文章编号:1004-0609(2015)-07-1882-08

热型连铸铝线的制备及其显微组织和性能

胡 炜1,王彦红1,赵小军1,肖来荣1, 2,饶 博1,章 玮1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用自制的热型连铸设备制备铝线材料,研究铸型温度和拉铸速度等工艺参数对材料表面质量、显微组织及力学性能的影响,通过对最佳工艺条件下制备的铸锭断口形貌进行观察和分析,探讨其相关机理。结果表明:当铸型温度为675~685 ℃、拉铸速度为90~120 mm/min时,可以制备出表面质量较佳的铸锭;同时,工艺参数会对晶体的择优取向产生一定影响,当铸型温度和拉铸速度分别为680 ℃和90 mm/min时,晶体的取向更倾向于沿<100>方向生长,铸型温度越高,铸锭力学性能越优异。当拉铸速度为90 mm/min时,制备的热型连铸铝线具有最佳的塑性加工能力。相比于普通多晶铝线,热型连铸铝线具有更好的塑性。

关键词:热型连铸;表面质量;晶体取向;力学性能;断口形貌

中图分类号:TG146.2 文献标志码:A

Preparation of aluminum wire by Ohno continuous casting and its microstructure and properties

HU Wei1, WANG Yan-hong1, ZHAO Xiao-jun1, XIAO Lai-rong1, 2, RAO Bo1, ZHANG Wei1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metals Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: Aluminum wires were prepared using the self-made Ohno continuous casting equipment. The effects of process parameters, such as the mold temperature and casting rate, on the surface quality, microstructure and mechanical properties of aluminum wires were investigated. Besides, the microstructures of fracture surfaces of Al wires prepared under optimal process parameters were evaluated, and the relevant mechanisms were identified. The results show that the Al ingots with good surface quality can be successfully fabricated at the mold temperature of 675-685 ℃ and the casting speed of 90-120 mm/min. Meanwhile, the process parameters have a great effect on the preferred orientation of crystals. When the mold temperature is 680 ℃ and the casting speed is 90 mm/min, the crystal orientation of grain tends to grow along the direction of <100>. Moreover, when the casting speed is constant, the mechanical properties of ingots are improved with the increasing mold temperature. Furthermore, when the casting speed is 90 mm/min, the plastic processing capacity is the best. In comparison to polycrystalline Al wires, the Al wires prepared by Ohno continuous casting have better integrated performance.

Key words: Ohno continuous casting; surface quality; crystal orientation; mechanical property; fracture morphology

铝是最早被采用的键合丝材料之一。由于它具有密度小、成本低以及良好的导电(单位质量的导电能力是铜的两倍)、导热和耐蚀性能等优点,在键合丝的生产中具有明显优势[1]。热型连铸制备的铝线具有定向凝固组织,其结晶方向与拉丝方向相同,且具有优良的力学性能和拉丝性能,是拉制微细丝的理想材料[2-4]。

国外经过对热型连铸技术多年的研究,已经取得了重大成果[5]。自1978年日本千叶工业大学教授OHNO发明自热型连铸法以来,该技术在日本引起了广泛的应用研究,并取得卓越成绩[6]。例如,日本三井公司开发了各种截面形状复杂的热型连铸铜管;日本大阪富士公司用热型连铸法生产了高硬度Al-35%Cu合金焊条并应用于柴油机活塞环槽的硬面堆焊及铝合金件的焊补;日本古河电器公司已成功地应用热型连铸技术制备了单晶线材并在市场上得到了广泛的推广和应用 [7]。在工艺研究方面,国外早期主要对低熔点金属,如锡、铅、锌及其合金的形成工艺进行了大量的研究,如加拿大多伦多大学于1988年建立的单晶热型连铸实验室,已可用来生产低熔点金属Sn、Bi、Al以及高熔点金属Ni、Co等[8]。特别是随着信息技术的发展,广大国外研究者通过采用计算机模拟的方式展开对热型连铸技术中的温度场、固液界面的形状和位置、晶体结晶过程以及竞争生长等方面的研究,使得热型连铸技术研究取得了更大的突 破[9-10]。自1986年,西安交通大学刑建东[11]首次将热型连铸技术介绍到中国,国内才展开对热型连铸Sn、Al线材等的研究。随后,广东工业大学的蔡莲淑等[12]在Al、Cu、Sn等形状记忆合金的热型连铸研究工作中取得一定的技术成果。西北工业大学的何平[13]自行连铸出单晶Al、Cu线材,并进一步研究了单晶组织演化机理、热型连铸工艺过程等。北京科技大学、甘肃工业大学在热型连铸技术和温度场模拟等方面取得了一定的突破[14-15]。总体而言,国外对热型连铸技术的工艺研究与开发较为活跃与成熟,能生产出多种复杂以及难以加工的合金连铸型材。而我国由于对热型连铸技术的研究起步较晚,对热型连铸的工艺控制缺乏系统理论,同时研究的金属品种较少,应用热型连铸技术开发的产品只有线材,在实际应用上更是少见,与实现热型连铸技术的生产还有相当长的距离[8]。因此,开展热型连铸技术的攻关研究,跟踪世界先进科技,对推进我国材料领域的科技进步具有重大意义。

