废弃电路板环氧树脂真空热解及产物分析

丘克强,吴 倩,湛志华

(中南大学 化学化工学院,湖南 长沙,410083)

摘 要:在真空条件下,应用程序升温的管式炉反应器对废弃电路板中环氧树脂热解规律进行研究,考察不同的热解终温、升温速率、真空度(压力)及保温时间等各种因素对产物产率的影响。此外,利用傅里叶红外(FT-IR)和气质联用(GC/MS)技术对热解油产物进行表征分析。实验结果表明:温度对产物产率的影响最大,升温速率、真空度及保温时间对热解产物产率也有重要影响。选择适当的热解温度(400~550 ℃)、升温速率(15~20 ℃/min)、真空度(压力15 kPa)及保温时间(30 min)有利于提高热解液体产品的产率;热解油的主要成分是酚类物质,其总含量为84.08%,其中,含溴化合物含量为15.34%。

关键词:真空热解;废弃电路板;环氧树脂;气相色谱-质谱;红外光谱

中图分类号:X705 文献标识码:A 文章编号:1672-7207(2009)05-1209-07

Vacuum pyrolysis characteristics of waste printed circuit

boards epoxy resin and analysis of liquid products

QIU Ke-qiang, WU Qian, ZHAN Zhi-hua

(School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: The effect of pyrolysis conditions on the products yield of epoxy resin in waste printed circuit boards was investigated using the vacuum pyrolysis oven heated by temperature controller. The effects of temperature, heating rate, pressure and reaction time on the yield of vacuum pyrolysis production were analyzed. In addition, the compositions of liquid products were analyzed by FT-IR and GC/MS. The experimental results show that temperature is the key factor in the vacuum pyrolysis process. At the same time, heating rate, pressure and rest time cannot be neglected. The optimisation conditions for the liquid yield from the vacuum pyrolysis process are as follows: temperature 400-550 ℃, heating rate 15-20 ℃/min, pressure 15 kPa, and reaction time 30 min. The main composition in the product yield is Phenolic organic compounds with the total of 84.08%, while considerable amount of brominated products is up to 15.34%, which lowers the value of liquid products.

Key words: vacuum pyrolysis; waste printed circuit boards; epoxy resin; liquid products; gas chromato-graph/-mass spectrometry(GC/MS); fourier transform infrared spectroscopy(FT-IR)

随着电子产品更新换代频率加快,废弃电子电器产品已成为继城市生活垃圾和工业垃圾之后增长最快且难处理的固体废弃物,而由此产生的废弃电路板数量也迅速增加。电路板(PCB) 是一种热固性复合材料,由覆铜薄板压制而成,主要成分为环氧树脂、玻璃纤维、铜箔、金属(Sn, Pb, Fe, Ni等)等[1]。如何有效处理废弃电路板,同时避免二次污染已成为当前研究的热点问题之一[2-6]。热解技术处理废弃电路板,不仅能够实现树脂、玻璃纤维等非金属成分的资源化,而且有利于回收其中的金属。人们对热解技术处理废弃电路板进行了大量研究[7-11],主要是在非真空热解条件下,对废弃电路板热解特性、机理及动力学方面进行探讨[12-13]。从反应原理上看,降低压力,即在真空条件下,有利于分子发生裂解,因而有利于热解反应,且有利于一次热解反应得到的挥发物迅速从颗粒内部和表面离开,从而强化气相的挥发过程,更容易实现“闪速热解”,大大限制二次裂解及再聚合反应发生,特别是降低卤化氢发生二次反应生成卤代烃的几率,提高热解油的产率,降低固体和气体产品的产率。真空热解已成功应用于废聚氯乙烯(PVC)、汽车废物等方面的回收[14-15],而其在处理废弃电路板方面的应用有待于进一步研究。

