文章编号:1004-0609(2015)-01-0241-09

高砷烟尘碱浸渣制备焦锑酸钠的新工艺

易 宇,石 靖,田庆华,郭学益

(中南大学 冶金与环境学院,长沙 410083)

摘 要:以高砷烟尘碱浸脱砷渣为研究对象,采用硫化钠浸出-空气氧化法选择性提取锑并制备焦锑酸钠产品。结果表明:在硫化钠浓度为100 g/L、氢氧化钠浓度为40 g/L、反应时间为3.0 h、液固质量比为5:1、反应温度为90 ℃、搅拌速度为400 r/min条件下,锑的浸出率为84.81 %;在空气流量为1.5 L/min、反应时间为9 h、反应温度为60 ℃、搅拌速度为300 r/min条件下,锑浸出液中锑沉淀率为98.51%;氧化沉淀产物经盐酸溶解、水解、转化后得到焦锑酸钠产品。硫化钠浸出-空气氧化工艺可以有效地分离提取高砷烟尘碱浸渣中的锑,并制备得到焦锑酸钠产品,实验过程简单、清洁,生产成本低,具有产业化前景。

关键词:高砷烟尘碱浸渣;硫化钠浸出;空气氧化;焦锑酸钠

中图分类号:TF09 文献标志码:A

Novel technology for preparation of sodium pyroantimonate from alkali leaching residue of high arsenic dust

YI Yu, SHI Jing, TIAN Qing-hua, GUO Xue-yi

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: A promising process, including sodium sulfide leaching and air oxidation, was proposed to prepare sodium pyroantimonate from alkali leaching residue of high arsenic dust. The results show that the leaching efficiency of antimony is 84.81% under the conditions of sodium sulfide concentration 100 g/L, sodium hydroxide concentration 40 g/L, time 3.0 h, mass ratio of liquid to solid 5.0, temperature 90 ℃, stirring speed 400 r/min. The antimony is precipitated from the leaching solution containing antimony. The precipitation efficiency of antimony is 98.51% under the conditions of air flow rate 1.5 L/min, time 3.0 h, temperature 60 ℃, stirring speed 300 r/min. The sodium pyroantimonate is obtained from oxidation precipitation containing antimony by the processes including HCl dissolution, hydrolyzation and conversion. The antimony can be effectively extracted by sodium sulfide leaching from alkali leaching residue of high arsenic dust, and sodium pyroantimonate product can be made by air oxidation. The experimental process is simple, clean and low cost, which is promising for industrialization in the future.

Key words: alkali leaching residue of high arsenic dust; sodium sulfide leaching; air oxidation; sodium pyroantimonate

脆硫铅锑矿在火法冶炼过程中产生大量含砷量较高的铅锑烟尘(简称高砷烟尘),含有大量的铅、锑、铟等有价金属,具有较高的经济价值。目前, 处理此类高砷烟尘的方法有两种: 一是返回冶金炉熔炼,二是堆存暂缓处理。采用前一种方法会增加返回的中间物料的数量, 降低冶金炉的熔炼能力和冶炼作业指 标[1],同时,砷还会在流程内逐渐积累,从而降低产品的品质。而采用后一种方法不仅需要占用堆场, 导致资源的极大浪费;同时,由于雨水冲刷、浸溶、微生物作用等原因,高砷烟尘中的可溶性砷盐、重金属离子被溶解,砷化合物、重金属离子、悬浮物随地表水移动对环境造成严重污染[2-3],对人群健康构成严重危害,对生命构成严重威胁[4]。在高砷烟尘堆置区,工厂工人及附近居民往往会发生慢性砷中毒,癌症发病率明显高于其它人群。开展高砷烟尘的综合处理,回收高砷烟尘中的铅锑等有价金属,使高砷烟尘资源化,降低高砷烟尘堆存量,对于治理和控制高砷烟尘污染具有极其重要的意义。

焦锑酸钠是一种重要的无机精细化工产品,其应用十分广泛,它可用作显像管玻璃、光学玻璃和其他高档玻璃的澄清剂和脱色剂, 纺织品和塑料制品的阻燃剂[5],优质搪瓷和陶瓷制品的乳白剂以及制造铸件用漆的不透明填料材料等,尤其在国内外电子行业受到越来越多的重视[6]。

