文章编号:1004-0609(2015)02-0308-07

变形温度对2A14铝合金显微组织和力学性能的影响

刘文胜,刘东亮,马运柱,王 娟,杨波平

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:在300~450 ℃温度范围内对2A14铝合金进行恒应变速率的多向压缩实验,模拟其多向锻造过程,采用金相显微镜(OM)、扫描电镜(SEM)、透射电镜(TEM)和室温力学性能测试等手段研究变形温度对2A14合金的显微组织和力学性能的影响。结果表明:随着变形温度的升高,合金的软化机制由动态回复向动态再结晶转变,位错密度随之降低;变形后的2A14铝合金在热处理过程中,发生静态再结晶,变形过程中累积的形变储能对再结晶的形核及长大具有促进作用。随着变形温度的升高,时效态2A14铝合金的平均晶粒尺寸随之增大,分布变得不均匀,其强度与平均晶粒尺寸满足Hall-Petch关系式;室温拉伸断口形貌表现出韧性断裂特征,且随着变形温度的升高,单位面积内韧窝数量减少、尺寸增大,合金的塑性变差。

关键词:2A14铝合金;变形温度;显微组织;力学性能;多向压缩

中图分类号:TG146.2 文献标志码:A

Effects of deformation temperature on microstructure and mechanical properties of 2A14 aluminum alloy

LIU Wen-sheng, LIU Dong-liang, MA Yun-zhu, WANG Juan, YANG Bo-ping

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083)

Abstract: The multi-axial compression tests of 2A14 aluminum alloy were carried out with a constant strain rate to simulate the multi-forging process in the temperature range from 300 to 450 ℃. The effects of hot deformation temperature on microstructure and mechanical properties of 2A14 aluminum alloy were investigated by optical microscopy, scanning electron microscopy, transmission electron microscopy and mechanical property testing. The results show that, with the increase of the deforming temperature, the dislocation density decreases, and the softening behavior of the alloy transforms from dynamic recovery to dynamic recrystallization. The compressed samples have stored high deformation energy, which can supply driving force for nucleation and grain growth of static recrystallization during heat-treatment. With the increase of the deformation temperature, the average grain size of the aged alloy increases and presents uneven distribution, meanwhile, the relationship between the strength and average grain size meets the Hall-Petch equation. The microstructure of the fracture is consisted of a large number of equiaxed dimples, and with the increase of the deforming temperature, the number of dimples decreases while the size of dimples increases which indicates a toughness fracture mode during tensile testing.

Key words: 2A14 aluminum alloy; deformation temperature; microstructure; mechanical properties; multi-axial compression

强塑性变形方法(SPD)是一种细晶/超细晶材料的制备方法[1],通过反复变形与再结晶,可以获得均匀致密的细晶/超细晶组织,在保持材料塑性与韧性的前提下,能够显著提高其强度,并减弱各向异性,引起了国内外学者的广泛关注,并在近些年得到迅速发展。目前,应用较多的强塑性变形方法主要包括等径角挤压(ECAP)、高压扭转(HPT)、多向锻造(MDF)、往复挤压(CEC)、累计叠轧(ARB)等[2]。与其它几种强塑性变形方法相比,多向锻造通过不断改变变形方向以达到细化晶粒、显著提高材料强度与韧性的目的,具有工艺简单、成本低廉、可利用现有装备制备大块致密细晶材料的优点,在工业生产中得到越来越广泛的应用[3-4]。目前,国内外学者对多向锻造的研究主要集中在Mg合金[5-7]、TiAl合金[8-9]、铜合金[10-11]、不锈钢[12]与7xxx铝合金[13-14]等方面:郭强等[6]系统研究了Mg-Al-Zn系合金高温多向压缩行为,研究认为镁合金的多向压缩大变形晶粒细化机制为变形带诱发晶粒破碎,同时伴随着动态再结晶的发生;BELYAKOV等[10]对多晶纯铜的多向锻造过程进行了研究,发现随着变形量的增加,应变诱发的晶界平均取向差值逐步增大,合金内部小角晶界数量减少,大角晶界增多;BELYAKOV等[12]在对304不锈钢的多向压缩中发现,在一定范围内降低变形温度或提高变形速率,均会导致合金内部位错密度增大,有利于晶粒的细化,合金的力学性能与Z值(Zener-Hollomon参数)存在线性关系;SITDIKOV等[13]在对铸态7475铝合金的多向锻造研究过程中发现,提高每道次变形量△ε,可以有效增加细化晶粒在合金内部的体积分数,而对晶粒尺寸的影响不大。2A14铝合金属于Al-Cu-Mg系可热处理强化的变形铝合金,具有强度高、热塑性好、服役温度较高等优点,可以制备成形状复杂的自由锻件和精密模锻件,广泛应用于航空航天及民用交通工具等领域[15-16]。然而,目前2xxx系铝合金强塑性变形的研究较少。本文作者采用2A14铝合金作为实验对象,通过在不同温度下进行多向压缩,结合适当的热处理工艺,研究了变形温度对2A14铝合金的显微组织和力学性能的影响。

