文章编号:1004-0609(2009)11-2000-06

Laves相NbCr2金属间化合物的缺陷结构及其韧化效应

聂小武1,谢 珊2,何 燕1,鲁世强3,王克鲁3

(1. 湖南铁路科技职业技术学院 机械系,株洲 412000;

2. 湖南化工职业技术学院 基础科学系,株洲 412004;

3. 南昌航空大学 材料科学与工程学院,南昌330063)

摘 要:采用机械合金化和热压粉末冶金工艺制备Laves相NbCr2合金试样,应用X射线和密度测量法研究在Laves相固溶度范围内(即Cr含量为61%~69%(摩尔分数))NbCr2金属间化合物的缺陷结构,并对Laves相NbCr2金属间化合物中的缺陷结构与其力学性能的关系进行分析。结果表明:当Laves相NbCr2成分偏离化学计量比为33.3%Nb~66.7%Cr时,合金中存在反位置缺陷;与其它结构的金属间化合物不同,NbCr2的显微硬度在化学计量处取得最大值9.41 kN/mm2,断裂韧性在化学计量比处最小为5.55 MPa?m1/2;随成分偏离化学计量比,NbCr2脆性度逐渐降低,缺陷的存在对NbCr2具有韧化作用。

关键词:Laves相NbCr2;点缺陷;维氏硬度;断裂韧性

中图分类号:TG 146.2;TF 122.5 文献标识码:A

Defect structure in NbCr2 Laves-phase intermetallics and its toughening effect

NIE Xiao-wu1, XIE Shan2, HE Yan1, LU Shi-qiang3, WANG Ke-lu3

(1. Department of Mechanical Engineering, Hunan Vocational College of Railway Technology, Zhuzhou 412000, China;

2. Department of Basic Science, Hunan Chemical Industry Vocational Technology Institute, Zhuzhou 412004, China;

3. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: NbCr2 composite materials were prepared by mechanical alloying and hot pressing. The relationship between the defect structure and mechanical properties in the NbCr2 Laves-phase compound was discussed. The defect structures of NbCr2 alloys in the Laves-phase solubility ranges (i.e. the Cr contents range is 61%-69% (mole fraction)) were studied by XRD and density measurement methods. The results show that the anti-site defects exist in the NbCr2 Laves-phase intermetallics when its composition deviates from the stoichiometric composition (33.3%Nb-66.7%Cr). The maximum hardness of 9.41 kN/mm2 and minimum fracture toughness of 5.55 MPa?m1/2 occur in the stoichiometric composition, which is not similar with the behavior of most other intermetallic compounds. Meanwhile, the brittleness of the compound decreases when the composition deviates from the stoichiometry. The presence of point defects results in toughening effect in the NbCr2 Laves-phase, which is contrary to the behavior of most other intermetallic compounds.

Key words: NbCr2 Laves-phase; point defect; Vicker hardness; fracture toughness

合金元素Cr与难熔金属Nb形成的Laves相NbCr2具有很高的熔点(1 770 ℃)和适当的密度(约7.7 g/cm3),而且由于大量Cr的存在,使这类化合物具有非常好的潜在的高温抗氧化性、热腐蚀力及蠕变性能,成为航空发动机用候选结构材料之一[1-4],使用温度可望超过1 200 ℃[5]。虽然这类Laves相NbCr2化合物具有作为新型高温结构材料的应用潜力,但和其它金属间化合物一样,其室温脆性是目前限制其工程应用的主要障碍[6-7]。Laves相金属间化合物的分子式为AB2型,理想结构的原子半径之比(rA/rB)为1.225,组分原子体积占单胞体积的71%,Laves相NbCr2金属间化合物是一种典型的Laves相,在高温下为亚稳定的C14结构,室温下为稳定的C15结构[8-9]。在已知的二元Laves相中,大约25%的Laves相存在一定的溶解度范围[10],在相图上NbCr2金属间化合物也表现出一定的溶解度范围,即Cr含量可以在61%~69%范围内变化。

缺陷结构会影响合金的物理冶金及力学性能[11-12],因此,研究Laves相NbCr2的缺陷结构有助于深入探索改善合金脆性的方法。对于Laves相NbCr2偏离计量比成分时的缺陷结构,THOMA等[13]的研究结果表明,在Laves相溶解度范围内富Nb的合金具有空位缺陷,而富Cr的合金具有反位置缺陷;而ZHU 等[11-12]的研究结果表明,在计量比成分的两侧(即富Nb和富Cr)合金都是反位置缺陷,从已有的研究中难以获悉NbCr2合金的缺陷结构。上述研究所采用的试样都是用熔铸法制备的,由于Nb和Cr的熔点分别为 2 469 ℃和1 863 ℃,两者相差很大,且Cr在1 200 ℃以上易挥发,导致采用熔铸法很难制备出无偏析、组织均匀的Laves相NbCr2合金,这会给研究结果带来一定的误差。而利用粉末冶金工艺制备试样则可克服这一缺点。

