文章编号:1004-0609(2015)-11-3223-06

中非铜-钴氧化矿两段浸出过程

李淑梅,刘凯华,李 辉,丛自范

(沈阳有色金属研究院 冶金研究所,沈阳 110141)

摘 要:研究一种非洲铜-钴氧化矿两段浸出过程。采取两段浸出的目的是实现矿石中铜和钴的选择性浸出。第一段主要用硫酸浸出矿石中的铜,第二段用硫酸和还原剂浸出矿石中的钴。第一段浸出的最佳技术条件:矿石粒度小于75 μm的比例占89%,硫酸加入量为铜-钴氧化矿质量的13%,液固比为4:1,浸出时间为60 min,温度为常温(25 ℃);第二段浸出的最佳技术条件:浸铜渣液固比为4:1,温度为65 ℃,时间为150 min,初始酸浓度为20 g/L,还原剂加入量为理论量的1.5倍。结果表明:两段浸出过程铜和钴的浸出率分别达到97.13%和96.05%。

关键词:铜-钴氧化矿;两段浸出;还原浸出;浸出率

中图分类号:TF811;TF816 文献标志码:A

Two stage leaching process of copper-cobalt oxide ore in Central Africa

LI Shu-mei, LIU Kai-hua, LI Hui, CONG Zi-fan

(Metallurgical Institute, Shenyang Research Institute of Nonferrous Metals, Shenyang 110141, China)

Abstract: A two stage leaching process of the copper-cobalt oxide ore from Africa was investigated. The two stage leaching process was used to realize selective leaching of copper and cobalt in the ore. The first stage was the leaching of copper in ore using sulfuric acid, and the second stage was the leaching of cobalt using sulfuric acid and reductant. The optimum conditions for the first stage are as follows: the ratio of ore less than 75 μm is 89%, sulfuric acid mass fraction of the ore is 13%, liquid-solid ratio is 4:1, leaching time is 60 min and temperature is 25 ℃. The optimum conditions for the second stage are follows: liquid-solid ratio is 4:1, temperature is 65 ℃, time is 150 min, initial acid concentration is 20 g/L and reductant dosage is 1.5 times of the theory amount. The results show that the leaching efficiencies of copper and cobalt in two stage leaching process reach 97.13% and 96.05%, respectively.

Key words: copper-cobalt oxide ore; two stage leaching; reduction leaching; leaching efficiency

中非铜带蕴藏有丰富的铜钴资源。据有关资料报道[1],中非铜-钴矿矿床一般包括上下两层:上层是被风化的氧化矿,含钴矿物主要是水钴矿,含铜矿物主要是孔雀石和硅孔雀石;下层是未被风化的硫化矿,含钴矿物主要是硫铜钴矿,含铜矿物主要是辉铜矿和蓝辉铜矿等。中非铜-钴矿,特别是中非铜-钴氧化矿的开发和利用越来越受到世界各国的重视。寻求处理中非铜-钴氧化矿的先进冶炼工艺具有重要意义。

中非铜-钴氧化矿通常采用湿法冶金方法加以处理。湿法冶金方法具有工艺成熟,产品方案灵活和环境友好等特点,被认为是处理铜-钴氧化矿最适宜的工艺。目前,处理中非铜-钴氧化矿的湿法工艺一般采用一段浸出方案[2-5]:产出的浸出渣经逆流倾析(CCD)洗涤得到洗液和弃渣;产出的浸出液经溶剂萃取得到硫酸铜溶液,通过电沉积过程生产阴极铜,得到的萃余液返回浸出;从浸出渣洗液和萃余液抽取液中回收钴。近年来研究的一种新方案是将铜-钴氧化矿经过一段浸出得到的浸出液送旋流电解,首先电解提取铜,然后电解提取钴[6]。铜-钴氧化矿浸出过程中的关键技术是需要加入还原剂将矿石中的水钴矿还原浸出。工业生产和前期研究使用的还原剂主要包括焦亚硫酸钠[3]、硫酸亚铁[7-8]、气(液)态SO2[9]、亚硫酸钠[5, 10-12]等。最近一些研究采用的还原剂还包括:在硫酸浸出过程中,通过黄铁矿生化浸出产生的亚铁离子作为还原剂[13];利用硫代硫酸铜分解产物作为还原剂[14];用双氧水作还原剂[15-16];在盐酸浸出过程中,采用氯化亚铁作为还原剂[17]。

