文章编号:1004-0609(2007)04-0649-08

硫酸渣复合球团还原焙烧法制备高品位磁铁精矿

朱德庆1,李 建1,李青春2,潘 建1,徐小锋1,翟 勇1,唐艳云1,崔 瑜1

(1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 江西铜业集团化工有限公司,德兴 334202)

摘 要:进行了硫酸渣复合球团还原焙烧-磁选实验。研究结果表明:以铁品位低(TFe 45.56%)、铜和硫含量高(Cu 0.19%,S 1.45%)的某硫酸渣为原料,添加复合添加剂5%,在圆盘造球机上制备复合球团,将生球干燥后进回转窑还原焙烧,往每吨复合球团中喷入煤300 kg,在700~800 ℃还原焙烧20 min,将还原焙烧后产物通过两段球磨、四段磁选工艺,可得到铁品位高(总铁含量为66.23%),Cu和S含量低(Cu 0.048%,S 0.053%)的优质磁铁精矿,其铁回收率达73.32%,铜脱除率达74.73%,硫脱除率达96.34%。实验的关键技术是复合粘结剂促进铁氧化物的还原及铜、硫等杂质的转化,在磁选分离过程中脱除杂质。使用此新工艺,能综合利用硫酸渣中铁资源,扩大钢铁工业原料来源。

关键词:硫酸渣;复合球团;还原焙烧;磁选

中图分类号:TF 046 文献标识码:A

Preparation of high quality magnetite concentrate from pyrite cinder by composite pellet reduction-roasting and magnetic-separation

ZHU De-qing1, LI Jian1, LI Qing-chun2, PAN Jian1, XU Xiao-feng1, ZHAI Yong1, TANG Yan-yun1, CUI Yu1

(1. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Jiangxi Copper Chemical Co. Ltd., Dexing 334202, China)

Abstract: A new technology of composite pellet reduction-roasting and magnetic-separation (CPRM) was developed for utilization of pyrite cinder, a common by-product in vitriol industry. Pyrite cinder, containing 45.56% Fe, 0.19% Cu and 1.45% S, was pelletized with addition of 5% composite agent in balling disc. Green balls after drying were reduced at 700-800 ℃ for 20 min with 300 kg/t pulverized coal injection in rotary kiln. After two-stage ball-grinding and four stages magnetic separation, magnetite concentrate with iron grade of 66.23% Fe and containing 0.048% Cu and 0.053% S were made. And iron recovery of 73.32%, desulphurization degree of 96.34% and decoppering degree of 74.73% were achieved. Key technique is that composite agent can accelerate reduction of Fe2O3 and transfer copper and sulphur into water-soluble inorganic salts, which are removed during wet magnetic concentration. This new technology can be used to fully utilize pyrite cinder and produce high quality magnetite concentrate as iron-bearing feed for steel industry, which will help to solve the pollution of pyrite cinder and extend raw material sourcing for Chinese steel industry.

Key words: pyrite cinder; composite pellet; reduction roasting; magnetic-separation

