文章编号:1004-0609(2012)05-1440-08

梯度硬质合金梯度层形成的计算机模拟及验证

陈伟民1, 2,徐 涛1,张伟彬3,张 颢1,杜 勇1, 3,谭澄宇2,陈 利1, 3,张忠建1,刘向中1

(1. 硬质合金国家重点实验室,株洲 412007;2. 中南大学 材料科学与工程学院,长沙 410083;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:结合相图热力学计算,使用DICTRA软件计算模拟Co-W-Ti-C-N、Co-W-Ti-Nb-C-N和Co-W-Ti-Ta-C-N体系梯度硬质合金梯度层形成过程,对比计算模拟和实测的梯度硬质合金中Co含量的距离变化曲线。通过分析各相体积分数及组元成分随距离的分布研究烧结时间、烧结温度、Co含量和Ti含量对梯度层厚度的影响。结果表明:计算模拟与实验数据吻合较好。延长烧结时间、升高烧结温度和增加Co含量均会促进梯度层厚度的增加,而增加Ti含量则会抑制梯度层厚度的增加。

关键词:梯度硬质合金;梯度层;计算机模拟;DICTRA

中图分类号:TG146 文献标志码:A

Computer simulation of gradient zone formation in cemented carbides and its verification

CHEN Wei-min1, 2, XU Tao1, ZHANG Wei-bin3, ZHANG Hao1, DU Yong1, 3,

TAN Cheng-yu2, CHEN Li1, 3, ZHANG Zhong-jian1, LIU Xiang-zhong1

(1. State Key Laboratory of Cemented Carbides, Zhuzhou 412007, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China?

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The gradient zone formation in Co-W-Ti-C-N, Co-W-Ti-Nb-C-N and Co-W-Ti-Ta-C-N cemented carbides was simulated by using the DICTRA software package in conjunction with thermodynamic calculations. Simulated elemental concentration profiles for Co were compared with the experimental results. Taking into account the volume fractions of different phases and elemental concentration profiles, the effects of sintering time, sintering temperature, as well as the contents of Co and Ti on gradient zone formation, were investigated. The results show that the simulated results agree reasonably with the experimental data. The long sintering time, high sintering temperature and large content of Co increase the thickness of the gradient zone, but the high content of Ti restrains the thickness of gradient zone increasing.

Key words: gradient sintering of cemented carbides; gradient zone; computer simulation; DICTRA

硬质合金是一种以难熔金属化合物(WC、TiC、TaC和NbC等)为基体,以过渡族金属(Co、Fe、Ni)为粘结相,通过粉末冶金方法制备的金属陶瓷工具材料[1-3],广泛用作刀具、钻具、耐磨零件等,被誉为“工业的牙齿”。然而,均匀结构硬质合金的硬度和韧性是一对相互矛盾的性能,这种特性制约其应用领域的进一步扩大,难以满足现代工业发展对硬质合金提出的高硬度和高韧性要求[4-6]。

梯度硬质合金是一种粘结相和基体相的体积分数和形貌呈连续梯度变化的新型非均匀复合材料,可依据材料各部分使用功能要求不同来调整其基体相、粘结相含量的分布,从而有效解决均匀硬质合金中存在的硬度与韧性相互矛盾的问题[7-8]。

随着新型梯度材料的发展,合理控制梯度合金梯度层厚度可以获得综合性能优异的梯度结构合金[9],因此准确预测梯度层的形成显得非常重要[10-11]。1981年,SUZUKI等[12]通过简单热力学和动力学模型定性研究了烧结时间对梯度硬质合金梯度层的影响。1988年,SCHWARZKOPF等[13]就Co含量对表面无立方相梯度硬质合金表面区域厚度的影响进行了研究。由于在计算时对扩散动力学模拟作了部分假设,计算结果与实验结果存在一定的差异。2001年,Sandvik公司的FRYKHOLM等[14]使用DICTRA(Diffusion Controlled TRAnsformation)软件研究立方相成分对梯度硬质合金梯度层形成的影响。但FRYKHOLM等[14]只考虑了添加Nb和Ta的效果,没有单独分析Ti对梯度层的影响。近期,本课题组张伟彬等[15]建立了具有自主知识产权的梯度硬质合金体系的热力学和扩散动力学数据库,并对几种多元梯度硬质合金梯度层的形成进行了计算机模拟,其模拟结果与实验值吻合较好,验证了数据库的准确性。