热型连铸工艺参数主要有铸型温度、拉铸速度、冷却距离等,它们的改变与相互匹配直接影响着固液界面的位置与形状,从而影响线材组织及性能[16]。其中,铸型温度和拉铸速度是造成固液界面位置与形状变化的主要因素,铸型温度的控制是热型连铸技术的关键,在热型连铸过程中铸型温度必须控制在金属的液相线温度以上。合适的铸型温度不仅可以避免金属液体在铸型内凝固,而且可以保证固液界面维持在铸型出口附近,使铸型出口处的铝线表层生成液体膜[17]。同时,研究表明拉铸速度的改变与热型连铸晶体生长取向有密切关系[18]。

本文作者研究不同工艺参数对热型连铸铝线的显微组织和力学性能的影响,并对热型连铸晶体竞争生长的最佳工艺参数及机理进行探讨。

1 实验

本实验以纯铝块(纯度为99.99%(质量分数))为主要材料,并在自制的热型连铸设备上进行实验,制备得到d 3 mm的铝线。熔炼温度为700 ℃,铸型温度为665~695 ℃,拉铸速度为70~130 mm/min,冷却距离为30 mm,冷却水量为50 L/h,压杆静压头为3 mm。

采用D/Max 2500型X射线衍射仪(XRD)对热型连铸试样的相组成及晶体取向特征进行测试和分析,测试条件如下:靶材为Cu靶,加速电压和电流强度分别为40 kV和250 mA,扫描角度(2θ)为10°~80°。其中,每步扫描的时间为15 s,扫描步长为0.02°。采用DDL100万能试验机对热型连铸试样的室温拉伸性能进行测试,选取拉伸载荷500 kN,加载速度1 mm/min,试样尺寸均为d 3 mm×50 mm;试样断裂后,采用Sirion200场发射扫描电镜对热型连铸铝线和普通多晶铝线(某厂传统铸造生产)的断口形貌进行观察和分析。

