京: 中国铁道出版社, 2005: 2-3.

HE Huawu. Ballastless track technology[M]. BeiJing: China Railway Publishing House, 2005: 2-3.

[3] QUINN A D, HAYWARD M, BAKER C J, et al. A full-scale experimental and modelling study of ballast flight under high-speed trains[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2010, 224(2): 61-74.

[4] KWON H B, PARK C S. An experimental study on the relationship between ballast flying phenomenon and strong wind under high speed train[C]// Proceedings of the World Congress on Rail Research. Montreal, Canada, 2006: 83-93.

[5] 井国庆, 丁东, 邵帅. 基于Monte Carlo高速铁路飞砟可靠性分析研究[J]. 铁道科学与工程学报, 2016, 13(7): 1234-1240.

JING Guoqing, DING Dong, SHAO Shuai. Reliability assessment on high speed railway ballast flight based on Monte Carlo[J]. Journal of Railway Science and Engineering, 2016, 13(7): 1234-1240.

[6] 殷浩, 高亮, 蔡小培, 等. 高速列车作用下道床表面风场特性研究[J]. 铁道学报, 2018, 40(12): 137-144.

YIN Hao, GAO Liang, CAI Xiaopei, et al. Wind field characteristics on surface of track bed under action of high-speed train[J]. Journal of the China Railway Society, 2018, 40(12): 137-144.

[7] KALTENBACH H J, PORTILLO I A, SCHOBER M. A generic train-underfloor experiment for CFD validation[C]// SHIRAISHI N. Bluff Bodies Aerodynamics and Applications. Milano, Italy: Elsevier Science Ltd, 2008: 20-24.

[8] SAUSSINE G, VOIVRET C, PARADOT N,et al. A risk assessment method for ballast flight; managing the rolling stock/infrastructure interaction[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2015, 229(6): 581-593

[9] DING Dong, OUAHSINE A, XIAO Weixuan, et al. Numerical study of ballast-flight caused by dropping snow/ice blocks in high-speed railways using Discontinuous Deformation Analysis (DDA)[J]. Transportation Geotechnics, 2020, 22: 100314.

[10] 井国庆, 丁东. 严寒地区高速铁路冰雪飞溅特性及防治研究[J]. 铁道工程学报, 2017, 34(9): 29-34.

JING Guoqing, DING Dong. Snow flight characteristic and prevention research on the high speed railway in cold region[J]. Journal of Railway Engineering Society, 2017, 34(9): 29-34.

[11] 井国庆. 铁路有砟道床[M]. 北京: 中国铁道出版社, 2012: 122-137.

JING Guoqing. Railway ballast bed[M]. Beijing: China Railway Publishing House, 2012: 122-137.

[12] 林建, 井国庆, 黄红梅. 严寒地区高速铁路冰雪飞溅与防治[J]. 铁道科学与工程学报, 2016, 13(1): 28-33.

LIN Jian, JING Guoqing, HUANG Hongmei. High-speed railway snow flying and prevention measures in cold regions[J]. Journal of Railway Science and Engineering, 2016, 13(1): 28-33.

[13] 颜华, 韩义涛. 中德铁路轨道技术标准对比分析[J]. 铁道工程学报, 2009, 26(8): 18-22.

YAN Hua, HAN Yitao. Comparative analysis of the railway track technical standards between China and Germany[J]. Journal of Railway Engineering Society, 2009, 26(8): 18-22.

[14] 林建. 基于计算流体力学有砟道床飞砟力学特性研究[D]. 北京: 北京交通大学土木工程学院, 2014: 3-18.

LIN Jian. Mechanical properties research of ballast flying based on computational fluid dynamics[D]. Beijing: Beijing Jiaotong University. School of Civil Engineering, 2014: 3-18.

[15] TG/GW 116—2013. 高速铁路有砟轨道线路维修规则(试行)[S].

TG/GW 116—2013.Maintenance rules for high-speed railway ballasted track[S].

[16] KWON H, PARK C. A study on the ballast-flying phenomena by strong wind induced by high-speed train[J]. Journal of the Korean Society for Railway, 2005, 8(1): 6-14.

[17] 黄啟明. 阻塞比对风洞试验结果的影响及修正研究[J]. 建设科技, 2014(11): 97-98.

HUANG Qiming. Influence of blockage ratio on wind tunnel test results and its correction[J]. Construction Science and Technology, 2014(11): 97-98.

[18] 毛军, 郗艳红, 杨国伟. 侧风风场特征对高速列车气动性能作用的研究[J]. 铁道学报, 2011, 33(4): 22-30.

MAO Jun, XI Yanhong, YANG Guowei. Research on influence of characteristics of cross wind field on aerodynamic performance of a high-speed train[J]. Journal of the China Railway Society, 2011, 33(4): 22-30.

[19] 周宇, 钱炜祺, 邓有奇, 等. k-ω SST两方程湍流模型中参数影响的初步分析[J]. 空气动力学学报, 2010, 28(2): 213-217.

ZHOU Yu, QIAN Weiqi, DENG Youqi, et al. Introductory analysis of the influence of Menter's k-ω SST turbulence model's parameters[J]. Acta Aerodynamica Sinica, 2010, 28(2): 213-217.

[20] 刘小平,董治宝. 空气动力学粗糙度的物理与实践意义[J]. 中国沙漠, 2003, 23(4): 3-12.

LIU Xiaoping, DONG Yebao. The physical and practical significance of aerodynamic roughness[J]. Journal of Desert Research, 2003, 23(4): 3-12.

[21] GB/T 511—2011. 轨道机车车辆发射噪声测量[S].

GB/T 511—2011. Acoustics measurement of noise emitted by railbound vehicle[S].

[22] 刘小平, 董治宝. 砾石床面的空气动力学粗糙度[J]. 中国沙漠, 2003, 23(1): 38-45.

LIU Xiaoping, DONG Zhibao. Aerodynamic roughness of gravel beds[J]. Journal of Desert Research, 2003, 23(1): 38-45.

[23] 井国庆, 付豪, 贾文利, 等. 框架优化型Ⅲc轨枕道床横向阻力试验研究[J]. 西南交通大学学报, 2018, 53(4): 727-732.

JING Guoqing, FU Hao, JIA Wenli, et al. Experimental study on lateral resistance of optimized Ⅲc sleeper with different frame types[J]. Journal of Southwest Jiaotong University, 2018, 53(4): 727-732.

(编辑 秦明阳)

收稿日期: 2020 -02 -21; 修回日期: 2020 -04 -20

基金项目(Foundation item):国家自然科学基金资助项目(51578051) (Project(51578051) supported by the National Natural Science Foundation of China)

通信作者:丁东,博士,从事轨道结构研究;Email:dong.ding@utc.fr