本文作者在上述数据库基础上,利用DICTRA软件研究表面无立方相梯度硬质合金梯度层的形成过程,将计算结果与实验值进行对比,并且分析烧结时间、烧结温度、Co含量和Ti含量对梯度硬质合金梯度层形成的影响。本研究的目的是进一步证实热力学和扩散动力学计算在梯度硬质合金成分及工艺参数设计的指导作用。

1 梯度层形成机理及计算模拟

1.1 梯度层形成机理

表面无立方相梯度硬质合金是通过预烧结和梯度烧结制成的。经过预烧结得到的无梯度致密体在无氮气氛梯度烧结的条件下,硬质合金表面碳氮化物立方相分解生成N2逸出,N由内向外扩散[12],形成氮浓度梯度。由于N和Ti强烈的热力学耦合,在液相粘结相中氮活度梯度驱动着钛原子向内迁移[13],形成一个与氮浓度梯度呈正比关系且方向相反的钛浓度梯 度[16],从而引发Ti向内迁移。向内扩散的Ti与合金内部的C和N等原子发生反应生成新的立方相。图1所示为表面无立方相梯度硬质合金形成机理示意图。由图1可见,一方面,N原子逸出合金表面和Ti原子向合金内部扩散导致合金的表面区域形成空隙;另一方面,液相粘结相向合金表面流动。两种现象的综合作用形成具有无立方相和富粘结相的梯度结构表层韧性区域,这种结构既有利于涂层与基体的结合,又可在涂层中形成韧性缓冲区。当裂纹扩展到该区时,其良好的塑性和韧性可以吸收裂纹扩展时的能量,进而有效地阻止涂层中形成的裂纹向合金内部扩展、提高界面结合强度和降低界面应力集中,延长合金切削工具的使用寿命[17]。

图1 表面无立方相梯度硬质合金形成机理示意图

Fig. 1 Schematic diagram of formation mechanism of graded cemented carbides with cubic carbide free layer

1.2 计算模拟

DICTRA是用来模拟多元体系扩散控制相变的软件包,模拟时假设所有的相界面上均为局部热力学平衡。模拟计算是基于多组元扩散方程的数值计算[18]。DICTRA是基于原子移动性参数,所用扩散系数是通过原子移动性参数及热力学因子由下列方程计算得到的:

(1)

(1)

式中:xk为k元素的摩尔分数;Mi是i元素的原子移动性;μi为化学势;n是参考态元素。原子移动性参数与温度的关系由以下方程表示:

(2)

(2)

DICTRA 软件使用的热力学参数来自于Thermo- Calc的热力学数据库[19],而原子移动性参数储存于动力学数据库中,结合原子移动性参数和有关热力学参数便可模拟扩散相变过程。

本研究采用张伟彬等[15]所建立的硬质合金热力学和扩散动力学数据库进行DICTRA模拟。由于缺少实验信息,假设C和N等非金属元素在液相粘结剂中具有相同的迁移率。在本工作计算时,激活能Q取为65 kJ/mol,扩散频率因子取为6.5×104 J/mol[20]。Co、Ti、W、Nb和Ta等金属元素的移动性参数则由金属液相扩散Sutherland方程[21]获取。

由于连续基体相中分散相的存在会阻碍扩散通道,因此为了得到各组元在粘结相中有效扩散速率,可引入迷宫因子 (其中f是粘结相的体积分数)来减少粘结相扩散系数矩阵[20]。粘结相中有效扩散系数可以由式(1)乘以迷宫因子