2 结果与讨论

2.1 工艺参数对表面质量的影响

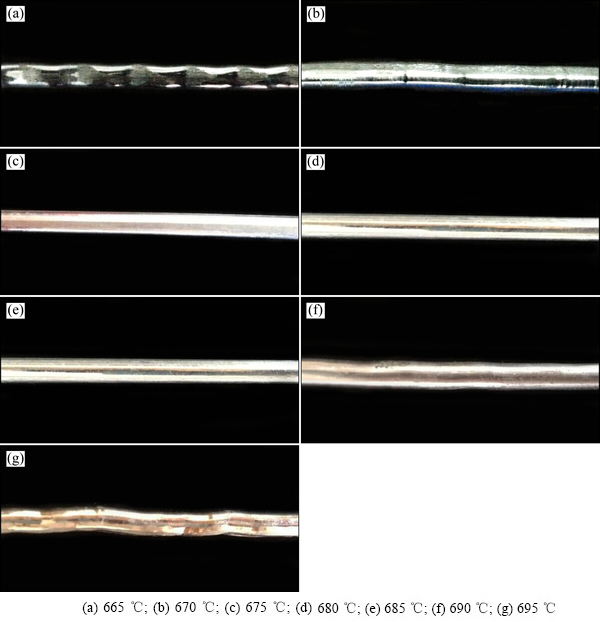

图1所示为铸型温度对铝线表面质量的影响(拉铸速度为90 mm/min)。由图1可见,当铸型温度为665和670 ℃时,铝线表面存在划痕;当铸型温度分别为675、680和685 ℃时,铸锭表面光滑;当铸型温度为690和695 ℃时,铸型表面存在波纹。这是由于铸型温度的升高使得铸锭凝固时所释放的结晶潜热增加,当热量不能及时传出时会导致铸型内熔体温度升高,固液界面必须通过外移来提高散热速度,以平衡结晶放热。因此,固液界面会随着铸型温度的升高而逐渐外移,铸锭的表面质量也随之发生改变[19-21]。当铸型温度较低时,固液界面在铸型内,铝液在铸型内部就开始凝固,导致铝线与铸型内壁的摩擦力增大,造成铝线表面严重划伤。随着铸型温度升高,固液界面外移至固铸型出口附近,因液体膜与铸型间的摩擦最小,故其表面质量最佳。但当铸型温度高于690 ℃时,由于固液界面外移至距铸型出口较远的位置,熔融铝液受自身质量影响较大,使得拉铸出的铝线易产生波纹,表面质量较差。在本实验中,当冷却距离为30 mm时,铸型温度保持在675~685 ℃之间进行d 3 mm铝线拉铸较为合适。

图1 拉铸速度为90 mm/min时不同铸型温度对铝线表面质量的影响

Fig. 1 Effects of different mold temperatures on surface quality of Al wires at casting speed of 90 mm/min

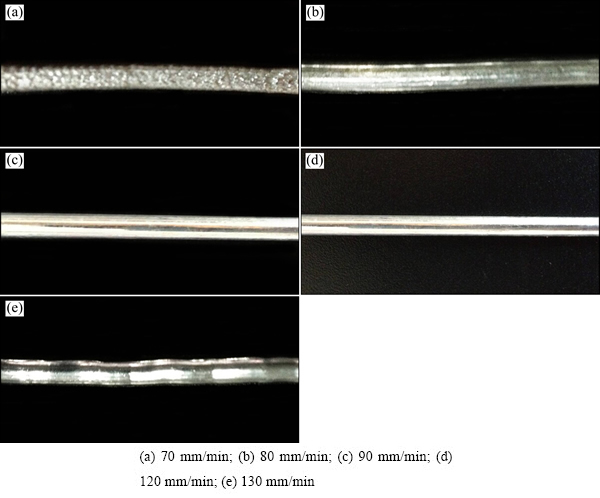

图2所示为拉铸速度对铝线表面质量的影响(铸型温度为680 ℃)。由图2可见,当拉铸速度从70增加到120 mm/min时,热型连铸铝线表面质量逐渐提高。这是由于拉铸速度的提高使得合金凝固时结晶潜热的释放增加,致使铸型温度升高[22]。因此,固液界面必须通过外移来增加散热,最终使铸型温度保持不变。固液界面向外移动,减小了铸锭与铸型内壁的接触面积,提高了铸锭表面质量。但当拉铸速度达到130 mm/min时,由于界面与型口间的距离过大,合金液体的表面张力会小于液体的重力,铝线易产生波纹,表面质量较差,严重时甚至会发生漏液现象。当冷却距离为30 mm时,拉铸速度保持在90~120 mm/min有利于得到光滑的铝线,且高的拉铸速度可以提高生产效率,有利于大规模工业化生产。

