DOI: 10.11817/j.issn.1672-7207.2016.06.004

低负荷下蓄热式加热炉燃烧策略数值模拟

刘颖1, 2,刘义平3,陶曙明4,温治1, 5

(1. 北京科技大学 机械工程学院,北京,100083;

2. 重庆市计量质量检测研究院,重庆,401123;

3. 宝钢工业炉工程技术有限公司,上海,201900;

4. 宝钢钢管条钢事业部设备能环部,上海,201900;

5. 北京科技大学 冶金工业节能减排北京市重点实验室,北京,100083)

摘要:针对低负荷下蓄热式加热炉燃烧性能下降的问题,以某钢厂蓄热式加热炉为研究对象,利用软件Fluent建立炉内气体流动、传热及燃烧过程数学模型。炉内气体的流动采用标准k-ε模型计算,燃烧过程的模拟采用混合分数/PDF模型,辐射换热采用DO模型计算。通过所建立的数学模型计算低负荷时,比例控制和脉冲控制2种情况下,炉内气体流动、气体体积分数及温度的分布。计算结果表明:在低负荷下,脉冲控制有利于加强煤气与空气的混合,提高煤气燃烧速率,防止O2在钢坯表面的聚集,有利于减小钢坯的氧化烧损,提高钢坯表面热流沿炉宽方向分布的均匀性。

关键词:蓄热式加热炉;低负荷;数值模拟;燃烧策略;比例控制;脉冲控制

中图分类号:TF068 文献标志码:A 文章编号:1672-7207(2016)06-1843-07

Numerical simulation of combustion strategy in a regenerative reheating furnace under low thermal load

LIU Ying1, 2, LIU Yiping3, TAO Shuming4, WEN Zhi1, 5

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Chongqing Academy of Metrology and Quality Inspection, Chongqing 401123, China;

3. Baosteel Industrial Furnace Engineering & Technology Co., Ltd, Shanghai 201900, China;

4. Tube Pipe and Bar Business Unit, Equipment & Energy Department,

Equipment Technology Division, Baoshan Iron & Steel Co., Ltd., Shanghai 201900, China;

5. Beijing Key Laboratory of Energy Saving and Emission Reduction for Metallurgical Industry,

University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In order to solve the problem of combustion performance decrease caused by the decrease of thermal load in a regenerative reheating furnace, a mathematical model was developed to describe heat transfer, gas flow and combustion processes in a regenerative reheating furnace by Fluent. The standard k-ε turbulence model was used for modeling the gas flow. The mean mixture fraction/PDF model was used to describe combustion process in the furnace. The discrete ordinates model was used for modeling the radiative heat transfer. The characteristics of gas flow, distribution of volume fraction of gas species and temperature distribution for furnace under proportional control and pulse control under low thermal load were analyzed by the model. The results show that under low thermal load, the pulse control is beneficial to strengthen the mix of gas and air, increase the combustion rate, prevent the accumulation of O2 on the surface of billet,decrease the oxidation burning loss of the billet, and improve the uniformity of distribution of heat flux to billet surface along the furnace width direction.

Key words: regenerative reheating furnace; low thermal load; numerical simulation; combustion strategy; proportional control; pulse control

