氰化渣磁化焙烧过程中铁化合物反应行为的热力学分析

张亚莉1, 2,于先进2,李小斌1,张丽鹏2,李德刚2

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 山东理工大学 化工学院,山东 淄博,255002)

摘要:通过对磁化焙烧过程中氧化铁还原的热力学平衡分析,以及Fe2O3与硅酸钙、铁橄榄石与氧化钙、Fe3O4与二氧化硅反应的热力学分析,研究氰化渣中含铁化合物在磁化焙烧过程中的热力学反应规律。对氰化渣进行焙砂-磁选实验研究,采用全谱直读等离子体(ICP)、X线衍射(XRD)、X线荧光(XRF)等方法对氰化渣和焙烧渣进行分析和表征。研究结果表明:Fe2O3在较低温度范围内易被还原为Fe3O4,且CaO与SiO2的物质的量比n(CaO)/n(SiO2)为1:1时,Fe2O3不与硅钙化合物反应,不会造成铁的损失;产物Fe3O4在焙烧炉料中与SiO2不能发生反应,有CO存在时,加入适量的添加剂,亦能够稳定存在;在焙烧过程中加入氧化钙,铁橄榄石中的铁能被取代出来,可以提高磁化焙烧效率,且氧化钙的配入量是影响磁化焙烧效率的重要因素;当n(CaO)/n(SiO2)=1:1,时间为90 min,N2和CO的物质的量比n(N2)/n(Co)为4:1,添加1% Na2SO4,温度为880 K时,铁的回收率达到84%,铁精粉中铁品位达到60%,符合工业炼铁的原料要求。实验结果与热力学理论计算结果相吻合。

关键词:氰化渣;焙烧;Fe2O3;Fe3O4;热力学分析

中图分类号:TF801 文献标志码:A 文章编号:1672-7207(2011)12-3623-07

Thermodynamics analysis of ferric compound during roasting-preparing process of cyanide tailings

ZHANG Ya-li1, 2, YU Xian-jin2, LI Xiao-bin1, ZHANG Li-peng2, LI De-gang2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. College of Chemical Engineering , Shandong University of Technology, Zibo 255081, China)

Abstracts: Based on the thermodynamic analyse of ferric oxide reductive and ferric oxide with calcium silicates, fayalite with calcium oxide and Fe3O4 with silicon dioxide during roasting-preparing process, respectively, the thermodynamic of those reactions was determined. The magnetic roasting followed by magnetic separation experiments was done, cyanide tailing and calcine were characterized by ICP, XRD and XRF. The results show that ferric oxide can be reduced to Fe3O4 at low temperature and low concentrations of CO, and when molar ratio of CaO and SiO2 i.e., n(CaO)/n(SiO2) is 1:1, ferric oxide does not react with composition of calcium and suicides, which will not result in the loss of iron. Even when CO is added, Fe3O4 can be in steady existence with the proper amount of additives. If calcium oxide is added, the iron in fayalite can be replaced, thus the roasting effect can be promoted. The adding capacity of calcium oxide is an important factor of influencing roasting effect. When n(CaO)/n(SiO2)=1:1, time is 90 min, n(N2):n(CO)=4:1, and temperature is 880 K, a iron ore concentrate with total iron content of 60% and Fe recovery rate of 84% can be received. The experiment results well accord with the calculation results.

