文章编号: 1004-0609(2006)03-0442-05

钽的加工硬化速率及其显微组织

张行健, 姜国圣, 王志法

(中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 借助力学性能实验、 金相显微镜和透射电镜等手段研究了纯钽的加工硬化速率。 研究结果表明: 纯钽的宏观加工硬化速率比较低。 通过TEM观察, 发现变形95%后, 纯钽的位错密度都不是很高, 存在有位错胞亚结构。 其原因可能是因为钽的层错能高, 位错容易交滑移, 使位错密度降低。 根据林位错硬化理论, 也可以认为, 钽在室温下塑性变形时, 滑移系主要为{110}〈111〉, 次滑移系的激活比较少, 因此穿过主滑移系的林位错密度比较低, 位错之间相互作用少, 导致钽的加工硬化速率低。

关键词: 钽; 加工硬化; 位错密度 中图分类号: TG146.4

文献标识码: A

Work hardening rate and microstructure of tantalum

ZHANG Xing-jian, JIANG Guo-sheng, WANG Zhi-fa

(School of Materials Science and Engineering, Central South University,

Changsha 410083, China)

Abstract: The work hardening rate of pure tantalum was studied by tension test, optical microscope and TEM. The results show that the work hardening rate of pure tantalum is low. TEM analysis indicates that the dislocation density of pure tantalum is not high and dislocation cells occur after 95% cold rolling reduction. Because the stacking fault energy (SFC) of tantalum is high, the dislocation cross slips easily which can lower the dislocation density. On the other hand, according to the tree dislocation theory, it is assumed that when pure tantalum is deformed at room temperature, the slip system is mainly{110}〈111〉, while the secondary slip systems are seldom activated. So the density of tree dislocation penetrating the main slip plane is low and the interaction between dislocations is weak, which leads to low work hardening rate of pure tantalum.

Key words: tantalum; work hardening; dislocation density

钽是一种典型的无相变的体心立方结构金属, 具有熔点高、 耐酸蚀、 延性好、 蒸气压低、 导热导电性能优良和化学稳定性高等特性, 是高新技术领域中不可缺少的材料[1-5]。 纯钽广泛用于电子、 化工、 航空航天、 医疗卫生、 军事等领域[6-8] 。 对钽及其合金的研究始于20世纪50年代, 早期的研究主要集中于讨论冶金以及微结构对材料物理、 化学性能的影响[9, 10]。 20世纪80年代后, 其动态力学性能引起了科技人员的重视, 国外学者开始关注杂质含量、 晶粒大小、 温度和应变率的变化对钽的力学性能的影响[11, 12]。 国内对钽的研究不多, 张新民等人主要研究了钽的织构问题[13, 14]。

金属的加工硬化是一个既古老而又普遍的现象, 但至今对它的本质还没有一个公认的统一理论, 有些问题甚至存在原则分歧。 不过目前普遍认为加工硬化现象是位错运动阻力随形变增加而增大的结果[15, 16]。 加工硬化与金属的结构、 纯度等有关。 在3种典型金属中, 体心立方金属的加工硬化行为的研究资料相对较少, 而对于纯钽的加工硬化的研究则更少。 纯钽的塑性很好, 我们在全钽电容器外壳的生产中发现冷加工变形量达到90%以上都不需要中间退火, 国外有人甚至发现二次电子束熔炼的纯钽模锻真应变ε>5以上都不用中间退火[17]。 这表明纯钽对加工硬化不敏感。 如果省掉不必要的中间退火, 就可以减少能耗, 节约成本, 提高效率。 因此, 本文作者对钽加工硬化的微观机理做初步的研究, 这不仅具有一定学术价值, 而且还有一定的应用价值。

1 实验

实验材料采用国内某厂生产的电子束熔炼的纯钽锭。 开坯后轧制成3mm板材, 由前期的工作得出电子束熔炼的纯钽起始再结晶温度在800℃左右, 于是在900℃真空退火30min, 使样品成为再结晶软化状态。 截取小部分样品进行抛光后再拉伸和压缩的实验, 然后在POLYVER-MET大型金相显微镜下观察其滑移线情况。 将其余的3mm钽板单向冷轧, 变形量分别为20%、 40%、 60%、 80%、 90%和95%, 取样做力学性能、 硬度测试。 选取变形量为20%、 95%的样品, 手工磨薄后在MTP-1双喷电解减薄仪上进行电解双喷减薄、 穿孔。 电解双喷液为V(H2SO4)∶V(CH3OH)=1∶4(体积比), 电压为20V, 温度为-15℃。 在荷兰PHLIPS公司产TECNAI G2透射电镜上观察。