目前,焦锑酸钠的生产主要分为火法生产工艺和湿法生产工艺。火法生产工艺主要是以金属锑或者三氧化二锑为原料,用硝酸钠在高温和碱性介质条件下进行氧化,然后经水洗、洗涤、过滤、烘干而得到产品[7]。湿法生产工艺主要以金属锑、氧化锑或者含锑物料等为原料,使用氢氧化钠、硫化钠或者盐酸等浸取原料中的锑[8-11],锑浸出液采用空气、双氧水或者氯气等进行氧化[12-15],然后再经净化、水解、中和而得到产品[16-19]。与火法生产工艺相比, 湿法生产工艺具有反应进行彻底、转化效率高、能耗较低、工艺条件易控制、产品质量稳定和生产设备简单等优点。目前,工业上焦锑酸钠的生产主要采用双氧水氧化法和空气氧化法。双氧水氧化法具有生产工艺简单、流程短、产品质量好、收率高等优点,但是该方法需要使用杂质含量较低的锑白作为原料,且双氧水的价格比较高,导致其生产成本比较高。空气氧化法从锑精矿中提取制取焦锑酸钠的生产工艺具有生产工艺简单、设备简单、原辅材料价格低、生产成本低等优点,其存在的缺点主要是氧化时间比较长,产品中Sb3+含量偏高。

本文作者在前期研究中采用碱性浸出对高砷烟尘进行了脱砷研究,脱砷后碱浸渣中的主要成分为铅和锑,本研究中采用硫化钠浸出-空气直接氧化法从高砷烟尘碱浸渣中选择性提取锑并制备焦锑酸钠产品,为高砷烟尘的资源化和综合利用探索可行工艺。

1 实验

1.1 原料

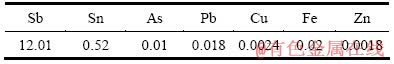

本研究所用原料为高砷烟尘碱浸脱砷后的浸出渣(以下简称高砷烟尘碱浸渣),于105 ℃鼓风干燥12 h,破碎至200 μm。高砷烟尘取自广西某铅锌冶炼厂铜浮渣鼓风炉熔炼烟尘,高砷烟尘碱浸渣的化学成分以及XRD谱分别见表1和图1。在高砷烟尘碱浸脱砷研究中采用的优化实验条件为:氢氧化钠与高砷烟尘质量比为0.5、硫化钠与高砷烟尘的质量比为0.2、硫磺与高砷烟尘质量比为0.1、液固比为5、浸出温度为90 ℃、浸出时间为2 h、搅拌速度为400 r/min。

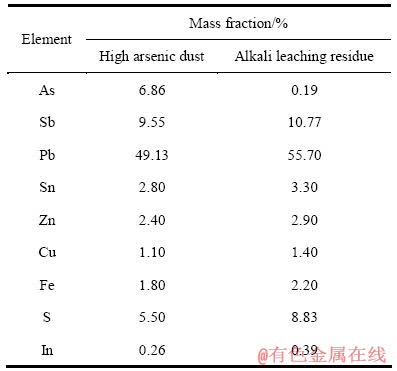

表1 高砷烟尘及碱浸渣的化学成分

Table 1 Chemical component of high arsenic dust and alkali leaching residue

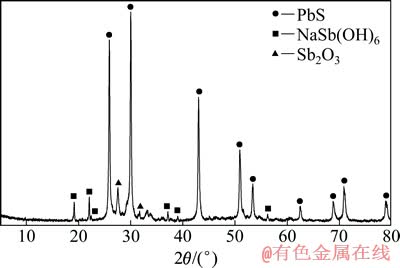

图1 高砷烟尘碱浸渣的XRD谱

Fig. 1 XRD patterns of alkali leaching residue of high arsenic dust

从表1可以看出:高砷烟尘碱浸渣中除砷以外,其他元素相比于高砷烟尘均有不同程度的富集,碱浸渣中含量较高的元素有铅、锑、锡、锌、铜、铁和硫。从图1中可以看到:碱浸渣中含量最高的元素铅的物相为PbS,锑的存在物相为Sb2O3和NaSb(OH)6,其他元素因为含量较低而未能产生衍射峰。

1.2 实验原理

在高砷烟尘碱浸渣硫化钠浸出-空气氧化制备焦锑酸钠过程中,三氧化二锑和水合锑酸钠等难溶于水的锑化物,在硫化钠碱性溶液中能转化成硫代锑酸盐而较易溶于热液中;硫化铅的溶度积很小(Ksp=9.3×10-28),在硫化钠碱性溶液中游离铅离子浓度接近于0。因此, 采用硫化钠碱性浸出体系可以选 择性地浸出碱浸渣中的锑,而将铅抑制在浸出渣中,从而实现碱浸渣中锑与铅的有效分离。浸出液中的硫代锑酸钠与硫代亚锑酸钠能被空气中的氧气氧化为锑酸钠,然后水解生成水合锑酸钠,即焦锑酸钠,硫被氧化成硫代硫酸钠。