本文作者利用机械合金化(MA)和热压(HP)的粉末冶金工艺制备试样,应用X射线和密度测量法研究C15结构的Laves相NbCr2金属间化合物的点缺陷结构,利用压痕诱发裂纹的长度来测量材料的断裂韧性,并进一步研究Laves相NbCr2金属间化合物中缺陷与其力学性能之间的关系,为Laves相NbCr2金属间化合物的工程实际运用提供理论支撑。

1 实验

实验原料为纯度大于99%(质量比)Cr粉(<150 μm)和Nb粉(<150 μm),化学成分列于表1。MA在QM- ISP2-CL型行星式高能球磨机上进行。球磨罐容积为2 L,材质为不锈钢,参照作者前期的研究结 果[14-15],球料比定为13?1,转速为400 r/min,球磨介质为不锈钢圆球。将称量后的粉末混合均匀后与球磨介质装入球磨罐中并密封,抽真空后充入高纯氩气,再抽真空,反复3次,使球磨罐处于真空状态,以防止粉末在球磨过程中氧化,球磨时间20 h。

表1 Laves相NbCr2金属间化合物试样的化学成分

Table 1 Chemical compositions of NbCr2 Laves-phase compounds

HP在真空热压炉进行,采用单向压制,压力45 MPa。热压温度1 250 ℃,保压时间0.5 h。保压结束后炉冷时,为防止热压压坯高温下氧化,将温度降到200 ℃以下后再关闭真空系统。

试样的化学成分采用ICPS-8100型电感耦合等离子发射光谱仪(ICP)测试;相组成和晶格参数用X射线衍射法测试;用排水法测量试样密度;在HV-10型小型维氏硬度计上测定维氏硬度(载荷10 N)和断裂韧性(采用维氏硬度压痕法,载荷100 N)。

维氏硬度Hv和断裂韧性的计算使用下列公式:

a为压痕两对角线的算术平均值,mm;E为弹性模量,根据文献[16-17]为218 MPa;l为尖角裂纹长度,mm。

应用上式计算KIC,需满足裂纹l≥2a,且裂纹尺寸不超过试样厚度的1/10。

2 结果及讨论

2.1 Laves相NbCr2中的点缺陷结构

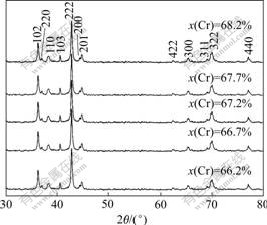

5种成分的Laves相NbCr2金属间化合物的XRD谱如图1所示。从图1可以看出,所有试样都为C15结构的NbCr2 Laves相,与Nb-Cr的二元相图[13]是吻合的。

图1 Laves相NbCr2金属间化合物的XRD谱

Fig.1 XRD patterns of NbCr2 Laves-phase compounds

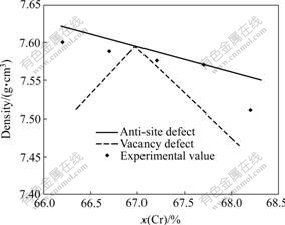

图2所示为根据XRD谱计算出的C15结构NbCr2的晶格常数。图中实线代表理论值、黑点表示经过计算得到的实验值。当合金成分偏离化学配比成分时,必然会导致合金的晶体规则排列结构存在缺陷。Laves

相NbCr2属于拓扑密堆结构,由于具有拓扑密排结构的Laves相空间填充度很高,过剩的原子不会进入晶胞内的间隙,而只可能要么占据原来的点阵位置从而在另一原子点阵位置上形成结构空位(Constitutional vacancies),要么占据另一原子的点阵位置,形成反位置点缺陷(Anti-site substitution)[11]。CHEN等[18]曾假设Laves相结构中的缺陷全部为反位置缺陷,则C15 Laves相的晶格常数可采用平均原子半径的方法计算。用aR表示C15结构的晶格常数,由于单胞中24个原子的空间占有率为71%,有如下等式成立:

根据组成原子A和B的原子半径和各自的摩尔分数计算得到的,即

图2 C15结构Laves相NbCr2晶格常数与成分的关系

Fig.2 Relationship between lattice constant and composition of NbCr2 Laves-phase with C15 structure