工业生产和前期研究采用一段浸出方案的不足之处如下:铜和钴的浸出率较低;浸出渣洗液和萃余液抽取液中的钴含量较低,对后续钴回收工艺不利。采用还原剂的不足之处如下:采用硫酸亚铁作还原剂的效果较好,但由于铁离子被引入浸出体系会导致浸出液中铁含量升高,造成后续除铁过程困难且钴的损失过大。使用焦亚硫酸钠、亚硫酸钠和SO2作还原剂的优点是不会向浸出体系引入杂质铁,浸出反应速度也比较快,但由于在酸性浸出液中容易析出二氧化硫气体使浸出过程操作环境恶化,并会导致还原剂消耗量增大,操作成本过高。最近一些研究采用的还原剂均处在初步研究阶段,黄铁矿生化浸出、硫代硫酸铜制备和双氧水的利用率和价格等一些问题还需要进一步考察。

针对铜-钴氧化矿一段浸出技术方案和所采用还原剂存在的不足,本文作者提出一种采用铁粉作为还原剂的两段浸出方案。两段浸出方案的工艺路线如下:第一段浸出过程是在常温下用硫酸浸铜,第二段浸出过程是在加热和用铁粉作还原剂的条件下用硫酸浸出钴。本研究的贡献和创新表现在如下两点:一是将铜-钴氧化矿一段浸出改为两段浸出,二是采用铁粉作为水钴矿还原浸出的还原剂。铜-钴氧化矿两段浸出过程具有如下优点:能实现矿石中铜和钴的选择性浸出,导致第一段浸出液铜含量较高,第二段浸出液钴含量较高,有利于后续工艺对铜和钴的回收;铜钴矿物均通过两次浸出,有利于提高铜和钴的浸出率;第二段浸出采用铁粉作为还原剂,水钴矿还原浸出的效果好,进入溶液的铁量少,操作环境友好。

1 实验

1.1 实验原料

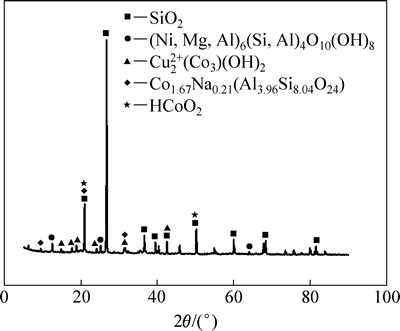

实验用铜-钴氧化矿来自刚果(金)一侧的中非铜带,是由中国有色矿业集团谦比希湿法冶炼有限公司提供的。矿石的化学成分及物相分析结果如表1和图1所示。

从表1和图1可以看出,矿样中的含铜矿物是铜孔雀石,矿石中的钴主要是水钴矿,少量两价钴以硅铝酸盐形式存在。矿石中二氧化硅含量较高(为70.09%(质量分数));消耗硫酸的碱性氧化物如氧化钙、氧化镁和氧化铝等含量较低,铁含量相对也较低。

实验所用试剂:分析纯硫酸试剂(质量分数为96%~98%);还原剂为铁粉,铁含量大于 98%(质量分数),粒径小于75 μm的铁粉占37.5%。

表1 矿石化学化学成分

Table 1 Chemical composition of ore (mass fraction,%)

图1 铜-钴氧化矿的XRD谱

Fig. 1 XRD pattern of copper-cobalt oxide ore

1.2 实验装置

实验所用仪器设备主要有振动磨样机、振动套筛、加热器、多功能搅拌器、电接点玻璃温度仪、真空泵、抽滤瓶、布氏漏斗、电子天平、电热恒温鼓风干燥箱、pH计等。

1.3 实验步骤

第一段浸出工艺如下:将100 g试验矿样与水按一定的液固比加入到1 L的烧杯中;将烧杯置于安装有多功能搅拌器的加热器上;向烧杯中加入定量的硫酸,同时开动搅拌并开始计时;当浸出达到预定反应时间时停止搅拌;反应结束后进行固液分离,得到滤液和浸铜渣;浸铜渣用水洗涤2次,滤液与洗液合并后标定体积,并取样送化验分析;洗后浸铜渣烘干、称质量,取样送化验分析;根据渣中铜和钴的含量分别计算出第一段浸出过程中铜和钴的浸出率。