轧钢加热炉的作用是根据钢坯加热工艺,在保证钢坯温度均匀性满足要求的前提下,将钢坯加热到一定温度,便于轧机将其轧制成一定形状和规格的产品[1-2]。加热炉是热轧生产线上的重要设备,同时也是能耗最高的设备[3],如何降低加热炉的能源消耗一直是冶金行业研究的热点问题。20世纪90年代,日本学者将高温空气燃烧技术[4-5]应用到加热炉,开发出蓄热式加热炉,大幅度降低了加热炉的能耗。蓄热式加热炉可将排烟温度从600 ℃降低至烟气露点温度附近,将常温空气预热至800~1 000 ℃。由于采用高温预热空气助燃,蓄热式加热炉可使用低热值燃料,炉内一般没有局部高温区域,NOx排放大幅度降低[6-7]。正是由于这些优点,蓄热式加热炉在冶金行业得到了广泛的应用[8]。蓄热式加热炉内的流动、燃烧、传热问题十分复杂,很难通过实验的方法对其进行全面的研究。随着数值求解技术的发展,数值模拟方法已经成为研究加热炉内热过程的主要研究方法之一[9-12]。近年来,不少学者对蓄热式加热炉的工作过程进行了数值模拟研究。宋小飞等[13]建立了空气单蓄热加热炉内流动、传热及燃烧过程数学模型,并对喷口角度、空气喷口长宽比进行了优化。杨湘等[14]利用流体力学计算软件CFX对蓄热式加热炉内的流场进行了数值模拟,模拟结果表明与传统加热炉相比,蓄热式加热炉内的流场分布更有利于燃料和助燃空气的混合,并且能提高钢坯沿长度方向的温度均匀性。OU等[15]通过建立蓄热式加热炉内流动与传热数学模型,并对蓄热式加热炉的燃烧控制方式进行了研究,研究结果表明,采用部分同侧换向的燃烧方式,有利于提高钢坯的加热温度及温度均匀性。ISHII等[16]对蓄热式加热炉的燃烧特性进行了数值模拟,通过模拟研究了炉膛几何结构和操作参数对炉内传输过程的影响。WANG等[17]建立了蓄热室加热炉内热过程数学模型,在模型中考虑了NOx的生成。以上学者主要研究了炉膛热负荷为满负荷时,炉内气体的流动和传热过程。在满负荷时,烧嘴的燃烧性能以及炉膛气流组织都处于设计的最佳状态,炉膛热效率最高。在某些情况下,如炉内板坯数量减少、板坯热送热装、待轧等,需要降低炉膛热负荷,此时,炉膛压力会发生波动,炉内气体流速、温度以及气氛浓度的分布规律也会发生变化。根据国内某钢厂的生产经验,在低负荷下,如果燃烧策略选择不当,会造成板坯氧化烧损增加,能耗增大等问题,因此,有必要开展低负荷下蓄热式加热炉内燃烧特性及燃烧策略的研究。本文作者以某公司蓄热式加热炉为研究对象,建立蓄热式加热炉内热过程数学模型,通过模型计算结果分析热负荷降低时,不同的燃烧控制策略下蓄热室加热炉内的燃烧特性。

1 模型的建立

1.1 物理模型

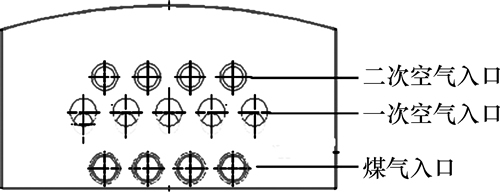

图1所示为某钢厂蓄热式加热炉,炉膛长×宽×高为10 600 mm×9 700 mm×2 030 mm,沿炉长方向分为4个段,分别是预热段、加热1段、加热2段和均热段。在炉膛两侧的侧墙上对称布置有28对蓄热烧嘴,烧嘴喷口截面如图2所示。煤气喷口倾斜向上,与水平面成5°夹角,一次风喷口倾斜向下,与水平面成10°夹角。燃料采用混合煤气,煤气成分如表1所示。烧嘴燃烧产生的烟气一部分用于加热蓄热体,经蓄热烧嘴排出,另一部分经烟道排出。加热炉内的板坯将炉子分为上、下2个部分,上、下炉膛空间的燃烧控制是相互独立的。为了减少计算量,本文以加热2段上部分的炉膛空间作为研究对象,并假设气体为不可压缩流体,流动与燃烧过程均为稳态过程。

图1 蓄热式加热炉结构示意图

Fig. 1 Schematic of regenerative reheating furnace

图2 蓄热烧嘴喷口结构示意图

Fig. 2 Schematic of nozzles of a burner used in regenerative reheating furnace

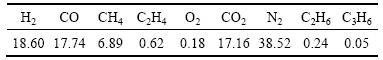

表1 混合煤气成分(质量分数)

Table 1 Fuel gas composition %

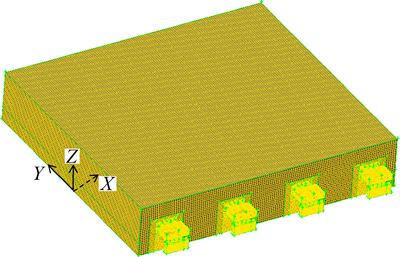

1.2 网格划分

网格划分采用Fluent前处理软件Gambit实现。由于烧嘴喷口直径小,结构复杂,采用分区结构化网格对计算区域进行网格划,并对烧嘴附近网格进行局部加密,计算区域网格数量为2 090 802,网格系统图如图3所示。为了验证网格的独立性,同时对网格数量为3 039 003的情况进行数值计算,计算结果表明:在2种情况下得到的烟气出口温度、速度的相对误差均小于1%,可认为在该条件下获得的解为网格无关解。

