文章编号:1004-0609(2011)09-2105-06

Ce对F102镍基自熔合金的微合金化作用

尚丽娟1, 高 华2, 于兴福1

(1.沈阳工业大学 材料科学与工程学院,沈阳 110178;2. 辽阳技师学院 机械系,辽阳 111000)

摘 要:采用热喷焊工艺在20号钢基体上制备F102及含0.5%Ce的F102镍基自熔合金涂层,通过组织分析和性能测试,研究Ce对F102合金的变质作用及机理。 结果表明:两种合金涂层均由γ-Ni、Ni3B、CrB、Ni3Si、(Cr, Fe)23C6和(Cr, Fe)7C3相组成,在连续γ-Ni基体上弥散分布棒状CrB、粒状(Cr, Fe)7C3、小球状Ni3Si及枝状混合共晶化合物,但Ce使组织明显细化。该合金与20号钢相比,其硬度和耐磨性分别提高3.8倍和3.2倍;与F102合金相比,其硬度和耐磨性分别提高14.8%和18%,同时该合金的耐蚀性明显增强。其原因是Ce富集于液固界面,降低Fe-Cr-C共晶转变温度,细化合金显微组织。合金中的Ce参与Fe-Cr-C系统反应,是改变共晶转变温度的主要原因。

关键词:镍基自熔合金;稀土;涂层;共晶温度;微合金化

中图分类号:TG113 文献标志码:A

Microalloying role of Ce on F102 Ni-based self-fluxing alloy

SHANG Li-juan1, GAO Hua2, YU Xing-fu1

(1. School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110178, China;

2. Department of Mechanical Engineering, Liaoyang Technician College, Liaoyang 111000, China)

Abstract: The coatings of F102 and F102 Ni-based self-fluxing alloy with 0.5%Ce were made on 20# steel by fire spray welding. The metamorphism and mechanism of Ce on F102 alloy were studied based on the microstructure analysis and properties testing. The results show that two kinds of alloy coatings consist of γ-Ni, Ni3B, CrB, Ni3Si, (Cr, Fe)23C6 and (Cr, Fe)7C3, the columnar CrB, granular (Cr, Fe)7C3, small spherical Ni3Si and some dendritic eutectic mixtures are well distributed in the γ-Ni matrix, but the grains in the alloy after adding Ce are much finer than before. The average hardness and wearing resistance of the alloy coating increase by 3.8 and 3.2 times, respectively, compared with those of 20# steel, and also increase by 14.8% and 18%, respectively, compared with those of F102 alloy. Moreover, the corrosion resistance performance of the alloy is increased significantly. The reason is that the element Ce enriched in the liquid-solid interface decreases the eutectic transforming temperature, thus the microtructure of the alloy are refined. The element Ce existing in the alloy participates in the reaction of Fe-Cr-C system, which is the main reason why the eutectic transforming temperature is changed.

Key words: Ni-based self-fluxing alloy; rare earths; coating; eutectic temperature; micro alloying

用火焰喷焊技术制备的涂层可靠性高,能成倍提高金属材料的耐磨性,因而在多种材料的表面强化和修复中获得广泛应用[1-2]。镍基自熔合金以其优良的综合性能及较高的性价比成为火焰喷焊包括其他典型表面熔覆工艺的主要材料[3-5]。近年来,人们十分重视用稀土改性镍基自熔合金,以期获得性能更佳的涂层[6-9],但对稀土的变质机理尚缺乏认识。本文作者以F102合金为研究对象,在合金中加入微量的稀土元素Ce得到F102-Ce合金,进而借助氧-乙炔焰喷焊工艺在20号钢基体上获得两种合金涂层,通过对合金层组织和性能的比较分析,探讨Ce对F102合金的改性作用及实质。

1 实验

将20号钢加工成15 mm×50 mm×4.5 mm规格作为母材,喷焊材料为F102镍基自熔合金粉末(成分见表1,粒度为50 μm)。取适量的Ce,按(质量分数)0.5%的比例加入F102合金,经充分搅拌得到混合粉末,称F102-Ce合金。母材经粗化后,用2H-2/h型喷焊炬进行喷焊处理。条件如下:氧气压力p(O2)=0.3 MPa,乙炔压力p(C2H2)=0.045 MPa,喷距L=250 mm,涂层厚度H=0.6~0.8 mm。