第二段浸出工艺如下:取50 g浸铜渣与水按一定的液固比加入到500 mL的烧杯中,同时加入定量的硫酸和还原剂(铁粉);浸出过程操作及浸出结束后浸出液、浸出渣的处理同第一段浸出。根据浸出渣分析结果分别计算出两段浸出过程铜、钴、铁的总浸出率。

2 结果与讨论

2.1 第一段浸出过程

第一段浸出过程是用硫酸将矿石中的铜最大限度地浸出,而将钴和铁尽可能地留在浸出渣中,实现铜与钴的初步分离。考虑实际生产,第一段浸出试验在常温(25 ℃)下进行,固定浸出液固比为4:1,主要考察硫酸加入量(以占矿样质量分数来表示)、矿石粒度和反应时间对铜-钴氧化矿浸出过程的影响。

2.1.1 硫酸加入量对浸出的影响

所用矿样的粒径小于75 μm的含量占 60%,矿浆液固比为4:1,常温下(25 ℃)搅拌120 min,硫酸加入量对铜和钴浸出率的影响如图2所示。

图2 硫酸加入量对铜和钴浸出率的影响

Fig. 2 Effect of sulfuric acid content on leaching rates of Cu and Co

从图2可以看出,硫酸加入量对铜的浸出影响较大,铜浸出率随硫酸加入量的增加呈逐渐升高的趋势;当硫酸加入量由铜-钴氧化矿质量的10%增加到13%时,铜浸出率从79.58%升高到90.85%,继续增大硫酸加入量,铜浸出率升高缓慢;钴浸出率随硫酸加入量的增加略有升高,但不明显。矿石的XRD 分析结果表明,矿石中的含铜矿物为孔雀石。铜孔雀石与硫酸反应Cu2(CO3)(OH)2+2H2SO4=2CuSO4+CO2+3H2O容易进行,图2中的铜浸出行为与工业生产的情况基本一致。矿石中的含钴矿物主要是水钴矿,二价钴含量不高,因此第一段浸出过程的钴浸出率较低。

2.1.2 物料粒度对浸出的影响

矿样初始粒度小于75 μm的含量占40%,用振动磨样机将矿样细磨3、6、9和12 min后,粒度小于75 μm的矿样质量分数可分别达到60%、76%、89%和99%。在固定矿浆液固比为4:1、硫酸加入量为矿样质量的13%和常温搅拌时间为120 min的条件下,矿样粒度对铜和钴浸出率的影响如图3所示。

图3 粒度对铜和钴浸出率的影响

Fig. 3 Effect of particle size on leaching rates of Cu and Co

由图3可知,在本试验条件下,铜、钴的浸出率随物料粒度变细都呈现逐渐上升趋势;当矿样粒度小于75 μm的含量占89%,即磨矿时间为9 min时,铜浸出率达到93.1%,钴浸出率为12.86%。当物料进一步磨细后,铜、钴浸出率提高幅度不大。在后续试验中采用矿样粒度小于75 μm的含量占89%是合适的。物料粒度对铜浸出率影响较大进一步说明铜孔雀石与硫酸之间的表面反应比较容易进行,浸出过程为扩散控制过程。

2.1.3 时间对浸出的影响

在粒径小于75 μm的含量占89%的铜-钴氧化矿100 g、矿浆液固比4:1、常温搅拌、硫酸加入量为矿样质量的13%的条件下,反应时间对浸出过程的影响如图4所示。

由图4可知,浸出前60 min,随浸出时间的延长,Cu、Co 浸出率增加的幅度都较大。在60 min 时,铜浸出率达到92.91%,钴浸出率为10.98%;超过60 min后,随着浸出时间的延长,铜的浸出率变化不大。结果表明,矿石中含铜矿物与硫酸反应速度较快,第一段浸出过程的主要任务是浸出铜,所需时间选择60 min是合适的。