式(4)表明,在NbCr2的Laves相固溶度范围内,晶格常数与成分呈线性,且随原子半径较小的Cr含量的增加而减小。从图2可以看出,C15结构Laves相NbCr2的晶格常数随着Cr含量的增加而减小,这是因为Nb原子半径比Cr的大,晶格常数与成分的关系和理论计算值的变化基本吻合。因此,在Laves相的固溶度范围内,当成分偏离化学计量比时,NbCr2合金中存在反位置缺陷,即成分处于富Nb区时,缺陷为 Nb→Cr的反位置缺陷;若成分处于富Cr区,则缺陷为Cr→Nb的反位置缺陷。

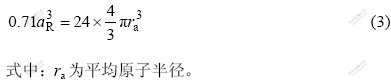

为了进一步分析Laves相NbCr2金属间化合物中的缺陷结构,采用排水法测量试样的密度。图3所示为试样密度与Cr含量的关系。图中实线为Laves相化合物中引入反位置组分缺陷的化合物理论密度,虚线为Laves相化合物中引入组分空位后化合物的理论密度。空位型化合物的理论密度随着成分偏离计量比而迅速减小,而反位置缺陷型化合物的理论密度则随Cr含量的增加缓慢减小。虽然实验测定的密度与反位置缺陷型化合物理论密度的误差小于3%,但其变化趋势与反位置型化合物的变化趋势完全一致,而与空位型化合物的差异显著。因此可以认为,当成分偏离化学计量比时,NbCr2中存在着反位置缺陷,不存在组分空位,变化趋势从图中可以看出随着试样成分偏离Laves相NbCr2的化学配比,试样烧结前后的致密度增加。因此可以认为,当成分偏离化学计量比时,C15结构的NbCr2Laves相金属间化合物中存在着反位置缺陷,不存在组分空位,这与ZHU等[11-12]的研究结果相同。孙学松等[19]在研究Laves相ZrCr2合金的结构缺陷时也得到相似的结论。

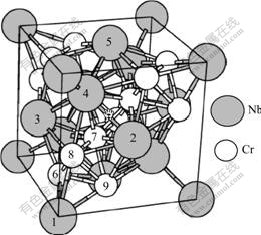

由于AB2型Laves相金属间化合物属于拓扑密排结构,在3种晶体结构中,每种晶体结构具有相同的基本堆垛单元。但与一般FCC和HCP结构不同的是,Laves相的基本堆垛单元不是单层原子面,而是由四层原子面组成。其中,大原子A和小原子B各占两层原子面。C15基本单元的堆垛顺序类似于通常的立方FCC结构,即沿[111]方向按…ABCABC…的顺序堆垛;C14的堆垛顺行类似于通常的HCP结构,沿[0001]方向按…ABAB…顺序堆垛;而C36则按…ABACABAC…的顺序堆垛排列。图4所示为C15结构Laves相晶胞结构图。大小原子分别代表A原子(Nb)和B原子(Cr)。例如2A2B点阵由2、4、7和8原子组成;1A3B点阵由1、6、8和9原子组;4B点阵由6、7、8和9原子组成。在Laves相NbCr2金属间化合物中,当成分为富Cr时,多余Cr原子占据Nb位置;当成分为富Nb时,多余半径大的原子Nb占据半径小的原子Cr的位置。显然,这必定会引起晶格畸变。在Nb-Cr二元相图[13]上,Cr在NbCr2Laves相中的溶解度比Nb的溶解度大,这也印证上述结构的特征。

图3 Laves相NbCr2合金密度与成分的关系

Fig.3 Relationship between density and composition of NbCr2 Laves-phase alloys

图4 C15结构Laves相晶胞结构图

Fig.4 Crystal cell structure diagram of Laves-phase with C15 structure

2.2 缺陷结构对Laves相NbCr2力学性能的影响

利用显微硬度仪研究Laves相NbCr2化合物试样的显微硬度和断裂韧性等力学性能,其结果如图5所示。图5(b)中虚线处为化学计量比成分。从图5可以看出,合金硬度随着成分偏离化学计量比而逐渐减小,硬度在化学计量比66.7%Cr处取得最大值。

