DOI: 10.11817/j.ysxb.1004.0609.2020-39454

锆钛酸铅压电陶瓷的流延法制备及其性能

张少峰1,袁 晰1, 3,闫明洋1,王晓宇2,高 峰2,周科朝1,张 斗1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 北京空间飞行器总体设计部,北京 100094;

3. 中南大学 化学化工学院,长沙 410083)

摘 要:流延法工艺具有工艺便捷、尺寸可调、成膜质量好等优势。采用流延法制备PZT压电陶瓷,通过扫描电子显微镜观察压电陶瓷微观形貌,通过准静态d33测量仪测试压电陶瓷的压电应变常数d33。探究粉末粒径以及流延工艺参数包括刮刀高度、流延速度、热压压力等对PZT压电陶瓷性能的影响,获得的PZT压电陶瓷其压电应变常数d33最高可达454 pC/N,致密度最高可达97.68%。该方法适用于制备大尺寸压电器件。

关键词:锆钛酸铅;压电陶瓷;流延成型;致密度;压电应变常数

文章编号:1004-0609(2020)-02-0326-07 中图分类号:TB321 文献标志码:A

锆钛酸铅(Pb(Zr1-xTixO3),PZT)陶瓷具有优良压电、介电性能。由于其稳定性好,精度高,能量转换效率高,响应速度快,机械品质因子、压电系数、机电耦合常数明显优于无铅压电陶瓷,广泛应用于压电传感及驱动领域[1],如超声换能器[2]等,对结构健康检测[3]、能量采集[4-6]等领域具有重大意义。

目前,压电陶瓷主要制备方法为固相烧结法,为了提高无铅压电陶瓷的性能,模板晶粒生长法[7]也体现出巨大的优势。1947年HOWATT等[8]首次提出了流延法用来生产陶瓷片层电容器。流延成型(Tape casting)技术是一种陶瓷材料成型方法[9],主要通过将陶瓷粉体与各种添加剂混合得到均一稳定的浆料,然后在流延机上制备出一定厚度的陶瓷厚膜。流延成型技术因其制备工艺简单、生产效率高、获得的产品质量好等优点而被广泛应用于生产各种陶瓷样品,目前,流延技术在陶瓷工艺中已经较为成熟且日益多样化,在制备陶瓷基板[10]、多层陶瓷[11-12]、多孔陶瓷[13-15]、陶瓷织构[16-18]、功能梯度陶瓷(FGCs)[19-20]等方面都有广泛应用。通过流延技术制备的压电陶瓷,具有尺寸大,性质均一,产品效率高等一系列优点[21-22]。

对流延技术制备陶瓷的工艺探究一直是研究的重点,Lü等[23]研究者已通过水性流延法制备稳定的SiC浆料,研究了分散剂、固体负载、烧结助剂、粘合剂和增塑剂等对流变性能和黏度的影响,研究并优化了制备稳定SiC浆料的条件。YU等[24]选择蓖麻油、磷酸酯和蓖麻油磷酸盐作为分散剂,制备出Al2O3浆料,研究了浆料中分散剂含量、粘合剂含量、增塑剂/粘合剂比以及固相含量等对生坯和氧化铝陶瓷样品的力学性能的影响。DA SILVA等[25]系统研究了固相压片烧结与流延法制备陶瓷的区别,表明流延法制备出的陶瓷质地更均匀,具有更高的力学性能。因此,研究流延过程工艺条件对流延样品性能的影响,提高流延工艺的普适性,更有利于陶瓷的制备。CHOI等[26]通过流延法制造了由Pb(Zn1/3Nb2/3)0.2(Zr1/2Ti1/2)0.8 (PZN-PZT) 压电层和银金属层组成的大面积多层陶瓷致动器。大部分的压电器件对压电陶瓷的尺寸要求较高,因此,研究流延法制备较大尺寸的压电陶瓷具有重要意义。

