文章编号:1004-0609(2008)09-1622-06

AZ91镁合金旋转喷吹除气理论分析及实验研究

胡中潮1,张二林2, 曾松岩1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨150001;

2. 中国科学院 金属研究所,沈阳 110016)

摘 要:通过分析旋转喷吹除气过程中氢在惰性气泡表面和金属熔体/空气界面的质量传输,建立适用于镁合金旋转喷吹除气的理论模型。通过计算,分析工艺参数对除气效率的影响。结果表明:随着旋转喷吹转速由230 r/min增大到330 r/min时,熔体中气泡总表面积由1.49 10?2 m2增大到3.44

10?2 m2增大到3.44 10?2 m2,这增大了熔体中氢向气泡的单位时间扩散量,从而使除气效率随着转速的增加而增大。利用减压凝固方法对旋转喷吹除气的效果进行实验验证,实验结果与理论模型计算结果吻合较好。该模型可以用来指导镁合金熔体除气工艺的优化。

10?2 m2,这增大了熔体中氢向气泡的单位时间扩散量,从而使除气效率随着转速的增加而增大。利用减压凝固方法对旋转喷吹除气的效果进行实验验证,实验结果与理论模型计算结果吻合较好。该模型可以用来指导镁合金熔体除气工艺的优化。

关键词:AZ91镁合金;旋转喷吹;除气;熔体净化

中图分类号:TG 146 文献标识码:A

Theoretical analysis and experimental research of degassing of

AZ91 magnesium alloy by spinning spraying degassing

HU Zhong-chao1, ZHANG Er-lin2, ZENG Song-yan1

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Institute of Metal Research Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: A theoretical model was established for the degassing of magnesium alloy by a spinning spray based on the analysis of the mass transformation of hydrogen at the surfaces of Ar gas bubbles and the interface between the melt and air. The effect of the process parameters, such as the rotation speed on the degassing efficiency was calculated and analyzed. The results show that the total surface area of the gas bubbles increases with increasing rotation speed of spinning, i.e. the total surface area increase from 1.49 10?2 m2 to 3.44

10?2 m2 to 3.44 10?2 m2 with increasing rotation speed from 230 r/min to 330 r/min. As a result, the diffusion content of hydrogen increases with rotation speed increasing, and the degassing efficiency increases. Verification experiment was conducted by measuring the density of the samples solidified under a reduced pressure. The theoretical predication is in good agreement with the experimental results, suggesting that the model could be used for the optimization of degassing processes of magnesium alloy.

10?2 m2 with increasing rotation speed from 230 r/min to 330 r/min. As a result, the diffusion content of hydrogen increases with rotation speed increasing, and the degassing efficiency increases. Verification experiment was conducted by measuring the density of the samples solidified under a reduced pressure. The theoretical predication is in good agreement with the experimental results, suggesting that the model could be used for the optimization of degassing processes of magnesium alloy.