Key words: cyanide tailings; roasting; Fe2O3; Fe3O4; thermodynamics analysis

氰化渣是黄金冶炼生产过程中排出的固体粉状废弃物,无论是常规氰化,还是焙烧氰化,都会产生大量尾渣,尾渣中含有一定量的金及其他可综合回收的金属,其中,全铁含量达到30%~40%,主要以赤铁矿的形式存在[1]。国大黄金集团产生的高铁氰化渣,年产量达到40~50万t。在目前铁矿石资源紧张、价格不断上涨的情况下,研究铁的回收利用具有重要的战略和现实意义,而且尾渣中铁的成功分离与提取可以使其他有价金属得到富集,对其回收利用意义重大[2-3]。高铁氰化渣还原磁化焙烧是一种过程简单、易于实现规模化工业应用的方法[4-6]。关于赤铁矿的还原焙烧有诸多报道,其热力学和工艺条件也有相关报 道[7-10]。但是,氰化渣中的赤铁矿的还原焙烧与单纯的赤铁矿焙烧有很大不同,氰化渣中除赤铁矿外,还含有大量的石英和其他杂质,其组分和焙烧过程中的反应错综复杂[11-12]。铁元素在焙烧过程中的行为至今仍不甚清楚,在此,本文作者对氰化渣中铁元素在磁化焙烧过程中的反应行为进行系统的热力学分析,以便为寻找最佳工艺途径提供理论依据。同时,以氰化渣为原料进行磁化焙烧单因素实验,考察温度和CaO与SiO2物质的量比n(CaO)/n(SiO2)对磁化焙烧效果的影响,并验证热力学理论计算结果。

1 物料特性

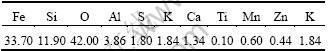

招远黄金冶炼厂高铁氰化渣中含Au和Ag分别为6.05 g/t和32.55 g/t,其他元素化学成分(质量分数)见表1。

表1 氰化渣主要化学成分

Table 1 Chemical composition of cyanide tailings %

由表1可知:原料中铁元素含量达到33.70%,具有很高的回收利用价值。为进一步确定渣中铁的赋存状态,进行X线衍射分析,结果如图1所示。由图1可以看出:氰化渣中的铁和硅含量较高,根据矿相分析结果,主要铁矿物为α-Fe2O3和铁橄榄石,Fe2O3是金精矿中所伴生的FeS2氧化焙烧后得来的,经堆放干燥后,一部分Fe2O3会和渣中的含硅化合物变成铁的复合硅酸盐。

图1 氰化渣XRD图谱

Fig.1 XRD pattern of cyanide tailings

2 热力学分析结果与讨论

氰化渣磁化焙烧是将其中的无磁性化合物或弱磁性化合物转变成强磁性化合物,通过弱磁选达到铁与其他物质分离的效果。

2.1 Fe2O3还原磁化焙烧热力学分析

氰化渣中将近80%的含铁化合物是Fe2O3,通入CO后在一定条件下焙烧,当温度高于843 K时,Fe2O3与CO反应方程式为:

3Fe2O3+CO=2Fe3O4+CO2 (1)

1/4(Fe3O4) +CO=3/4Fe+CO2 (2)

FeO +CO=Fe+CO2 (3)

Fe3O4+CO=3FeO+CO2 (4)

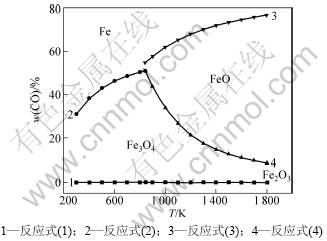

还原氧化铁的热力学平衡图[13]如图2所示,其中,T为热力学温度。

图2 氧化铁还原的热力学平衡图

Fig.2 Thermodynamic equilibrium diagram of iron oxide reduction

由图2可知:3条热力学平衡曲线将区域分为Fe稳定区、FeO稳定区和Fe3O4稳定区。在Fe3O4区,Fe3O4能稳定存在,可以实现磁化焙烧。

2.2 复杂含铁化合物磁化焙烧热力学分析

在氰化渣堆存过程中,一部分Fe2O3会转变成铁的复合硅酸盐。在还原磁化焙烧过程中,还有相当多的铁氧化物与硅酸盐发生固相反应,生成铁橄榄石。铁橄榄石是无碱性添加剂焙烧的主要矿相,该相中铁氧化物被石英包裹,强度大,结构致密,很难被还原,此时,焙烧产率低,难以有效实现磁分选[14]。因此,加入碱性添加剂破坏铁橄榄石的结构是提高铁回收率的有效方法。铁橄榄石与生石灰的主要反应为:

CaO+Fe2SiO4=CaSiO3+2FeO (5)

Fe3O4+CO=3FeO+ CO2 (6)

反应(5)~(6)的吉布斯自由能变化与温度的关系分别为:

=-56 233-28.58T

=-56 233-28.58T

=35 380-40.16T

=35 380-40.16T

反应式(5)~(6)吉布斯自由能变化与温度的变化曲线如图3所示。

图3 反应(5)和(6)的吉布斯自由能与温度的关系

Fig.3 Relationship between Gibbs free energy changes of reactions (5) and (6) and temperature

从图3可以看出:在氰化渣中加入CaO后,在300~1 400 K时,CaO与铁橄榄石反应的吉布斯自由能小于0 kJ/mol。从热力学角度来说,反应趋势较大,并且随温度升高反应趋势增大。而Fe3O4被CO还原的反应在温度低于843 K时,反应的吉布斯自由能是正值,即在该温度下,FeO不能稳定存在,可以生成Fe3O4。热力学计算结果表明,CaO还能将复杂氧化物中的FeO取代出来,促使FeO的活度提高,成为自由状的FeO,控制一定的温度条件和气氛,使FeO与气氛中的CO2反应,转变成Fe3O4,有利于提高磁化焙烧的效率。

2.3 Fe2O3与含硅化合物的反应热力学分析

为了和黄金生产工序相衔接,加入生石灰,其目的有:(1) 固定氰化渣中的S和As;(2) 满足氰化过程中pH=9.5~11的要求;(3) 确保尾渣的稳定性[15]。CaO根据添加量的不同,可与SiO2反应生成CaO·SiO2和2CaO·SiO2,进而Fe2O3与硅酸钙可能反应生成CaO·Fe2O3和2CaO·Fe2O3[16]。Fe2O3与硅酸钙的反应见方程式(7) ~ (12),其反应的吉布斯自由能变化与温度的变化曲线如图4所示。

图4 反应(7)~(12)的吉布斯自由能与温度的关系

Fig.4 Relationship between Gibbs free energy changes of reactions (7)-(12) and temperature

CaO·SiO2+Fe2O3=CaO·Fe2O3+SiO2 (7)

1/2(2CaO·SiO2)+Fe2O3=CaO·Fe2O3+1/2SiO2 (8)

2CaO·SiO2+Fe2O3=CaO·Fe2O3+CaO·SiO2 (9)

2(2CaO·SiO2)+2Fe2O3=2CaO·Fe2O3+2(CaO·SiO2) (10)

2(CaO·SiO2)+2Fe2O3=2CaO·Fe2O3+2SiO2 (11)

2CaO·SiO2+Fe2O3=2CaO·Fe2O3+SiO2 (12)

由图4可见:在焙烧温度范围内,CaO·SiO2与Fe2O3反应的吉布斯自由能大于0,不与Fe2O3反应生成2CaO·Fe2O3或CaO·Fe2O3。2CaO·SiO2与Fe2O3的作用根据热力学数据图显示有2种情况:一种是Fe2O3置换出2CaO·SiO2的SiO2生成2CaO·Fe2O3和SiO2;另一种是生成CaO·Fe2O3和CaO·SiO2或SiO2。反应(9)和反应(10)的吉布斯自由能大于0 kJ/mol,并且随温度的改变变化不大,故不会和2CaO·SiO2反应生成CaO·Fe2O3。而反应(12)的吉布斯自由能随温度升高而降低,并且在焙烧温度范围内,其值小于0 kJ/mol,说明Fe2O3和2CaO·SiO2有反应生成2CaO·Fe2O3和SiO2的趋势。该反应不利于Fe2O3的磁化焙烧,可以降低Fe2O3磁化焙烧的转化率,减少铁的回收率。因此,在添加CaO配料时,除考虑CaO与铁橄榄石反应的添加量及CaO调节氰化渣浸出时溶液的pH外,应尽量使CaO与SiO2反应生成CaO·SiO2,避免过量时生成2CaO·SiO2。