本研究通过流延法制备出较大尺寸的PZT压电陶瓷,并探究流延过程中粉末粒径、刮刀高度、流延速度、热压压力等因素对制备出的PZT压电陶瓷性能的影响,进而得到高品质PZT压电陶瓷,为制备大尺寸压电器件奠定基础。

1 实验

1.1 实验原料

选择淄博宇海生产的PZT-5A陶瓷预烧粉作为主要粉料,以二甲苯和酒精的共混物作为溶剂、磷酸三乙酯(TEP)作为分散剂、聚乙二醇(PEG)、邻苯二甲酸二丁酯(DBP)作为增塑剂,聚乙烯醇缩丁醛(PVB)作为粘结剂、正丁醇作为除泡剂,并将原料按照合适的比例配置成流延浆料。

1.2 实验过程

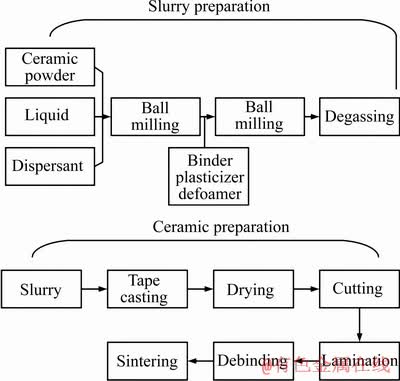

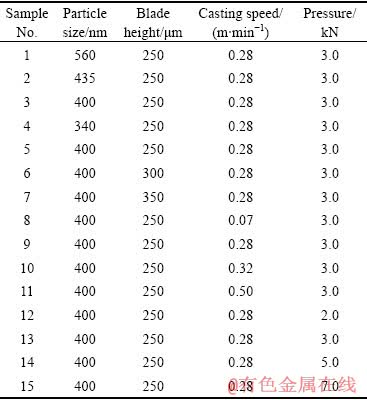

采用流延工艺制备Pb(Zr1-xTixO3)压电陶瓷,工艺流程如图1所示,首先将PZT-5A陶瓷预烧粉与溶剂、分散剂一起球磨24 h,再加入粘结剂、增塑剂、除泡剂等按照合适的比例配置成浆料,将真空除泡后的浆料在不同的刮刀高度、流延速度下经流延成型在玻璃板上得到PZT压电厚膜,将PZT压电厚膜切割成30 mm×35 mm,叠加10层,通过万能力学试验机在80 ℃、不同压力下进行热压,干燥后的样品在500 ℃排胶后经埋烧法在1250 ℃下保温2 h后得到样品1~15号,样品具体制备工艺参数如表1所列。将得到的PZT压电陶瓷样品进行打磨、被银后施加2.5 kV/mm的电场、在80 ℃的温度下油浴极化20 min,放置24 h后测量其压电性能。

图1 流延工艺示意图

Fig. 1 Schematic diagram of casting process

1.3 分析与测试

采用AUW120D电子分析天平分析测量陶瓷样品的密度与致密度,使用Nova Nano SEM 230场发射扫描电镜(SEM)对流延制备出的压电陶瓷厚膜表面、烧结后的压电陶瓷断面等进行微观形貌的表征。采用Agilent 4294A阻抗分析仪测量压电陶瓷及其器件的阻抗等,使用准静态d33测量仪测量压电陶瓷的压电常数。