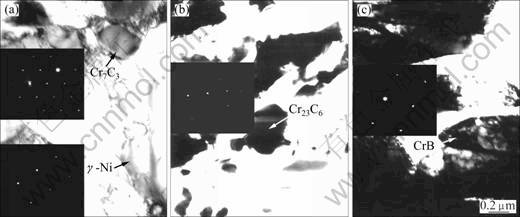

表1 F102镍基自熔合金粉末的化学成分

Table 1 Chemical composition of F102 Ni-based self-fluxing alloys (mass fraction, %)

借助S-3400N型扫描电镜观察组织形貌,用EPM-810型电子探针和D/max-2500pc型X射线衍射仪分别进行微区成分测试及物相分析,用岛津DT-30型示差热分析仪测定合金的DTA曲线,条件如下:Al2O3坩埚,误差±50 μV,氩气保护,加热速度为10 ℃/min,加热温度区间为20~1 250 ℃。此外,用JEM-2000FXⅡ型透射电镜进行微观组织观察及相结构测试。

用71型显微硬度计测定涂层硬度分布(质量载荷为0.1 kg)。用失重法在MLD-10型动载磨料磨损实验机上进行耐磨性实验,磨料为d=1 mm石英砂 (m(SiO2)≥96%),时间为4 h,条件如下:转速为200 r/min,用10-4 g感量的分析天平称量。

采用EGQG公司325电化学测试系统测定了合金涂层在1 mol/L的H2SO4水溶液中的阳极极化曲线。测试条件:扫描速度10 mV/min,扫描范围相对于开路电路-150 ~ 1 300 mV,测试时,先将试样放置溶液中至开路电位稳定(5 min内上下波动不超过1 mV)后,开始测量。

2 结果与分析

2.1 合金组织及相组成

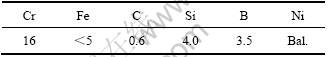

F102和F102-Ce合金涂层的XRD谱,如图1所示。由图1可知,两种合金组成相均包括γ-Ni、Ni3B、CrB、(Cr, Fe)23C6、Ni3Si和Cr7C3。

图1 F102 (a)和F102-Ce (b)合金涂层的XRD谱

Fig.1 XRD patterns of F102 (a) and F102-Ce (b) alloy coatings

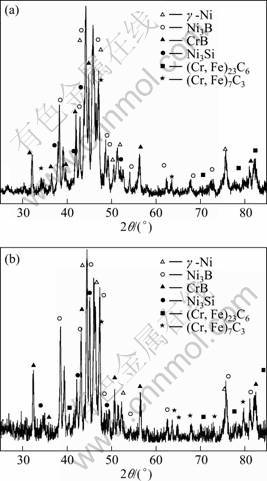

图2(a)和(b)所示分别为F102和F102-Ce合金的组织形貌。由图2可见,合金中加入Ce以后组织形态没有发生变化,但各相均得到明显细化。F102-Ce合金的局部高倍组织形貌如图3所示,由图3可见,该合金组织是在连续的基体相上分布着棒状、粒状、小球状以及细枝状相。

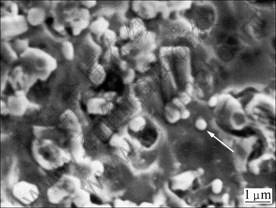

在TEM下对主要相进行观察及电子衍射分析显示:基体相为γ-Ni,块状相为Cr7C3,如图4(a) 所示;不规则的粒状相为Cr23C6(见图4(b));棒状相则为CrB(见图4(c))。 经统计测试,CrB的径向尺寸为1.0~1.5 μm,长度为3.0~5.0 μm,Cr7C3和Cr23C6的径向尺寸分别为0.5~1.0和0.4~0.5 μm;借助EPMA测试小球状相成分(摩尔分数,%)(62.71Ni+Fe12.26+ 0.54Cr+24.49Si)表明该相为Ni3Si(如图3中箭头所示)。至于枝状组织可认为是由γ-Ni与Ni3B组成的共晶混合物。