2.2 工艺参数对组织结构的影响

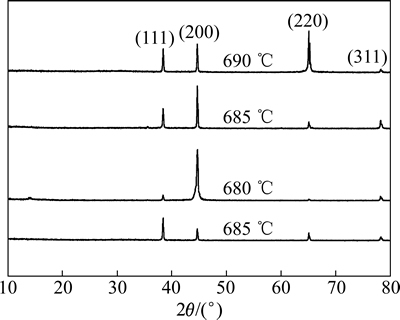

图3所示是在不同铸型温度下制备的热型连铸铝线的XRD谱(拉铸速度为90 mm/min)。由图3可看出,当铸型温度为665 ℃时,热型连铸铝线组织存在4种不同的晶粒取向,其中(111)晶面衍射峰最强,该晶面的晶粒数较多;当铸型温度为680 ℃时,发现(200)晶面的衍射峰最强,(111)、(200)和(311) 3个晶面的衍射峰强度明显减弱;当铸型温度增加至685和690 ℃时,除存在(200)晶面外,还存在其他晶面。

铸型温度改变造成晶体竞争生长是因为晶体的竞争生长是通过控制固-液界面的形状来达到的,而工艺参数改变对固液界面的位置及形状有很大影响[23]。因此,晶体的竞争生长与工艺参数的改变密不可分[18]。另有研究表明,凸形的固-液界面有利于晶体生长过程的淘汰,能够实现单晶连铸[24-25]。当铸型温度较低时,固液界面为凹形,晶体竞争生长方向沿固-液界面前沿温度分布场扩散,因此,杂晶生长不受基体限制,反而基体的生长受到杂晶的限制,最终生长出定向凝固的多晶或柱状晶。当铸型温度升高时,由于加热铸型的温度高于铝的熔点,避免了型壁上的成核,固液界面呈凸出形状,此时其晶体竞争生长方向向固液界面前沿温度分布场中心聚拢,杂晶生长受到基体限制,不能长大,逐渐被淘汰,从而生长出晶粒较少的柱状晶乃至单晶。另一方面,铸型温度继续升高时,固液界面的位置将会受到较大影响。因此,合适的铸型温度将有利于晶体的择优生长。由于铝为面心立方结构,其<100>晶向为晶体择优生长方向,其次是<011>晶向,而<111>晶向的生长速度最慢,这样各晶粒在生长时由于不同晶面上的择优生长,使生长方向与热流方向不一致的晶粒逐渐被淘汰,直至达到稳定凝固阶段。结果表明,当铸型温度为680 ℃时,晶体的取向特征更加明显,其生长晶面为(200),晶体取向为垂直于(200)面的<100>方向。

图2 铸型温度为680 ℃时不同拉铸速度对铝线表面质量的影响

Fig. 2 Effect of different casting speeds on surface quality of Al wires at mold temperature of 680 ℃

图3 拉铸速度为90 mm/min时不同铸型温度下制备的热型连铸铝线XRD谱

Fig. 3 XRD patterns of Al wires prepared by Ohno continuous casting at different mold temperatures at casting speed of 90 mm/min

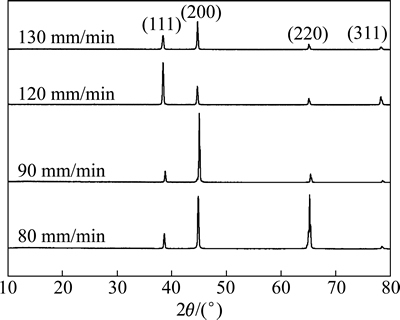

图4所示是不同拉铸速度下制备的热型连铸铝线的XRD谱(铸型温度为680 ℃)。由图4可看出,当拉铸速度为80 mm/min时,(200)和(220)晶面衍射峰均较强,晶粒数相对较多;当拉铸速度增加到90 mm/min时,(311)晶面逐渐被淘汰,(111)和(220)晶面强度较弱,(200)晶面衍射峰最强;当拉铸速度增加到120和130 mm/min时,其他晶面的衍射峰强度出现增大现象。这是因为拉铸速度的变化会改变固液界面的形状。当拉铸速度增加时,由于凝固过程的传热条件受到很大影响,铸型热辐射造成的热损失增加,致使横向温度梯度增大,造成凝固界面严重凹陷,固液界面的形状会由凸变凹,杂晶的生长不受限制,将会得到取向较多的晶粒[23]。因此,低的拉铸速度有利于得到晶粒较少的柱状晶甚至单晶。然而当拉铸速度降低时,固液界面位置向铸型内移动,从而影响热型连铸铝线的表面质量。因此,合适的拉铸速度不仅有利于维持固液界面的形状及位置,而且有利于得到具有择优取向的晶粒。结果表明,当拉铸速度为90 mm/min时,晶体的竞争生长情况更明显,且其择优生长方向为<100>。