表1 样品制备工艺参数

Table 1 Specific process parameters of samples

2 结果与讨论

2.1 粉末粒径对样品性能的影响

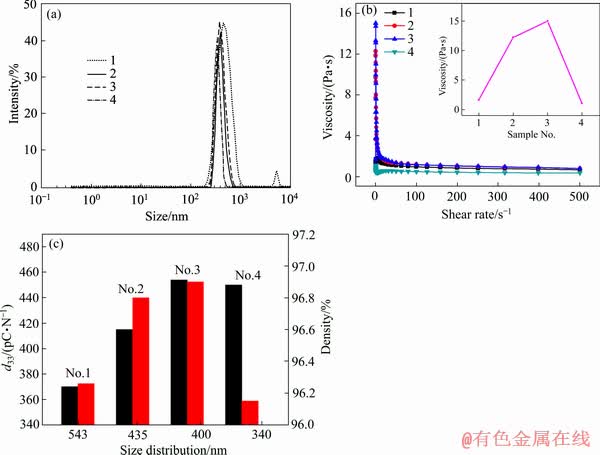

将PZT-5A陶瓷预烧粉末利用行星球磨机分别球磨0 h、1.5 h、3 h、6 h后得到平均粒度分别为560 nm、435 nm、400 nm、340 nm的4种陶瓷粉末,其粒度分布如图2(a)所示。将其制备陶瓷样品可得到1~4号样品,用球磨过的4种样品粉末分别配置出对应的1~4号样品浆料,并测试其黏度,如图2(b)所示。其中2号、3号样品成型性较好,得到的压电厚膜表面光滑,厚度均匀,无明显缺陷;1号、4号样品浆料的黏度较低,流动性大,成型后压电厚膜厚度不均匀,多次实验发现当流延的浆料黏度在10 Pa·s以上时,样品较易成型。1~4号样品的压电常数d33及致密度如图2(c)所示,其中2号、3号样品的致密度明显偏高,与浆料黏度的规律趋势一致,3号样品的致密度最高可达96.9%。同时,3号样品的压电常数d33最高,可达453 pC/N,4号样品压电性能与3号相差不大,但样品较难成型,得到的数据稳定性差。因此,选择粒径为400 nm左右的PZT-5A陶瓷预烧粉末可配制出合适的浆料,得到的压电厚膜表面光滑平整,厚度均匀,无明显缺陷。

2.2 刮刀高度对样品性能的影响

CHOU等[27]发现流延制备出的压电厚膜厚度D与其他各种流延参数的关系如式(1)所示,其中α为收缩系数,h为刮刀高度,△P为压力,η为浆料黏度,v0 为流延速度,L为刮刀长度。通过实验选择不同的刮刀高度得到样品5~7号,得到的压电厚膜厚度分别为60 μm、80 μm、100 μm左右,压电厚膜厚度与刮刀高度成明显的正相关。

(1)

(1)

通过扫描电子显微镜观察压电样品的形貌如3所示,其中图3(a)~(c)所示为PZT压电厚膜表面形貌,当刮刀高度为250 μm时得到的压电厚膜表面孔隙较小, 且较为均匀,当刮刀高度为350 μm时,压电厚膜表面孔隙较为明显,且出现了较大的裂纹,主要是由于刮刀高度的增加使得在流延过程中增大了与空气的接触面积,使得气泡增多,同时干燥过程中由于厚度较大,上下表面干燥速度差异较大,在表面张力的作用下使样品表面出现了裂纹。图4所示为样品5~7号的压电常数d33及致密度对比,其中随着刮刀高度的增大,压电常数d33逐渐减小,5号样品压电常数d33最大,可达到451 pC/N,同时5号样品的致密度也达到最大,为97.58%。因此,当刮刀高度为250 μm时,将获得的压电厚膜叠10层、热压后可以得到最终厚度为500 μm,致密度较高,表面光滑无明显缺陷的压电厚膜生坯,烧结后得到的压电陶瓷形貌良好。

图2 1~4号样品的粒度分布、黏度性能和压电常数d33与致密度对比曲线

Fig. 2 Comparison curves of size distribution(a), viscosity performance(b) and piezoelectric constant d33 with density of No.1-4 sample

图3 不同刮刀高度下压电厚膜的SEM像以及不同刮刀高度下的压电陶瓷断面BSED图

Fig. 3 SEM images of piezoelectric thick film with different blade heights((a)-(c)) and BSED diagrams of piezoelectric ceramic section with different blade heights((d)-(f))

图4 刮刀高度对样品压电常数d33与致密度的影响

Fig. 4 Effect of blade height to piezoelectric constant d33 and density of samples