图3 计算区域网格系统图

Fig. 3 Computational grid of computational domain

1.3 数学模型

1.3.1 流动模型

为了考察湍流脉动的影响,一般采用Reynolds平均法,炉内烟气的湍流流动采用标准k-ε模型计算,近壁区的流动采用壁面函数法计算。湍流时均流动控制方程以及能量时均输运方程如下。

连续性方程为

(1)

(1)

动量方程为

(2)

(2)

k方程为

(3)

(3)

ε方程为

(4)

(4)

能量方程为

(5)

(5)

式中:ρ为气体密度,kg/m3;ui为x,y和z方向上的速度分量,m/s;p为压力,Pa;μ和μt分别为气体黏性系数和湍流黏性系数,Pa·s;μeff为等效黏性系数,表达式为μeff=μ+μt,Pa·s;k为湍动能,m2/s2;ε为湍动耗散率,m2/s3;Gk为由于平均速度梯度产生的湍动能,Pa/s;C1ε,C2ε,σk和σε为经验常数,分别为1.44,1.92,1.0和1.3;E为流体内能,J/kg;cp为定压比热容,J/(kg·K);λ为流体热导率,W/(m·K);Prt为湍动Prandtl数;S为源项,W/m3。

1.3.2 燃烧模型

煤气与空气的燃烧属于非预混燃烧,采用混合分数/PDF模型[18]计算。该模型不单独求解每个组分的输运方程,而是求解平均混合分数 以及混合分数均方值

以及混合分数均方值 的守恒方程。湍流对化学反应的影响通过概率密度函数(PDF)来描述。混合分数的定义为

的守恒方程。湍流对化学反应的影响通过概率密度函数(PDF)来描述。混合分数的定义为

(6)

(6)

式中:Zi为元素i的质量分数,下标ox表示氧化剂,fuel表示燃料。

平均混合分数守恒方程为

(7)

(7)

平均混合分数均方值守恒方程为

(8)

(8)

式中: ;v为速度矢量,m/s;σt,Cg和Cd为经验常数,分别为0.85,2.86和2.00。

;v为速度矢量,m/s;σt,Cg和Cd为经验常数,分别为0.85,2.86和2.00。

1.3.3 辐射模型

在不考虑散射的情况下,在位置r,沿传播方向s辐射传播方程(RTE)为

(9)

(9)

式中:r为位置向量;s为辐射传播方向向量;a为吸收系数;I为辐射强度。辐射换热的计算采用DO模型,吸收系数a采用灰气体加权和模型(WSGGM)[19]计算。

1.4 定解条件

空气、煤气入口采用速度入口边界条件,空气预热温度为1 273 K,煤气进口温度为573 K。烟气出口采用压力出口边界条件。钢坯表面采用无滑移边界条件,表面温度给定,并且沿炉长变化,表面黑度设为0.8。炉墙采用无滑移壁面边界条件,给定热流。

1.5 数值求解方法

本文采用流体力学计算软件Fluent对模型进行数值求解,控制方程的离散采用有限容积法,离散方程的格式采用隐式差分格式,对流项采用一阶迎风格式,压力与速度的耦合求解采用SIMPLE算法。

2 数值模拟结果分析

本文通过对比炉膛温度的计算值和测试值来验证模型的正确性。在测试过程中,将热电偶从炉膛加热2段炉顶的测量孔中插入炉膛内部来测量炉膛烟气温度。在炉膛实际热负荷为满负荷50%的情况下,热电偶的测量温度为1 170 ℃,相同工况下模型的计算值为1 177 ℃,两者吻合较好,说明本文建立的数学模型可以用于模拟加热炉内的热过程。

加热炉热负荷的控制方式通常有比例控制和脉冲控制。比例控制是通过调节每个烧嘴的煤气供应量来满足炉膛热负荷的需求。比例控制简单易操作,应用广泛,但当炉膛热负荷远离额定热负荷时,烧嘴的工作状态远离额定状态,导致烧嘴燃烧性能降低。脉冲控制是通过控制烧嘴的开启个数和燃烧时间来控制炉膛的煤气供应量。烧嘴一旦开启,就处于额定状态下工作,因此烧嘴的燃烧性能处于设计的最佳状态。脉冲控制加热均匀性好,能耗低,是一种前沿控制技术。本文模拟了炉膛热负荷为额定热负荷的25%时,2种控制方式下炉膛内的传热,流动以及燃烧过程。比例控制通过同时降低所有烧嘴的空、煤气流量至额定流量的25%来实现热负荷的降低,脉冲控制通过关闭3对烧嘴来实现热负荷的调节。