1 实验

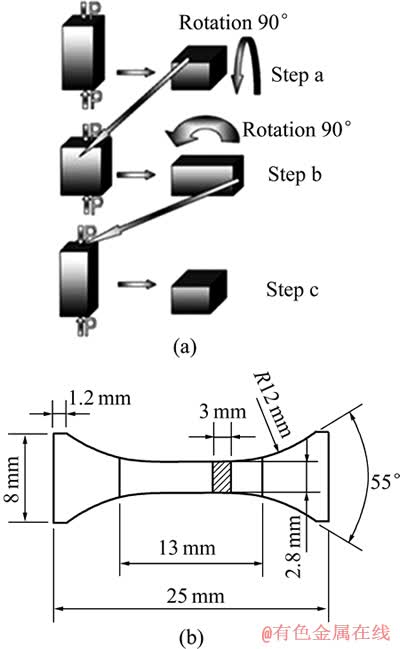

实验所用2A14铝合金铸锭为西南铝业(集团)有限责任公司提供,其名义化学成分(质量分数,%)如下:Cu 4.76、Mg 0.66、Si 0.43、Mn 0.87、Fe 0.20、余量为Al。铸锭经(495 ℃,12 h)均匀化处理之后,线切割成30 mm×24 mm×20 mm的方块状试样。多向压缩实验在300 kN液压机上进行,压力机空载下压速度控制在5 mm/s,实验前试样在电阻炉中由室温加热至变形温度,保温30 min后进行多次轴向压缩,采用MoS2作为润滑剂减小摩擦力对试样成形的影响。变形温度分别为300、350、400、450 ℃。多向压缩过程如图1(a)所示,压缩方向总是平行于最长轴向,每道次变形量ε=0.4,通过不断翻转,进行6道次多向压缩。压缩后的试样在500 ℃下固溶处理1 h,然后在水中淬火至室温;时效制度采用传统的T6时效,即在160 ℃保温12 h后空冷。

选取与最后压缩方向平行的试样中心截面作为观察面。采用Keller腐蚀试剂(φHF:φHCl:φHNO3:φH2O= 2:3:5:190)分别对热处理前后试样进行腐蚀处理,在Leica DFC 500型金相显微镜上观察材料的晶粒大小与形态;采用双喷电解的方法制备TEM试样,利用JEM-2100F透射电镜观察热处理前后合金内部亚结构,加速电压为200 kV。在截面上选取15个点进行Vikers硬度测定,加载载荷为9.8 N;沿与最后压缩方向垂直的方向截取室温拉伸试样,尺寸规格如图1(b)所示,拉伸测试在Instron 3369力学试验机上进行,加载速度为1.00 mm/min,并在FEI Nova Nano 230扫描电镜上观察拉伸断口形貌。

图1 2A14合金多向压缩过程与室温拉伸试样示意图

Fig. 1 Schematic diagrams of multiple-compression process(a) and tensile sample(b) of 2A14 aluminum alloy