图2 F102和F102-Ce合金的组织形貌

Fig.2 Microstructures of F102 (a) and F102-Ce (b) alloy coatings

2.2 合金的性能

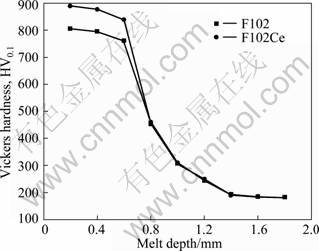

喷焊时发现F102-Ce合金的浸润性明显优于F102合金,这与Ce的界面吸附,降低合金液体的界面张力有关。硬度测试结果(见图5)显示,F102-Ce涂层的平均硬度为867 HV,与基体20号钢的硬度(181 HV)相比提高了3.8倍,比F102合金涂层的平均硬度(755 HV)提高了14.8%。

图3 F102-Ce合金的局部组织形貌

Fig.3 Local microstructure of F102-Ce alloy coating

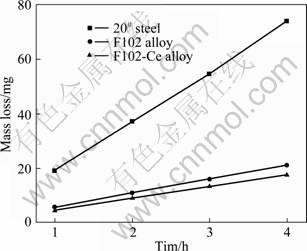

动载荷磨料磨损试验结果如图6所示。由图6可见,F102合金层的耐磨性与20号钢的相比提高了2.5倍,而F102-Ce合金的耐磨性与20号钢的相比提高了3.2倍,比F102合金的提高了18%。

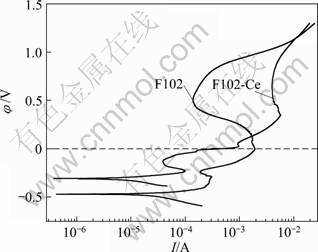

测试阳极极化曲线如图7所示。由图7可见,F102-Ce合金层比 F102合金层具有更低的腐蚀电流及较高的腐蚀电位,表明Ce在强化合金的同时也改善了合金耐蚀性。

2.3 讨论

在F102合金中,Si和B是造渣元素,剩余的Si除少量形成Ni3Si外,基本溶于γ-Ni。同样,B的实际含量也远低于理论值,Fe与Cr晶格类型相同,两者可部分相互取代,同时还能溶于γ-Ni。从F102合金的成分及组成相看,可参考Ni-Cr-B和Fe-Cr-C两个合金系统。

图4 F102-Ce合金组成相的TEM像及衍射斑

Fig. 4 TEM images and electron diffraction pattern of phases in F102-Ce alloy coatings: (a) Cr7C3, γ-Ni; (b) Cr23C6; (c) CrB

图5 合金涂层的硬度分布

Fig.5 Hardness distribution of alloy coatings

图6 磨损损失与磨损时间关系

Fig.6 Relationship between wear mass loss and wear time

图7 合金涂层的阳极极化曲线

Fig.7 Polarization curves of alloy coatings

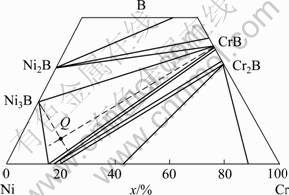

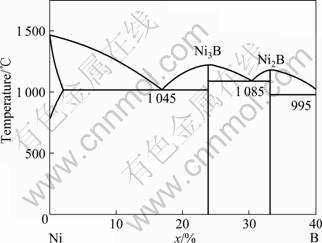

Cr与C结合能力强,根据生成的(Cr, Fe)23C6和Cr7C3相,参照1 150 ℃和850 ℃Fe-Cr-C三元合金相图[10],可以认为M(Cr, Fe):C约为10:1,则Cr的余量为12%。假设B由于造渣反应等损失1/2,于是在Ni-Cr-B三元系统中,各元素的摩尔分数比x(Ni)?x(Cr)?x(B)=75.0?14.4?10.6,由Ni-Cr-B三元合金相图[11](见图8)可知,本合金系统应落在γ-Ni、CrB与Ni3B三相区内约Q处,根据杠杆定律可计算出γ-Ni、CrB、Ni3B三相的摩尔分数大致分别为67%、10%和23%。此外,由Ni-B相图[12] (见图9)可以断定Ni3B是与γ-Ni以共晶形式存在的。

图8 Ni-Cr-B三元合金相图

Fig.8 Phase-diagram of Ni, Cr and B ternary alloys (1 000 ℃)