3 磁化焙烧产物Fe3O4稳定性的热力学分析

当磁化焙烧到一定程度时,随Fe3O4含量的增大和温度的升高,焙砂中存在一个Fe3O4含量降低的区域,一般认为该区域内造成Fe3O4损失的主要原因是部分Fe3O4与石英和CaO的相互作用生成2FeO·SiO2和FeO·SiO2。在选矿过程中随Fe3O4一同选出,造成铁精粉品位降低。

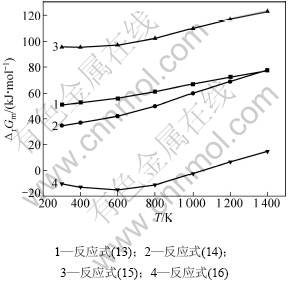

Fe3O4与石英的可能反应见方程式(13)~(16),其反应的吉布斯自由能与温度的变化曲线如图5所示。

图5 反应(13)~(16)的吉布斯自由能与温度的关系

Fig.5 Relationship between Gibbs free energy changes of reactions (13)-(16) and temperature

Fe3O4+SiO2=FeO·SiO2+Fe2O3 (13)

2Fe3O4+SiO2=2FeO·SiO2+2Fe2O3 (14)

Fe3O4+3SiO2+CO=3(FeO·SiO2)+CO2 (15)

2Fe3O4+3SiO2+2CO=3(2FeO·SiO2)+2CO2 (16)

SiO2与CaO的可能反应见方程式(17)~(18)。

SiO2+CaO=CaO·SiO2 (17)

SiO2+2CaO=2CaO·SiO2 (18)

反应式(17)~(18)的吉布斯自由能温度的变化曲线如图6所示。

图6 反应(17)和(18)的吉布斯自由能与温度的关系

Fig.6 Relationship between Gibbs free energy changes of reactions (17) and (18) and temperature

根据热力学数据及实验数据,在高铁氰化渣烧结炉料中,Fe2O3与还原性气体CO在一定条件下易生成Fe3O4。氰化渣中除含有大量铁以外,还含有相当数量的SiO2,由图6可知:生成的磁铁矿与SiO2反应的吉布斯自由能为正值,并且随温度的升高而增加,这说明Fe3O4在此温度范围内不与SiO2反应而能稳定存在。在CO存在的情况下,Fe3O4,SiO2和CO三者反应生成FeO·SiO2的吉布斯自由能为正值,说明三者反应不能生成FeO·SiO2;而三者反应生成2FeO·SiO2的吉布斯自由能为负值,随温度升高而增大,到达1 000 K时,数值变为正值,说明在较低温度下,Fe3O4,SiO2和CO有反应生成2FeO·SiO2的趋势,造成磁铁矿的损失。

在炉料烧结过程中,根据铁橄榄石的量和保证氰化浸出时的pH,加入一定量的CaO,从图6可知,CaO与SiO2反应的吉布斯自由能为负值,并且远小于0 kJ/mol。从热力学上其反应趋势很大,并且比较生成CaO·SiO2和2CaO·SiO2,更容易生成2CaO·SiO2。2CaO·SiO2与Fe3O4易反应生成2CaO·Fe2O3,会降低磁化焙烧的效率。而CaO与SiO2反应生成CaO·SiO2的趋势大于Fe3O4与SiO2反应生成2FeO·SiO2的趋势,即CaO与SiO2的亲和力大于Fe3O4与SiO2的亲和力,因此,控制CaO的量,使其生成CaO·SiO2,避免生成2CaO·SiO2,以提高磁化焙烧效率。