(其中f是粘结相的体积分数)来减少粘结相扩散系数矩阵[20]。粘结相中有效扩散系数可以由式(1)乘以迷宫因子 获得:

获得:

(3)

(3)

瑞典皇家工学院的EKROTH等[22]在早期的研究中假设 等于f 2。但2003年FRYKHOLM等[20] 通过实验和计算模拟研究了这一假设的可靠性,发现将

等于f 2。但2003年FRYKHOLM等[20] 通过实验和计算模拟研究了这一假设的可靠性,发现将 改为f可以使计算结果更好地符合实验结 果,MOHAMMADPOUR等[23]通过实验验证了FRYKHOLM等[20]的假设,所以本工作中λ(f)取为f。

改为f可以使计算结果更好地符合实验结 果,MOHAMMADPOUR等[23]通过实验验证了FRYKHOLM等[20]的假设,所以本工作中λ(f)取为f。

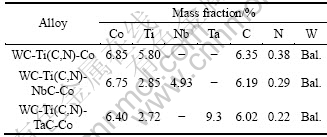

2002年FRYKHOLM等[14]对WC-Ti(C,N)-Co、 WC-Ti(C,N)-NbC-Co和WC-Ti(C,N)-TaC-Co合金梯度层的形成进行了细致的实验研究。表1所列为FRYKHOLM等[14]制备的3种不同合金中各组分的成分。本工作利用多组元梯度硬质合金的数据库对它们进行计算模拟,对比FRYKHOLM等[14]的实验结果,检验数据库的准确性。

表1 WC-Ti(C,N)-Co, WC-Ti(C,N)-TaC-Co和WC-Ti(C,N)- NbC-Co[14]合金成分配比

Table 1 Chemical composition of WC-Ti(C,N)-Co, WC-Ti(C, N)-TaC-Co and WC-Ti(C,N)-NbC-Co[14] alloys

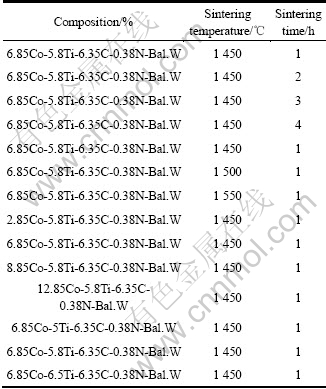

同时,设计各种WC-Ti(C,N)-Co合金及烧结制度(如表2所列),分析模拟烧结时间、烧结温度和合金成分对梯度层形成的影响。

2 结果与讨论

2.1 计算模拟结果与实验值的对比

表2 计算机模拟WC-Ti(C,N)-Co合金成分及烧结制度

Table 2 Composition and sintering condition for WC-Ti(C, N)-Co alloy during computer simulation