硫酸渣是硫铁矿制酸后的废渣,一般含铁30%~50%,有害元素Cu和S等含量高。2005年,我国生产硫酸4 462.2万t,其中采用硫铁矿制酸1 494.8万t,占硫酸总产量的33.3%[1-2]。按照用硫铁矿制1 t 硫酸产生0.8~1.0 t硫酸渣计算,2005年,全国产生硫酸渣1 195.8~1 494.8万t,约占化工废渣的1/3。加上历年累积堆存,未得到有效利用的硫酸渣达上亿吨。其中,仅有30%左右硫酸碴在建材行业作为水泥的添加剂和制砖得到应用,其他被作为废渣堆存,占用大量土地资源,严重污染环境[3]。早在1950年,我国许多企业就开始对烧渣炼铁进行实验研究。近年在硫酸渣综合利用方面进行了大量研究,主要集中在以下几方面:1) 与优质铁矿石掺烧炼铁[4];2) 选矿法[5-9];3)磁化焙烧-磁选法[10-12];4) 高温氯化法回收有色金 属[13];5) 制备铁系颜料,包括铁红[14-16]、铁黄[15, 17]、钾铁蓝[18]等。目前,利用硫酸渣生产铁红的技术已基本成熟,关键是降低生产成本[19];6) 制备铁盐,如硫酸亚铁[20-21]、聚合硫酸铁[22]、三氯化铁[23]等。7) 制海绵铁[24-25]。目前,制约硫酸渣利用的关键是如何大规模利用硫酸渣。将硫酸碴作为炼铁原料是一种有效的方法,但必须对其进行选择和处理,以便获得铁品位高、铜和硫等有害杂质含量低的优质铁精矿。目前,我国钢铁工业对铁矿石需求量很大,2005年虽然进口铁矿石价格提高71.5%,我国仍进口铁矿石2.75亿t,2006年,铁矿石价格再次升高19%,进口3.26亿t,因此,加强对硫酸渣的综合利用研究,对扩大钢铁企业原料来源、降低炼铁成本具有重要的现实意义。硫酸渣中的矿物属于人造矿物,无论在外形还是物化性能上都与天然矿物有很大差别。张德海[26]认为由于硫酸渣本身特性所限,仅通过常规选矿很难使铁品位和分选指标同时最佳。采用磁化焙烧-磁选工艺可得到高铁品位和较好的分选指标,但储谦慎等[5]认为此工艺的最大不足是不能脱除铜。为此,本文作者开发硫酸渣复合球团还原焙烧-磁选工艺,以期同步实现铁的富集以及Cu和S等有害元素的脱除,为硫酸渣的高效利用开辟新的途径。

1 实验

1.1 原料性能

实验用硫酸渣为硫酸厂产酸后的废渣,化学成分(质量分数, %)为:全铁TFe 45.56,FeO 3.16,SiO2 22.74,Al2O3 3.70,CaO 0.84,MgO 0.56,Cu 0.19,P 0.055,S 1.45;Ag 9.17 g/t。这种烧渣铁含量较低,并含有一定量的有色金属和贵金属,硫含量偏高。硫酸渣FeO含量仅为3.16%,这表明在制酸过程中,硫铁矿氧化较彻底,绝大部分Fe2+氧化成Fe3+,使硫酸渣中铁大部分以弱磁性矿物形式存在,难以采用常规选矿工艺富集该渣。

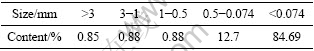

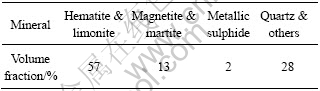

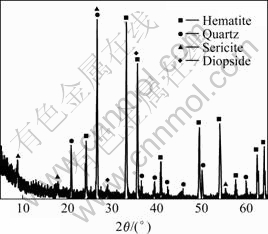

硫酸渣的粒度组成见表1,某硫酸渣的X射线衍射分析结果见图1,主要矿物的体积分数见表2。

表1 硫酸渣的粒度组成

Table 1 Size distribution of pyrite cinder

表2 硫酸渣中主要矿物含量

Table 2 Main mineral contents of pyrite cinder

图1 硫酸渣的X射线衍射谱

Fig.1 XRD spectrum of pyrite cinder

硫酸渣经镜下鉴定和X射线衍射分析发现,样品中铁矿物以赤铁矿为主,其次是磁铁矿、假象赤铁矿和褐铁矿。硫主要以金属硫化物形式存在,少量以硫酸盐如石膏形式存在。金属硫化物以磁黄铁矿居多,其次是黄铁矿。

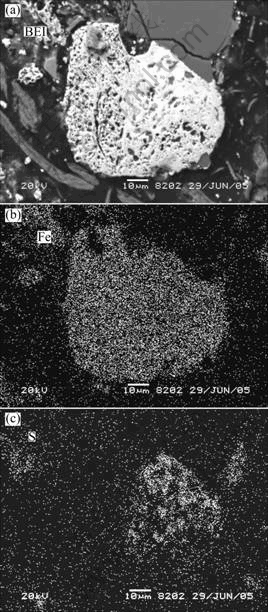

磁黄铁矿的扫描电镜照片如图2所示。可见,脉石矿物含量较高的是石英,其次是绢云母和透辉石。

图2 磁黄铁矿呈微细的交代残余嵌布在赤铁矿内部的扫描电镜照片

Fig.2 SEM images of replacement of remnant by pyrrhotite in hematite: (a) BEI image of pyrrhotite; (b) Elemental face-scanning of Fe; (c) Elemental face-scanning of S