图9 Ni-B二元合金相图

Fig.9 Phase diagram of Ni and B binary alloys

Cr、Si、Fe在γ-Ni中起到了固溶强化的作用。同时,Cr、Si还能提高合金耐蚀性。Ni3B、CrB和(Cr, Fe)23C6起硬质相强化作用。

Ce为轻稀土元素,与Ni原子半径差超过15%,故在γ- Ni中的溶解度甚微。 根据液体界面前方溶质分布表达式[13]:

(1)

(1)

(2)

(2)

式中:c0 为合金平均成分;K0为溶质分配系数;R为常数;X为液相到固、液界面的距离;D0为扩散系数。稀土的扩散系数及溶质分配系数极小,当X=0时有:

(3)

(3)

由此可知,在固相表面稀土浓度显著增大。由液固界面前方液体溶质浓度cL随X的变化率

(4)

(4)

可以证明,cL随X的增加急剧下降,即在固液界面上富集Ce,从而降低界面活性,阻碍析出相长大,由此使组织细化。

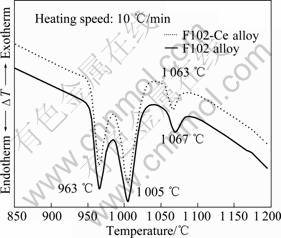

测试DTA曲线结果显示,两种合金的γ-Ni与Ni及Ni3B与Ni2B共晶转变温度几乎相同,均低于理论值,说明该共晶温度的变化主要是受Si的影响,而没有受到Ce的影响。然而,Ce的加入却明显降低了合金中Fe-Cr-C的共晶温度,使之由原来的1 067 ℃下降到1 063 ℃,如图10所示,这与Ce对F314合金的作用相同。分析认为,产生这一现象的原因是Ce在Cr中有较高的固溶度[12],从而可以部分替代Cr参与Fe-Cr-C系统反应。对F314合金的研究结果[14]也证明了这一点。

热喷焊与其它加热情况不同,可根据熔体的状态灵活掌握。材料不同,加热温度不同。对于F102-Ce合金而言,因其熔点低、粘度小、浸润性好,可在相对较低的温度下成型,因此硬质相生长受到抑制,并减少基体的稀释,这是合金组织得到细化的又一原因。

图10 合金的DTA曲线

Fig.10 DTA-curve of F102 and F102-Ce alloys

综上所述,Ce富集于固液界面,降低了合金的共晶转变温度,使组织细化、分布均匀,从而提高合金的硬度及耐磨性。由于界面合金元素增多,界面电阻增大,同时稀土可提高表面氧化膜的韧性和致密 性[15-16],因此,合金的耐蚀性能得到改善。故与F102合金相比,F102-Ce合金表现了更加优良的综合性能。

3 结论

1) 采用O2-C2H2焰喷焊工艺在20号钢上制备了F102及含0.5%Ce 的F102-Ce合金层,两者均由γ-Ni、Ni3B、CrB、Ni3Si、(Cr, Fe)23C6和(Cr, Fe)7C3相组成,其组织是在连续的γ-Ni基体上弥散分布棒状CrB、粒状(Cr, Fe)7C3、小球状Ni3Si以及枝状共晶混合物,但F102-Ce合金组织更加细小弥散。

2) 与基体20号钢及F102合金相比,F102-Ce合金的平均硬度(867 HV)分别提高3.8倍和14.8%,耐磨性分别提高3.2倍和18%,同时耐腐蚀性能明显增强。

3) Ce富集于固液界面,可降低Fe-Cr-C的共晶转变温度,使涂层在较低温度下成型,从而减少基体稀释,抑制组织粗化,是改善合金性能的重要因素。

4) Ce可部分替代Cr参与合金系统反应,是其改变合金相变温度的主要原因。

致谢:

本作者特别感谢沈阳工业大学董晓强副教授在实验中给予的大力支持和无私帮助。

REFERENCES

[1] XIE G Q, LI S. Densification of gas atomized Ni-based metallic glassy powders by spark plasma sintering[J]. Materials Transactions,2009, 50(6): 1273-1278.

[2] HAN H, BABA S, KITAGAWA H, SUILIK S A, HASEZAIKI K, KATO T, ARAKAWA K, NODA Y. Plasma-carburization of nickel-based self-fluxing alloy [J]. Vacuum, 2005, 78(1): 27-32.