2.3 流延速度对样品性能的影响

在不同的流延速度下制备得到8~11号样品,其中11号样品由于流延速度过快,浆料流延过程中无法连续成型,无法获得完整的压电厚膜。图5所示为8~10号样品的阻抗-相位角频谱图,样品的第一谐振频率都在150 kHz左右,说明相同尺寸的压电陶瓷极化后性能差异较小,然而8号、10号样品的第一谐振峰存在轻微变形且杂峰较多,主要是因为压电陶瓷自身的缺陷导致在极化过程中漏电流偏大,而9号样品的谐振峰最为明显,杂峰较少,其阻抗性能最为优异。8~10号样品的压电常数d33及致密度对比如图6所示,相关规律与阻抗规律一致,9号样品的致密度可达97.55%,压电性能较好。过快的流延速度使得浆料无法均匀流动,无法在玻璃板上形成完整的压电厚膜;过慢的流延速度加大了浆料在流延过程中与空气的接触时间,使得气孔在厚膜中逐渐扩散,增大了厚膜的缺陷。因此,选择0.28m/min作为最佳流延速度,可得到致密度较好,d33较高的PZT压电陶瓷。

2.4 热压压力对样品性能的影响

在叠层热压过程中,采用不同的压力压制得到样品12~15号,其陶瓷样品断面形貌如图7所示,随着压力的增大,样品断面的气孔逐渐减少,且孔径减小,当压力为3.0 kN时断面气孔最少,当压力达到7.0 kN左右时样品断面出现了部分裂纹,主要是由于热压压力过大,压电厚膜之间会发生错位,剪切力过大导致厚膜断裂进而产生了部分裂纹。同时测试压电陶瓷样品的压电应变常数d33和致密度如图8所示,压电陶瓷样品的压电常数及致密度规律一致,随着叠层热压压力的增大,压电常数及致密度都是先增大后减小,当压力为3.0 kN时,压电陶瓷样品的压电常数及致密度最大,分别为454 pC/N和97.68%。主要是由于当热压压力较小时,多层陶瓷厚膜之间无法完全接触,导致层间存在间隙。当热压压力过大时,层间剪切力也较大,使得多层厚膜之间易发生错位等现象,烧结之后样品断面出现了裂纹,使得样品的压电常数与致密度降低。因此,选择3.0 kN的热压压力可以得到性能优异的压电陶瓷。

图5 8~10号样品的阻抗-相位角频谱图

Fig. 5 Impedance-phase angle spectrum of samples 8(a), 9(b) and 10(c)

图6 流延速度对样品压电常数d33与致密度的影响

Fig. 6 Effect of casting speed on piezoelectric constant d33 and density of samples

图7 不同流延压力下的压电陶瓷断面形貌

Fig.7 Sectional morphology of piezoelectric ceramics obtained by casting under different pressures

图8 热压压力对PZT压电陶瓷压电常数d33与致密度的影响

Fig. 8 Effect of pressure on piezoelectric constant d33 and density of PZT ceramics in process of hot-press

3 结论

1) 采用流延法制备出30 mm×35 mm的PZT压电陶瓷片,当使用粒径为400 nm左右的PZT-5A陶瓷预烧粉末可配制出合适的浆料,得到的压电厚膜表面光滑平整,厚度均匀,无明显缺陷。

2) 在流延过程中,当刮刀高度为250 μm、流延速度为0.28 m/min、叠层热压压力为3.0 kN时,可以得到厚度为500 μm、致密度较高、压电性能较好的压电陶瓷,其压电应变常数d33最高可达454 pC/N,致密度最高可达97.68%,由于流延法工艺获得的样品尺寸可调性佳,可用于制备大尺寸压电器件,获得大驱动、大变形能力,具有良好的应用前景。

REFERENCES

[1] JASIM A, WANG H, YESNER G, SAFARI A, MAHER A. Optimized design of layered bridge transducer for piezoelectric energy harvesting from roadway[J]. Energy, 2017, 141: 1133-1145.