2 结果与分析

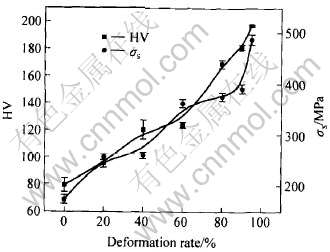

钽板屈服强度和硬度随变形量变化的曲线如图1所示。

图1 强度、 硬度与变形量的关系

Fig.1 Relationship of strength, hardness with deformation rates

由图1可以看出, 钽板硬度随变形量变化平缓, 从未变形到变形95%, 硬度由79.4增加到197, 只增加了一倍多。 强度的变化趋势与硬度的变化趋势大体一致。 随着加工量的增加, 屈服强度逐渐增加, 但增加较慢。 宏观上表现为加工硬化速率比较小。

研究金属的加工硬化速率, 经典方法是用单晶的应力—应变曲线的dτ/dε来表示, 也有人用多晶体的dσ/dε来讨论, 文献[18]用单位压缩率的强度变化来表示。 本文作者将轧制变形后的多晶钽做力学性能实验, 用单位预变形量的屈服强度变化dσ/dε以及硬度随预变形量的变化dH/dε来讨论钽的加工硬化速率。 其结果见表1。

表1 钽的加工硬化速率

Table 1 Work hardening rate of pure tantalum

由表1可以看出, 钽的加工硬化速率都是相当低的, dσ/dε最高才达到4.149MPa/%, 变形量每增加1%, 硬度增值最大为1.238, 都远低于一般的金属材料。

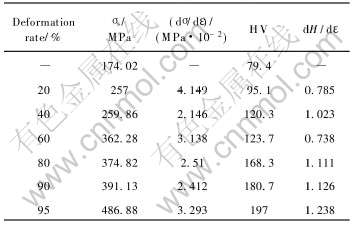

此外多晶钽板在拉伸试验中的拉伸应力—应变曲线的形状也可以用来定性地评价其加工硬化的宏观表现。 本实验中不同状态钽的拉伸应力—应变曲线如图2所示。 由图可以看出, 不论是退火态的多晶钽还是经过预先冷变形后变形的多晶钽, 在屈服后有一小段斜率很小的硬化, 之后其拉伸应力—应变曲线基本上很平坦, 表明在拉伸时随应变的增加, 应力增加缓慢, 即加工硬化速率很小。 和其他一些金属材料不同的是, 纯钽的应力—应变曲线在达到最高的应力值后明显出现一个平台(尤其在图2(a)中很明显), 随应变增加应力值不变, 显示加工硬化速率几乎为零。

图2 纯钽拉伸应力—应变曲线

Fig.2 Stress—strain curves of pure tantalum

综上所述, 多种实验的结果都表明体心立方金属钽在变形时的加工硬化速率是很小的, 所以在冷加工中变形90%以上也不需要中间退火。

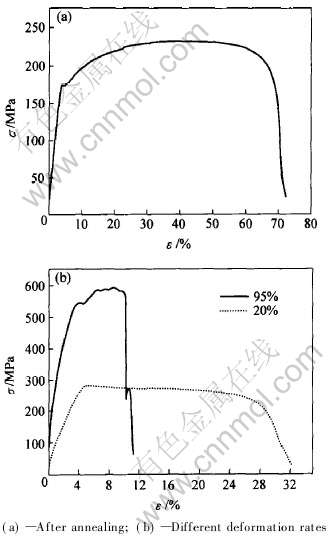

图3所示为退火态的纯钽抛光后拉伸和压缩的金相照片。 由图可以看出, 滑移线是由一列列近似平行线所组成。 但这些滑移线有碎化和弯曲现象(图3(a)), 在压缩时(图3(b))滑移线的碎化处有交滑移痕迹。 尽管体心立方钽的滑移系比较多, 却没有看到双滑移和多滑移现象。 一般认为体心立方金属的层错能较高, 为400~1000mJ/m2[13], 当然可以认为钽的层错能很高[17], 扩展位错很窄, 容易束集, 交滑移容易发生。