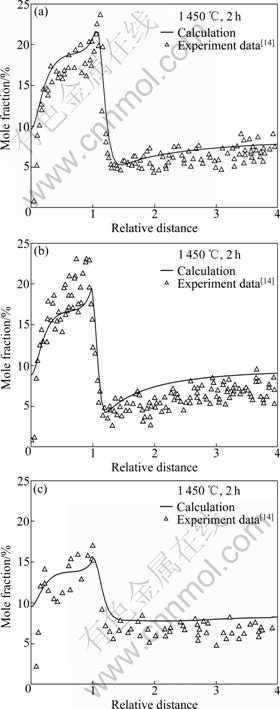

本工作计算模拟了FRYKHOLM等[14]制备的Co-W-Ti-C-N、Co-W-Ti-Nb-C-N和Co-W-Ti-Ta-C-N体系表面无立方相梯度硬质合金(如表1所列),并结合相应实验结果进行对比。表面无立方相梯度硬质合金梯度层厚度是指从合金表层到立方相刚出现之间的距离。通过扫描电子显微镜(SEM)获取梯度硬质合金显微组织背散射图像,再采用analySIS软件3.0版(或者更高版本)分析合金中各相分布情况,从而可以得到硬质合金梯度层厚度。上述3种合金的实验梯度层厚度分别为33、31和38 μm[14],而本工作模拟结果分别是31、34和38 μm。为了更好地观察和对比梯度层厚度不同的硬质合金相体积或合金成分的距离变化情况,通常将距离标准化,即扩散距离/梯度层厚度[14, 22],从而得到相体积或合金成分的相对距离变化关系。图2所示为计算模拟的Co-W-Ti-C-N、Co-W-Ti-Nb-C-N和Co-W-Ti-Ta-C-N体系硬质合金中Co含量的相对距离变化曲线和实验结果[14]的比较。

由图2可知,Co-W-Ti-C-N、Co-W-Ti-Nb-C-N和Co-W-Ti-Ta-C-N体系硬质合金通过电子探针显微分析仪(EPMA)所测得的Co含量由表层开始逐渐增加,在梯度层边缘达到最高值后又骤降到最低值,再缓慢过渡到合金基体含量。本工作计算模拟结果与实验值吻合较好,能够很好地反映出Co含量由表层到芯部的变化趋势,验证张伟彬等[15]建立的多组元梯度硬质合金数据库的准确性和使用DICTRA计算模拟硬质合金梯度层形成过程的可行性。对比图2(a)~(c)可知,Co-W-Ti-C-N、Co-W-Ti-Nb-C-N和Co-W-Ti-Ta-C-N体系硬质合金Co含量的相对距离变化曲线大致相同,梯度层内Co含量由表层开始逐渐增加,在梯度层厚度附近达到Co含量的峰值,再过渡到芯部的均称含量。这是因为硬质合金形成梯度层主要依靠Ti和N之间的热力学耦合,添加Nb或Ta均不能显著影响这种耦合在梯度层形成过程中所起的作用。

图2 Co-W-Ti-C-N、Co-W-Ti-Nb-C-N和Co-W-Ti-Ta-C-N体系硬质合金中Co含量的相对距离变化曲线(曲线为计算模拟结果,符号为实验值[14])

Fig. 2 Elemental concentration profiles for Co in cemented carbides: (a) Co-W-Ti-C-N; (b) Co-W-Ti-Nb-C-N; (c) Co-W- Ti-Ta-C-N alloys (Calculation: curve; Experiment value[14]: symbols)

2.2 烧结工艺及成分对梯度层的影响

本工作设计了各种WC-Ti(C,N)-Co合金及烧结制度(如表2所列)进行计算模拟。下面分析随烧结时间、烧结温度、Co含量和Ti含量变化的计算模拟结果。

2.2.1 相体积分数

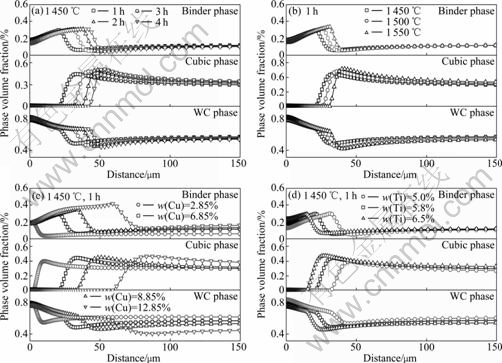

图3所示为Co-W-Ti-C-N体系梯度硬质合金随烧结时间、烧结温度、Co含量和Ti含量变化的相体积分数—距离变化曲线。

由图3可知,硬质合金表层富集了WC相,且无立方相;立方相出现在中间层(表层与芯部的过渡区域),且其含量迅速上升,达到最大值后才会向芯部缓慢下降;粘结相则会在立方相出现之前达到最高峰,当立方相出现之后会过渡到芯部的均称含量。在无氮气氛梯度烧结条件下,表面碳氮化物立方相分解,分解所产生的C与W结合形成WC相,导致表面富集WC相。N和Ti强烈的热力学耦合,引起Ti向合金内部扩散。而随着扩散距离的增加,Ti扩散所留下的空位由液相粘结相填充,粘结相的含量必然随之增多,从而到达最高峰。同时,在中间层Ti和合金内部的C和N等原子发生反应形成立方相化合物导致立方相急速上升,从而导致在此区域内粘结相含量减少。