2 结果与分析

2.1 2A14铝合金的显微组织演变规律

2.1.1 多向压缩过程中合金的显微组织

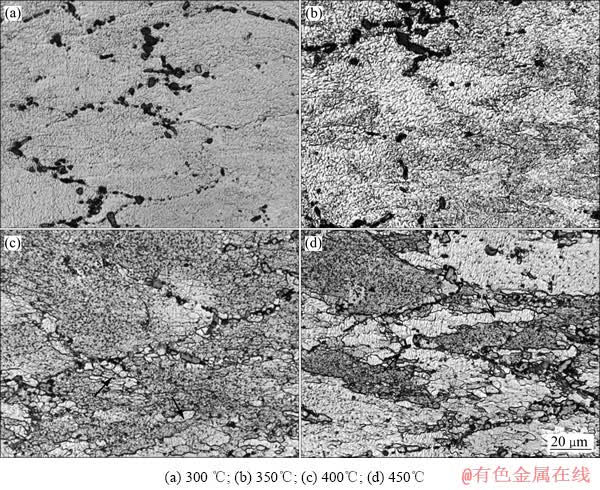

图2所示为2A14铝合金在不同温度下进行多向压缩后的显微组织。由图2可知,合金经多次轴向压缩后,部分原始晶粒被拉长,晶界产生滑移,分布于晶界上的第二相颗粒在压力作用下发生机械破碎(图2中黑色质点所示)。在300 ℃变形时,部分晶体内部以及晶界交汇处形成少量条纹状的变形剪切带,晶粒变形程度较低,合金仅发生动态回复,并未形成新的晶粒;随着变形温度的升高,合金内部变形带数量增加,晶界滑移易于进行,导致晶粒变形程度增大,动态回复作用增强;当变形温度升至400 ℃时,原始晶界处开始出现细小的再结晶晶粒,表明该条件下发生了较低程度的动态再结晶,部分区域仍保留有大量的大尺寸原始晶粒;当变形温度达到450 ℃时,组织由灰白交错的区域组成,部分再结晶晶粒合并长大,最终呈条状和等轴状分布。

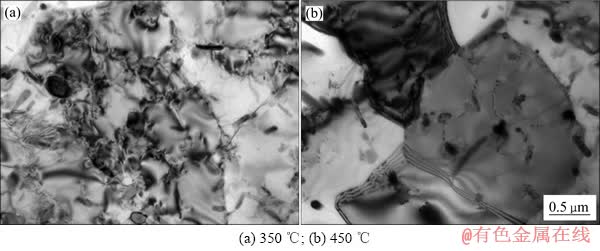

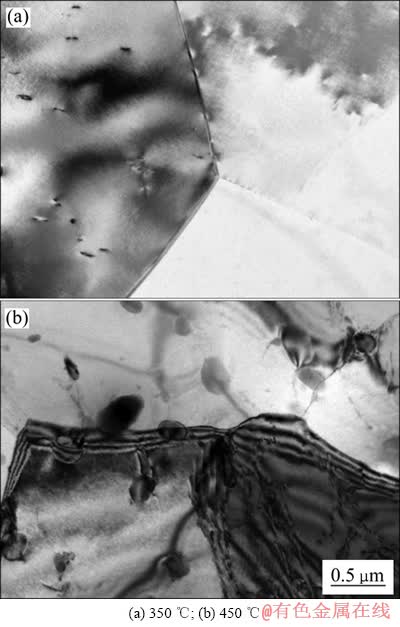

图3所示为2A14铝合金在两种变形温度下进行多向压缩后的TEM像。在350℃变形时,合金内部存在较大程度的晶格畸变,发生加工硬化,在晶界与第二相粒子周围产生大量位错塞积。在高密度位错区域,由于刃位错的攀移和螺位错的交滑移造成异号位错相互吸引而抵消、同号位错相互排斥,形成大量封闭位错胞壁(见图3(a)),随着变形的进行,位错胞壁多边形化形成规则的边界,构成小角度亚晶界[17]。合金内部积累了较多的变形储能,为道次变换期间的亚动态再结晶以及后续热处理过程中静态再结晶的形核与晶粒长大提供驱动力。合金在450 ℃变形时,位错密度显著降低,发生连续动态再结晶(见图3(b)),表明变形温度的升高使得金属原子热振动的动能增加,原子间的结合力减弱,位错滑移阻力减小,不断产生新的滑移,位错间的相互抵消和重组作用加强,动态回复得以充分进行。小角度亚晶界(LAGB)通过不断地吸收新的位错逐步转化为具有大角度晶界(HAGB),形成再结晶晶粒[18],变形储能显著降低,此时,合金的软化机制由动态回复向动态再结晶转变。