复合添加剂具备多种功能,主要如下:1) 粘结作用,在复合球团制备过程中能强化造球,提高生球强度和热稳定性;2) 催化作用,在还原焙烧过程中,能促进还原反应的进行;3) 脱除有害元素铜、硫、铅、锌等有色金属元素的能力,能将硫酸渣中铜、硫等有害元素转变成非磁性物料或水溶性物质,在磁选过程中被脱除,这大幅度降低铁精矿中有害元素的含量。本实验中使用了自行开发的2种复合添加剂B和F。

1.2 研究方法

硫酸渣复合球团还原焙烧制取高品位磁铁精矿的试验流程包括:将硫酸渣、复合添加剂和水进行配料、混匀、造球、干燥,在回转窑中还原焙烧、冷却、磨矿、磁选,得到磁铁精矿和尾矿。硫酸渣制成复合球团置入回转窑,一方面,可减少物料在焙烧过程中的粉尘吹损,同时可降低因粉料而导致回转窑结圈现象的发生;另一方面因球团可减少物料与空气接触被再氧化的表面积,有利于提高物料磁化率[27]。还原焙烧后,将硫酸渣复合球团水淬冷却,然后磨矿、磁选。

实验用造球设备为1 000 mm×200 mm(直径×高)圆盘造球机,倾角为45?,转速为28 r/min;干燥设备为300 mm×300 mm(直径×高)链篦机模拟装置;还原焙烧设备采用300 mm×1 500 mm(直径×长)回转窑,转速1~2 r/min;磨矿设备采用XMQ-240×90锥形球磨机;磁选设备采用磁选管(小型实验)和XCRS-450 mm×325 mm筒式弱磁选机(扩大实验),分选磁鼓转速为41 r/min,场强均可调,筒式磁选机处理量为0.36 t/d。

2 结果与分析

人们对硫酸渣还原焙烧-磁选工艺进行大量的研究,根据参考文献[11-12],确定本实验所用添加剂粒度均低于0.1 mm,还原焙烧时间为20 min,研究复合添加剂对硫酸渣制取铁精矿过程脱铜、脱硫效果的影响以及复合球团外配不同还原剂和还原焙烧温度对磁选结果的影响。

2.1 复合添加剂对磁选结果的影响

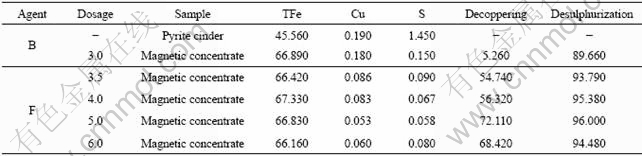

一般来说,硫酸渣中除了主要含Fe2O3以外,常含有少量铜、铅、锌等有色金属的氧化物和硫。这些元素必须在炼铁之前脱除。常规的硫酸渣磁化焙烧-磁选工艺不能脱除铜,铁精矿中铜一般少量富集,储谦慎等认为[5]这是磁化法存在的最大不足。在此,本文作者在前人大量实验研究的基础上,运用分子设计理论,开发复合添加剂B和F,能在提高铁品位的同时降低铁精矿中铜和硫的含量。表3所示为2种添加剂对磁选精矿铜、硫的影响。实验条件如下:添加剂内配造球,还原焙烧温度为700~800 ℃,焙烧时间为20 min,磁选设备为磁选管,采用一段磁选,磁感应强度为139.3 mT,磁选矿浆固液比为1?2,磁选时间为3.5 min。

表3 添加剂对铁精矿中铜和硫含量的影响

Table 3 Effect of agents on copper and sulfur content of magnetic concentrate(%)