2.2.2 组元成分分布

图4所示为Co-W-Ti-C-N梯度硬质合金组元成分随烧结时间、烧结温度、Co含量和Ti含量变化的距离分布曲线。

由图4可知,合金表面未含有Ti,Ti是从中间层开始出现的,Ti含量会在比较狭窄的区域内迅速增加,然后缓慢回落到合金芯部的含量;而表层Co含量偏低,随着离表层距离的增加,会出现Co含量的最高峰,再过渡到芯部的均称含量。这是因为N向外扩散,引起Ti向内迁移,改变局部的原子浓度,Ti迁移后所留下的空位则由Co来填充,从而获得Co元素的梯度分布。对比图3和图4可知,Co和Ti质量分数随距离变化曲线与粘结相和立方相的变化趋势是一致的,这是因为粘结相主要的成分就是Co,而Ti几乎只溶解在立方相中。

图3 Co-W-Ti-C-N体系梯度硬质合金随烧结时间(a)、烧结温度(b)、Co含量(c)和Ti含量(d)变化的相体积分数—距离曲线

Fig. 3 Phase volume fractions of Co-W-Ti-C-N cemented carbide versus several variables: (a) Sintering time; (b) Sintering temperature; (c) Content of Co; (d) Content of Ti

图4 Co-W-Ti-C-N体系梯度硬质合金组元成分随烧结时间、烧结温度、Co含量和Ti含量变化的距离分布曲线

Fig. 4 Elemental concentration profiles of Co-W-Ti-C-N cemented carbide versus several variables: (a) Sintering time; (b) Sintering temperature; (c) Content of Co; (d) Content of Ti

由图4(b)所示,随着烧结温度的升高,Ti扩散速率会升高,从而导致Co和Ti浓度变化会更加剧烈。由图4(c)可知,Co含量增加提供更多扩散通道,促进Ti向芯部扩散。

2.2.3 梯度层厚度

由图3(a)和图4(a)可以得到Co-W-Ti-C-N体系梯度硬质合金梯度层厚度随烧结时间增加的变化趋势,从而可以分析烧结时间对梯度层厚度的影响。图5所示为梯度层厚度与烧结时间的关系。

图5 Co-W-Ti-C-N体系梯度硬质合金梯度层厚度随烧结时间变化情况

Fig. 5 Gradient zone thickness of Co-W-Ti-C-N cemented carbide versus sintering time

由图5可知, Co-W-Ti-C-N体系梯度硬质合金梯度层厚度的平方与烧结时间呈线性增加,即x2=kt(x为梯度层厚度,t为烧结时间,k是常数)。这一计算结果也与蔡俊等[24]的实验结果相符(梯度烧结时间越长,梯度层厚度越厚)。这是因为烧结时间越长,表面碳氮化合物立方相所分解的Ti通过液相粘结相向合金芯部扩散的距离就越远,扩散的Ti与内部C和N等反应形成立方化合物。同时,验证了梯度层形成的过程是由扩散控制的[11],因此,使用DICTRA软件模拟梯度层形成是合理的。

由图3(b)~(d)和图4(b)~(d)可以分别得到Co-W-Ti- C-N体系梯度硬质合金梯度层厚度随烧结温度、Co含量和Ti含量改变的变化趋势,从而可以分析和讨论烧结温度、Co含量和Ti含量对梯度层厚度的影响。图6~8分别表示梯度层厚度与烧结温度、Co含量和Ti含量的关系。