2.1.2 热处理后合金的显微组织

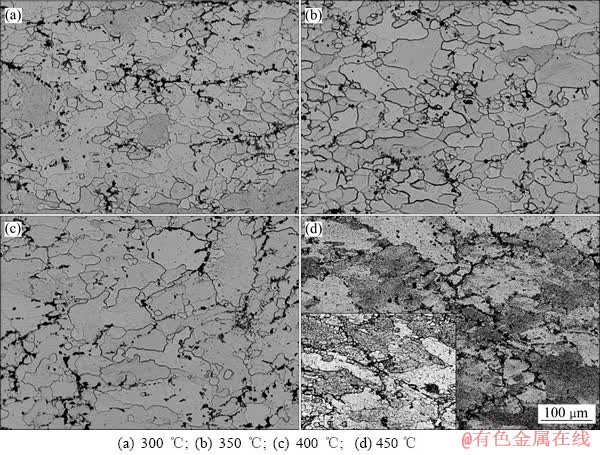

不同变形温度下多向压缩后的时效态2A14铝合金在热处理过程中发生了明显的静态再结晶及长大现象,其显微组织如图4所示。由图4可知,2A14铝合金在300 ℃变形时,热处理过程中回复组织发生再结晶,形成大量的等轴状再结晶晶粒,沿变形带均匀分布,平均晶粒尺寸约为25 μm;在350 ℃变形时,热处理态合金内部沿变形带方向形成均匀分布的再结晶晶粒,平均晶粒尺寸增大至35 μm;400 ℃变形的合金经过热处理后,部分区域仍存在具有亚结构的回复组织,等轴状的再结晶晶粒较少,表明在热处理过程中,静态再结晶未能充分进行,合金的平均晶粒尺寸约为60 μm;与400 ℃变形的合金相比,当变形温度提高至450 ℃时,热处理后回复组织的体积分数明显增加,而沿晶界分布的再结晶晶粒尺寸变化不大,合金的静态再结晶程度进一步降低,合金的平均晶粒尺寸显著增加,约为100 μm。

图2 不同温度下多向压缩后2A14铝合金的显微组织

Fig. 2 Microstructures of 2A14 aluminum alloy deformed at different temperatures

图3 不同温度下多向压缩后的2A14铝合金的TEM像

Fig. 3 TEM images of 2A14 aluminum alloy deformed at different temperatures

图4 不同变形温度下多向压缩时效态2A14铝合金的显微组织

Fig. 4 Microstructures of aged 2A14 aluminum alloy deformed at different temperatures

图5所示为2A14铝合金在不同温度下变形并进行热处理之后的TEM像。由图5(a)可知,相比于热处理之前,350℃变形时的合金内部形成清晰且平直的亚晶界,位错密度显著降低,短棒状第二相数量减少。低温变形时,合金内部动态回复未能充分进行,形变储能以高密度位错的形式存储下来,为热处理过程中静态再结晶的形核及晶粒长大提供驱动力,变形储能越高,形核率越大,最终形成具有大角度晶界的等轴状再结晶晶粒。当变形温度提高至450 ℃时,对比图3(b)和5(b)可以看出,热处理前后亚晶粒并未发生明显变化,部分区域仍存在少量位错。原因在于变形过程中合金由于发生动态再结晶使得位错密度降低,被粒子钉扎的位错变为可动并被吸附到亚晶界上,由于晶界滑动使亚晶发生转动,从而导致晶界位错取向增大[19](见图5(b)),热处理过程中,晶界的迁移受到钉扎在大角晶界上的第二相颗粒的阻碍作用,动态再结晶晶粒长大程度有限。

图5 不同变形温度下时效态2A14铝合金的TEM像

Fig. 5 TEM images of aged 2A14 aluminum alloy deformed at different temperatures

2.2 2A14铝合金的力学性能

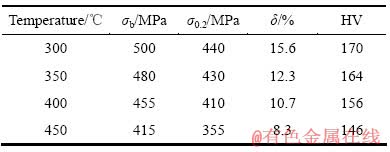

表1所列为2A14铝合金在不同温度下变形并进行热处理后的室温力学性能。由表1可知,当变形温度为300 ℃时,T6态2A14铝合金的室温力学性能最优,其中极限拉伸强度为500 MPa,屈服强度为440 MPa,伸长率为13.6%,硬度值为170;随着变形温度的升高,T6态2A14铝合金的室温力学性能逐渐变差,在350 ℃时,下降幅度较小,与300 ℃时相当;当变形温度升至450 ℃时,T6态2A14铝合金的各项力学性能指标均显著降低,极限拉伸强度为415 MPa,屈服强度为355 MPa,伸长率为9.3%,硬度值为146。合金的力学性能的下降与组织均匀性、平均晶粒尺寸的改变等因素相关。材料强度与平均晶粒尺寸之间满足Hall-Petch关系式[20]为

