文章编号:1004-0609(2008)12-2132-08

喷射沉积5A06铝合金楔压变形的数值模拟

张 昊1, 2,陈振华2,陈 鼎2

(1. 长沙学院 机电工程系,长沙 410003;

2. 湖南大学 材料科学与工程学院,长沙 410082)

摘 要:为优化楔压变形的工艺参数,采用Deform-3D有限元软件对喷射沉积5A06铝合金楔压变形进行了数值模拟。压头压下速度为0.1~10 mm/s,变形温度为350~550 ℃。结果表明:压下速度越大,坯料的平均密度和变形抗力越高,楔压表面质量越好,不容易产生台阶,但所需的压力机吨位也越大。变形温度对坯料的致密没有明显的影响,然而温度太低容易在压制过程产生裂纹,而温度过高时坯料表面容易出现畸变,并且组织会发生过烧。因此,喷射沉积5A06铝合金楔压变形的最佳工艺参数为:压头压下速度1.0 mm/s,变形温度为450 ℃。

关键词:5A06铝合金;喷射沉积;楔压;数值模拟

中图分类号:TG 146.2 文献标识码: A

Numerical simulation on sequential motion compacting of spray deposited 5A06 aluminum alloy

ZHANG Hao1, 2, CHEN Zhen-hua2, CHEN Ding2

(1. Department of Mechanical and Electrical Engineering, Changsha University, Changsha 410003, China;

2. College of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: In order to optimize the processing parameter, the sequential motion compacting of spray deposited 5A06 alloy was simulated by using rigid-plastic finite element method (FEM) on DEFORM-3D software. During the sequential motion compacting, the depressed velocity of head is 0.1?10 mm/s, the range of deformation temperature is 350?550 ℃. The results show that with increasing depressed velocity, the average density of preform and resistance of deformation become higher, the surface quality becomes better and there are no steps on the surface, but the press tonnage also becomes higher. Although the effect of deformation temperature on densification of preform is obscure, when the temperature is too low, the cracks occur easily, and when the temperature is too high, the aberration appears easily on the surface, the overburning microstructure can be found at the meantime. Thus, the optimal processing parameters of sequential motion compaction for spray deposited 5A06 alloy are: depressed velocity of head of 1.0 mm/s, deformation temperature of 450 ℃.

Key words: 5A06 alloy; spray deposition; sequential motion compacting; numerical simulation

喷射沉积坯是一种松疏的多孔非连续体材料,通常含有一定量的孔隙,颗粒与沉积层边界也存在一定量的氧化膜,颗粒之间未达到理想的冶金结合,直接使用时性能比较差,其最终能否得到成功的应用,取决于制坯后的致密化加工过程中所获得的性能[1?3]。因此,为了获得所要求力学性能,必须对喷射沉积坯进行后续塑性加工,如采用挤压、锻造、轧制等金属塑性加工方法[4]。而致密化过程中的坯件横向变形是使孔隙完全封闭以及喷射颗粒的溅射界面在切变力下产生冶金结合的关键。然而,采用通常的挤压、锻造、轧制等技术,却难以实现大型方坯件的致密化加工。楔形压制工艺(或称循环压制)是粉末冶金过程中粉末压制方法之一[5]。作者根据楔形压制的原理提出了喷射沉积坯料的楔形压制工艺,研究表明该工艺可以有效地提高喷射沉积坯料的致密性[6?8]。

随着计算科学的快速发展和有限元技术应用的日益成熟,运用有限元法模拟金属塑性成形过程是当前国际上塑性加工领域的前沿研究内容,已用于多种成形工艺的理论分析[9?10]以及多孔材料的塑性变形过程分析[11]。

本文作者利用采用Deform-3D有限元软件对喷射沉积5A06铝合金楔压变形进行了数值模拟,分析了压头压下速度和变形温度等工艺条件对变形和致密化的影响,以获得喷射沉积5A06坯的最佳楔压条件,为合理制定其热加工工艺提供指导。