图4 铸型温度为680 ℃时不同拉铸速度下制备的热型连铸铝线的XRD谱

Fig. 4 XRD patterns of Al wires prepared by Ohno continuous casting at different casting speeds and molding temperature of 680 ℃

2.3 工艺参数对力学性能的影响

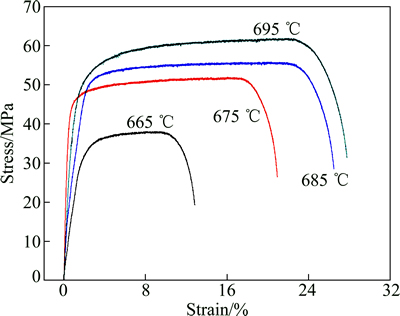

图5所示是不同铸型温度下制备的热型连铸铝线的拉伸应力-应变曲线(拉铸速度为90 mm/min)。从图5可以看出,在塑性变形开始后,流变应力在很长一段时间内保持不变,试样只发生均匀伸长,直到颈缩,应力下降。对比分析可见,当铸型温度为695 ℃时,流变应力最大,铸锭可发生较大的均匀塑性变形。这说明铸型温度越高,加工硬化现象越不明显,在拉伸过程中只需应力超过屈服强度,就可发生较大的均匀塑性变形。这一结果表明制备热型连铸线材时,铸型温度越高铸锭的塑性越好,越有利于材料的进一步深加工。

图5 拉铸速度为90 mm/min时不同铸型温度下制备的铸锭的拉伸应力-应变曲线

Fig. 5 Stress-strain curves of ingots prepared at different mold temperatures and casting speed of 90 mm/min

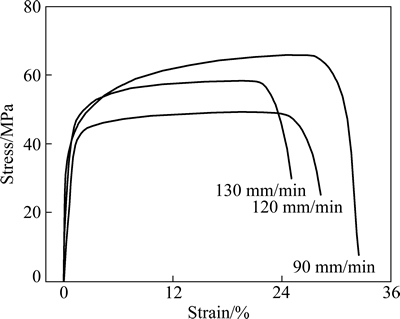

图6所示为不同的拉铸速度下制备的热型连铸铝线的拉伸应力-应变曲线(铸型温度为680 ℃)。从图6可以看出,当拉铸速度为90 mm/min时,材料的抗拉强度最大,且均匀塑性变形程度最大,热型连铸铝线的塑性最好。

图6 铸型温度为680 ℃时不同拉铸速度下制备的铸锭的拉伸应力-应变曲线

Fig. 6 Stress-strain curves of ingot prepared at different casting speeds and molding temperature of 680 ℃

结合图5和6可知,面心立方铝的易滑移面{111}与试样的拉伸方向<100>(择优生长方向)呈45°。这样在滑移面上临界分切应力较大,滑移启动容易,故未出现易滑移阶段。对于高层错能的纯铝,抛物线性硬化阶段的起始应力很低,故该阶段开始得很早,掩盖了线性硬化阶段的特征。因此,在应力-应变曲线上,只有很长的抛物线性硬化阶段。抛物线性硬化过程具有明显的动态回复现象,使得加工硬化指数降低。因此,热型连铸铝线可在较低应力下发生很长的均匀变形,具有优异的塑性加工能力。