[2] SEBASTIAN T, KOZIELSKI L, ERHART J. Co-sintered PZT ceramics for the piezoelectric transformers[J]. Ceramics International, 2015, 41(8): 9321-9327.

[3] PARK S, INMAN D J, YUN C B. An outlier analysis of MFC-based impedance sensing data for wireless structural health monitoring of railroad tracks[J]. Engineering Structures, 2008, 30(10): 2792-2799.

[4] TIANCHENG X, GOO Y H, SUAN T M. Wearable inertial energy harvester with sputtered bimorph lead zirconate titanate (PZT) thin-film beams[J]. Smart Materials and Structures, 2018, 27(8): 085026.

[5] GUPTA R, RANA L, TOMAR M. Characterization of lead zirconium titanate thin films based multifunctional energy harvesters[J]. Thin Solid Films, 2018, 652: 39-42.

[6] LIN X J, ZHOU K C, ZHANG X Y, ZHANG D. Development, modeling and application of piezoelectric fiber composites[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 98-107.

[7] DURAN C, TROLIER-MCKINSTRY S, MESSING G L. Fabrication and electrical properties of textured Sr0.53Ba0.47Nb2O6 ceramics by templated grain growth[J]. Journal of the American Ceramic Society, 2004, 83(9): 2203-2213.

[8] HOWATT G N, BRECKENRIDGE R G, BROWNLOW J M. Fabrication of thin ceramic sheets for capacitors[J]. Journal of the American Ceramic Society, 1947, 30(1): 237-242.

[9] 李冬云, 乔冠军, 金志浩. 流延法制备陶瓷薄片的研究进展[J]. 硅酸盐通报, 2004, 23(2): 44-47.

LI Dong-yun, QIAO Guan-jun, JIN Zhi-hao. Research development of ceramic slice by tape-casting technique[J]. Bulletin of the Chinese Ceramic Society, 2004, 23(2): 44-47.

[10] 李婷婷, 彭超群, 王日初, 王小锋, 刘 冰. 电子封装陶瓷基片材料的研究进展[J]. 中国有色金属学报, 2010, 20(7): 1365-1374.

LI Ting-ting, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LIU Bing. Research progress in ceramic substrate material for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1365-1374.

[11] SCHWARTZ B. Review of multilayer ceramics for microelectronic packaging[J]. Journal of Physics and Chemistry of Solids, 1984, 45(10): 1051-1068.

[12] HE Z, ANDERSEN K B, NYGAARD F B. A combined SEM, CV and EIS study of multi-layered porous ceramic reactors for flue gas purification[J]. Ceramics International, 2013, 39(1): 847-851

[13] NISHIHORA R K, RACHADEL P L, QUADRI M G N. Manufacturing porous ceramic materials by tape casting—A review[J]. Journal of the European Ceramic Society, 2018, 38(4): 988-1001.

[14] OHJI T, FUKUSHIMA M. Macro-porous ceramics: Processing and properties[J]. International Materials Review, 2012, 57(2): 115-131.

[15] ZHANG L Y, ZHOU D L, CHEN Y. Preparation of high open porosity ceramic foams via direct foaming molded and dried at room temperature[J]. Journal of the European Ceramic Society, 2014, 34(10): 2443-2452.

[16] MORIANA A D, ZHANG S J. Lead-free textured piezoceramics using tape casting: A review[J]. Journal of Materiomics, 2018, 4(4): 277-303.

[17] BAI W, CHEN D, LI P. Enhanced electromechanical properties in  -textured (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 lead- free piezoceramics[J]. Ceramics International, 2016, 42(2): 3429-3436.

-textured (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 lead- free piezoceramics[J]. Ceramics International, 2016, 42(2): 3429-3436.

[18] ZHANG K, GUO Y, PAN D. Phase transition and piezoelectric properties of dense (K0.48Na0.52)0.95Li0.05Sbx- Nb(1-x)O3-0.03Ca0.5(Bi0.5Na0.5)0.5ZrO3 lead free ceramics[J]. Journal of Alloys and Compounds, 2016, 664: 503-509.