1 模拟条件

1.1 本构模型选择

目前,金属材料热变形过程中,在任何应变或稳态下的高温流变应力σ强烈地取决于变形温度T和应变速率 ,通常可采用以下形式[12?13]加以描述:

,通常可采用以下形式[12?13]加以描述:

热变形条件通常可表达为Zener-Hollomon参数[14]:

根据前期的研究表明[15],喷射沉积5A06铝合金多孔材料热压缩变形流变应力行为符合如下本构方程:

1.2 楔压工艺

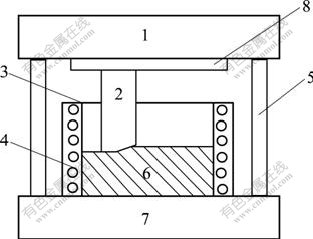

楔压装置示意图如图1所示,楔压工艺过程示意图见图2,楔压工艺参数如表1所列。数值模拟采用于尺寸为345 mm×215 mm×200 mm的长方形,与实际实验尺寸保持一致,楔压时压头压下速度分别为0.1、1.0和10 mm/s,楔压温度为350、450和550 ℃。

图1 楔压装置示意图

Fig.1 Schematic diagram of sequential motion compacting: 1—Hydrostatic machine; 2—Punch; 3—Die; 4—Electrical bar; 5—Caging device; 6—Preform; 7—Backup plate; 8—Guide rail

图2 楔压过程示意图

Fig.2 Schematic of sequential motion compacting process

表1 楔压相关工艺参数

Table 1 Processing parameter of sequential motion compacting

1.3 模拟条件

1.3.1 材料参数

实验用5A06铝合金基体化学成分见表2,初始相对密度为0.81,其相关性能参数如表3所列。

表2 实验用5A06Al铝合金的化学成分

Table 2 Chemical composition of 5A06 alloy (mass fraction, %)

表3 5A06铝合金相关性能参数

Table 3 Property parameter of 5A06 Al Alloy

1.3.2 模拟参数

1) 设定模具及坯料的温度及属性,如表4所列。材料屈服准则为Deform软件默认的Von Mises屈服 准则。

表4 工件及模具的温度及属性

Table 4 Temperature and attribute of preform and die

2) 摩擦模型

Deform软件提供了部分摩擦因数推荐值:常温成形一般选0.08~0.12,温成形一般选0.25,有润滑的热成形一般选0.2~0.3,无润滑表面一般选0.7~0.9。本实验选取塑性剪切(Shear)摩擦模型,摩擦因数选择系统默认值0.3。

3) 损伤值计算模型

在Deform软件中,用损伤值来预测材料发生断裂的情况,损伤越大,材料发生断裂的可能性也越大。损伤值Df根据Cockcroft-D. J. Latham准则定义为

(6)

(6)