高砷烟尘碱浸渣硫化钠浸出过程和锑浸出液空气氧化过程的主要化学反应如下所示:

NaSb(OH)6+4Na2S=Na3SbS4+6NaOH (1)

Sb2O3+6Na2S+3H2O=2Na3SbS3+6NaOH (2)

Na3SbS4+4O2+2NaOH+2H2O=NaSb(OH)6+2Na2S2O3 (3)

2Na3SbS3+7O2+2NaOH+5H2O=2NaSb(OH)6+3Na2S2O3 (4)

1.3 实验方法

高砷烟尘碱浸渣硫化钠浸出:称取一定量的高砷烟尘碱浸渣置于500 mL四口烧瓶中,然后加入一定量配制好的硫化钠碱性浸出剂,将四口烧瓶置于恒温水浴锅内,开启搅拌和冷却水,在设定温度下搅拌浸出。浸出结束后抽滤,用少量水直接在漏斗内喷淋洗涤浸出渣,浸出渣干燥、称取质量;浸出液和洗涤液合并成混合液,记录体积,取适量混合液氧化、酸化、定容。

锑浸出液空气氧化:将浸出条件实验得到的锑浸出液混合,搅拌均匀,备用。每次实验量取300 mL浸出液加入500 mL四口烧瓶中,将四口烧瓶置于恒温水浴锅内,开启搅拌和冷却水,启动小型空气压缩机向浸出液中鼓入空气,使用流量计控制空气流量,在设定温度下搅拌氧化。氧化结束后抽滤,用少量水直接在漏斗内喷淋洗涤焦锑酸钠结晶,焦锑酸钠结晶干燥、称取质量;氧化后液和洗涤液合并成混合液,记录体积,取适量混合液氧化、酸化、定容。

砷和锑使用AFS-2202E原子荧光光度计进行分析,其他元素使用WFX-130B原子吸收分光光度计进行分析。锑的浸出率按渣计算,锑的氧化沉淀率按溶液计算。

2 结果与分析

2.1 高砷烟尘碱浸渣硫化钠浸出

2.1.1 硫化钠浓度对锑浸出率的影响

在高砷烟尘碱浸渣为60 g、氢氧化钠浓度为30 g/L、反应温度为98 ℃、反应时间为2 h、液固比为5:1、搅拌速度为400 r/min的条件下,考察了硫化钠浓度对浸出过程锑浸出率的影响,其结果如图2所示。

图2 硫化钠浓度对锑浸出率的影响

Fig. 2 Effect of sodium sulfide concentration on leaching efficiency of Sb

从图2可知,锑浸出率随着硫化钠浓度的增加而增加,浸出渣中锑含量随着硫化钠含量的增加首先急剧降低,然后缓慢降低直至趋于稳定。在60 g/L之前,锑浸出率随着硫化钠浓度的增加急剧增加;而在60 g/L之后,锑浸出率的增加幅度逐渐降低;当硫化钠浓度增加至100 g/L之后,锑浸出率趋近稳定,这个远远高于理论计算所需的浓度(50 g/L)。一般来说,氧化锑、锑酸钠等锑的氧化物料相对于硫化锑要难于溶解于硫化钠溶液中,它们只有先与硫化钠反应生成硫代亚锑酸钠和硫代锑酸钠才能进入溶液,因此,需要过量的硫化钠才能实现良好的溶解,同时浸出液中需要一定量的硫化钠来防止硫代锑酸盐的水解。综合考虑浸出成本和浸出率,选择硫化钠浓度为100 g/L比较合适。

2.1.2 氢氧化钠浓度对浸出率的影响

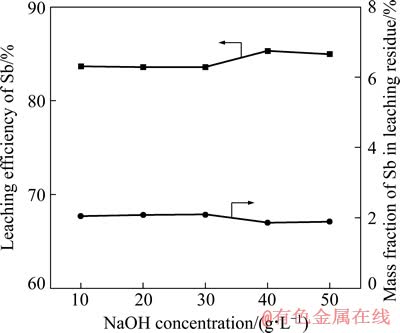

在高砷烟尘碱浸渣为60 g、硫化钠浓度为100 g/L、反应温度为98 ℃、反应时间为2 h、液固质量比为5:1、搅拌速度为400 r/min的条件下,考察了氢氧化钠浓度对浸出过程锑浸出率的影响,其实验结果如图3所示。

从图3可知,锑浸出率随着氢氧化钠浓度的增加先增加后减小,在40 g/L时锑浸出率达到最高;浸出渣中锑的含量随着氢氧化钠浓度的增加逐渐降低。硫化钠在水溶液中容易水解生成氢氧化钠、硫氢化钠和硫化氢,因此,在浸出体系中加入氢氧化钠可以有效抑制硫化钠的水解,同时,当硫化钠用量不足时,氢氧化钠能够部分代替硫化钠溶解锑。综合考虑,选择氢氧化钠浓度为40 g/L比较合适。