添加复合添加剂B时,铁精矿铁品位大幅度提高,S含量大幅度降低,但铜含量基本不变,与文献[11]中的研究结果基本一致。使用复合添加剂F后,硫酸渣中铜含量明显降低,添加5%复合添加剂F时,铁精矿中铜含量为0.053%,比原渣中铜含量明显降低,铜脱除率达72.11%;铁精矿中硫含量为0.058%,硫脱除率达96.00%,铁品位达66.83%,是一种优质磁铁精矿。其成分完全能满足烧结或球团工艺要求。此外,还可通过直接还原工艺生产我国急需的海绵铁,由此确定以下实验研究均添加5%复合添加剂F。

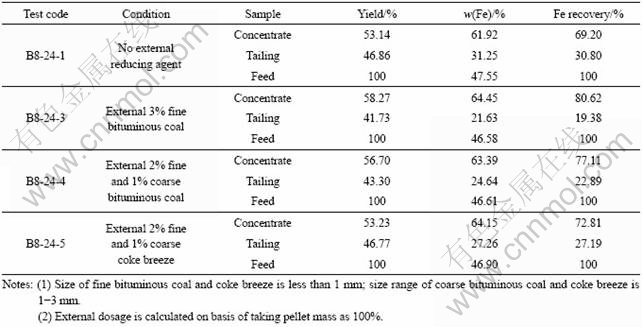

2.2 复合球团外配还原剂对磁选结果的影响

外配还原剂种类和粒度对磁选结果影响见表4。试验条件为:球团内配5%复合添加剂,还原焙烧温度为700 ℃,焙烧时间为20 min,磁选设备为磁选管,采用一段选矿,磁感应强度为139.3 mT,磁选矿浆固液比为1?2,磁选时间为3.5 min。

表4 磁选管磁选试验结果

Table 4 Results by magnetic concentration tube

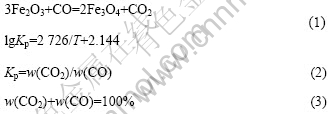

还原焙烧的目的是将硫酸渣中弱磁性的Fe2O3还原成强磁性的Fe3O4,在回转窑中,主要发生的还原反应为:

式中 Kp为反应平衡常数;T为热力学温度,K;w(CO2)和w(CO)分别为CO2和CO的浓度,%。

联立式(1)、(2)和(3),当反应温度为500、600、700和800 ℃时,反应所需CO含量分别0.000 918%,0.001 65%,0.002 63%和0.003 85%[28]。因此,回转窑内只需极少量的CO,就可以使硫酸渣中Fe2O3还原成Fe3O4。然而,在实际还原过程中,由于还原剂与空气不可能达到理想混合,硫酸渣中Fe2O3不可能全部接触到CO,温度也不特别稳定。当外配3%细烟煤(B8-24-3)时,由于细粒烟煤反应性好,使回转窑料层中形成更好的还原气氛,促进复合球团中弱磁性铁氧化物快速还原。还原较好的复合球团磁选指标也好。不外配还原剂时,铁回收率最低,可能使复合球团外部的Fe3O4裸露在氧分压高的气流中再氧化,重新形成弱磁性α-Fe2O3,导致分选指标变差。通过比较不同还原剂的磁选效果,确定以下实验中均外配3%细烟煤。

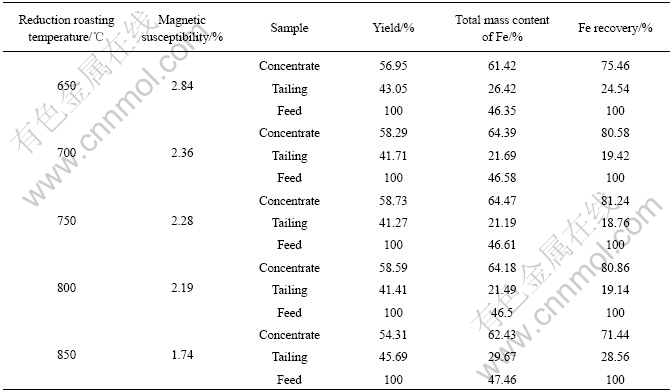

2.3 还原焙烧温度对磁选结果的影响

还原焙烧温度对磁选结果的影响见表5。实验条件如下:球团内配5%复合添加剂,外配3%细烟煤,焙烧时间为20 min,磁选设备为磁选管,采用一段选矿,磁感应强度为139.3 mT,磁选矿浆固液比为1?2,磁选时间为3.5 min。