式中 σ*为拉伸最大主应力,σ为等效应力,d ε为有效应变增量, 为断裂时应变。

为断裂时应变。

2 模拟结果分析与讨论

2.1 楔压压头压下速度对变形与致密化的影响

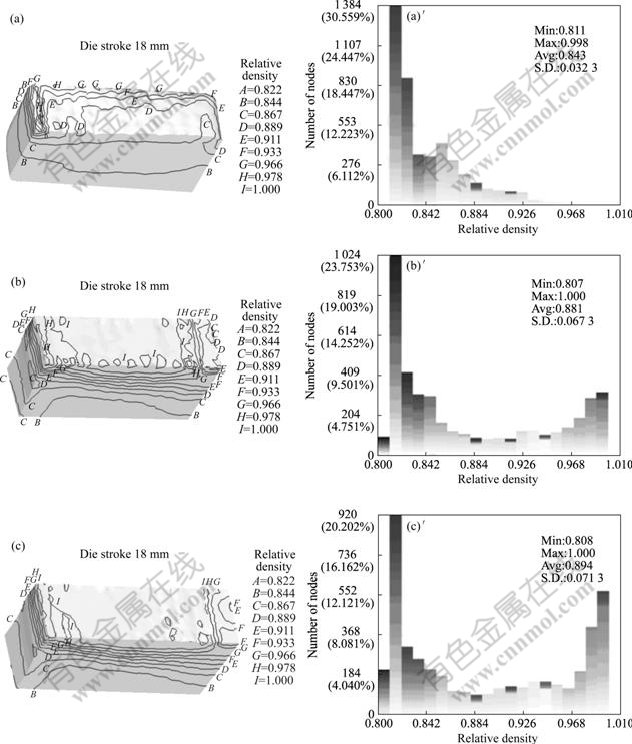

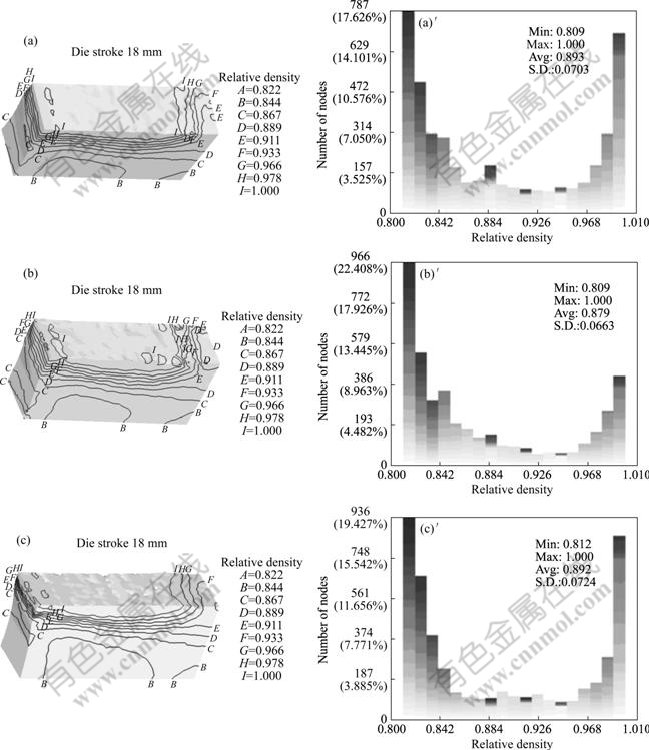

为了选取一定的高向压下量来研究变形工艺参数对致密化的影响,设定高向压下量为18 mm,横向(长度方向)变形量为5%,温度取450 ℃。此条件下,平均相对密度的大小及分布结果如图3所示。图中坯料上的等值线代表相对密度的大小及分布;右边图表中横坐标代表平均相对密度,纵坐标代表不同密度所处节点数目占总结点数目的比例,亦即不同密度的分布比例;表中上方自动显示相对密度的最大值、最小值及平均相对密度和标准偏差的大小。相同条件下,取与楔压压头移动方向垂直的宽度方向任一截面,观察不同压下速度时宽度方向密度的分布,结果如图4所示。

总的来看,随着压制速度的升高,坯料压制结束时平均相对密度d也随之升高。由图3可见,压制速度相对较低(v为0.1 mm/s)时,平均相对密度d相对较低,且材料充型能力较好,中间变形量大,边部变形量小,而当压制速度相对较高(v为1.0和10 mm/s)时,平均相对密度d相对较高。另外图4所示模拟结果还显示,v=0.1 mm/s时,坯料中心密度明显低于边部密度,密度分布很不均匀,而v为1.0和10 mm/s时中心密度与边部密度十分接近,密度分布均匀。

这种现象可以解释为:速度较低时,材料变形抗力相对较低,材料有足够的时间发生塑性流动,金属在压头作用下主要发生塑性流动,而致密化效果不明显。坯料在楔压斜面压头的作用下,中间部分流动速度快,边部流动速度慢,因此中心处于两向压应力状态,而边部由于受到与模具接触表面摩擦力的影响处于三向压应力,所以材料边部更容易发生致密化。而压制速度较高时,材料变形抗力相对较高,塑性流动不易发生,主要发生致密化,因而平均相对密度较高,且宽度方向平均相对密度分布也比较均匀。