由图6可知,梯度层厚度随烧结温度升高而增加。此结果与蔡俊等[24]的实验结果相一致(梯度烧结温度越高,梯度层厚度越厚)。这是因为随着温度升高,Ti和N在Co粘结相中的溶解度增加,扩散速率提高,从而导致扩散距离的增加。

图6 Co-W-Ti-C-N体系梯度硬质合金梯度层厚度随烧结温度变化情况

Fig. 6 Gradient zone thickness of Co-W-Ti-C-N cemented carbide versus sintering temperature

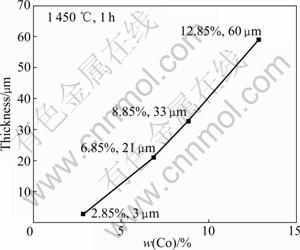

图7 Co-W-Ti-C-N体系梯度硬质合金梯度层厚度随Co含量变化情况

Fig. 7 Gradient zone thickness of Co-W-Ti-C-N cemented carbide versus content of Co

如图7所示,随着Co含量的增加,硬质合金梯度层也会随之呈线性增加。这一结论不同于SCHWARZKOPF等[13]早期假设梯度层厚度与Co含量的平方根呈正比,但与FRYKHOLM等[20]研究结果相似(Co体积分数趋近于5%,梯度层仍会形成)也与张武装等[1]和蔡俊等[24]的实验结果(合金Co含量越多,合金梯度结构越明显,梯度层厚度越厚)相吻合。这是因为Co主要存在于粘结相中,Co含量的增加为梯度层的形成提供了更多的扩散通道,促使合金内部原子扩散更加充分,从而导致合金表层TiN和Ti(C、N) 等分解加剧,梯度形成能力增强。

图8 Co-W-Ti-C-N体系梯度硬质合金梯度层厚度随Ti含量变化情况

Fig. 8 Gradient zone thickness of Co-W-Ti-C-N cemented carbide versus content of Ti

由图8所示,随着Ti含量的增加,硬质合金扩散层厚度减小,这一计算结果与张武装等[25]的实验结果(Ti(C,N)含量增多,梯度层厚度减小)相符。

3 结论

1) 计算模拟的Co-W-Ti-C-N、Co-W-Ti-Nb-C-N和Co-W-Ti-Ta-C-N体系硬质合金Co含量随距离变化及梯度层厚度与实验值吻合较好。

2) Co和Ti质量分数随距离变化曲线与粘结相和立方相的变化趋势是一致的。随着烧结温度的升高,Ti扩散速率会升高,导致Co和Ti浓度变化会更加剧烈。Co含量增加促进Ti向芯部扩散。

3) 梯度层厚度的平方与烧结时间呈线性增加,验证了梯度硬质合金梯度层形成的过程是由扩散控制的。

4) Co含量的增加引起梯度层厚度的线性增长,而Ti含量的增加反而会导致梯度层厚度的减小。升高烧结温度会导致梯度层厚度的增加。

REFERENCES

[1] 张武装, 刘 咏, 贺跃辉, 王海兵. Co含量对硬质合金梯度结构和性能的影响[J]. 中国钨业, 2004, 19(6): 34-37.

ZHANG Wu-zhuang, LIU Yong, HE Yue-hui, WANG Hai-bing. Effect of cobalt content on the gradient structure and properties of gradient cemented carbides[J]. China Tungsten Industry, 2004, 19(6): 34-37.

[2] 饶秋华, 张丽娟, 贺跃辉. 新型梯度硬质合金的组成分布函数与弹性系数模型[J]. 中国有色金属学报, 2007, 17(5): 763-769.

RAO Qiu-hua, ZHANG Li-juan, HE Yue-hui. New multi-stage models of component distribution and elastic coefficient of gradient cemented carbide [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(5): 763-769.