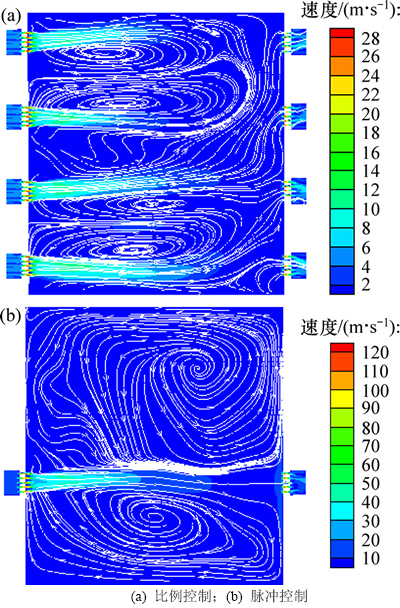

2.1 速度分布

图4所示为比例控制和脉冲控制2种情况下经过烧嘴中心水平截面上的速度分布。从图4可以看出:从烧嘴喷口喷出的气体沿流动方向速度逐渐降低,最终趋于均匀。由于喷口喷出的气流速度高,会形成低压区,卷吸周围的气体,形成漩涡。漩涡区的出现有利于烟气循环扰动。在比例控制下,由于气体喷入炉膛速度较小,在气体还未到达对面侧墙便开始回流,形成的漩涡区域较小,不利于沿炉膛宽度方向上气体混合均匀。在脉冲控制下,气体喷入炉膛动量大,形成的漩涡区的影响范围也较大,使得炉膛的气体整体混合较为均匀。

图4 经过烧嘴中心水平截面(z=990 mm)上的速度分布云图

Fig. 4 Velocity distribution on horizontal surface of z=990 mm

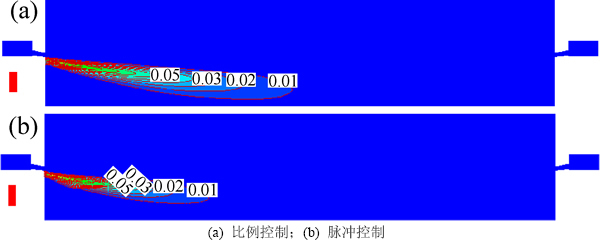

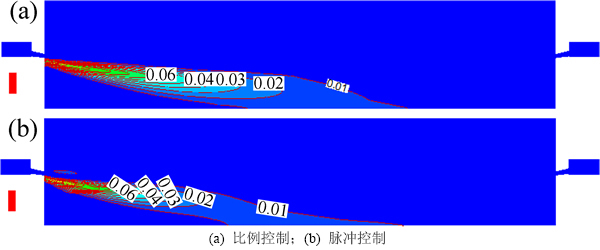

2.2 气氛浓度分布

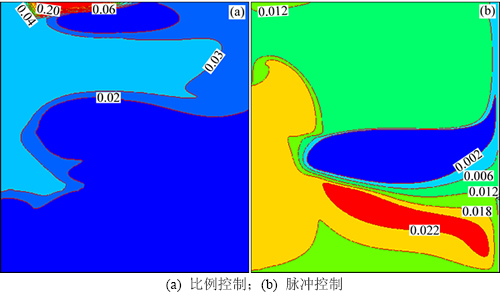

图5和图6所示分别为比例控制和脉冲控制2种情况下,加热炉内经过烧嘴中心竖直截面上H2和CO体积分数分布。从图5和图6可以看出:H2和CO体积分数沿着炉宽方向逐渐降低,脉冲控制下,CO体积分数降低得更加迅速。这是因为喷进炉膛的煤气和空气的燃烧属于非预混燃烧,燃烧速率受混合速率的控制,脉冲控制条件下,气体喷出速度大,对流体造成的扰流更强烈,有利于煤气与空气的混合。图7所示为钢坯表面O2体积分数分布。从图7可以看出:在比例控制下,在钢坯表面左上方区域内存在O2的聚集,氧气体积分数高达20%,容易造成这部分区域钢坯氧化烧损严重。在脉冲控制条件下,钢坯表面O2体积分数分布相对均匀,整体O2体积分数小于2.2%。