由图3可见,压制速度相对较低(v为0.1 mm/s)时,表面出现明显台阶。这是因为低速条件下,材料变形抗力相对较低,材料更容易发生塑性流动,表层金属在楔压压头楔面的作用下往同一方向流动。当表面与

模壁接触后,相同的压下量会造成金属向已变形部分流动,使得金属表面向上挤压产生凸台。而在v为1.0和10 mm/s时,未发现明显台阶。

图3 压下速度与平均相对密度的关系

Fig.3 Relationships between depress velocity and average relative density: (a), (a’) v=0.1 mm/s, dAverage=83.3%; (b), (b’) v=1.0 mm/s, dAverage=88.1%; (c), (c’) v=10 mm/s, dAverage=89.4%

且由图4可知,v为1.0和10 mm/s时致密化较好,观察发现单个条件下平均相对密度相差并不大,而v为1.0 mm/s时的变形抗力比v为10 mm/s时的低, 所需压力机吨位较低。因此从致密化效果以及对设备的要求等各方面综合考虑,压制速度应选为v=1.0 mm/s。

图4 压下速度对宽度方向密度的影响

Fig.4 Effects of depress velocity on density in width direction: (a) v=0.1 mm/s; (b) v=1.0 mm/s; (c) v=10 mm/s

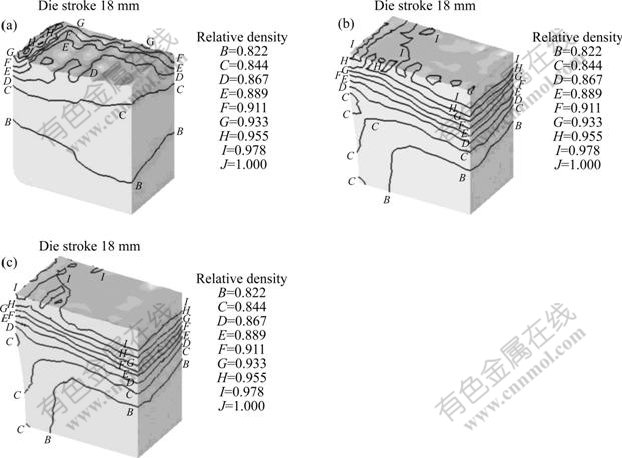

2.2 变形温度对变形与致密化的影响

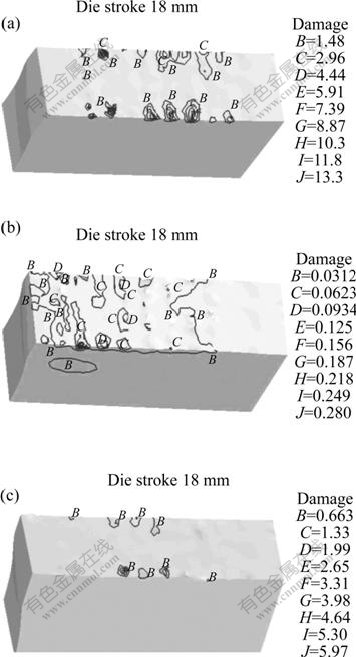

图5和6所示分别为横向变形量为5%。高向压下量为18 mm、压头下压速度取1.0 mm/s条件下,平均相对密度和损伤值的对比。图5所示坯料上的等值线代表相对密度的大小及分布;右边图表中横坐标代表平均相对密度,纵坐标代表不同密度所处节点数目占总结点数目的比例,亦即不同密度的分布比例;表中上方自动显示相对密度的最大值最小值及平均相对密度和标准偏差的大小。

图5 变形温度对平均相对密度的影响

Fig.5 Effects of deformation temperature on average relative density: (a), (a’) 350 ℃; (b), (b’) 450 ℃; (c), (c’) 550 ℃

图6 变形温度对Damage值的影响

Fig.6 Effects of deformation temperature on damage value: (a) 350 ℃; (b) 450 ℃; (c) 550 ℃