[19] EWAIS E, BESISA D, ZAKI Z. Influence of MgO addition on the properties of new tailored FGZM/A ceramics[J]. Materials Science and Engineering A, 2013, 578: 197-206.

[20] ACIKBAS N C, SUVACI E, MANDAL H. Fabrication of functionally graded SiAlON ceramics by tape casting[J]. Journal of the American Ceramic Society, 2006, 89(10): 3255-3257

[21] ABHINAY S, MAZURNDER R, SEAL A. Tape casting and electrical characterization of 0.5Ba(Zr0.2Ti0.8)O3- 0.5(Ba0.7Ca0.3)TiO3 (BZT-0.5BCT) piezoelectric substrate[J]. Journal of the European Ceramic Society, 2016, 36(13): 3125-3137.

[22] 谢雨洲, 彭超群, 王小锋, 王日初, 刘家杰, 徐 健. 流延成型技术的研究进展[J]. 中国有色金属学报, 2015, 25(7): 1846-1857.

XIE Yu-zhou, PENG Chao-qun, WANG Xiao-feng, WANG Ri-chu, LIU Jia-jie, XU Jian. Research progress of tape casting[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1846-1857.

[23] Lü Zhi-hui, ZHANG Tao, JIANG Dong-liang. Aqueous tape casting process for SiC[J]. Ceramics International, 2009, 35(5): 1889-1895.

[24] YU M, ZHANG J, LI X. Optimization of the tape casting process for development of high performance alumina ceramics[J]. Ceramics International, 2015, 41(10): 14845-14853.

[25] DA SILVA A L, BERNARDINA M, HOTZA D. Forming of thin porcelain tiles: A comparison between tape casting and dry pressing[J]. Ceramics International, 2014, 40(2): 3761-3767.

[26] CHOI J J, LEE J H, HAHN B D. Co-firing of PZN-PZT/Ag multilayer actuator prepared by tape-casting method[J]. Materials Research Bulletin, 2008, 43(2): 483-490.

[27] CHOU Y T, KO Y T, YAN M F. Fluid flow model for ceramic tape casting[J]. Journal of the American Ceramic Society, 2005, 70(10): 234-237.

Preparation and properties of lead zirconate titanate piezoelectric ceramics via tape casting

ZHANG Shao-feng1, YUAN Xi1, 3, YAN Ming-yang1, WANG Xiao-yu2, GAO Feng2, ZHOU Ke-chao1, ZHANG Dou1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Beijing Spacecraft System Engineering, Beijing 100094, China;

3.School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: The tape casting method has several advantages, such as convenient process, adjustable size and better film forming quality. The lead zirconate titanate (PZT) piezoelectric ceramics were prepared by tape casting. The microstructure of the piezoelectric ceramics was observed by scanning electron microscope. The d33 of piezoelectric ceramics was detected by a berlincourt d33 meter. The effects of powder particle size, blade height, casting speed were studied, and the pressure of hot pressing process on properties of PZT ceramics was also studied. Then, high quality PZT piezoelectric ceramics were obtained with the piezoelectric strain constant d33 reaching up to 454 pC/N, and the highest density could reach to 97.68%. This method is also suitable for the preparation of large-size piezoelectric devices.

Key words: lead zirconate titanate; piezoceramic; tape casting; density; piezoelectric strain constant

Foundation item: Project(51672311) supported by the National Natural Science Foundation of China; Project (2016WK2022) supported by the Science and Technology Project of Hunan Province, China

Received date: 2019-01-10; Accepted date: 2019-06-02

Corresponding author: YUAN Xi; Tel: +86-731-88877196; E-mail: xiyuan@csu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51672311);湖南省科技计划项目(2016WK2022)

收稿日期:2019-01-10;修订日期:2019-06-02

通信作者:袁 晰,博士后;电话:0731-88877196;E-mail:xiyuan@csu.edu.cn