图4 浸出时间对铜、钴浸出率的影响

Fig. 4 Effect of leaching time on leaching rates of Cu and Co

2.2 第二段浸出过程

在用还原剂铁粉进行还原浸钴的试验中,所用试样是第一段最佳浸出工艺技术条件下得到的浸铜渣,浸铜渣中铜、钴、铁含量分别为0.495%、1.70%和4.16%。试验每次称取浸铜渣50 g,重点考察初始酸浓度、浸出温度、还原剂加入量和浸出时间等工艺参数对还原浸出过程的影响。在第二段浸出结束后,铜、钴、铁浸出率的计算是根据第二段浸出渣中的金属含量进行的,得出的数据是两段浸出过程的总浸出率。

2.2.1 初始酸浓度对钴浸出过程的影响

图5 初始酸浓度对还原浸出过程影响

Fig. 5 Effect of initial acid concentration on reduction leaching process

初始酸浓度试验是在液固比4:1、浸出温度85 ℃、反应时间150 min、还原剂加入量为理论量的1.5倍的条件下进行的。试验结果如图5所示。

由图5可知,随初始酸浓度的增加,铜、钴浸出率都逐渐升高;初始酸浓度为20 g/L时,铜浸出率达到97.73%,钴浸出率达到96.24%,铁的浸出率达到27.87%。当初始酸浓度超过20 g/L后,铜、钴浸出率增加幅度都不大,但铁浸出率继续上升。综合考虑,初始酸浓度选择20 g/L是合适的。第二段浸出过程主要是在加热条件下用铁粉作为还原剂的水钴矿浸出过程,其化学反应如式(1)和(2)所示:

2HCoO2+2FeSO4+3H2SO4=2CoSO4+Fe2(SO4)3+4H2O (1)

Fe2(SO4)3+Fe=3FeSO4 (2)

联立式(1)和(2)即可得第二段还原浸出过程的总反应:

2HCoO2+Fe+3H2SO4=2CoSO4+FeSO4+4H2O (3)

由图5可知,在试验条件下,按式(3)浸出水钴矿可取得较好效果,钴浸出率达96%以上。从表面上看,HCoO2与铁之间的反应为固-固反应,反应速度可能比较慢。然而,由于浸出体系中存在有Fe2+和Fe3+作催化剂,HCoO2与铁之间的反应得以快速进行。这种利用Fe2+/Fe3+或Cu+/Cu2+作催化剂加速浸出过程的原理在湿法冶金中得到广泛应用。由于第二段浸出的温度较高、时间长,第一段浸出渣中残留的铜也会在第二段继续被浸出,使铜浸出率升高到97%以上。

2.2.2 温度对钴浸出过程的影响

在固定浸出液固比4:1、初始硫酸浓度20 g/L、浸出反应时间150 min、还原剂的加入量为理论量的1.5倍的条件下,当浸出温度分别为常温(25 ℃)、45、55、65、75、85 ℃时,试验结果如图6所示。

图6 温度对还原浸出过程影响

Fig. 6 Effect of temperature on reduction leaching process

从图6可以看出,浸出温度在25~65 ℃区间,随温度的提高,铜和钴浸出率都有所上升;浸出温度为65 ℃时,铜浸出率达到97.21%,钴浸出率达到96.09%;当温度超过65 ℃后,铜和钴的浸出率变化不大,但铁浸出率继续升高。选择还原浸出温度65 ℃可取得铜和钴的浸出率较高,而铁的浸出率较低的结果。由于钴的价格较高,提高钴浸出率有利于提高浸出过程的经济效益。因此,非洲铜-钴氧化矿浸出的生产过程通常在较高温度下进行。

2.2.3 还原剂加入量对钴浸出过程的影响

在液固比4:1、浸出温度65 ℃、反应时间150 min、初始酸浓度20 g/L的条件下,还原剂加入量对钴浸出过程的影响如图7所示。

图7 还原剂加入量对还原浸出过程影响

Fig. 7 Effect of reductant content on reduction leaching process

由图7可知,随还原剂加入量的增加,铜浸出率变化不大,还原剂加入量的增加对钴浸出率影响很大。当还原剂加入量为理论量的1.5倍时,钴浸出率达到96.09%;铁浸出率随还原剂加入量增加有所提高,然后趋于平缓。铁粉加入量过高会导致进入浸出渣的铁量增加,对铁浸出率的影响不大。根据试验结果,还原剂加入量为理论量的1.5倍为宜。