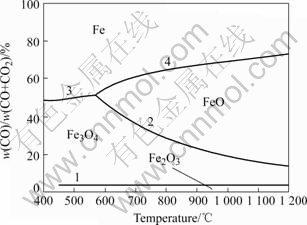

由于反应(1)的气体反应物和产物的量相同,因此,影响反应(1)的主要因素为温度和CO浓度。温度的变化对还原焙烧过程的进行和焙烧矿的质量有很大影响,见图3。

图3 CO还原铁氧化物的平衡气相组成与温度的关系[25]

Fig.3 Relationship between temperature and equilibrium gas composition when iron oxide reduced by CO: 1—3Fe3O4+ CO═2Fe2O3+CO2; 2—Fe2O3+CO═3FeO+CO2; 3—Fe3O4+ CO═Fe+CO2; 4—FeO+CO═Fe+CO2

由图3可见,磁化焙烧所需的气相CO浓度很低(曲线1仅为示意线,实际线位置紧靠横坐标)。硫酸渣的还原焙烧温度应该严格控制。温度过高将导致弱磁性的FeO生成,这样会降低焙烧矿的磁性,磁选分离效果变差;当温度较低时,虽然赤铁矿可以被还原成Fe3O4,并且不发生过还原现象,但反应速度较慢,降低设备的生产能力,而且在低温下生成的Fe3O4磁性较弱。结合表5所示的实验结果,硫酸渣适宜的还原焙烧温度为700~800 ℃。

表5 还原焙烧温度对磁选结果的影响

Table 5 Effect of reduction roasting temperature on magnetic separation

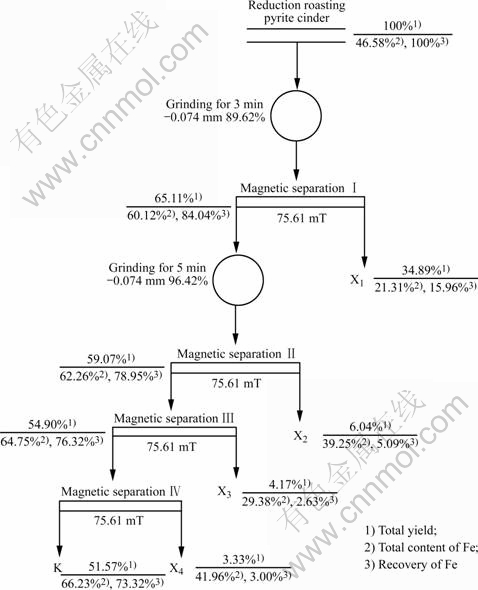

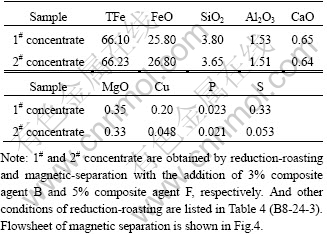

2.4 磁选流程实验

作者通过硫酸渣复合球团还原焙烧提取高品位铁精矿探索实验,发现磁化焙烧后产物采用闭路分选流程比采用开路流程铁回收率高4%,铁品位降低2%。为了提高铁精矿的品位,扩大试验的磨矿磁选流程实验采用两段球磨、四次筒式磁选机磁选开路流程,B8-24-3焙烧矿选别流程和磁选指标见图4,铁精矿化学成分见表6。

图4 硫酸渣磨矿-磁选开路流程图

Fig.4 Open circuit flowsheet of ball-grinding and magnetic separation process

表6 磁铁精矿化学成分

Table 6 Chemistry contents of magnetic concentrate(mass fraction, %)

由表6可知,铁精矿2中铜、硫含量比1号铁精矿的硫含量大幅度降低,筒式磁选机磁选结果与磁选管结果基本一致,再次验证了复合粘结剂F可明显降低铁精矿中铜、硫有害杂质元素的含量,铜脱除率达74.73%,硫脱除率达96.34%。