图5 NbCr2合金的力学性能与成分的关系

Fig.5 Relationship between mechanical properties and composition of NbCr2 alloys

断裂韧性通过维氏硬度压痕诱发的裂纹长度来研究,其典型的压痕及其诱发的裂纹扫描电镜照片如图6所示。从图5(b)可以看出,当NbCr2的成分为66.7%Cr时,合金的断裂韧性最小,随着成分偏离化学配比,断裂韧性有所提高。所有试样都具有较好的断裂韧性,远大于熔铸工艺制备的Laves相NbCr2的断裂韧性1.5 MPa?m1/2[20]。脆性度(Brittleness)被定义为显微硬度与断裂韧性之比,即Hv/KIC。图5(c)表明,合金的脆性度随着偏离化学配比而逐渐减小。CHEN等[21]用这种方法测量过Laves相TiCr2金属间化合物的硬度,发现在化学计量比处取得最大值,随着偏离化学计量比而逐渐减小,这与本研究的结果相似,这也为本文作者认为的NbCr2在化学计量比处的硬度出现最大值和断裂韧性出现最小值提供佐证。也就是说结构缺陷的存在使得Laves相铬化物出现了所谓的“软化效应”(Softening effect)[6],在ZrCr2中也有类似的现象[6, 19]。

图6 Laves相NbCr2合金典型压痕及诱发裂纹的SEM像

Fig.6 SEM image of typical indentation of NbCr2 Laves- phase alloys

本文作者的最新研究结果[22]称这种现象为“韧化效应”(Toughening effect)。由于Laves相的特点之一就是化合物的拓扑密排结构而产生的高强度,即使在高温下,如1 200 ℃时,Laves相Cr-8.0Ta-5.0Mo-0.5Ti- 0.01Ce的铸态和热挤压状态合金的屈服强度仍分别为476和259 MPa,伸长率分别达到5.3%和39%,而大多数镍基高温合金在此温度下强度已消失[6],这种性能是其它金属间化合物(如NiAl、FeAl、TiAl等)难以具有的。由于rNb/rCr=1.14,与形成Laves相的理想原子半径比(1.225)存在差异,为了形成更规则的Laves相结构,就要求rA/rB的实际比例更接近于1.225,这样原子半径比偏离1.225的合金中则存在一种原子被压缩而另一种原子膨胀的现象[8],这将产生一个弹性应变能,它将降低化合物总的结合能。结构缺陷的出现使拓扑密排结构的Laves相化合物的弹性应变能释放并使某些高度密排结构松弛,位错运动阻力减轻,故此产生韧化效果,这为Laves相的脆性改善提供一条思路。总之,缺陷的存在对Laves相NbCr2合金的增韧有一定的效果。

3 结 论

1) 采用机械合金化(球磨时间为20 h,球料质量比为13?1)和真空热压(温度为1 250 ℃,热压时间为0.5 h)的粉末冶金工艺能够有效地制备Laves相NbCr2化合物。

2) 在Laves相固溶度范围内(即Cr含量为61%~69%),当NbCr2成分偏离化学计量比33.3%Nb~ 66.7%Cr时,合金中存在反位置(组分)缺陷。

3) 在Laves相固溶度范围内,NbCr2金属间化合物的显微硬度在化学计量处取得最大值9.41 kN/mm2,断裂韧性在化学计量比处最小为5.55 MPa?m1/2;随其成分偏离化学计量比,NbCr2脆性度逐渐降低,缺陷的存在对NbCr2具有韧化作用。

REFERENCES

[1] JIANG Chao. Site preference of early transition metal elements in C15 NbCr2[J]. Acta Materialia, 2007, 55(5): 1599-1605.

[2] 聂小武, 鲁世强, 王克鲁, 郑海忠, 肖 璇. Laves相铬化物的高温抗氧化性能研究进展[J]. 金属热处理, 2006, 31(9): 31-34.

NIE Xiao-wu, LU Shi-qiang, WANG Ke-lu, ZHENG Hai-zhong, XIAO Xuan. Research progress in high temperature oxidation-resistance properties of Laves phase chrominide compounds[J]. Heat Treatment of Metals, 2006, 31(9): 31-34.

[3] YAO Q, SUN J, LIN D, LIU S, JIANG B. First-principles studies of defects, mechanical properties and electronic structure of Cr-based Laves phases[J]. Intermetallics, 2007, 15(5/6): 694-699.

[4] KAZANTZIS A V, AINDOW M, JONES I P, de TRIANTANTAFYLLIDIS G K M, HOSSON J T H. The mechanical properties and the deformation microstructures of the C15 Laves phase Cr2Nb at high temperatures[J]. Acta Materialia, 2007, 55(6): 1873-1884.

[5] 聂小武, 鲁世强, 王克鲁, 郑海忠, 苏 倩. Laves相铬化物的制备研究进展[J]. 铸造技术, 2006, 27(7): 756-759.

NIE Xiao-wu, LU Shi-qiang, WANG Ke-lu, ZHENG Hai-zhong, SU Qian. Development on preparing investigation of Laves phase chrominide compounds[J]. Foundry Technology, 2006, 27(7): 756-759.