2.2.4 时间对钴浸出过程的影响

在液固比4:1、浸出温度65 ℃、还原剂加入量为理论量的1.5倍、始酸浓度20 g/L的条件下,时间对钴浸出过程的影响如图8所示。

由图8可知,浸出60 min以后,延长还原浸出时间对铜的浸出几乎没有影响,而钴和铁浸出率随时间的延长而明显提高。当还原浸出时间为60 min时,钴浸出率为92.83%,铁浸出率为20.52%;当浸出时间为150 min时,钴浸出率达到96.09%,铁浸出率为26.89%;随着浸出时间的进一步延长,钴浸出率提高的幅度不大,而铁浸出率显著提高。故还原浸出的浸出时间选择150 min是合适的。

图8 浸出时间对还原浸出过程影响

Fig. 8 Effect of leaching time on reduction leaching process

2.3 优化条件下的试验

取粒径小于75 μm含量占89%的铜-钴氧化矿1 kg、液固比4:1、硫酸加入量为铜-钴氧化矿质量的13%(即硫酸加入量为130 g)、常温浸出60 min、液固分离,得到浸铜渣和浸铜液;将浸铜渣(含水率按30%计)在液固比4:1、初始硫酸浓度20 g/L、还原剂加入量为理论量的1.5倍、温度65 ℃、浸出时间150 min条件下进行还原浸出,试验结果如表2所列。

表2 优化条件下的试验结果

Table 2 Test results under optimum conditions

3 结论

1) 通过实施铜和钴选择性浸出和采用铁粉作为水钴矿浸出的还原剂,中非铜-钴氧化矿两段浸出过程具有铜和钴浸出率高,铜钴分离效果好,浸钴液中钴含量高等优点,在工业生产中应用的可行性强。

2) 用铁粉作为水钴矿浸出过程的还原剂不但浸出效果好,浸出操作环境友好,而且铁粉价格便宜,与用硫酸亚铁作还原剂比较,进入浸出液的铁量也较少。

3) 由于试验用铁粉粒度较粗,小于75 μm的含量占37.5%,水钴矿还原浸出过程的效果会受到一定影响。如果将铁粉进一步磨细,则浸出过程中铁粉的用量可能会减少。

REFERENCES

[1] SEETHARAMAN S, MKLEAN A, GUTHRIE R, SEETHARAMAN S. Treatise on process metallurgy (Volume 3)[M]. English: Elsevier, 2014: 633.

[2] NISBETT A, FEATHER A, MILLER G. Implementation of the split circuit concept into copper agitation leach plants[J]. Proceedings Hydrocopper, 2007: 185-190.

[3] CRUNDWELL F, MOATS M, RAMACHANDRAN V, ROBINSON T, DAVENPORT W G. Extractive metallurgy of nickel, cobalt and platinum-group metals[M]. Amsterdam: Elsevier, 2011: 168-385.

[4] 李 明. 刚果(金)氧化铜钴矿冶炼工艺综述[J]. 有色冶金设计与研究, 2012, 33(1): 16-18.

LI Ming. Overview on the smelting process of the cobalt-copper oxide mines in Congo-Kinshasa[J]. Design and Research of Nonferrous Metallurgy, 2012, 33(1): 16-18.

[5] 石玉臣, 黄蕴成, 孙 蕊, 阿茹娜, 王含渊. 从刚果(金)铜钴氧化矿提取钴的试验研究[J]. 中国有色冶金, 2012(5): 63-66.

SHI Yu-chen, HUANG Wen-cheng, SUN Rui, A Ru-na, WANG Han-yuan. Hydrometallurgical test of extracting cobalt from copper-cobalt oxide ore in Democratic Republic of the Congo[J]. China Nonferrous Metallurgy, 2012(5): 63-66.

[6] 郭学益, 姚 标, 李晓静, 石文堂, 田庆华. 水钴矿中选择性提取铜和钴的新工艺[J]. 中国有色金属学报, 2012, 22(6): 1778-1784.

GUO Xue-yi, YAO Biao, LI Xiao-jing, SHI Wen-tang, TIAN Qing-hua. Novel process of selective extraction of copper and cobalt from heterogenite[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1778-1784.