图3 氢氧化钠浓度对锑浸出率的影响

Fig. 3 Effect of sodium hydroxide concentration on leaching efficiency of Sb

2.1.3 反应时间对浸出率的影响

在高砷烟尘碱浸渣为60 g、硫化钠浓度为100 g/L、氢氧化钠浓度为40 g/L、反应温度为98 ℃、液固比为5:1、搅拌速度为400 r/min的条件下,考察了反应时间对浸出过程锑浸出率的影响,实验结果如图4所示。

从图4可知,锑浸出率随着反应时间的延长先增加然后降低,浸出渣中锑含量随着反应时间的延长先降低然后增加,一般来说碱性浸出需要的反应时间比较长,但随着反应时间的进一步延长,浸出液中的硫代锑酸钠长时间与空气接触被氧化成锑酸钠而进入浸出渣,从而导致锑浸出率的降低。综合考虑,选择反应时间为3 h比较合适。

图4 反应时间对锑浸出率的影响

Fig. 4 Effect of reaction time on leaching efficiency of Sb

2.1.4 液固比对浸出率的影响

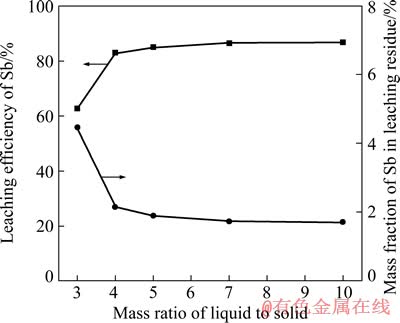

在硫化钠浓度为100 g/L、氢氧化钠浓度为40 g/L、反应温度为98 ℃、反应时间为3 h、搅拌速度为400 r/min的条件下,考察了液固比对浸出过程锑浸出率的影响,其结果如图5所示。

图5 液固比对锑浸出率的影响

Fig. 5 Effect of mass ratio of liquid to solid on leaching efficiency of Sb

从图5可知,锑浸出率随着液固比的增加而增加,在液固比为4.0之前,锑浸出率增加的幅度很大;在液固比为4.0之后,锑浸出率增加比较缓慢。随着液固比的增加,浸出平衡时浸出液中过剩的硫化钠浓度增加,促使锑浸出反应向右进行,锑浸出增加;但是随着液固比的增加,硫化钠的用量亦大幅度增加。综合考虑,液固比选择5.0比较合适。

2.1.5 反应温度对浸出率的影响

在高砷烟尘碱浸渣为60 g、硫化钠浓度为100 g/L、氢氧化钠浓度为40 g/L、液固质量比为5、反应时间为3 h、搅拌速度为400 r/min的条件下,考察了反应温度对浸出过程锑浸出率的影响,其结果如图6所示。

从图6可知,锑浸出率随着反应温度的增加而增加,浸出渣中锑的含量随着反应温度的增加而降低,当反应温度升高至90 ℃以后,锑浸出率趋于稳定。综合考虑,选择反应温度为90 ℃比较合适。

图6 反应温度对锑浸出率的影响

Fig. 6 Effect of reaction temperature on leaching efficiency of Sb

2.1.6 优化实验

通过以上的系列实验研究,可得出高砷烟尘碱浸渣硫化钠浸出的优化工艺条件:硫化钠浓度为100 g/L、氢氧化钠浓度为40 g/L、反应时间为3.0 h、液固质量比为5:1、反应温度为90 ℃、搅拌速为400 r/min。在此优化工艺条件,进行了3次实验,实验结果如表3和表4所列。浸出渣的化学成分如表5所列,浸出渣的XRD谱如图7所示。

由表3和4可以看出:在优化实验条件下,锑的平均浸出率为84.81%,锡的平均浸出率为10.52%,砷的平均浸出率为6.72%,铅、锌、铜、铁、铟等元素的浸出率都低于1 %,铅、锌、铜、铁、铟等元素几乎全部进入浸出渣中;锑浸出液中锡的浓度为0.5 g/L左右,铅、锌、铜、铁、铟、砷等元素的浓度均小于0.1 g/L,锑浸出液中杂质浓度低,可以直接制备焦锑酸钠产品。从表5可以看出:浸出渣中铅、锡、锌、铜、铟等有价金属元素都得到不同程度的富集。从图7中仅只能看到PbS的衍射峰,对比高砷烟尘碱浸渣的XRD谱可以看出,在硫浸渣的XRD谱中锑的物相Sb2O3和NaSb(OH)6的衍射峰消失了,衍射峰的变化说明了锑在硫化钠浸出过程中被浸出。