由图5可知,随着变形温度的升高,坯料平均密度并无明显变化。图7(a)~(c)的平均密度均比较接近,说明温度对致密化的影响并不明显。由图6可知,随着变形温度的升高,损伤值随温度的升高逐渐减小。在350 ℃时损伤值较大,温度继续上升,损伤值逐渐减小,说明材料在350 ℃时容易发生开裂。进一步观察发现,较大损伤值多集中在楔压坯料表面的侧边,这里将是裂纹的源头。在楔压压头的作用下,坯料横向变形是从表层开始逐渐向下传递,裂纹将有可能从这里沿平行于楔压方向向下产生扩展。这是由于温度较低时材料的变形抗力较大,塑性较差,加上微观孔洞的存在,进一步加速了材料的断裂行为。而在变形过程中,楔压压头不断将坯料往间隙方向推移,使得材料沿间隙方向产生拉应力,当拉应力达到一定程度时,将产生裂纹扩展。

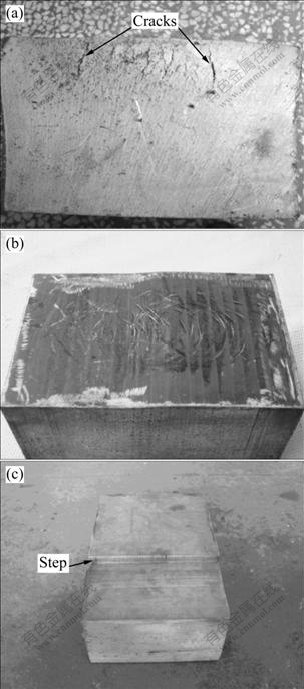

另外,由图5(c)和图6(c)还可以看出,当温度过高时,坯料表面出现畸变,表面质量变差。图7和图8所示的实际楔压实验结果也证明了模拟结果:坯料在350 ℃时侧边开裂;在450 ℃时表面质量较好,侧边也没有裂纹;而550 ℃时没有发现宏观侧面裂纹,进一步研究表明,在550 ℃时材料显微组织还发生了晶粒粗化,组织存在过烧现象。

图7 不同变形温度的楔压试样[16]

Fig.7 Samples of sequential motion compacting at different deformation temperatures[16]: (a) 350 ℃; (b) 450 ℃; (c) 550 ℃

图8 不同温度楔压的显微组织[16]

Fig.8 Microstructures of sequential motion compacting at different deformation temperatures[16]: (a) 350 ℃; (b) 450 ℃; (c) 550 ℃

3 结论

1) 对于不同的压制速度来说,压制速度相对较低(v为0.1 mm/s)时,平均相对密度d相对较低,表面出现明显台阶;而在压下速度为1.0和10 mm/s时,致密化较好,未发现明显台阶。综合考虑致密化效果以及对设备的要求,喷射沉积5A06铝合金楔压工艺的压制速度应选取1.0 mm/s。

2) 在不同温度进行楔压变形时,温度对致密化效果的影响并不明显,但是在较低温度(350 ℃)时,损伤值较大,坯料表面的侧边容易产生裂纹;而在变形温度较高(550 ℃)的情况下,坯料表面出现畸变,影响材料的表面质量,与实验结果一致。

3) 在550 ℃进行楔压时,材料显微组织会发生晶粒粗化,组织存在过烧现象。综合分析后得出合理的楔压温度应控制在450 ℃左右。

REFERENCES

[1] BERGMANN D, FRITSCHING U. Sequential thermal modelling of the spray-forming process[J]. International Journal of Thermal Sciences, 2004, 43: 403?415.

[2] LAVERNIA E J, GRANT N J. Spray deposition of metals: A review[J]. Mater Sci Eng A, 1988, A98: 381?394.

[3] 陈振华, 贺毅强, 陈志钢, 尹显觉, 陈 刚. SiCp/Al-8.5Fe- 1.3V-1.7Si复合材料的显微组织及室温力学性能[J]. 中国有色金属学报, 2007, 17(6): 858?864.