3 结论

1) 铁品位低(全铁含量45.56%)、铜和硫含量高(Cu0.19%,S1.45%)的某硫酸渣,添加5%复合添加剂F,在圆盘造球机上制备复合球团,干燥后,在700~800 ℃还原焙烧20 min,物料填充率为15.73%。采用两段球磨、四段筒式磁选开路流程,能得到铁品位高(TFe66.23%),Cu和S等有害杂质含量低(Cu 0.048%,S 0.053%)的优质磁铁精矿,铁回收率为73.32%,铜硫脱除率分别为74.73%和96.34%。

2) 硫酸渣配加复合添加剂F制备复合球团,可降低回转窑还原焙烧的粉末率,有效防止回转窑结圈;同时,可使球团内部产生好的还原气氛,促进弱磁性铁氧化物快速还原为强磁性铁氧化物。

3) 复合添加剂F具有多重功能,既提高生球强度和热稳定性,又能显著降低铁精矿中铜和硫等有害杂质的含量,克服了传统磁化焙烧-磁选法不能脱除硫酸渣中铜的不足,具有广阔的推广应用前景。

REFERENCES

[1] 中国化工资讯网. 国外低价硫酸大量涌入, 国内市场遭遇大搅局[EB/OL]. http://www.chchin.com, 2006-02-16.

China Chemical Engineering Information Network. Domestic sulphuric acid market affect by imported low price sulphuric acid [EB/OL]. http://www.chchin.com, 2006-02-16.

[2] 中国硫酸工业协会. 中国硫酸工业协会2005年工作总结[EB/OL]. http://www.aglook.net, 2006-01-14.

China Sulphuric Acid Industry Association(CSAIA). 2005 annual report of CSAIA[EB/OL]. http://www.aglook.net, 2006-01-14.

[3] 刘心中, 杨新春, 董凤芝,刘家弟,姚 德. 硫酸烧渣综合利用[J]. 金属矿山, 2002, 37(9): 51-54.

LIU Xin-zhong, YANG Xin-chun, DONG Feng-zhi, LIU Jia-di, YAO De. Comprehensive utilization of burned slags of sulphuric acid making [J]. Metal Mine, 2002, 37(9): 51-54.

[4] 刘全军, 周兴龙, 李华伟. 硫酸渣综合利用的研究现状与进展[J]. 云南冶金, 2003, 32(2): 27-29, 19.

LIU Quan-jun, ZHOU Xing-long, LI Hua-wei. Current situation and progress of research on comprehensive utilization of roasted pyrite [J]. Yunnan Metallurgy, 2003, 32(2): 27-29,19.

[5] 储谦慎, 王兴艳. 铜陵硫酸渣综合利用[J]. 河北理工学院学报, 2003, 25(4): 17-22.

CHU Qian-shen, WANG Xing-yan. A research on synthesized utilization of sulfate slag in Tongling [J]. Journal of Hebei Institute of Technology, 2003, 25(4): 17-22.

[6] 王雪松, 张德海, 任允芙. 黄铁矿烧渣的特性及其利用[J]. 环境工程, 1999, 18(1): 58-61.

WANG Xue-song, ZHANG De-hai, REN Yun-fu. Characteristics of pyrite cinder and its application[J]. Environmental Engineering, 1999, 18(1): 58-61.

[7] 吴德礼, 朱申红, 马鲁铭. 化学法处理硫酸渣工艺的机理分析[J]. 化工环保, 2004, 24(S1): 135-137.

WU De-li, ZHU Shen-hong, MA Lu-ming, et al. Mechanism analysis of chemic method utilzing pyrite cinder [J]. Environmental Protection of Chemical Industry, 2004, 24(S1): 135-137.

[8] 付克文, 刘作政. 云浮硫铁矿烧渣选矿试验[J]. 化工矿山技术, 1994, 23(6): 26-28.

FU Ke-wen, LIU Zuo-zhen. Beneficiation test for calcined cinder of pyrite ore from Yunfu pyrite mine [J]. Technology of Chemical Industry & Mine, 1994, 23(6): 26-28.