图3 钽板的滑移线

Fig.3 Slip lines of tantalum plate

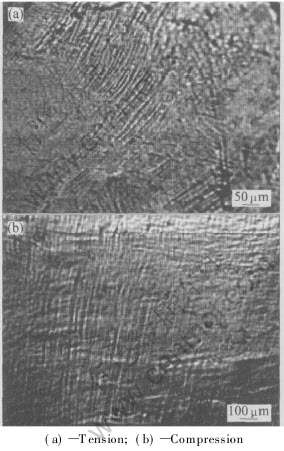

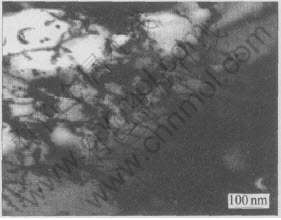

图4所示为纯钽在20%变形量后的TEM照片。 由图可以看出位错密度不高, 没有形成位错胞。

图4 纯钽变形20%后的TEM照片

Fig.4 TEM image of tantalum deformed by 20%

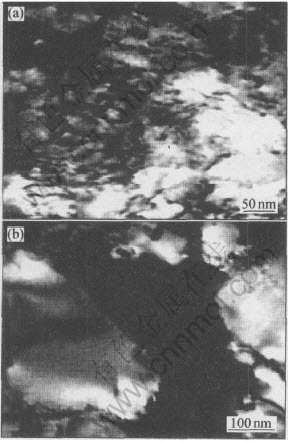

图5所示为纯钽变形95%后的TEM照片。 由图5(a)可以看到一些蜷曲的位错线, 位错缠结不是很严重, 位错密度不高。 由图5(b)可以看到明显的位错胞, 胞壁颜色很浓, 是由大量的位错组成的, 但胞壁的厚度还是很小, 胞内清晰, 几乎没有位错。

图5 纯钽变形95%后的TEM照片

Fig.5 TEM images of pure tantalum deformed by 95%

层错能随材料杂质含量的降低而提高[16]。 电子束熔炼纯钽杂质含量低, 故层错能更高, 高层错能晶体中扩展位错窄, 位错能借助交滑移来克服运动时所遇到的障碍, 具有较大的移动性。 随着变形量的增加, 位错不断增殖和运动, 塞积群中的螺型位错易于与另一塞积群中反号螺型位错在交滑移面内互毁[19], 只剩下刃型位错, 形变温度不高时, 就形成胞状亚结构。 当冷变形量足够大, 畸变能增加到一定程度时, 在室温下位错即可在弹性应力场的作用下使滑移和交滑移顺利进行, 释放出大量的畸变能, 缓解内应力。 根据加工硬化理论中的林位错硬化理论以及未观察到纯钽中有双滑移和多滑移现象的事实, 也可以认为, 尽管体心立方的钽其潜在滑移系较多(滑移面可能是{110}、 {112}、 {123}), 但它在室温下塑性变形时, 其滑移系主要为{110}〈111〉[13], 次滑移系的激活比较少, 因而穿过主滑移系的林位错密度比较低, 位错间相互交割作用少, 割阶硬化也比较小, 位错缠结少(这一点用图5(b)可以说明, 冷变形95%以后, 纯钽中的位错缠结仍然较少), 导致钽的加工硬化速率低。

3 结论

1) 纯钽的宏观加工硬化速率比较低。

2) 钽的加工硬化速率低可能是因为: 钽的层错能高, 位错容易交滑移, 螺位错交滑移后在交滑移面内与反号螺位错互毁, 使位错密度降低。 根据林位错硬化理论, 也可以认为, 钽在室温下塑性变形时, 其滑移系主要为{110}〈111〉, 次滑移系的激活比较少, 因此穿过主滑移系的林位错密度比较低, 位错之间相互作用少, 导致钽的加工硬化速率低。

REFERENCES

[1]刘世友. 钽在高新技术中的应用[J]. 稀有金属与硬质合金, 1998, 133(6): 55-57.

LIU Shi-you. Applications of tantalum in high-tech[J]. Rare Metals & Cemented Carbides, 1998, 133(6): 55-57.

[2]Г·В·沙穆素诺夫, В·И·康士坦丁诺夫. 钽与铌[M].卜宝林, 刘恩鸿译. 北京: 中国工业出版社, 1962.