CHEN Zhen-hua, HE Yi-Qiang, CHEN Zhi-Gang, YIN Xian-jue, CHEN Gang. Micrrostructure and ambient temperature mechanical properities of SiCp/Al-8.5Fe-1.3V-1.7Si composite [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 858?864.

[4] ZHAN Mei-Yan, CHEN Zhen-Hua, YAN Hong-Ge, XIA Wei-Jun. Deformation behaviors of porous 4032 Al alloy preform prepared by spray deposition during hot rolling[J]. Journal of Materials Processing Technology, 2007, 182: 174?180.

[5] DEIBEL C, THORNBURG D R, EMLEY F. Continuous compaction by cyclic pressing[J]. Powder Metallurgy, 1960, 5: 32?44.

[6] CHEN Zhen-hua, ZHANG Hao, CHEN Ding, YAN Hong-ge, CHEN Gang. Advanced plastic processing techniques for the densification of spray deposited preforms[J]. Materials Science Forum, 2007, 561/565: 827?830.

[7] 陈 刚, 刘鹏飞, 范才河, 陈振华. 大型喷射沉积环件的楔压致密化加工[J]. 矿冶工程, 2006, 26(2): 100?102.

CHEN Gang, LIU Peng-fei, FAN Cai-he, CHEN Zhen-hua. Densification of large-size spray-deposited rings by wedge pressing[J]. Mining and Metallurgical Engineering, 2006, 26(2): 100?102.

[8] 袁武华, 吉 喆, 陈振华. 循环压制对喷射沉积7075/SiCp致密化的影响[J]. 湖南大学学报: 自然科学版, 2006, 33(2): 82?85.

YUAN Wu-hua, JI Zhe, CHEN Zhen-hua. Effects of cyclic pressing on densification of spray formed 7075/SiCp composite [J]. Journal of Hunan University: Nature Sciences, 2006, 33(2): 82?85

[9] KOBAYASHI S I, AHAN T. Metal forming and the finite element method[M]. New York: Oxford University Press, 1989: 1?13.

[10] 周 飞, 苏 丹, 彭颖红, 阮雪榆. 有限体积法模拟铝型材挤压成形过程[J]. 中国有色金属学报, 2003, 13(11): 65?70.

ZHOU Fei, SU Dan, PENG Ying-hong, RUAN Xue-yu. Simulation of aluminum material extrusion process with finite volume method[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(11): 65?70.

[11] MORI K, OSAKADA K. Analysis of the forming process of sintered powder metals by a rigid-plastic finite-element method[J]. International Journal of Mechanical Sciences, 1987, 29(4): 229?238.

[12] TAKUDA H, FUJIMOTO H, HATTA N. Modeling on flow stress of Mg-Al-Zn alloys at elevated temperatures [J]. Journal of Materials Processing Technology, 1998, 80/81(8): 513?516.

[13] ZENER C, HOLLOMON J H. Effect of strain-rate upon the plastic flow of steel [J]. J Appl Phys, 1944, 15(1): 22.

[14] ZENER C, HOLLOMON J H. Problems in non-elastic deformation of metals [J]. J Appl Phys, 1946, 17(2): 69?82.

[15] 王战锋, 张 辉, 张 昊, 陈振华. 喷射沉积5A06铝合金热压缩变形流变应力行为研究[J]. 中国有色金属学报, 2006, 16(11): 1938?1944.

WANG Zhan-feng, ZHANG Hui, ZHANG Hao, CHEN Zhen-hua. Flow stress behaviors of spray-deposited 5A06 aluminum alloy under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1938?1944.

[16] 范才河. 喷射沉积5A06铝合金楔压致密化工艺的研究[D]. 长沙: 湖南大学, 2006.

FAN Cai-he. Study on the densification process of spray-deposited 5A06 aluminum alloy by wedge pressing[D]. Changsha: Hunan University, 2006.

基金项目:湖南省科技厅资助项目(06FJ3041)

收稿日期:2008-02-27;修订日期:2008-07-10

通讯作者:陈振华,教授,博士;电话/传真:0731-8821648;E-mail: zhanghao0122@126.com

(编辑 陈爱华)