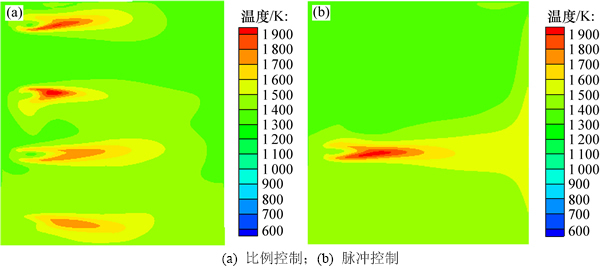

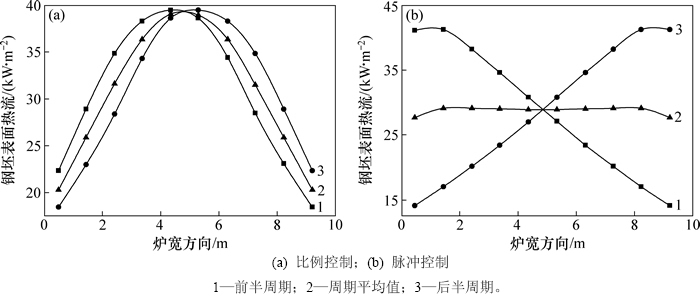

2.3 温度分布

图8所示为喷口下方水平截面上的温度分布。从图8可以看出:在比例控制下,炉膛火焰较短,炉膛两端温度较低。在脉冲控制下,火焰长度较长,有利于增强火焰的辐射能力。图9所示为在1个周期内比例控制和脉冲控制下钢坯表面热流沿炉宽方向的变化。从图9可以看出:在比例控制下,钢坯表面热流沿炉宽方向先升高后降低,在炉膛中部,钢坯表面热流最大,为4 kW/m2。脉冲控制下,在1个周期内,除端部外,钢坯表面热流沿炉宽方向近似为直线分布,端部热流略微降低,这是由火焰根部温度较低造成的。在1个换向周期内,钢坯表面平均热流沿炉宽方向分布均匀,热流平均值为3 kW/m2左右。

图5 经过烧嘴中心竖直截面(x=6.7 m)上H2体积分数分布云图

Fig. 5 H2 volume fraction distribution on vertical surface of x=6.7 m

图6 经过烧嘴中心竖直截面(x=6.7 m)上CO体积分数分布云图

Fig. 6 CO volume fraction distribution on vertical surface of x=6.7 m

图7 钢坯表面(z=0)O2体积分数分布云图

Fig. 7 O2 volume fraction distribution on surface of billet

图8 喷口下方水平截面(z=660 mm)上温度分布云图

Fig. 8 Temperature distribution on horizontal surface of z=660 mm

图9 钢坯表面热流沿炉宽的变化

Fig. 9 Variation of heat flux to billet surface along direction of furnace width

3 结论

1) 在比例控制下,由于气体喷入炉膛速度较小,在气体还未到达对面侧墙时便开始回流,形成的漩涡区域较小,不利于炉膛内煤气与空气的混合。在脉冲控制下,气体喷入炉膛动量大,形成的漩涡区较大,使得炉膛内气体整体混合较为均匀。

2) 在脉冲控制下,炉内煤气的燃烧更加迅速,钢坯表面没有O2聚集,O2体积分数整体小于2.2%。在比例控制下,钢坯表面局部区域O2体积分数高达20%。

3) 在比例控制下,钢坯表面平均热流沿炉宽方向分布不均匀,先升高后降低,在钢坯中间热流最大,为4 kW/m2。在脉冲控制下,在1个周期内,钢坯表面平均热流沿炉宽方向分布均匀,为3 kW/m2左右。

参考文献:

[1] 李宝宽, 齐凤升, 王芳, 等. 一种间歇式轧钢加热炉温度场的研究[J]. 东北大学学报(自然科学版), 2008, 29(5): 701-704.

LI Baokuan, QI Fengsheng, WANG Fang, et al. Study on temperature field in an intermittent reheating furnace[J]. Journal of Northeastern University (Natural Science), 2008, 29(5): 701-704.

[2] STEINBOECK A, WILD D, KIEFER T, et al. A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media[J]. International Journal of Heat and Mass Transfer, 2010, 53(25/26): 5933-5946.

[3] ZHANG C, ISHII T, SUGIYAMA S. Numerical modeling of the thermal performance of regenerative slab reheat furnaces[J]. Numerical Heat Transfer, Part A: Applications, 1997, 32(6): 613-631.

[4] KHOSHHAL A, RAHIMI M, ALSAIRAFI A A. Diluted air combustion and NOx emission in a HiTAC furnace[J]. Numerical Heat Transfer, Part A: Applications, 2011, 59(8): 633-651.