Самсонов Г·В, Константинов В·И. Tantalum and Niobium[M]. PU Bao-lin, LIU En-hong, transl. Beijing: China Industry Press, 1962.

[3]Cardonne S M, Kumar P, Michaluk C A, et al.Tantalum and its alloys[J]. International Journal of Refractory Metals and Hard Materials, 1995, 13(4): 187-194.

[4]娄燕雄, 刘贵材. 钽铌译文集[M]. 长沙: 中南工业大学出版社, 1987.

LOU Yan-xiong, LIU Gui-cai. Translation Corpus about Tantalum and Niobium[M]. Changsha: Central South University of Technology Press, 1987.

[5]Moser K D. The manufacture and fabrication of tantalum[J]. JOM, 1999, 51(4): 29-31.

[6]Rowe C E D. The use of tantalum in the process industry[J]. JOM, 1997, 49(1): 26-28.

[7]Buckman R W Jr. New applications for tantalum and tantalum alloys[J]. JOM, 2000, 52(3): 40-41.

[8]吴全兴. 钽及其合金的用途[J]. 稀有金属快报, 2002(3): 23-24.

WU Quan-xing. Applications of tantalum and its alloys[J]. Rare Metals Letters, 2002(3): 23-24.

[9]Kock W, Paschen P. Tantalum processing properties and application[J]. J Metals, 1989, 12(1): 33-40.

[10]Clark J B, Garrett R K Jr, Jungling T L, et al. Influence of initial ingot breakdown on the microstructural and textural development of high-purity tantalum[J]. Metall Trans A, 1991, 22A(12): 2959-2968.

[11]Zerilli F J, Armstrong R W. Description of tantalum deformation behavior by dislocation mechanics based constitutive relations[J]. J Appl Phys, 1990, 68(4): 1580-1591.

[12]Meyers M A, Chen Y J, Marquis F D S, et al. High-strain, high-strain-rate behavior of tantalum[J]. Metall Trans A, 1995, 26A(10): 2493-2501.

[13]张新明, 张少睿, 周卓平, 等. 钽丝的拉拔及退火织构[J]. 中国有色金属学报, 1999, 9(4): 774-778.

ZHANG Xin-ming, ZHANG Shao-rui, ZHOU Zhuo-ping, et al. Cold drawing and annealing textures of tantalum wires[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 774-778.

[14]张新明, 袁韧, 周卓平. 硅元素对钽丝再结晶行为的影响[J]. 中国有色金属学报, 2002, 12(6): 1104-1108.

ZHANG Xin-ming, YUAN Ren, ZHOU Zhuo-ping. Effect of silicon on recrystallization behavior of tantalum wires during annealing[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1104-1108.

[15]哈宽富. 金属力学性质的微观理论[M]. 北京: 科学出版社, 1983.

HA Kuan-fu. Microscopic Theory of Mechanical Property of Metal[M]. Beijing: Science Press, 1983.

[16]冯端, 王业宁, 丘第荣. 金属物理[M]. 北京: 科学出版社, 1975.

FENG Duan, WANG Ye-ning, QIU Di-rong. Physics of Metal[M]. Beijing: Science Press, 1975.

[17]Hupalo M F, Sandim H R Z. The annealing behavior of oligocrystalline tantalum deformed by cold swaging[J]. Materials Science and Engineering, 2001, 318(11): 216-223.

[18]吴斌, 杨恒, 刘礼华. 镍钛合金材料加工硬化的力学性能和机制[J]. 江苏冶金, 1997(4): 26-30.

WU Bin, YANG Heng, LIU Li-hua. Mechanical property and mechanism of work hardening of Ti-Ni alloy[J]. Jiangsu Metallurgy, 1997(4): 26-30.

[19]赖祖涵. 金属的晶体缺陷与力学性质[M]. 北京: 冶金工业出版社, 1988.

LAI Zu-han. Crystal Defect and Mechanical Property of Metal[M]. Beijing: Metallurgical Industry Press, 1988.

收稿日期: 2005-05-30; 修订日期: 2005-11-07

作者简介: 张行健(1979-), 男, 硕士

通讯作者: 张行健; 电话: 0731-8877698; E-mail:z_xjian@126.com

(编辑何学锋)