(1)

(1)

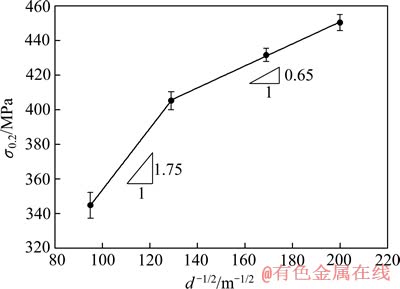

式中: 为材料的屈服应力;

为材料的屈服应力; 为移动单个位错时产生的晶格摩擦阻力;K为常数;d为材料的平均晶粒尺寸。图6所示为对不同变形温度下合金的屈服强度与平均晶粒尺寸进行线性拟合所得到的关系曲线。由图6可知,T6态2A14铝合金的屈服强度值随晶粒尺寸的减小而增大,结合表1,根据变形过程中温度的不同分为两个阶段:1) 当变形温度低于400 ℃时,

为移动单个位错时产生的晶格摩擦阻力;K为常数;d为材料的平均晶粒尺寸。图6所示为对不同变形温度下合金的屈服强度与平均晶粒尺寸进行线性拟合所得到的关系曲线。由图6可知,T6态2A14铝合金的屈服强度值随晶粒尺寸的减小而增大,结合表1,根据变形过程中温度的不同分为两个阶段:1) 当变形温度低于400 ℃时, 随晶粒尺寸的减小迅速增大,曲线符合关系式

随晶粒尺寸的减小迅速增大,曲线符合关系式 =325+ 0.65d-1/2;2) 当变形温度高于400℃时,

=325+ 0.65d-1/2;2) 当变形温度高于400℃时, 增大趋势减缓,曲线符合关系式

增大趋势减缓,曲线符合关系式 =175+1.75d-1/2。综上所述,合金的屈服强度随着合金平均晶粒尺寸的增大而逐步减小,

=175+1.75d-1/2。综上所述,合金的屈服强度随着合金平均晶粒尺寸的增大而逐步减小, 与d-1/2呈线性关系,符合H-P关系。

与d-1/2呈线性关系,符合H-P关系。

表1 T6态2A14铝合金力学性能

Table 1 Mechanical properties of T6 aged 2A14 aluminum alloy deformed at different temperatures

图6 时效态2A14铝合金的屈服强度与平均晶粒尺寸之间关系拟合曲线

Fig. 6 Fitting curve of relationship between yield strength (σ0.2) and grain size (d) of aged 2A14 aluminum alloy