[9] 戚志正. 我国硫酸渣的选矿[J]. 金属矿山, 1993, 28(8): 47-51.

QI Zhi-zheng. Beneficiation of sulfuric acid slags in China [J]. Metal Mine, 1993, 28(8): 47-51.

[10] 胡宾生, 王 晖. 铜陵硫酸渣磁化焙烧—磁选过程中铜、金、银赋存状态的变化[J]. 矿产综合利用, 2002, 23(2): 16-18.

HU Bin-sheng, WANG Hui. The transition of occurrence of copper, gold and silver in Tongling pyrite cinder during magnetic roasting and separation [J]. Multipurpose Utilization of Mineral Resources, 2002, 23(2): 16-18.

[11] 胡宾生, 张景智. 铜陵硫酸渣磁化焙烧-磁选的试验研究[J]. 矿冶工程, 1996, 16(3): 44-47.

HU Bin-sheng, ZHANG Jing-zhi. An experimental study on magnetizing reduction-magnetic concentration of tongling burnt ore [J]. Mining and Metallurgical Engineering, 1996, 16(3): 44-47.

[12] 王雪松, 李朝祥, 付元坤. 硫铁矿烧渣磁化焙烧的试验研究[J]. 钢铁研究学报, 2005, 17(3): 10-14.

WANG Xue-song, LI Chao-xiang, FU Yuan-kun. Experimental study on magnetic roasting pyrite cinder in rotary kiln [J]. Journal of Iron and Steel Research, 2005, 17(3): 10-14.

[13] 李家瑞. 工业企业环境保护[M]. 北京: 冶金工业出版社, 1992.

LI Jia-rui. Environmental Protection of Industrial Enterprise [M]. Beijing: Metallurgical Industry Press, 1992.

[14] 张龙银. 淄博钴厂以硫酸为中心的资源综合利用[J]. 硫酸工业, 1991, 33(1): 28-32.

ZHANG Long-yin. Comprehensive utilization of resource centred on sulphuric acid production [J]. Sulphuric Acid Industry, 1991, 33(1): 28-32.

[15] 张顺利, 马同森, 吴志申,陈蔚萍,李明玉. 硫铁矿烧渣制备氧化铁黄和氧化铁红[J]. 化学研究, 1999, 13(1): 47-50.

ZHANG Shun-li, MA Tong-sen, WU Zhi-shen, CHEN Wei-ping, LI Ming-yu. Preparation of iron oxide yellow and iron oxide red with pyrite cinder [J]. Chemical Researches, 1999, 13(1): 47-50.

[16] 冯业铭, 徐桂英, 张双全, 王永志. 利用铁泥或硫铁矿烧渣制取氧化铁颜料[J]. 环境保护, 1994, 22(2): 37-39.

FENG Ye-ming, XU Gui-ying, ZHANG Shuang-quan, WANG Yong-zhi. Preparation of iron oxide palette from pyrite cinder or waste iron mud [J]. Environmental Protection, 1994, 22(2): 37-39.

[17] 陈白珍,龚竹青,黄 坚,郑雅杰,王之平. 硫铁矿烧渣制备铁黄颜料的工艺研究[J]. 无机盐工业, 2001, 33(4): 39-42.

CHEN Bai-zhen, GONG Zhu-qing, HUANG Jian, ZHENG Ya-jie, WANG Zhi-ping. The technological study on the preparation of iron yellow from sulfide slag [J]. Inorganic Chemicals Industry, 2001, 33(4): 39-42.

[18] 郑雅杰, 陈梦君, 黄桂林. 硫铁矿烧渣制备钾铁蓝[J]. 中南大学学报: 自然科学版, 2006, 37(2): 252-256.

ZHENG Ya-jie, CHEN Meng-jun, HUANG Gui-lin. Preparation of potassium iron blue from pyrite cinders [J]. Journal of Central South University: Science and Technology, 2006, 37(2): 252-256.

[19] 刘 闯, 蒋其胜, 王志勇, 高 静. 论硫铁矿烧渣的再生与利用[J]. 安徽地质, 2000, 10(4): 290-293.