4 实验验证

4.1 实验方法和分析检测方法

本实验采用自组装的高温气氛炉对氰化渣的焙烧过程进行单因素实验研究。焙砂经过水冷干燥后配成一定浓度的浆液,在XCGS-Φ50磁选管中进行磁选实验。分别考察40 g氰化渣在N2与CO物质的量比n(N2):n(CO)=4:1,焙烧时间为90 min,粒度<45 μm的颗粒占95%条件下,不同反应温度、不同n(CaO)/n(SiO2)对磁化焙烧效果的影响。

使用美国的Leeman公司的ProdigyXP型全谱直读等离子体光谱仪(ICP)和日本理学3070e型X-荧光光谱仪对氰化渣和磁选精矿中Au,Ag和Fe等含量进行检测,使用荷兰帕纳克公司PW2040和60型X线衍射仪进行XRD物相分析。

4.2 实验结果分析

4.2.1 温度对磁化焙烧效果影响

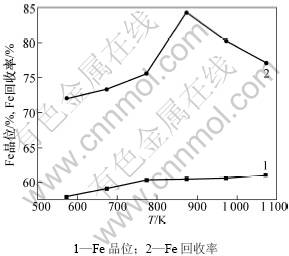

在n(CaO)/n(SiO2)为1,时间为90 min,n(N2):n(CO)=4:1时,添加1% Na2SO4,在不同温度下焙烧,焙烧冷却后配成一定浓度的浆液,在1 kHz的磁场强度下磁选,结果如图7所示。

图7 温度对磁化焙烧效果的影响

Fig.7 Effects of temperature on Fe grade of concentrate and recovery rate

由图7可知:在500~1 100 K之间,铁精矿的品位大于55%,且随温度的升高有所增加,均达到工业中铁精矿中高炉炼铁的工业要求。铁的回收率随温度的升高而升高,在880 K的时候达到最大值,而后呈下降趋势。由热力学分析图可知:在一定的CO浓度范围内,在843 K以下是Fe3O4的稳定区,Fe2O3易被还原。由图3可知:随温度升高铁橄榄石中铁被取代出来的趋势增强,高温相对于低温,CaO取代铁橄榄石中铁的趋势增强。从动力学角度考虑,在保证反应进行的前提下,温度升高可以提高反应物的活化分子数,促进多相反应的动力学行为。因此,温度升高可以提高回收率。当温度大于880 K时,回收率有所下降,主要原因是高于此温度时进入了FeO的稳定区。

4.2.2 n(CaO)/n(SiO2)对磁化焙烧效果影响

在焙烧过程中,CaO是作为一种重要添加剂而被引入系统的。加入CaO一方面保证氰化渣中SiO2形成CaO·SiO2,防止SiO2与Fe2O3反应造成磁化焙烧率降低,另一方面取代铁橄榄石中铁,增加活性铁量,提高磁化率。

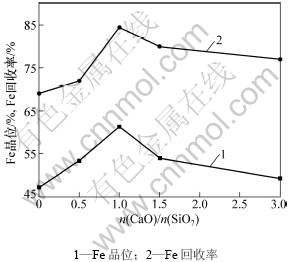

在温度为880 K,时间90 min,n(N2):n(CO)=4:1,添加1% Na2SO4,以不同n(CaO)/n(SiO2)添加CaO进行焙烧,经磁选后的结果如图8所示。

图8 n(CaO)/n(SiO2)对磁化焙烧效果影响

Fig.8 Effects of n(CaO)/n(SiO2) on Fe grade of concentrate and recovery rate

由图8可见,当n(CaO)/n(SiO2)<1时,随CaO添加量增多,铁精矿中铁的品位和铁的回收率均增加,在n(CaO)/n(SiO2)=1时达到最大值,其后随CaO添加量的增多而降低。这与热力学计算结果是一致的,CaO的添加量是影响磁化率的一个重要因素。实验应控制n(CaO)/n(SiO2)=1。