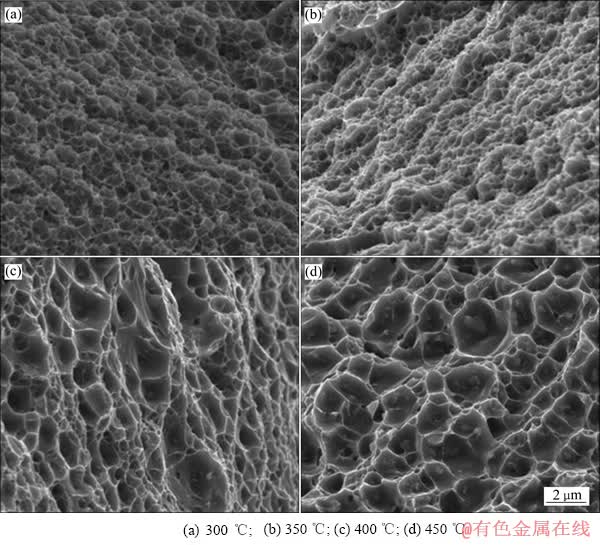

图7所示为2A14合金经室温拉伸后的断口韧窝SEM像。由图7可知,在300 ℃变形的合金经T6时效热处理之后,断口韧窝细小且均匀(见图7(a)),表明合金的塑性相对较好;当变形温度为350 ℃时,韧窝的形状与300 ℃时的形状相比变化不明显(见图7(b));400 ℃变形后,T6态2A14铝合金的断口韧窝尺寸变大,且分布变得不均匀,部分韧窝内由于存在气孔等缺陷,导致合金的塑性进一步降低(见图7(c));当变形温度提升至450 ℃时,韧窝尺寸明显增大,分布不均匀,韧窝中间存在大量的小颗粒,表明合金的塑性很差(见图7(d))。由图4可知,合金经T6时效处理后,内部仍存在较多数量的难溶脆性相(图4中的黑色质点),在拉伸时易形成局部应力集中,发生穿晶断裂,导致材料的塑性整体偏低。综上所述,2A14铝合金的断口形貌与材料的伸长率变化基本一致,且随着变形温度的升高,T6态2A14铝合金的塑性逐渐变差。

图7 T6态2A14铝合金的室温拉伸断口SEM像

Fig.7 SEM images of fractural morphologies of T6 aged 2A14 aluminum alloy deformed at different temperatures

3 结论

1) 2A14铝合金在300~450 ℃温度范围内的多向压缩过程中,变形温度对显微组织有着显著影响:在低变形温度(300~350 ℃)下,合金主要发生动态回复,形成高位错密度的亚结构;在高变形温度(400~450 ℃)下,合金主要发生动态再结晶并发生再结晶晶粒长大,位错密度降低。

2) 变形后的合金在热处理期间发生静态再结晶,再结晶尺寸与变形温度相关:在300 ℃变形时,T6态2A14铝合金的平均晶粒尺寸为25 μm,随着变形温度的升高,平均晶粒尺寸增大,分布变得不均匀;在450 ℃变形时,T6态2A14合金的平均晶粒尺寸增大至100 μm。

3) 2A14铝合金的力学性能随着变形温度的升高逐渐降低,其中屈服强度与合金平均晶粒尺寸之间的关系服从Hall-Petch关系式,表明通过晶粒的细化能够有效提高合金的强度;合金的室温拉伸断口表现出韧性断裂,随着变形温度的升高,韧窝数量减少,尺寸增大,合金的塑性变差。

REFERENCES

[1] AMUDA M O H, OLADOVE A M, AGUNSOVE J, FAROMBI O, SUBAIRW W. On the dependence of microstructure sensitive properties of cast 2xxx series aluminum alloy on solidification parameters[J]. Advanced Materials Research, 2011, 264/265: 317-322.

[2] MURAYAMA M, HORITA Z, HONO K. Microstructure of two-phase Al-1.7at%Cu alloy deformed by equal channel angular pressing[J]. Acta Materialia, 2001, 49(1): 21-29.

[3] RUSLAN Z V, YURI E, ZENJI H, TERENCE G L, MICHAEL J Z, YUNTIAN T Z . Producing bulk ultrafine-grained materials by severe plastic deformation[J]. Nanostructured Materials, 2006, 58(4): 33-39.

[4] DESRAYAUD C, RINGEVAL S, GIRARDI S, DRIVER J H. A novel high straining process for bulk materials-The development of a multi-pass forging system by compression along three axes[J]. Journal of Materials processing Technology, 2006, 172(1): 152-158.

[5] 吴远志, 严红革, 陈吉华, 朱素琴, 薄红伟, 王林伟. AZ31镁合金高应变速率多向锻造组织演变及力学性能[J]. 中国有色金属学报, 2012, 22(11): 3000-3005.

WU Yuan-zhi, YAN Hong-ge, CHEN Ji-hua, ZHU Su-qin, BO Hong-wei, WANG Lin-wei. Microstructure evolution and mechanical properties of AZ31 magnesium alloy fabricated by high strain rate triaxial-forging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3000-3005.

[6] 郭 强, 严红革, 陈振华, 张 辉. 多向锻造工艺对AZ80镁合金显微组织和力学性能的影响[J]. 金属学报, 2006, 42(7): 739-744.

GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Effect of multiple forging process on microstructure and mechanical properties of magnesium alloy AZ80[J]. Acta Metallurgica Sinica, 2006, 42(7): 739-744.

[7] 简炜炜, 康志新, 李元元. 多向锻造ME20M镁合金的组织演化与力学性能[J]. 中国有色金属学报, 2008, 18(6): 1005-1011.

JIAN Wei-wei, KANG Zhi-xin, LI Yuan-yuan. Microstructural evolution and mechanical property of ME20M magnesium alloy processed by multidirectional forging[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1005-1011.