2.4 热型连铸铝线断口特征

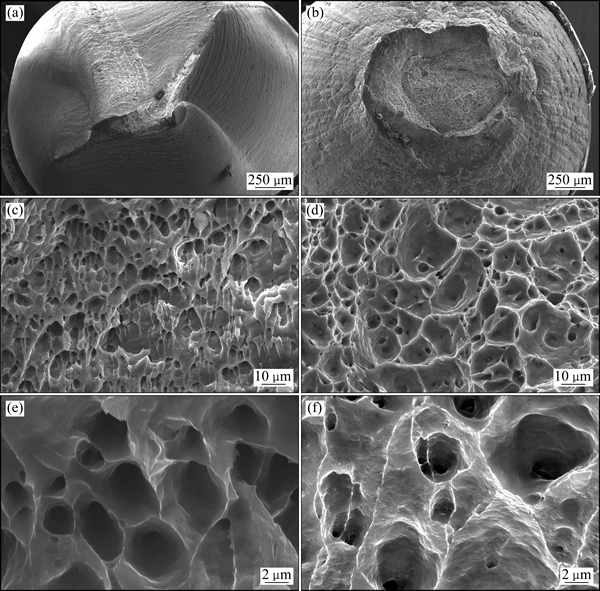

图7所示为合适的工艺参数下(铸型温度为680 ℃,拉铸速度为90 mm/min)制备的热型连铸铝线和普通多晶铝线拉伸试样的断口形貌。由图7可见,热型连铸铝线断口具有明显的塑性变形特征,其断口呈扁尖状,这种扁尖状断口的形成主要是由热型连铸铝线中的滑移系沿最大切应力方向滑移所致。普通多晶铝线断口为近圆形。从断口的特征来看,两者都属于韧性剪切型断口,只是热型连铸试样表现出完全的延性断裂,断口收缩剧烈,在断口上仍有明显的滑移线特征[26]。而普通多晶试样的断口收缩至一定程度后,各晶粒协调变形更加困难,需要的应力更大,进一步变形会在心部出现微观孔洞,随后聚集长大,形成纤维状断口,在宏观上表现为多晶试样的伸长率和断面收缩率都比热型连铸试样的小得多[27]。同时,热型连铸铝线韧窝多且密集,这说明热型连铸铝线的塑性加工性能很高,断口存在明显的塑性变形;而普通多晶铝线韧窝少,且比热型连铸铝线的浅,这也证明热型连铸铝线的塑性优于金属多晶铝线的塑性。

图7 热型连铸铝线与普通多晶铝线拉伸试样的断口形貌

Fig. 7 Fracture surface SEM images of aluminum wire prepared by Ohno continuous casting ((a), (c), (e)) and polycrystalline aluminum wire ((b), (d), (f)) after tensile tests

3 结论

1) 铸型温度和拉铸速度对热型连铸铝线的表面质量和力学性能影响较大。在冷却距离为30 mm的条件下,当铸型温度为675~685 ℃、拉铸速度为90~120 mm/min时,可以制备出表面质量较好、力学性能优良的铝线;当铸型温度为680 ℃、拉铸速度为90 mm/min时,制备的热型连铸铝线具有最佳的塑性加工性能。

2) 工艺参数的改变对晶体的择优取向产生较大的影响。当铸型温度为680 ℃、拉铸速度为90 mm/min时,晶粒沿着<100>方向生长,表现出明显的择优取向特征。

3) 与普通多晶铝线相比,热型连铸铝线断口呈扁尖状、韧窝多且密集,而普通多晶铝线断口为近圆形,且韧窝浅,这表明热型连铸铝线具有更好的塑性。

REFERENCES

[1] OKAYASU M, TAKASU S, YOSHIE S. Microstructure and material properties of an Al-Cu alloy provided by the Ohno continuous casting technique[J]. Journal of Materials Processing Technology, 2010, 210(11): 1529-1535.

[2] ZHANG Z M, LI T, XU C J, GUO X F. Microstructure of binary Mg-Al eutectic alloy wires produced by the Ohno continuous casting process[J]. Acta Metallurgica Sinica (English Letters), 2008, 21(4): 275-281.

[3] 马 颖, 郝 远, 阎峰云, 刘洪军. 热型连铸锌铝合金定向凝固线材的组织分析[J]. 中国有色金属学报, 2001, 11(2): 221-226.

MA Ying, HAO Yuan, YAN Feng-yun, LIU Hong-jun. Microstructure analysis of ZA alloy rod directionally solidified by heated mold continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 221-226.