Key words: AZ91 magnesium alloy; spinning spraying; degassing; melt purification

镁合金是最轻的工程结构材料,具有密度小、比强度和比刚度高、导热导电性好、高阻尼减震和电磁屏蔽性能良好以及废料容易回收等特点,已广泛应用于汽车、电子和航空航天等行业[1?6]。随着其应用越来越广泛,对其品质也提出更高的要求。由于镁合金熔体在熔炼的过程中大量吸气[7],这其中主要的气体杂质是氢[8],它几乎和周期表中的所有元素发生作用,在许多合金中其占全部气体含量的60%~90%[9]。氢的来源为空气中的水蒸气与高温镁合金熔体反应生成的氢,另一方面来源于未烘干的原材料以及潮湿的熔剂等。当合金从液态转变为固态时氢的溶解度差别越大,凝固后合金中气孔越发达。虽然氢在镁合金中溶解度的变化(SL/SS=1.62)相对较小[9],然而氢在镁合金熔体中溶解度的绝对数值较大,在730 ℃时氢的溶解度大约为30 mL/100 g[10],是铝合金的几十倍,其固液相之间氢的溶解度绝对数值相差也较大,所以氢对镁合金的影响也是不容忽视的问题。当然,氢对于镁合金的危害同其它合金一样主要不在于溶解,而在于析出,如果氢在固体金属中仍然保持溶解状态,其作用与其他金属元素一样具有固溶强化作用。但是当氢超过固溶极限时,所出现的第二相为气泡,其出现加剧缩松的出现,从而严重影响合金的性能[11?12]。旋转喷吹由于具有较高的除气效率和较低的成本而获得越来越广泛的应用[13],这种方法是向合金熔体中通入Ar等惰性气体,由于溶解于合金熔体中氢的化学位高于氩气泡中氢的化学位(氢在氩气泡中的化学位为0),氢从熔体向Ar气泡中扩散,之后随着气泡浮出熔体而释放到空气中,从而使熔体中的氢含量不断降低。本文作者主要利用理论预测镁合金旋转喷吹的除气效率,并对预测的除气效率进行实验验证(见表1)。

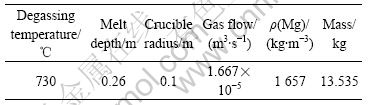

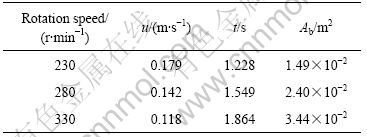

表1 旋转喷吹实验参数

Table 1 Experimental parameters of rotating impeller degassing

1 实验

实验所用材料为商用AZ91D合金,其化学成分为(质量分数):8.91%Al,0.61%Zn,0.20%Mn,0.001%Fe,0.000 8%Ni,余量Mg。熔炼和除气处理是在电阻炉中进行,坩埚由低碳钢制成。熔炼温度为730 ℃,镁合金熔体的温度采用NiCr-NiSi热电偶来测量。熔炼过程采用CO2和SF6混合气体进行保护。合金熔体净化所使用的是派罗特克公司生产的CALGAS2000型旋转喷吹除气机,旋转喷吹气体流量用LZB?2型气体流量计来控制,除气所用的气体为高纯氩气(纯度99.99%),除气效果用减压凝固后试样的密度来表征,密度用阿基米德法来测量。

2 理论计算

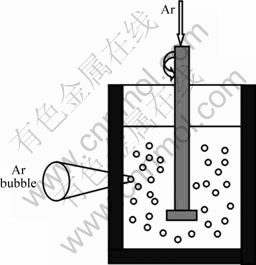

旋转喷吹除气实际上包括如下两个过程:空气中的水蒸气在高温熔体表面反应生成氢气,之后氢气离解成氢原子,最后是氢原子从表面向内部扩散;旋转喷吹时镁合金熔体中的氢向Ar气泡中扩散,并随着上升的气泡一起排到空气中去。旋转喷吹的示意图如图1所示。

图1 旋转喷吹示意图

Fig.1 Schematic diagram of rotary degassing process

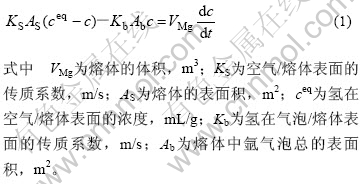

所以,旋转喷吹的状态下氢在熔体中的瞬时浓度用质量平衡方程来描述[14]:

式中 VMg为熔体的体积,m3;KS为空气/熔体表面的传质系数,m/s;AS为熔体的表面积,m2;ceq为氢在空气/熔体表面的浓度,mL/g;Kb为氢在气泡/熔体表面的传质系数,m/s;Ab为熔体中氩气泡总的表面 积,m2。

式(1)中左边第一项描述氢从大气中进入镁合金熔体中的通量,第二项描述氢从镁合金熔体中进入大气的通量,方程的右边表示熔体中氢浓度的随时间的变化。

2.1 KS、ceq的计算

没有氩气通入的情况下,用来描述熔体中氢浓度变化的方程可以用如下的方程来表示:

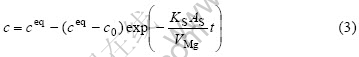

此时熔体中的氢的变化只取决于来自大气中的氢。解式(2)得到式(3):

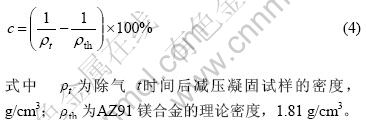

从式(3)可以得出,为了计算KS、ceq,需要了解氢在镁合金熔体中的原始浓度以及旋转喷吹不同时刻时熔体中氢的浓度。但是由于镁的蒸气压很高,很难测定氢在镁及镁合金中的浓度。假设在减压凝固过程中气体没有从镁合金熔体中溢出,也没有气体固溶在镁合金中,只是从熔体中析出,其在试样中以气泡的形式存在,可以用测量减压凝固后密度的方法来近似表征氢在镁合金熔体中的浓度,此时镁合金中氢的浓度可表示为

式中  为除气 t时间后减压凝固试样的密度,g/cm3;

为除气 t时间后减压凝固试样的密度,g/cm3; 为AZ91镁合金的理论密度,1.81 g/cm3。

为AZ91镁合金的理论密度,1.81 g/cm3。

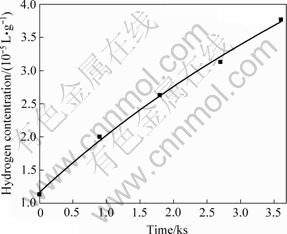

实验中,除气装置只进行旋转,不通入Ar。在旋转吸气前先将熔体中的氢用旋转喷吹的方法降到一定的程度,然后再测量旋转吸气,此时氢浓度的变化只是由于大气中的湿气和熔体反应生成氢进入熔体中,从而造成熔体中的氢浓度的变化。利用测量减压凝固试样密度的方法来计算镁合金熔体中氢的浓度,其数值如图2所示。

图2 280 r/min时熔体中的氢随旋转时间的变化(未通入Ar)

Fig.2 Hydrogen content in melt vs degassing time at 280 r/min (without Ar)

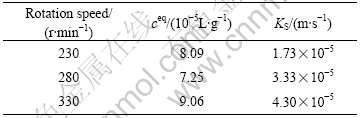

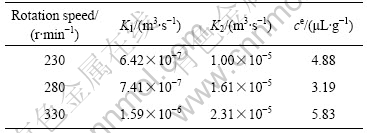

根据图2中的数据点可以拟合出参量KS和ceq。改变旋转速度做多组类似实验,每组都可以获得参量KS和ceq (见表2)。从表2可以看出,随着转速的增加镁合金熔体/空气界面上氢的质量迁移系数增加,表明随着转速的增加熔体中吸气严重。从表中还可以看出金属熔体/空气界面上的氢浓度存在着差别,这可能是由于不同湿度的空气与镁合金熔体反应造成的。

表2 实验获得的金属熔体/空气界面上质量迁移系数和金属熔体/空气界面的氢浓度

Table 2 Mass transfer coefficient at melt/air interfacial and concentration of hydrogen in experiment

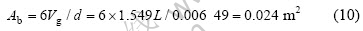

2.2 Ab的计算

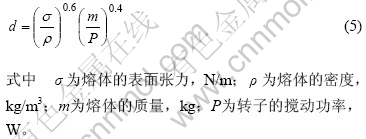

旋转喷吹的除气效率受扩散过程控制[13?15],熔体中气泡的表面积以及氢在熔体中的传质系数对扩散有直接的影响。氢在熔体中的传质系数不依赖于转速和气体流量[10?12],而受熔体的温度影响较大,在730 ℃其数值大约为:6.7 10?4 m/s[6]。所以,旋转喷吹的效率实际上只取决于气泡在熔体中总的表面积。假设气泡在熔体中的直径大小相等,这时旋转喷吹气泡的总的表面积与气泡在熔体中的平均直径大小密切相关。但是,在镁合金旋转喷吹的过程中,测量气泡直径的大小非常困难,所以我们决定采用理论计算旋转喷吹过程中气泡的大小,从而计算出旋转喷吹的效率。旋转喷吹气泡的直径可以用如下公式来表示[16]:

10?4 m/s[6]。所以,旋转喷吹的效率实际上只取决于气泡在熔体中总的表面积。假设气泡在熔体中的直径大小相等,这时旋转喷吹气泡的总的表面积与气泡在熔体中的平均直径大小密切相关。但是,在镁合金旋转喷吹的过程中,测量气泡直径的大小非常困难,所以我们决定采用理论计算旋转喷吹过程中气泡的大小,从而计算出旋转喷吹的效率。旋转喷吹气泡的直径可以用如下公式来表示[16]:

式中  为熔体的表面张力,N/m;

为熔体的表面张力,N/m; 为熔体的密度,kg/m3;m为熔体的质量,kg;P为转子的搅动功率,W。

为熔体的密度,kg/m3;m为熔体的质量,kg;P为转子的搅动功率,W。

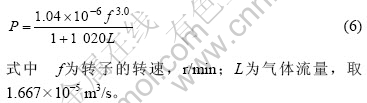

转动功率是转动的速率和气体流量的复合函数,可以用下式来计算[16]:

式中 f为转子的转速,r/min;L为气体流量,取1.667 10?5 m3/s。

10?5 m3/s。

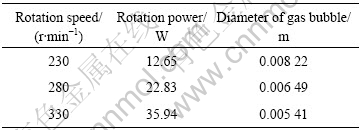

在730 ℃时,镁合金的表面张力为0.531 N/m[17],将此值和式(6)代入式(5)中,得到不同转速下镁合金熔体中气泡的直径(见表3)。

表3 不同转速下的气泡直径

Table 3 Diameter of air bubble at different rotation speeds

根据气泡表面更新模型[15],氢在气泡和熔体之间的传质系数如下:

式中 Kb为金属/气泡表面上的传质系数,m/s;D为氢在镁合金熔体的扩散速度,m2/s;d为气泡的直径,m;u为气泡在镁合金的上升速度,m/s。

在730 ℃时氢在镁合金熔体中的扩散系数大约为:1.617 10?8 m2/s[6],将此值和表3中的数值代入式(7)中,得出280 r/min时气泡在熔体中的上升速度为0.142 m/s (其他转速下气泡在熔体中的上升速度见表3)。从表1可知,熔体的深度为0.26 m,旋转喷吹除气时,旋转喷头距离坩埚底部的高度为0.04 m,所以气泡在熔体中的行走距离大约为0.22 m。在转速280 r/min时气泡在熔体中行走所用的时间为

10?8 m2/s[6],将此值和表3中的数值代入式(7)中,得出280 r/min时气泡在熔体中的上升速度为0.142 m/s (其他转速下气泡在熔体中的上升速度见表3)。从表1可知,熔体的深度为0.26 m,旋转喷吹除气时,旋转喷头距离坩埚底部的高度为0.04 m,所以气泡在熔体中的行走距离大约为0.22 m。在转速280 r/min时气泡在熔体中行走所用的时间为

式中 Hg为气泡在熔体中行走的路程,m。

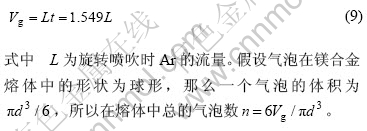

镁合金熔体中气体总的体积为:

式中 L为旋转喷吹时Ar的流量。假设气泡在镁合金熔体中的形状为球形,那么一个气泡的体积为 ,所以在熔体中总的气泡数

,所以在熔体中总的气泡数 。

。

一个气泡的表面积为 ,所以在280 r/min时,熔体中Ar泡总的表面积为

,所以在280 r/min时,熔体中Ar泡总的表面积为

根据式(10)计算不同的转速下熔体中气泡的表面积列于表4。

表4 镁合金熔体中气泡的总表面积

Table 4 Total surface area of air bubble in magnesium alloy melt

当旋转喷吹通入Ar时解式(1)得:

式中 r为坩埚的半径,m。

根据表1、表2及表4的数据得到K1、K2和ce,结果列于表5。

表5 K1、K2和ce数值

Table 5 Values of K1, K2 and ce

旋转喷吹的除气效率可表示为:

从式(14)可以看出,为了计算旋转喷吹除气效率,还需了解氢在镁合金中的原始浓度。

3 模型的验证

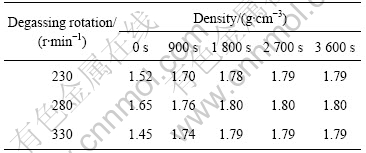

从式(4)可知,氢在镁合金熔体中的浓度可以用减压凝固试样密度来近似表示,表6所列为旋转喷吹不同时间试样的密度。从表6可以看出,在280 r/min时未除气的密度要明显比230和330 r/min的高,这可能是由于原材料中氢含量以及空气湿度不同造成的。

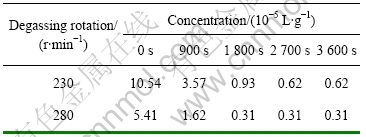

将表6中的数据代入式(4)中得出在旋转喷吹不同时间熔体中氢的浓度,结果列于表7中。

表7中0 s中的数据表示未除气氢的原始浓度(c0),将此值和表5中的数据代入式(14)中计算出不同的转速下的理论除气效率,结果如图3所示。从图中可以看出,在除气开始时330 r/min的除气效率明显高于280 r/min和230 r/min的除气效率,这是由于随着转速的提高气泡在镁合金熔体中分布越弥散(气泡直径越小),氢迁移的距离越短。因为旋转喷吹的效率还和熔体的吸气有关,随着转速的增加熔体的吸气越来越严重,所以随着旋转喷吹时间的增加3种转速的除气效率相差越来越小。图中的黑点为实验测得的旋转喷吹除气效率,从图中可以看出,在不同的转速下理论模型预测和试验测得数据吻合较好。

表6 不同转速下除气后镁合金减压凝固后试样的密度

Table 6 Density of magnesium alloy samples degassed at different rotation speeds

表7 不同转速下除气后熔体中氢气的浓度

Table 7 Concentration of hydrogen in melt after degassed at different rotation speeds

图3 理论计算的除气效率和测量结果比较

Fig.3 Comparison of theoretic predication of degassing efficiency and measured results: (a) 230 r/min; (b) 280 r/min; (c) 330 r/min

4 结论

1) 旋转喷吹镁合金熔体中气泡的表面积随着转速的增加而增加,导致除气效率也随着转速的增加而增加。

2) 理论计算和实际测量的结果吻合较好,此模型可以用来指导镁合金除气工艺的优化设计。

REFERENCES

[1] 师昌绪, 李恒德, 王淀佐, 李依依, 左铁镛. 加速我国金属镁工业发展的建议[J]. 材料导报, 2001, 15(4): 5?6.

SHI Chang-xu, LI Heng-de, WANG Dian-zuo, LI Yi-yi, ZUO Tie-yong. Suggestions for accelerating magnesium industry development of China[J]. Materials Review, 2001, 15(4): 5?6.

[2] CHEN Ji-hua, CHEN Zhen-hua, YAN Hong-ge, ZHANG Fu-quan, LIAO Kun. Effects of Sn addition on microstructure and mechanical properties of Mg-Zn-Al alloys[J]. Journal of Alloys and Compounds, 2008, 461(1/2): 209?215.

[3] WANG Ying-xin, ZENG Xiao-qin, DING Wen-jiang. Effect of Al-4Ti-5B master alloy on the grain refinement of AZ31 magnesium alloy[J]. Scripta Materialia, 2006, 54: 269?273.