[5] RAFIDI N, BLASIAK W. Heat transfer characteristics of HiTAC heating furnace using regenerative burners[J]. Applied Thermal Engineering, 2006, 26(16): 2027-2034.

[6] 王涛, 高源, 陈连生, 等. 蓄热式加热炉燃烧氛围及其优缺点[J]. 河北联合大学学报(自然科学版), 2012, 34(1): 14-17.

WANG Tao, GAO Yuan, CHEN Liansheng, et al. The merits and demerits and combustion thermo-atmosphere of regenerative mill furnace[J]. Journal of Hebei United University (Natural Science Edition), 2012, 34(1): 14-17.

[7] KHOSHHAL A, RAHIMI M, ALSAIRAFI A A, et al. CFD study on influence of fuel temperature on NOx emission in a HiTAC furnace[J]. European Archives of Uto-Rhino- Laryngology, 2012, 269(6): 1629-1633.

[8] GU M Y, CHEN G, LIU X, et al. Numerical simulation of slab heating process in a regenerative walking beam reheating furnace[J]. International Journal of Heat and Mass Transfer, 2014, 76(6): 405-410.

[9] 欧俭平, 詹树华, 马爱纯, 等. 蓄热式连续推钢加热炉内钢坯加热过程动态数值模拟[J]. 过程工程学报, 2007, 7(2): 209-215.

OU Jianping, ZHAN Shuhua, MA Aichun, et al. Transient numerical simulation on the billet heating process of a regenerative reheating furnace[J]. The Chinese Journal of Process Engineering, 2007, 7(2): 209-215.

[10] WEI Z, LI X, XU L, et al. Optimization of operating parameters for low NOx emission in high-temperature air combustion[J]. Energy & Fuels, 2012, 26(5): 2821-2829.

[11] PEI Pei, WANG Qicheng, WU Daohong. Application and research on regenerative high temperature air combustion technology on low-rank coal pyrolysis[J]. Applied Energy, 2015, 156: 762-766.

[12] SU Y, CHEN C, SU A. Simulation of high temperature air combustion with modified eddy-break-up combustion model[J]. Energy Procedia, 2012, 14: 127-132.

[13] 宋小飞, 刘训良, 温治, 等. 空气单蓄热室状加热炉内传输过程的数值模拟[J]. 浙江大学学报(工学版), 2007, 41(10): 1768-1772.

SONG Xiaofei, LIU Xunliang, WEN Zhi, et al. Numerical simulation of transport process in air uni-regenerative chamber furnace[J]. Journal of Zhejiang University (Engineering Science), 2007, 41(10): 1768-1772.

[14] 杨湘, 程素森, 郭汉杰, 等. 蓄热式加热炉流场的数值模拟[J]. 北京科技大学学报, 2003, 25(2): 135-138.

YANG Xiang, CHENG Susen, GUO Hanjie, et al. Numerical simulation on the flow field of a regenerate reheating furnace[J]. Journal of University of Science and Technology Beijing, 2003, 25(2): 135-138.

[15] OU J, MA A, ZHAN S, et al. Dynamic simulation on effect of flame arrangement on thermal process of regenerative reheating furnace[J]. Journal of Central South University of Technology, 2007, 14(2): 243-247.

[16] ISHII T, ZHANG C, HINO Y. Numerical study of the performance of a regenerative furnace[J]. Heat Transfer Engineering, 2002, 23(4): 23-33.

[17] WANG A, CAI J, XIE G. Numerical simulation of combustion characteristics in high temperature air combustion furnace[J]. Journal of Iron and Steel Research, International, 2009, 16(2): 6-10.

[18] ORSINO S, WEBER R, BOLLETTINI U. Numerical simulation of combustion of natural gas with high-temperature air[J]. Combustion Science and Technology, 2001, 170(1): 1-34.

[19] JONG KIM O, GORE J P, VISKANTA R, et al. Prediction of self-absorption in opposed flow diffusion and partially premixed flames using a weighted sum of gray gases model (WSGGM)-based spectral model[J]. Numerical Heat Transfer, Part A: Applications, 2003, 44(4): 335-353.

(编辑 赵俊)

收稿日期:2015-06-13;修回日期:2015-08-20

基金项目(Foundation item):中央高校基本科研业务费专项资金资助项目(FRF-SD-12-007B)(Project(FRF-SD-12-007B) supported by the Fundamental Research Funds for the Central Universities)

通信作者:温治,博士,教授,从事热过程模化与控制研究;E-mail:wenzhi@me.ustb.edu.cn