从优化实验结果可以看出:硫化钠浸出能高效选择性地分离提取高砷烟尘碱浸渣中的锑,硫浸渣中铅的主要物相为硫化铅,浸出渣既可以作为铅冶炼的原料返回铅厂回收铅,亦可以回收铟之后再返回铅厂处理。

表3 高砷烟尘碱浸渣硫化钠浸出优化实验结果

Table 3 Optimal experiment results of alkali leaching residue of high arsenic dust by sodium sulfide leaching

表4 高砷烟尘碱浸渣硫化钠浸出优化实验中各元素的浸出率

Table 4 Leaching efficiencies of main elements in sodium sulfide leaching experiments of alkali leaching residue of high arsenic dust under optimal experiment

表5 浸出渣的化学成分

Table 5 Chemical component of leaching residue (mass fraction, %)

2.2 锑浸出液空气氧化

将高砷烟尘碱浸渣硫化钠浸出实验得到的浸出液混合、搅拌均匀后,作为空气氧化制备焦锑酸钠的原料,其化学成分见表6。

图7 硫化钠浸出渣的XRD谱

Fig. 7 XRD pattern of sodium sulfide leaching residue

表6 浸出液的化学成分

Table 6 Chemical component of leaching liquor (g/L)

2.2.1 反应温度对沉锑效果的影响

理论上,反应温度直接影响反应的速度。一般来说,低温时的反应速度较慢,当温度升高时,分子的热运动速度加快,分子的碰撞概率增加,有利于反应过程的进行。在浸出液为300 mL、空气流量为5.5 L/min、反应时间为11 h、搅拌速度为300 r/min的条件下,考察了反应温度对空气氧化沉锑效果的影响,以确定合适的反应温度。实验结果如图8 所示。

从图8可知,氧化沉淀过程中锑沉淀率随着反应温度的升高而增加,沉淀后液中锑的浓度随着反应温度的升高而降低。硫代锑酸盐的空气氧气反应是吸热反应,因而随着反应温度的升高,反应平衡向正方向移动,锑沉淀率增加。在50 ℃之前,沉淀后液中锑的浓度随着反应温度的增加而急剧降低,锑沉淀率随着反应温度的增加而急剧增加;而在50 ℃之后,锑沉淀率增加的幅度逐渐降低,锑趋于完全沉淀。实验发现,在空气鼓入溶液的前期,产生的泡沫比较多,泡沫消解的速度跟反应温度呈正比,当反应温度较低时,泡沫消解的速度过慢,影响实验的正常进行。综合考虑,反应温度选择60 ℃比较合适。

图8 反应温度对沉锑效果的影响

Fig. 8 Effect of reaction temperature on precipitation efficiency of Sb

2.2.2 反应时间对沉锑效果的影响

在浸出液为300 mL、空气流量为6.0 L/min、反应温度为60 ℃、搅拌速度为300 r/min的条件下,考察了反应时间对空气氧化沉锑效果的影响,实验结果如图9所示。

图9 反应时间对沉锑效果的影响

Fig. 9 Effect of reaction time on precipitation efficiency of Sb

从图9可知,在空气氧化过程中,锑沉淀率随着反应时间的增加而增加,溶液中锑的浓度随着反应时间的增加而降低。在9 h以前,锑沉淀率随着反应时间的增加而快速增加;在9 h以后,由于溶液中锑离子基本上被氧化沉淀完全,锑沉淀率趋于稳定。进一步延长反应时间,锑沉淀率维持不变。综合考虑,反应时间选择9 h比较合适。

2.2.3 空气流量对沉锑效果的影响

在浸出液为300 mL、反应时间为9 h、反应温度为60 ℃、搅拌速度为300 r/min的条件下,考察了空气流量对空气氧化沉锑效果的影响,实验结果如图10所示。

图10 空气流量对沉锑效果的影响

Fig. 10 Effect of air flow on precipitation efficiency of Sb

从图10可知,在空气氧化过程中,锑沉淀率随着空气流量的增加而降低,沉淀后液中锑的浓度随着空气流量的增加而增加。空气氧化硫代锑酸盐反应属于气液反应体系,反应过程一般包括以下步骤:空气中的氧气向气-液界面上扩散,氧气在界面上溶解,溶解氧与液相中硫代锑酸钠和硫代亚锑酸钠发生反应等。空气通入浸出液后形成大量的气泡,通过搅拌的作用分散到整个溶液体系中,气泡穿过液体的运动速度主要取决于推动气泡上升的浮力与阻碍这种运动的黏滞力和形状阻力。随着空气流量的增加,单位时间内进入浸出液中的空气量增加,气泡受到的浮力增加,空气从溶液中逸出的速率增加,导致气泡来不及与硫代锑酸钠发生反应就迅速穿过浸出液进入空气中,这样就形成了锑沉淀率随着空气流量的增加反而降低的现象。同时,随着空气流量的增加,空气夹带走的水汽量增加,沉淀后溶液的体积随之减小,导致沉淀后溶液中锑浓度增加的幅度加大。综合考虑,空气流量选择1.5 L/min比较合适。