[3] ZHANG Y M, HIDA M, SAKAKIBARA A, TAKEMOTO Y. Effect of WC addition on microstructures of laser melted Ni-based alloy powder [J]. Surface and Coatings Technology, 2003(2): 384-387.

[4] SIDHU T S, MALIK A, PRAKASH S, AGRAWAL R D. Oxidation and hot corrosion resistance of HVOF WC-NiCrFeSiB coating on Ni- and Fe-based superalloys at 800 ℃[J]. Journal of Thermal Spray Technology, 2007, 16(5/6): 844-848.

[5] SIDHU T S, PRAKASH S, AGRAWAL R D. Characterizations and hot corrosion resistance of Cr3C2-NiCr coating on Ni-base superalloys in an aggressive environment [J]. Journal of Thermal Spray Technology, 2006, 15(4): 811-816.

[6] WANG K L, ZHANG Q B, SUN M L. Rare earth elements modification of laser-clad nickel-based alloy coatings [J]. Applied Surface Science, 2001, 174(3/4): 191-200.

[7] XU P Q, GONG H Y, XU G X, HE J P, YU Z S. Study on microstructure and properties of Ni-based alloy/Y2O3-deposited metals by laser cladding [J]. Journal of Materials Science, 2008, 43(5): 1559-1567.

[8] XUAN T P, MIN D. Effect of rare earth on microstructure of vacuum melting Ni-based serf-fluxing alloy coatings [J]. Journal of Rare Earths, 2004, 22(4): 517-520.

[9] ZHANG Z Y, WANG Z P, LIANG B. Microstructure and dry-sliding wear behavior of thermal sprayed and fused Ni-based coatings with the addition of La2O3 [J]. Tribology Letters, 2010, 37(2): 141-148.

[10] 侯曾寿, 陶岚琴. 实用三元合金相图[M]. 上海: 上海科技出版社, 1983: 89, 69.

HOU Zeng-shou, TAO Lan-qin. Utility ternary alloys phase-diagram [M]. Shanghai: Shanghai Science and Technology Press, 1983: 89, 69.

[11] 尚丽娟, 朱荆璞, 潭朝鑫. 激光熔覆镍基和钴基合金的研究[J]. 中国激光, 1990, 12(8): 26-29.

SHANG Li-juan, ZHU Jing-pu, TANG Chao-xin. Investigation on laser-deposition and the self-melted Co-base and Ni-base alloys[J]. Chinese Journal of Lasers, 1990, 12(8): 26-29.

[12] 虞觉奇, 易文质, 陈邦迪. 二元合金状态图集[M]. 上海: 上海科技出版社, 1987: 203.

YU Jue-qi, YI Wen-zhi, CHEN Bang-di. Binary alloys phase-diagram hand book[M]. Shanghai: Shanghai Science and Technology Press, 1987: 203.

[13] 谢希文. 材料科学基础[M]. 北京: 北京航空航天大学出版社, 1999: 34-35.

XIE Xi-wen. Fundamentals of materials science[M]. Beijing: Beijing University of Aeronautics & Astronautics Press, 1999: 34-35.

[14] SANG L J. Formation of gradient coating of Fe-based alloy with rare earths by plasma surfacing[J]. Acta Metallurgica Sinica, 2004, 17(5), 713-718.

[15] 王延庆, 杨栅森. 镧在高温合金中的作用[J]. 国外金属材料, 1984, 12(2): 26-29.

WANG Yan-qing. YANG Shan-sen. Action of La on superalloys[J]. Overseas Metal Materials, 1984,12(2): 26-29.

[16] 岳丽杰, 王龙妹, 朴秀玉, 徐成海, 朱京希. 10PCuRE钢的耐大气腐蚀性及耐蚀机理[J]. 钢铁研究学报, 2006, 18(1): 34-38.

YUE Li-jie, WANG Long-mei, PIAO Xiu-yu, XU Cheng-hai, ZHU Jing-xi. Weather resistance and its mechanism for 10PCuRE steel[J]. Journal of Iron and Steel Research, 2006, 18(1): 34-38.

(编辑 何学锋)

基金项目:辽宁省自然科学基金资助项目(20141301)

收稿日期:2010-09-25;修订日期:2011-01-24

通信作者:尚丽娟,教授,博士;电话:024-25496315;E-mail: shang_lij@163.com