5 焙砂中主要成分分析

图9所示为氰化渣以n(CaO)/n(SiO2)=1时磁化焙烧后所得焙砂的XRD图谱。由图9可以看出:焙砂中主要物相有Fe3O4,CaO·SiO2,还有少部分铁酸盐类留在脉石中。这说明在合适的n(CaO)/n(SiO2)条件下,SiO2主要形成了CaO·SiO2,没有与Fe3O4及Fe2O3反应,并且原料中的铁橄榄石的峰也消失,这与热力学分析结果相吻合。

图9 氰化渣磁化焙烧后焙砂的XRD图谱

Fig.9 XRD pattern of calcine after magnetic roasting

6 结论

(1) 在烧结条件下,Fe2O3在有还原性气体存在时,控制较低的CO浓度,在较低温度下易被还原成强磁性物质Fe3O4,在宽松条件下就能实现磁化焙烧,实现铁与其他物质分离的目的。

(2) 在高铁氰化渣炉料烧结过程中,应配入适量的CaO,以保证炉料中铁橄榄石中的铁被取代出来,增加FeO的活度,以提高磁化焙烧效率。CaO与SiO2反应易生成CaO·SiO2和2CaO·SiO2,2CaO·SiO2能够与Fe2O3反应生成2CaO·Fe2O3,造成铁的损失;CaO·SiO2与Fe2O3不能够反应,因此,选择配料时,CaO与SiO2物质的量比应为1:1。

(3) 磁化焙烧产物Fe3O4与SiO2不能发生反应,在有CO存在时,可以反应生成2FeO·SiO2,降低磁化焙烧效率。但是,配入CaO后,CaO与SiO2的亲和力大于Fe3O4与SiO2的亲和力,故CaO首先与SiO2反应,但是CaO过量时会生成2CaO·SiO2进而与Fe3O4反应。因此,CaO的添加量是提高磁化焙烧效率的一个重要因素。

(4) 温度是影响氰化渣中回收率的一个重要因素,在880 K时铁的回收率和铁精矿中铁品位达到最大值,这说明在热力学计算确定反应方向的基础上,温度同时作为一个动力学因素影响反应过程。在CaO与SiO2物质的量比等于1时,磁化效果最好,与热力学计算结果相吻合。

参考文献:

[1] 赵战胜. 从氰化尾渣中提取S, Fe, Au的方法[J]. 黄金, 2007, 28(7): 40-41.

ZHAO Zhan-sheng. Method for extracting S, Fe and Au form cyanide slag[J].Gold, 2007, 28(7): 40-41.

[2] 王筱留. 钢铁冶金学[M]. 北京: 冶金工业出版社, 2006: 14-15.

WANG Xiao-liu. Ferrous metallurgy[M]. Beijing: Metallurgical Industry Press, 2006: 14-15.

[3] 贾艳, 李文兴. 铁矿石烧结生产[M]. 北京: 冶金工业出版社, 2006: 44-48.

JIA Yan, LI Wen-xing. Sintering production of iron ore[M]. Beijing: Metallurgical Industry Press, 2006: 44-48.

[4] 罗立群, 乐毅. 难选物料磁化焙烧技术的研究与进展[J]. 中国矿业, 2007, 16(3): 55-58.

LUO Li-qun, LE Yi. Applied researches and new developments of magnetizing roasting on iron materials[J]. China Mining Magazine, 2007, 16(3): 55-58.

[5] 周建军, 朱庆山, 王华军, 等. 某鲕状赤铁矿流化床磁化焙 烧-磁选工艺[J]. 过程工程学报, 2009, 9(2): 307-313.

ZHOU Jian-jun, ZHU Qing-shan, WANG Hua-jun, et al. Magnetic roasting of an Oolitic hematite and limonite ore in a fluidized bed reaction[J]. The Chinese Journal of Process Engineering, 2009, 9(2): 307-313.

[6] 龚国华. 闪速磁化焙烧法处理大冶铁矿强磁选低品位铁精矿[D]. 武汉: 武汉理工大学资源与环境工程学院, 2004: 25-30.