[3] 龙郑易, 刘 咏, 贺跃辉, 肖逸锋, 周永贵, 李 芳. 渗碳时间对梯度硬质合金显微组织和抗弯强度的影响[J]. 中国有色金属学报, 2007, 17(2): 326-330.

LONG Zheng-yi, LIU Yong, HE Yue-hui, XIAO Yi-feng, ZHOU Yong-gui, LI Fang. Effects of carburizing time on microstructure and transverse rupture strength of graded cemented carbides [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 326-330.

[4] LENGAUER W, DREYER K. Functionally graded hardmetals [J]. Journal of Alloys and Compounds, 2002, 338(1/2): 194-212.

[5] ANDREN H O. Microstructure development during sintering and heat-treatment of cemented carbides and cermets [J]. Materials Chemistry and Physics, 2001, 67(1/3): 209-213.

[6] 肖逸锋, 贺跃辉, 丰 平, 谢 宏, 马自省, 张丽娟, 黄自谦, 黄伯云. 渗碳工艺对WC-Co梯度硬质合金的梯度结构和硬度的影响[J]. 中国有色金属学报, 2008, 18(3): 465-470.

XIAO Yi-feng, HE Yue-hui, FENG Ping, XIE Hong, MA Zi-xing, ZHANG Li-juan, HUANG Zi-qian, HUANG Bai-yun. Effects of carburizing process on gradient structure and hardness of WC-Co gradient cemented carbides [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 465-470.

[7] 丰 平, 贺跃辉, 肖逸锋, 谢 宏. 表面无立方相层功能梯度硬质合金的研究进展[J]. 中国有色金属学报, 2007, 17(8): 1221-1231.

FENG Ping, HE Yue-hui, XIAO Yi-feng, XIE Hong. Advance in functionally graded cemented carbides with cubic carbide free layer [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1221-1231.

[8] 温光华, 贺跃辉, 王社权, 文映湘, 吴明晶. Ti(C,N)的碳氮比及粒度对脱β层梯度硬质合金的影响[J]. 硬质合金, 2009, 26(4): 201-205.

WEN Guang-hua, HE Yue-hui, WANG She-quan, WEN Ying-xiang, WU Ming-jing. Effect of composition and grain size of Ti(C,N) on the cobalt-rich layer of gradient cemented carbide [J]. Cemented Carbide, 2009, 26(4): 201-205.

[9] 刘 咏, 王海兵, 羊建高, 贺跃辉, 龙郑易. 梯度硬质合金结构与性能的关系[J]. 粉末冶金材料科学与工程, 2005, 10(6): 356-360.

LIU Yong, WANG Hai-bing, YANG Jian-gao, HE Yue-hui, LONG Zheng-yi. Relationship between structure and properties of graded cemented carbide [J]. Materials Science and Engineering of Powder Metallurgy, 2005, 10(6): 356-360.

[10] JOS? G, ORLANDO P. Experimental investigations and DICTRA simulations on formation of diffusion-controlled fcc-rich surface layers on cemented carbides [J]. Applied Surface Science, 2011, 257(21): 8894-8900.

[11] JOS? G, GRETA L, ORLANDO P. Kinetics of formation of graded layers on cemented carbides: Experimental investigations and DICTRA simulations[J]. International Journal of Refractory Metals and Hard Materials, 2011, 29(2): 256-259.

[12] SUZUKI H, KOJI H, YASURO T. Beta-free layer formed near the surface of vacuum-sintered WC-beta-Co alloys containing nitrogen [J]. Trans Jpn Inst Met, 1981, 22(11): 758-764.

[13] SCHWARZKOPF M, EXNER H E, FISCHMEISTER H F. Kinetics of compositional modification of (W, Ti)C-WC-Co alloy surfaces [J]. Mater Sci Eng A, 1988, 105/106: 225-231.

[14] FRYKHOLM R, EKROTH M, JANSSON B, ANDR?N H O, ?GERN J. Effect of cubic phase composition on gradient zone formation in cemented carbides [J]. Int J Refract Met Hard Mater, 2001, 19: 527-538.