[6] KELLOU A, GROSDIDIER T, CODDET T, AOURAGH. Theoretical study of structural, electronic, and thermal properties of Cr2(Zr, Nb) Laves alloys[J]. Acta Materialia, 2005, 53(5): 1459-1466.

[7] 鲁世强, 黄伯云, 贺跃辉, 何双珍, 邓意达. Laves相合金的力学性能[J]. 材料工程, 2003(5): 43-47.

LU Shi-qiang, HUANG Bai-yun, HE Yue-hui, HE Shuang-zhen, DENG Yi-da. Mechanical properties of Laves phase alloys[J]. Materials Engineering, 2003(5): 43-47.

[8] 聂小武, 鲁世强, 王克鲁. 机械合金化Nb-Cr粉末的热力学分析[J]. 特种铸造及有色合金, 2007, 27(6): 477-479.

NIE Xiao-wu, LU Shi-qiang, WANG Ke-lu. Thermo-kinetic analysis of mechanical alloying Nb-Cr powders[J]. Special Casting and Nonferrous Alloys, 2007, 27(6): 477-479.

[9] YAO Q, SUN J, ZHANG Y, JIANG B. First-principles studies of ternary site occupancy in the C15 NbCr2 Laves phase[J]. Acta Materialia, 2006, 54(13): 3585-3591.

[10] BEWLAY B P, SUTLIFF J A, JACKSON M R. Microstructural and crystallographic relationships in directionally solidified Nb-Cr2Nb eutectics[J]. Acta Metall Mater, 1994, 42(8): 2869-2878.

[11] ZHU J H, PIKE L M, LIU C T. Point defects in binary NbCr2 Laves-phase alloys[J]. Scripta Materialia, 1998, 39(7): 833-838.

[12] ZHU J H, PIKE L M, LIU C T. Point defects in binary Laves phase alloys[J]. Acta Materialia, 1999, 47(7): 2003-2018.

[13] THOMA D J, PEREPEZKO J H. An experimental evaluation of the relationships and solubilities in the Nb-Cr system[J]. Mater Sci Eng A, 1992, 156(1): 97-108.

[14] NIE Xiao-wu, LU Shi-qiang, WANG Ke-lu. Phase transformations of NbCr2 intermetallics produced by mechanical alloying followed by hot-pressing consolidation[J]. Materials Characterization, 2008, 59(6): 816-819.

[15] NIE Xiao-wu, LU Shi-qiang, WANG Ke-lu. Effect of mechanical alloying on the structure and properties of NbCr2 fabricated by hot pressing[J]. Powder Technology, 2008, 184(3): 333-336.

[16] THMOMA D J, NIBUR K A, CHEN K C. The effect of alloying on the properties of (Nb, Ti)Cr2 C15 Laves phases[J]. Mater Sci Eng A, 2002, 329/331: 408-415.

[17] KIM W Y, YEO I D, KIM M S, TAKASUGI T. Phase relation and room temperature mechanical property of Cr2Zr based Laves phase[J]. Materials Science Forum, 2004, 449/452: 805-809.

[18] CHEN K C, PETERSON E J, THOMA D J. HfCo2 Laves phase intermetallics (part 1): Solubility limits and defect mechanisms[J]. Intermetallics, 2001, 9(9): 771-783.

[19] 孙学松, 孙 峰, 孙 坚. ZrCr2 Laves相金属间化合物缺陷结构及缺陷软化效应[J]. 中国有色金属学报, 2005, 15(4): 624-630.

SUN Xue-song, SUN Feng, SUN Jian. Defect structure and its softening effect in ZrCr2 Laves-phase compound[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 624-630.

[20] DAVIDSON D L, CHAN K S, ANTON D L. The effects on fracture toughness of ductile-phase composition and morphology in Nb-Cr-Ti and Nb-Si in-situ composites[J]. Metallurgical and Materials Transactions A, 1996, 27(10): 3007-3018.

[21] CHEN K C, ALLEN S M, LIVINGGSTON J D. Factors affecting the room-temperature mechanical properties of TiCr2-based Laves phase alloys[J]. Mater Sci Eng A, 1998, 242(1/2): 162-173.

[22] NIE Xiao-wu, LU Shi-qiang, WANG Ke-lu, CHEN Tong-cai, NIU Chun-lin. Fabrication and toughening of NbCr2 matrix composites alloyed with Ni obtained by powder metallurgy[J]. Mater Sci Eng A, 2009, 502(1/2): 85-90.

收稿日期:2008-11-25;修订日期:2009-07-16

通信作者:聂小武,硕士;电话:0731-22777049;E-mail: niexiaowu6567@sina.com

(编辑 李艳红)