[4] 余 琨, 黎文献. 王日初. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277?288.

YU Kun, LI Wen-xian, WANG Ri-chu. Application and development of wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277?288.

[5] ZHANG Jing, LI Zhong-sheng, GUO Zheng-xiao, PAN Fu-shen. Solidification microstructural constituent and its crystallographic morphology of permanent-mould-cast Mg-Zn-Al alloys[J]. Trans Nonferrous Met Soc China, 2006, 16(2): 452?458.

[6] SCHUMANN S, FRIEDRICH H. Currrent and future use of magnesium in the automotive industry[J]. Mater Sci Forum, 2003, 51: 419?422.

[7] EMLEY E F. Principles of magnesium technology. Headington Hill Hall[M]. Oxford: Pergamon Press Ltd, 1966. 191?195.

[8] ENGH T A. Principles of metal refining[M]. London: Oxford University Press, 1992. 302.

[9] CHERNEQA D F. 有色金属及其合金中的气体[M]. 黄良余, 严名山, 译. 北京: 冶金工业出版社, 1989: 57, 50.

CHERNEQA D F. The gas in the nonferrous and its alloy[M]. HUANG Liang-yu, YAN Ming-shan, transl. Beijing: Metallurgical Industry Press, 1989: 57.

[10] 张承甫, 龚建森, 黄杏蓉. 液态金属的净化与变质[M]. 上海: 上海科学技术出版社, 1989: 60.

ZHANG Cheng-pu, GONG Jian-sen, HUANG Xing-rong. Purification and metamorphosing of liquid metal[M]. Shanghai: Shanghai Science and Technology Publishing Company, 1989: 60.

[11] CHEN X G, KLINKENBER G, ELLERBROK R, ENGLER S. Efficiency of impeller degassing and regassing phenomena in aluminum melts[J]. Transaction of the American Foundrymen’s Society, 1994, 102: 191?197.

[12] WARKE V S, SHANKAAR S, MAKHLOUF M M. Modeling and computer simulation of molten aluminum cleansing by the rotating impeller degasser (Part Ⅰ): Fluid flow[J]. Journal of Materials Processing Technology, 2005, 168: 112?118.

[13] WU Rui-zhi, SHU Da, SUN Bao-de, WANG Jun, LI Fei, CHEN Hai-yan, LU Yan-Ling. Theoretical analysis and experimental study of spray degassing method[J]. Mater Sci Eng A, 2005, 408: 19?25.

[14] WARKE V S, SHANKAAR S, MAKHLOUF M M. modeling and computer simulation of molten aluminum cleansing by the rotating impeller degasser (Part Ⅱ): Removal of hydrogen gas and solid particles[J]. Journal of Materials Processing Technology, 2005, 168: 119?126.

[15] HAN J W, KIM D J, YOU B D, BYUN J Y, SHIM J D. Effect of gas bubbling and impeller agitation on degassing kinetics during magnesium alloy(AZ91D) melt recycling-water model approach[J]. Materials Science Forum, 2003, 439: 192?199.

[16] JOHANSEN S T, GR?DAHL S, GR?NTVEDT P O, TETLIE P, GAMMELS?TER R, VEN?S K, SKARET P, MYRBOSTAD E, RASCH B. The bubble size and mass transfer mechanisms in rotor stirred reactors[J]. Light Metal, 1997: 663?666.

[17] BRANDES E A, BROOK G B. Smithells metals reference book[M]. Bath: The Bath Press, 1992. 14?16.

[18] JOHANSEN S T, GRAADAHL S, TETLIE P, RASCH B, MYRBOSTAD E. Can rotor-based refining units be developed and optimised based on water model experiments[J]. Light Metals, 1998: 805?810.

收稿日期:2007-10-22;修订日期:2008-02-18

通讯作者:张二林,研究员;电话:024-23971605;E-mail: erlin.zhang@imr.ac.cn

(编辑 龙怀中)