LIU Chuang, JIANG Qi-sheng, WANG Zhi-yong, GAO Jing. On the recovery and utilization of roasted dregs of pyrite [J]. Geology of Anhui, 2000, 10(4): 290-293.

[20] 陈吉春, 陈永亮. 硫铁矿烧渣还原酸浸制取硫酸亚铁[J]. 矿产综合利用, 2004, 25(3): 42-45.

CHEN Ji-chun, CHEN Yong-liang. The preparation of ferrous sulfate from pyrite cinder by reduction roasting method [J]. Multipurpose Utilization of Mineral Resources, 2004, 25(3): 42-45.

[21] 郑雅杰, 陈白珍, 龚竹青, 陈文汩. 硫铁矿烧渣的熟化及机理[J]. 中国有色金属学报, 2001, 11(1): 144-147.

ZHENG Ya-jie, CHEN Bai-zhen, GONG Zhu-qing, CHEN Wen-mi. Maturation of pyrite cinders and its mechanism [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 144-147.

[22] ZHENG Ya-jie, GONG Zhu-qing, CHEN Bai-zhen, LIU Li-hua. Preparation of solid polyferric sulfate from pyrite cinders and its structure feature [J]. Trans Nonferrous Met Soc China, 2003, 13(3): 690-694.

[23] 刘长春, 许晓影, 冯海军. 利用硫铁矿渣制备聚合氯化铁铝净水剂[J]. 无机盐工业, 2001, 33(2): 38-39.

LIU Chang-chun, XU Xiao-ying, FENG Hai-jun. Preparation of polyaluminium-ferric chloride from sulphur-ferric ore dregs [J]. Inorganic Chemicals Industry, 2001, 33(2): 38-39.

[24] 许 斌,庄剑鸣,白国华,梁景晟. 硫酸烧渣综合利用新工艺[J]. 中南工业大学学报:自然科学版, 2000, 31(3): 215-218.

XU Bin, ZHUANG Jian-ming, BAI Guo-hua, LIANG Jing-sheng. A new way of comprehensive utilizing of pyretic slag[J]. Journal of Central South University of Technology: Nature Science, 2000, 31(3): 215-218.

[25] 龚竹青,龚 胜,陈白珍,周 波. 用硫铁矿烧渣制取海绵铁的碳还原过程[J]. 中南大学学报: 自然科学版, 2006, 36(4): 703-708.

GONG Zhu-qing, GONG Sheng, CHEN Bai-zhen, ZHOU Bo. Carbon reduction process in preparation of sponge iron using pyrite cinder [J]. Journal of Central South University: Science and Technology, 2006, 37(4): 703-708.

[26] 张德海. 黄铁矿烧渣工艺矿物学研究[J]. 黄金科学技术, 1999, 7(4/5): 102-105.

ZHANG De-hai. Study on process mineralogy of pyrite cinder [J]. Gold Science and Technology, 1999, 7(4/5): 102-105.

[27] 李思导, 傅菊英, 庄剑鸣. 大冶混合型铁矿综合开发研究[J]. 矿产综合利用, 1995, 26(3): 1-4.

LI Si-dao, FU Ju-ying, ZHUANG Jian-ming. Study on comprehesive utilization of Daye mixed type iron ore [J]. Multipurpose Utilization of Mineral Resources, 1995, 26(3): 1-4.

[28] 傅菊英, 姜 涛, 朱德庆. 烧结球团学[M]. 长沙: 中南工业大学出版社, 1996: 78.

FU Ju-ying, JIAN Tao, ZHU De-qing, Principle of Sintering and Pelletizing [M]. Changsha: Central South University of Technology Press, 1996: 78.

基金项目:国家教育部高等学校优秀青年教师教学科研奖励基金资助项目(教人司[2000]26);中南大学研究生教育创新基金资助项目(1343-75213)

收稿日期:2006-09-04;修订日期:2006-10-10

通讯作者:朱德庆,教授;电话:0731-8836041;E-mail: dqzhu@mail.csu.edu.cn

(编辑 陈灿华)