[4] HUANG Hai-you, NIE Ming-jun, LUAN Yan-yan, LIU Xue-feng. Fatigue property of single-crystal and columnar-grained polycrystalline Cu-12wt.% Al alloys[J]. Procedia Engineering, 2012, 27: 1686-1693.

[5] OKAYASU M, YOSHIE S. Mechanical properties of Al-Si13-Ni1.4-Mg1.4-Cu1 alloys produced by the Ohno continuous casting process[J]. Materials Science and Engineering A, 2010, 527(13): 3120-3126.

[6] OHNO A. Continuous casting of single crystal ingots by the OCC process[J]. Journal of Metals, 1986, 38(1): 14-16.

[7] SODA H, CHABCHOUB F. Experimental study of the horizontal Ohno continuous casting system[J]. Canadian Metallurgical Quarterly, 1992, 31(3): 231-239.

[8] KWON Y A, DAYA Z A, SODA H, WANG Z R, MCLEAN A. Deformation behavior of bismuth–tin alloy wires with eutectic morphology produced by the Ohno continuous casting process[J]. Materials Science and Engineering A, 2004, 368(1): 323-331.

[9] BOUHOUCHE S, LAHRECHE M, BAST J. Control of heat transfer in continuous casting process using neural networks[J]. Acta Automatica Sinica, 2008, 34(6): 701-706.

[10] CHANG Guo-wei, CHEN Shu-ying, ZHOU Cong, YUE Xu-dong, QI Yi-hui. Relationship between solid/liquid interface and crystal orientation for pure magnesium solidified in fashion of cellular crystal[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(2): 289-293.

[11] 邢建东. OCC法的两个试验[J]. 铸造技术, 1986, 1(001): 7-11.

XING Jian-dong. Two trials OCC experiments[J]. Foundry Technology, 1986, 1(001):7-11.

[12] 蔡莲淑, 余业球, 罗继辉, 黎沃光. 热型连铸超弹性CuAlNi合金丝的拉伸疲劳性能[J]. 热加工工艺, 2006, 35(9): 5-8.

CAI Lian-shu, YU Ye-qiu, LUO Ji-hui, LI Wo-guang. Tensile fatigue of superelastic CuAlNi SMA wires by heated mould continuous casting process[J]. Casting and Forging, 2006, 35(9): 5-8.

[13] 何 平. 连铸单晶铜动态冲击特性研究[D]. 西安: 西北工业大学, 2004: 51-71.

HE Ping. Study on the characteristics of continuous casting of single crystal Cu dynamic impact[D]. Xi’an: Northwestern Polytechnical University, 2004: 51-71.

[14] 丁雨田, 戴 雷, 杨守杰, 阎威武, 许广济. 热型连铸Al-Cu合金的组织与性能[J]. 甘肃工业大学学报, 2000, 26(2): 12-15.

DING Yu-tian, DAI Lei, YANG Shou-jie, YAN Wei-wu, XU Guang-ji. Microstructure and properties of Al-Cu alloy produced by OCC[J]. Journal of Gansu University of Technology, 2000, 26(2): 12-15.

[15] 梅 俊, 刘新华, 谢建新. BFe10白铜管材热冷组合铸型水平连铸凝固温度场模拟[J]. 中国有色金属学报, 2012, 22(5): 1430-1439.

MEI Jun, LIU Xin hua, XIE Jian xin. Solidification temperature field simulation of BFe10 cupronickel tube during heating cooling combined mold continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1430-1439.

[16] 彭 孜, 李明茂. 单晶连铸技术的发展及其在单晶铜生产中的应用[J]. 上海有色金属, 2009, 30(3): 134-137.

PENG Zi, LI Ming-mao. Development of Ohno continuous casting process and its applications for producing single crystalline copper[J]. Shanghai Nonferrous Metals, 2009, 30(3): 134-137.

[17] 余业球, 赵 锋, 黎沃光. 白铜管热型连铸的温度场[J]. 铸造技术, 2006, 26(11): 1054-1057.

YU Ye-qiu, ZHAO Feng, LI Wo-guang. Temperature fields in the heated mold continuous casting of cupronickel tubes[J]. Foundry Technology, 2006, 26(11): 1054-1057.