[7] 昆明冶金研究所.铜钴矿直接还原浸出的研究[J]. 云南冶金, 1975(3): 25-30.

Kunming Metallurgy Institute. Research on reductive leaching of copper-cobalt ore[J]. Yunnan Metallurgy, 1975(3): 25-30.

[8] 梁新星, 胡 磊, 欧阳全胜. 铜钴矿研究进展及发展趋势[J]. 湖南有色金属, 2014, 30(3): 42-45.

LIANG Xin-xing, HU Lei, OUYANG Quan-sheng. Research status and development trends of Cu-Co ore[J]. Hunan Nonferrous Metals, 2014, 30(3): 42-45.

[9] 刘大学, 王 云, 袁朝新, 郭持皓, 李 云, 孙 聪. 某铜钴矿的硫酸还原浸出研究[J]. 有色金属(冶炼部分), 2013(6): 18-21.

LIU Da-xue, WANG Yun, YUAN Chao-xin, GUO Chi-hao, LI Yun, SUN Cong. Study on sulfuric acid reduction leaching on copper-cobalt ore[J]. Nonferrous Metals (Extractive Metallurgy), 2013(6): 18-21.

[10] 刘 俊, 李林艳, 徐盛明, 池汝安. 还原酸浸法从低品位水钴矿中提取铜和钴[J]. 中国有色金属学报, 2012, 22(1): 304-309.

LIU Jun, LI Lin-yan, XU Sheng-ming, CHI Ru-an. Recovery of copper and cobalt from low-grade heterogenite with reductive acid leaching method[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 304-309.

[11] 卢苏君, 王书友, 诸葛福瑜, 张 晗, 张 鹏. Co(Ⅲ)-Na2SO3- H2SO4体系浸出钴的研究[J]. 有色金属(冶炼部分), 2013(5): 17-19.

LU Su-jun, WANG Shu-you, ZHUGE Fu-yu, ZHANG Han, ZHANG Pen. Study on cobalt leaching in Co(Ⅲ)-Na2SO3-H2SO4 system[J]. Nonferrous Metals (Extractive Metallurgy), 2013(5): 17-19.

[12] 翁 毅. 水钴矿制备氯化钴的工业化应用[J]. 金属材料与冶金工程, 2008, 36(3): 43-46.

WENG Yi. Industrial application of preparing cobalt chloride by heterogenite[J]. Metal Materials and Metallurgy Engineering, 2008, 36(3): 43-46.

[13]  Z, FANNY L, JEAN F, STOYAN G, AUGUSTIN I. Possibilities for Co(Ⅲ) dissolution from an oxidized ore through simultaneous bioleaching of pyrite[J]. Minerals Engineering, 2015(1): 14-27.

Z, FANNY L, JEAN F, STOYAN G, AUGUSTIN I. Possibilities for Co(Ⅲ) dissolution from an oxidized ore through simultaneous bioleaching of pyrite[J]. Minerals Engineering, 2015(1): 14-27.

[14] 李淑梅. 一种还原浸出水钴矿的新还原剂[J]. 湿法冶金, 2013, 32(6): 363-367.

LI Shu-mei. A novel reductant for reduction leaching heterogenite[J]. Hydrometallurgy of China, 2013, 32(6): 363-367.

[15] STUURMAN S, NDLOVU S, SIBANDA V. Comparing the dissolution of copper-cobalt ores from the DRC region[J]. The Journal of the Southern African Institute of Mining and Metallurgy, 2014, 114(4): 347-353.

[16] SEO Y, CHOI W S, KIM M J, TRAN T. Leaching of a Cu-Co ore from Congo using sulphuric acid hydrogen peroxide leachants[J]. Journal of Mining and Metallurgy Section B-Metallurgy, 2013, 49(1): 1-7.

[17] APUA M C, MULABA-BAFUBIANDI A F. Dissolution of oxidised Co-Cu ores using hydrochloric acid in the presence of ferrous chloride[J]. Hydrometallurgy, 2011, 108(3): 233-236.

(编辑 王 超)

收稿日期:2015-02-10;修订日期:2015-06-16

通信作者:李淑梅,高级工程师;电话:024-25814059;E-mail:sylishumei@163.com