[8] ZHEREBTSOV S V, SALISHCHEV G A, GALEYEV R M, VALIAKHMETOV O R, MIRONOV S Y, SEMIATIN S L. Production of submicrocrystalline structure in large-scale Ti-6Al-4V billet by warm severe deformation processing[J]. Scripta Materialia, 2004, 51(12): 1147-1151.

[9] MIRONOV S Y, SALISHCHEV G A, MYSHLYAEV M M, PIPPAN R. Evolution of misorientation distribution during warm ‘abc’ forging of commercial-purity titanium[J]. Materials Science and Engineering A, 2006, 418(1/2): 257-267.

[10] BELYAKOV A, GAO W, MIURA H, SAKAI T. Strain-induced grain evolution in polycrystalline copper during warm deformation[J]. Metallurgical and Materials Transactions A, 1998, 29 (12): 2957-2965.

[11] TRAVIS L B, CHRISTOPHER S, TEJAS G M, JAMES B M, YANG G, LARRY F A, ALEXANDER H K, DALE C W, KEVIN P T, SRINIVASAN C. A study of the interactive effects of strain, strain rate and temperature in severe plastic deformation of copper[J]. Acta Materialia, 2009, 57(18): 5491-5500.

[12] BELYAKOV A, SAKAI T, MIURA H. Microstructure and deformation behavior of submicrocrystalline 304 stainless steel produced by severe plastic deformation[J]. Materials Science and Engineering A, 2001, 319/321: 867-871.

[13] SITDIKOV O, SAKAI T, GOLOBORODKO A, MIURA H, KAIBYSHEV R. Effect of pass strain on grain refinement in 7475 Al alloy during hot multidirectional forging[J]. Materials Transactions, 2004, 45(7): 2232-2238.

[14] KAIBYSHEV R, SITDIKOV O, GOLOBORODKO A, SAKAI T. Grain refinement in as-cast 7475 aluminum alloy under hot deformation[J]. Materials Science and Engineering A, 2003, 344(1/2): 348-356.

[15] 潘复生. 张丁非. 铝合金及应用[M]. 北京: 化学工业出版社, 2006: 305-306.

PAN Fu-sheng, ZHANG Ding-fei. Aluminum alloy and its application[M]. Beijing: Chemical Industry Press, 2006: 305-306.

[16] 刘静安, 张宏伟, 谢水生. 铝合金锻造技术[M]. 北京: 冶金工业出版社, 2012: 386-387.

LIU Jing-an, ZHANG Hong-wei, XIE Shui-sheng. Forging technology of aluminum alloy[M]. Beijing: metallurgical Industry Press, 2012: 386-387.

[17] ZHANG Hui, JIN Neng-ping, CHEN Jiang-hua. Hot deformation behavior of Al-Zn-Mg-Cu-Zr aluminum alloys during compression at elevated temperature[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 437-442.

[18] GOURDET S, MONTHEILLET F. An experimental study of the recrystallization mechanism during hot deformation of aluminum[J]. Materials Science and Engineering A, 2000, 283(1/2): 274-288.

[19] 张廷杰, 张小明, 田 锋, 李中奎, 殷京瓯. 7075铝合金在多向大变形锻造和退火中细晶粒结构的演变[J]. 稀有金属材料与工程, 2001, 30(5): 335-338.

ZHANG Ting-jie, ZHANG Xiao-ming, TIAN Feng, LI Zhong-kui. YIN Jing-ou. Evolution of fine grained structure in 7075 aluminum alloy during hot forging and annealing[J]. Rare Metal Materials and Engineering, 2001, 30(5): 335-338.

[20] 卢 柯, 刘学东, 胡壮麒. 纳米晶体材料的Hall-Petch关系[J]. 材料研究学报, 1994, 8(5): 385-391.

LU Ke, LIU Xue-dong, HU Zhuang-qi. The Hall-Petch relation in nanocrystalline materials[J]. Chinese Journal of Materials Research, 1994, 8(5): 385-391.

(编辑 王 超)

基金项目:国家高新技术研究发展计划资助项目(2009AA034300);教育部“长江学者特聘教授”奖励计划

收稿日期:2014-03-23;修订日期:2014-11-07

通信作者:马运柱,副教授,博士;电话:0731-88877825;E-mail: zhuzipm@mail.csu.edu.cn