GONG Guo-hua. Study on treating low grade iron concentrate of high intensity magnetic separation of daye iron mine by flash magnetization roasting[D]. Wuhan: Wuhan University of Technology. School of Resources and Environmental Engineering, 2004: 25-30.

[7] Suckal V. Bulk density as method of evaluating reducibility of hard hematite ore in direct reduction process[J]. Mineral Processing and Extractive Metallurgy, 2003, 112(4): 52-53.

[8] Bahgat M, Khedr M H. Reduction Kinetics. Magnetic behavior and morphological changes during reduction of magnetic single crystal[J]. Mater Sci Eng B, 2007, 138: 251-258.

[9] Feilmagr C, Thurnhofer A, Winrer F, et al. Reduction behavior of hematite to magnetite under fluidized bed conditions[J]. ISIJ Int, 2004, 44(7): 1125-1133.

[10] 李小斌, 谭培龙, 吕卫君, 等. 高岭石碱石灰的烧结过程[J]. 硅酸盐学报, 2006, 34(4): 422-426.

LI Xiao-bin, TAN Pei-long, L? Wei-jun, et al. Sintering process between kaolinite and alkali lime[J]. Journal of the Chinese Ceramic Society, 2006, 34(4): 422-426.

[11] 钱让请, 杨晓勇, 黄德志, 等. 微细粒型金矿床金的赋存状态研究[J]. 中南工业大学学报: 自然科学版, 2002, 33(3): 225-229.

QIAN Rang-qing, YANG Xiao-yong, HUANG De-zhi, et al. Gold occurrence in the veinlet-impregnated gold[J]. Journal of Central South University of Technology: Natural Science, 2002, 33(3): 225-229.

[12] 徐莲芳. 我国有色金属及黄金的综合回收技术[J]. 世界有色金属, 1999, 10: 19-21.

XU Lian-fang. The technology of chinese nonferrous metals and synthetical recovery of gold[J]. World nonferrous Metals, 1999, 10: 19-21.

[13] LI Xiao-bin, XIAO Wei, LIU wei, et al. Recovery of alumina and ferric oxide from Bayer red mud rich in iron by reduction sintering[J]. Transactions of Nonferrous Metal Society of China, 2009, 19: 1342-1347.

[14] 张林楠, 张力, 王明玉. 高铁CaO-FeOx-SiO2三元体系氧化过程相变热力学分析[J]. 物理化学学报, 2008, 24(9): 1540-1546.

ZHANG Lin-nan, ZHANG Li, WANG Ming-yu. Thermodynamics of phase transformations in oxidation process of CaO-FeO-SiO2 system with high iron content[J]. Alta Phys-Chim Sin, 2008, 24(9): 1540-1546.

[15] 马红周, 兰新哲, 王耀宁. 焙烧氰化尾渣的利用研究[J]. 稀有金属, 2010, 34(2): 282-285.

MA Hong-zhou, LAN Xin-zhe, WANG Yao-ning. Utilization of tailings of roasting-cyaniding process[J]. Chinese Journal of Rare Metals, 2010, 34(2): 282-285.

[16] 周秋生, 齐天贵, 彭志宏, 等. 熟料烧结过程中氧化铁反应行为的热力学分析[J]. 中国有色金属学报, 2007, 17(6): 973-978.

ZHOU Qiu-sheng, QI Tian-gui, PENG Zhi-hong, et al. Thermodynamics of reaction behavior of ferric oxide during sinter-preparing process[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 973-978.

(编辑 赵俊)

收稿日期:2011-01-20;修回日期:2011-05-15

基金项目:山东省自然科学基金资助项目(ZR2010EL006)

通信作者:于先进(1962-),男,山东栖霞人,教授,博士后,从事冶金物理化学及有色金属冶金等研究;电话:0533-2781681;E-mail:xjy@sdut.edu.cn