[18] 李 克, 毕 云, 罗沛兰, 郭 峰. 基于有限差分法的单晶热型连铸凝固过程的数值模拟[J]. 南昌大学学报(工科版), 2008, 30(1): 32-35.

LI Ke, BI Yun, LUO Pei-lan, GUO Feng. Numerical simulation of solidification in OCC Process based on the finite difference method[J]. Journal of Nanchang University (Engineering and Technology), 2008, 30(1): 32-35.

[19] 范新会, 李建国, 傅恒志. 固液界面与单晶拉铸表面质量[J]. 材料研究学报, 2009, 13(3): 320-322.

FAN Xin-hui, LI Jian-Guo, FU Heng-zhi. Effects of solid-liquid interface on surface quality of CCSC[J]. Chinese Journal of Materials Research, 2009, 13(3): 320-322.

[20] 马 颖, 郝 远, 阎峰云. 锌铝合金热型连铸的工艺方法[J]. 中国有色金属学报, 2001, 11(S1): s56-s62.

MA Ying, HAO Yuan, YAN Feng-yun. Process for zinc-aluminum alloy of Ohno continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S1): s56-s62.

[21] 丁雨田, 张琴豫, 许广济, 衣冠玉, 寇生中. 纯铜热型连铸过程三维微观组织模拟[J]. 特种铸造及有色合金, 2006, 26(9): 554-558.

DING Yu-tian, ZHANG Qin-yu, XU Guang-ji, YI Guan-yu, KOU Sheng-zhong. Simulation of three-dimensional microstructure on pure copper of Ohno continuous casting process[J]. Special Casting and Nonferrous Alloys, 2006, 26(9): 554-558.

[22] 寇生中, 丁雨田. 热型连铸固液界面位置和形状的控制分析[J]. 铸造技术, 2008, 29(1): 72-74.

KOU Sheng-zhong, DING Yu-tian. Control and analysis of location and shape of solid/liquid interface in heated mold continuous casting[J]. Foundry Technology, 2008, 29(1): 72-74.

[23] WANG Zhen, LIU Xue-feng, XIE Jian-xin. Effects of solidification parameters on microstructure and mechanical properties of continuous columnar-grained Cu-Al-Ni alloy[J]. Progress in Natural Science: Materials International, 2011, 21(5): 368-374.

[24] 马 颖, 郝 远, 阎峰云, 刘洪军. 热型连铸锌铝合金的缺陷形成与机理[J]. 中国有色金属学报, 2001, 11(S2): s47-s53.

MA Ying, HAO Yuan, YAN Feng-yun, LIU Hong-jun. Defect formation and mechanism of cast zinc-aluminum alloy of continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S2): s47-s53.

[25] 王 鑫, 李 炳, 张战英, 范新会, 严 文. 热型连铸铜线材晶粒生长及演化特征的研究[J]. 铸造技术, 2006, 27(1): 11-14.

WANG Xin, LI Bing, ZHANG Zhan-ying, FAN Xin-hui, YAN Wen. Study on the characteristic of crystal growth and evolution of copper wires produced by OCC method[J]. Foundry Technology, 2006, 27(1): 11-14.

[26] MURPHY W J, HIGGINBOTHAM A, KIMMINAU G. The strength of single crystal copper under uniaxial shock compression at 100 GPa[J]. Journal of Physics: Condensed Matter, 2010, 22(6): 065404.

[27] 李兴霞, 崔国明. 热型连铸单晶金属的断口形貌与形成机制[J]. 上海金属, 2013, 35(4): 13-16.

LI Xing-xia, CUI Guo-ming. Fractography and formation mechanisms of single crystal metals prepared by Ohno continuous casting[J]. Shanghai Metals, 2013, 35(4): 13-16.

(编辑 王 超)

基金项目:广东省教育部产学研结合项目(2012A090300008)

收稿日期:2014-09-12;修订日期:2014-12-24

通信作者:肖来荣,教授,博士;电话:0731-88877499;E-mail:xiaolr@csu.edu.cn