[15] 张伟彬, 沙春生, 杜 勇, 温光华, 谢 文, 王社权. 涂层梯度硬质合金梯度层形成的实验及计算机模拟[J]. 金属学报, 2011, 47(10): 1307-1314.

ZHANG Wei-bin, SHA Chun-sheng, DU Yong, WEN Guang- hua, XIE Wen, WANG She-quan. Investigation and computer simulations of gradient zone formation in cemented carbides and verification [J]. Acta Metallurgica Sinica, 2011, 47(10): 1307- 1314.

[16] GUSTAFSON P, ?STLUND ?. Binder-phase enrichment by dissolution of cubic carbides [J]. Int J Refract Met Hard Mater, 1993/1994, 12: 129-136.

[17] 陈 利, 吴恩熙, 王社权, 刘昌斌, 尹 飞, 吕豫湘. WC- Ti(C,N)-Co梯度硬质合金表面韧性区的形成机理[J]. 中南大学学报: 自然科学版, 2006, 37(4): 650-654.

CHEN Li, WU En-xi, WANG She-quan, LIU Chang-bin, YIN Fei, L? Yu-xiang. Formation mechanism of surface ductile zones in WC-Ti(C,N)-Co gradient cemented carbide[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 650-654.

[18] ANDERS ENGSTROM, LARS H?GLUND, JOHN ?GREN. Computer simulation of diffusion in multiphase systems [J]. Metallurgical and Materials Transactions A, 1994, 25(6): 1127-1134.

[19] SUNDMAN B, JANSSON B, ANDERSSON J O. The Thermo- Calc databank system [J]. Calphad, 1985, 9(2): 153-190.

[20] FRYKHOLM R, EKROTH M, JANSSON B, ?GREN J, ANDR?N H O. A new labyrinth factor for modelling the effect of binder volume fraction on gradient sintering of cemented carbides [J]. Acta Mater, 2003, 51: 1115-1121.

[21] SUTHERLAND W. A dynamical theory of diffusion for non-electrolytes and the molecular mass of albumin [J]. Phil Mag, 1905, 9: 781-785

[22] EKROTH M, FRYKHOLM R, LINDHOLM M, ANDREN H O, ?GERN J. Gradient zones in WC-Ti(C, N)-Co-based cemented carbides-experimental study and computer simulations [J]. Acta Mater, 2000, 48: 2177-2185.

[23] MOHAMMADPOUR M, ABACHI P, PARVIN N, POURZARANG K. Study of cemented carbonitrides with nickel as binder: Experimental investigations and computer calculations [J]. Int J Refract Met Hard Mater, 2012, 31: 164-170.

[24] 蔡 俊, 丰 平, 贺跃辉. 烧结工艺对梯度结构硬质合金梯度层组织和厚度的影响[J]. 硬质合金, 2007, 24(2): 91-95.

CAI Jun, FENG Ping, HE Yue-hui. The effect of sintering process on microstructure and thickness of graded layer of functionally graded cemented carbides [J]. Cemented Carbide, 2007, 24(2): 91-95.

[25] 张武装, 刘 咏, 贺跃辉, 王海兵. Ti(CN)含量对硬质合金梯度结构和性能的影响[J]. 稀有金属与硬质合金, 2005, 33(2): 28-30.

ZHANG Wu-zhuang, LIU Yong, HE Yue-hui, WANG Hai-bin. Effect of Ti(CN) content on the gradient structure and properties of cemented carbides [J]. Rare Metals and Cemented Carbides, 2005, 33(2): 28-30.

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2010CB735807B);国家自然科学基金资助项目(51028101, 51001120, 51021063)

收稿日期:2011-10-10;修订日期:2012-01-12

通信作者:杜 勇,教授,博士;电话:0731-88877300; E-mail: yongducalphad@gmail.com