通过空气氧化沉锑条件实验得出优化的工艺条件:空气流量为1.5 L/min、反应时间为9 h、反应温度为60 ℃、搅拌速度为300 r/min。在此优化条件下,锑沉淀率为98.51 %,沉淀后液中锑浓度为0.18 g/L。

锑浸出液中的硫在空气氧化沉淀焦锑酸钠过程中大部分被氧化成硫代锑酸钠,部分被氧化成亚硫酸钠和硫酸钠,可以通过添加硫磺将溶液中的亚硫酸钠转化成硫代硫酸钠[20],然后蒸发浓缩,冷却结晶得到硫代硫酸钠产品[15]。

2.3 粗焦锑酸钠的精制及产品表征

空气氧化制备的粗焦锑酸钠外观为灰色粉末,杂质含量较高。将制备的粗焦锑酸钠用50% 盐酸溶液溶解、过滤,滤去不溶物质,得到清澈的氯化锑溶液;将氯化锑溶液缓慢加入到5倍体积的纯水中,在搅拌下水解30 min后过滤,锑水解产物用1%的盐酸洗涤一次;锑水解产物加水调浆,在搅拌下缓慢加入30%的NaOH溶液,在80 ℃下转化反应30 min后过滤,焦锑酸钠分别用5% NaOH溶液和纯水洗涤一次,再置于烘箱内在90 ℃下干燥12 h。精制后焦锑酸钠的外观为白色粉末,其化学成分如表7所列。

由表7可知,精制后焦锑酸钠中还有少量锡未除尽,其他杂质的含量都比较低;锑的含量为47.9 %、钠的含量为8.54 %,都比理论值稍低(其理论值分别为49.34 %和9.31 %),分析其原因有可能是焦锑酸钠中的吸附水未全部脱除。

表7 焦锑酸钠的化学成分

Table 7 Chemical component of sodium pyroantimonate (mass fraction, %)

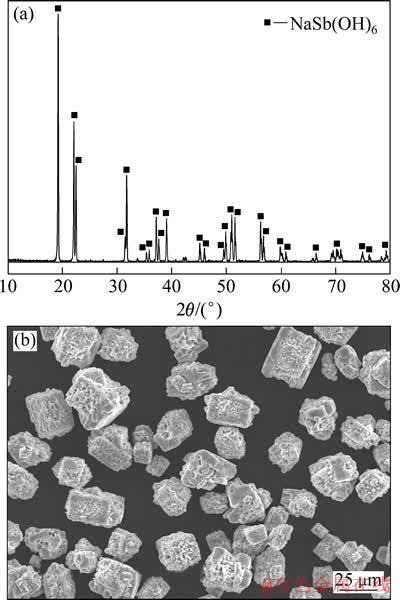

图11 焦锑酸钠的XRD谱和SEM像

Fig. 11 XRD pattern (a) and SEM image (b) of sodium pyroantimonate

图11所示为精制后焦锑酸钠的XRD谱和SEM像。从图11中可知,精制后得到的产品为纯净的单一物相,晶型完整的NaSb(OH)6;精制后的焦锑酸钠粉末为单分散、外形规整的颗粒,产品的粒度小于50 μm。

3 结论

1) 通过考察高砷烟尘碱浸渣硫化钠浸出过程中各因素对浸出过程的影响,确定了高砷烟尘碱浸渣硫化钠浸锑的最佳工艺条件:硫化钠浓度为100g/L、氢氧化钠浓度为40 g/L、反应时间为3 h、液固质量比为5:1、反应温度为90 ℃、搅拌速度为400 r/min。在此条件下,锑的浸出率为84.81 %,浸出渣中锑的含量为1.94 %,实现了锑的高效选择性浸出。

2) 通过考察锑浸出液空气氧化过程中各因素对锑沉淀率的影响,确定了空气氧化沉锑的最佳工艺条件:空气流量为1.5 L/min、反应时间为9 h、反应温度为60 ℃、搅拌速度为300 r/min。在此条件下,沉淀后液中锑浓度为0.18 g/L,锑沉淀率为98.51 %。

3) 精制后得到的产品为纯净的单一物相、晶型完整的NaSb(OH)6;精制后的焦锑酸钠粉末为单分散、外形规整的颗粒,产品的粒度小于50 μm。

4) 采用硫化钠浸出-空气氧化工艺,可以有效地分离提取高砷烟尘碱浸渣中的锑,并制备得到焦锑酸钠产品,浸出渣的主要成分为PbS,可以作为铅冶炼的原料返回铅厂回收铅,亦可以回收铟之后再返回铅厂处理。

REFERENCES

[1] 张荣良, 史宝良, 史爱波, 鞠洪博, 姜大伟, 王 伟, 颜 平. 从含锑烟灰中湿法提取立方晶型三氧化二锑[J]. 有色金属: 冶炼部分, 2011, 5: 12-15.

ZHANG Rong-liang, SHI Bao-liang, SHI Ai-bo, JU Hong-bo, JIANG Da-wei, WANG Wei, YAN Ping. Extraction of cubic crystal antimony trioxide from dusts containing antimony[J]. Nonferrous Metals: Extractive Metallurgy, 2011, 5: 12-15.

[2] 李 玲, 张国平, 刘 虹, 项 萌, 魏晓飞. 广西大厂多金属矿区河流中Sb和As的迁移及环境影响[J]. 环境科学研究, 2009, 22(6): 682-687.

LI Ling, ZHANG Guo-ping, LIU Hong, XIANG Meng, WEI Xiao-fei. Antimony and arsenic migration and environmental impacts on river draining in the Dachang multi-metalliferous mine area in Guangxi, China[J]. Research of Environmental Sciences, 2009, 22(6): 682-687.

[3] 胡 斌, 姚金江, 王智友, 周坐东. 含砷烟灰脱砷现状[J]. 湖南有色金属, 2013, 29(5): 41-44.

HU Bin, YAO Jin-jiang, WANG Zhi-you, ZHOU Zuo-dong. The review of arsenic removal technologies of arsenic ashes[J]. Hunan Nonferrous Metals, 2013, 29(5): 41-44.

[4] 凌 敏, 刘起展. 砷所致表观遗传改变与致癌作用的研究进展[J]. 中国地方病学杂质, 2012, 31(1): 107-110.

LING Min, LIU Qi-zhan. Arsenic due to epigenetic changes and carcinogenesis studies progress[J]. Chinese Journal of Endemiology, 2012, 31(1): 107-110.

[5] 张 亨. 无机锑系阻燃剂[J]. 上海塑料, 2012, 157(1): 6-10.

ZHANG Heng. Inorganic antimony series fire retardants[J]. Shanghai Plastics, 2012, 157(1): 6-10.

[6] 杜新玲. 焦锑酸钠生产工艺研究[J]. 湖南有色金属, 2008, 24(5): 24-26.

DU Xin-ling. Research on the production technology of sodium pyroantimonate[J]. Hunan Nonferrous Metals, 2008, 24(5): 24-26

[7] 赵天成. 锑冶金[M]. 长沙: 中南工业大学出版社, 1987: 358-462.

ZHAO Tian-cheng. Metallurgy of antimony[M]. Changsha: Central South University of Technology Press, 1987: 358-462.

[8] YANG Tian-zu, LAI Qiong-lin, TANG Jian-jun, CHU Guang. Precipitation of antimony from the solution of sodium thioantimonite by air oxidation in the presence of catalytic agents[J]. Journal of Central South University of Technology, 2002, 9(2): 107-111.

[9] 陈进中, 杨天足. 高锑低银铅阳极泥控电氯化浸出[J]. 中南大学学报: 自然科学版, 2010, 41(1): 44-49.

CHEN Jin-zhong, YANG Tian-zhu. Chlorination-leaching of lead anode slime with high antimony and low silver contents at controlled potential[J]. Journal of Central South University: Science and Technology, 2010, 41(1): 44-49.

[10] 郑雅杰, 滕 浩, 白 猛. 以高砷精炼铋烟尘为原料制备高纯氯氧化锑[J]. 中南大学学报: 自然科学版, 2011, 42(6): 1548-1554.

ZHENG Ya-jie, TENG Hao, BAI Meng. Preparation of high purity antimony oxychloride from high arsenic refined bismuth dust[J]. Journal of Central South University: Science and Technology, 2011, 42(6): 1548-1554.

[11] 陈进中, 曹华珍, 郑国渠, 支 波, 杨天足. 高锑低银类铅阳极泥制备五氯化锑新工艺[J]. 中国有色金属学报, 2008, 18(11): 2094-2099.

CHEN Jin-zhong, CAO Hua-zhen, ZHENG Guo-qu, ZHI Bo, YANG Tian-zu. Novel technology for preparation of SbCl5 from lead anode slime with high antimony and low silver content[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 2094-2099.

[12] 徐忠敏, 叶树峰, 庄宇凯. 含锑难处理金精矿加压氧化法制备焦锑酸钠的工艺研究[J]. 黄金, 2013, 34(11): 48-52.

XU Zhong-min, YE Shu-feng, ZHUANG Yu-kai. Process research on making sodium pyroantimonate from antimony-containing refractory gold concentrates using pressure oxidation method[J]. Gold, 2013, 34(11): 48-52.

[13] 刘鹊鸣, 单桃云, 金承永. 氧化锑矿碱法制备锑酸钠工艺探讨[J]. 湖南有色金属, 2014, 30(3): 31-33.

LIU Que-ming, SHAN Tao-yun, JIN Cheng-yong. Study of preparation of sodium antimonate from antimony oxidized ore with alkaline process[J]. Hunan Nonferrous Metals, 2014, 30(3): 31-33.

[14] 谢兆凤, 杨天足, 刘伟锋, 黄臻高. 高脆硫铅锑矿碱性熔炼渣的综合利用工艺研究[J]. 矿冶工程, 2010, 30(3): 77-81.

XIE Zhao-feng, YANG Tian-zu, LIU Wei-feng, HUANG Zhen-gao. Technical study on comprehensively utilizing alkaline smelting slag of Jamesonite[J]. Mining and Metallurgical Engineering, 2010, 30(3): 77-81.

[15] 王志明, 杨天足, 王卫东, 刘伟锋, 江名喜. 从锑精矿制备焦锑酸钠的工业试验[J]. 湖南冶金, 2005, 33(3): 17-20.

WANG Zhi-ming, YANG Tian-zu, WANG Wei-dong, LIU Wei-feng, JIANG Min-xi. Trial production of sodium pyroantimonate from antimony concentrate[J]. Hunan Metallurgy, 2005, 33(3): 17-20.

[16] 郑国渠, 黄荣斌, 潘 勇, 郑遗凡. 含氟三氯化锑溶液中和水解产物的物相[J]. 中国有色金属学报, 2005, 15(8): 1278-1282.

ZHENG Guo-qu, HUANG Rong-bin, PAN Yong, ZHENG Yi-fan. Phases of antimony trichloride solution containing fluorine neutralization-hydrolysis products[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1278-1282.

[17] 廖亚龙, 刘中华. 辉锑矿氯化浸出制取焦锑酸钠的工艺研究[J]. 有色金属, 2007, 59(2): 46-49.

LIAO Ya-long, LIU Zhong-hua. Investigation on technology of sodium antimonate synthesis from antimony concentrate by chloridizing leaching process technology[J]. Non-ferrous Metals, 2007, 59(2): 46-49.

[18] 郑雅杰, 洪 波. 漂浮阳极泥富集金银及回收锑铋工艺[J]. 中南大学学报: 自然科学版, 2011, 42(8): 2221-2226.

ZHENG Ya-jie, HONG Bo. Enrichment of Au and Ag and recovery of Sb and Bi from floating anode slime[J]. Journal of Central South University: Science and Technology, 2011, 42(8): 2221-2226.

[19] 陈白珍, 王中溪, 周竹生, 胡干武, 仇勇海. 二次砷碱渣清洁化生产技术工业试验[J]. 矿冶工程, 2007, 27(2): 47-49.

CHEN Bai-zhen, WANG Zhong-xi, ZHOU Zhu-sheng, HU Gan-wu, QIU Yong-hai. Commercial test of cleanly production technology of second arsenic alkali residue[J]. Mining and Metallurgical Engineering, 2007, 27(2): 47-49.

[20] 杨天足, 刘伟锋, 赖琼林, 江名喜, 王志明, 王卫东. 空气氧化法生产焦锑酸钠的氧化后液中砷和锑的脱除[J]. 中南大学学报: 自然科学版, 2005, 36(4): 576-581.

YANG Tian-zu, LIU Wei-feng, LAI Qiong-lin, JIANG Ming-xi, WANG Zhi-ming , WANG Wei-dong. Removal of arsenic and antimony from oxidated solution of sodium thioantimonite production by air oxidation[J]. Journal of Central South University: Science and Technology, 2005, 36(4): 576-581.

(编辑 李艳红)

基金项目:广西科技攻关计划资助项目(桂科攻12300001-2)

收稿日期:2014-07-13;修订日期:2014-10-20

通信作者:郭学益,教授,博士;电话:0731-88877863;E-mail:xyguo@csu.edu.cn