由于环氧树脂及其固化物的性能特点如力学性能、固化收缩率、电性能等明显比其他类型树脂的 优[18],故电路板基板的粘结剂主要选用环氧树脂。废弃电路板中环氧树脂热解而得到的热解油既可以作为燃油使用,能量利用效率比直接燃烧高得多,同时,由于热解油的主要成分为苯酚和异丙基苯酚,又可提取高附加值物质作为化工原料,因此,环氧树脂的回收也是废弃电路板资源化全面回收过程中至关重要的一个环节。本文作者采用程序升温的小型立式热裂解反应器对废弃电路板环氧树脂在真空条件下进行热解实验,考查热解终温,升温速率,真空度(压力)以及保温时间等因素对热解产物产率的影响,探讨真空热解废弃电路板环氧树脂规律,并在此基础上对热解油成分进行分析表征,以便为真空热解技术处理废弃电路板的技术应用提供一定的依据。

1 实 验

1.1 实验样品及其数据分析

真空热解所用废弃电路板由长沙煤炭研究所电路板厂提供。电路板类型为FR4光板(即除去废弃电路板表面的器件、各种金属及铜覆面,从而保证了样品的各部分组成的均一性),切割成长×宽为1 cm×1 cm的碎片。原料的元素分析和工业分析见表1及表2。

表1 试验原料元素分析

Table 1 Ultimate analysis of feedstock

表2 试验原料的工业分析

Table 2 Proximate analysis of feedstock

1.2 实验装置与实验方法

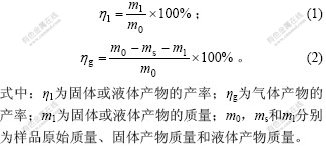

实验装置如图1所示。真空热解在小型立式热裂解反应器中进行,采用程序升温电阻炉加热,最高温度可达1 000 ℃。每次实验加入废弃电路板样品约 20 g,在一定压力下,以设定的升温速率加热到实验设定温度,保温一定时间,真空热解气体经过三级冷凝后进入酸性气体吸附器,不凝气中的溴化氢、二氧化碳等气体被吸附下来,净化后的气体经真空泵进入气体收集处理系统。在每次实验中,通过称重可得到真空热解废弃电路板的液体和固体产物的质量,样品原始质量与固体、液体产物质量的差值可视为气体产物的产量。真空热解产物产率按式(1)和(2)计算。

图1 真空热解实验示意图

Fig.1 Schematic diagram of tubular vacuum pyrolysis reactor

热解油成分的红外分析试验在AVATAR-360傅里叶变换红外光谱仪(美国Nicolet Magna 公司生产)上进行,样品直接涂在KBr压片上,测定波长范围为400~ 4 000 cm-1,扫描时间为32 s,分辨率为4 cm-1。GC/MS分析在Trace GC/Polaris Q GC/MSn气-质联用仪(美国Thermo-Finnigan公司生产)上进行。色谱条件如下:DB-1 30 mm×0.25 mm×0.25 μm弹性石英毛细管柱,柱始温为60 ℃,保持2 min。升温速率为5 ℃/min,柱终温250 ℃,保持20 min,进样口温度为260 ℃,流量为1 mL/min,采用Splitless进样方式,不分流。质谱条件:EI源电子能量为70 eV,电子倍增器电压为1.42 V,离子源温度为200 ℃,扫描间隔为0.43 s,质荷比扫描范围为40~650。

2 结果与讨论

热解是一个受传热、传质与化学反应共同影响的过程,温度、升温速率、真空度、保温时间等因素都会影响产物产量及成分分布。

2.1 热解终温温度的影响

不同的热解终温决定了物料不同热解机理及过程,从而决定了不同的气体、液体和固体产品的产率分布。

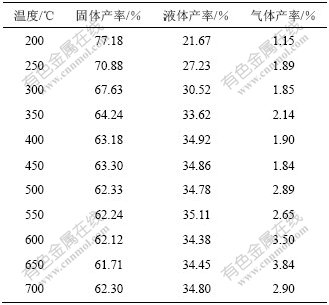

在加热速率为10 ℃/min,压力为5 kPa条件下,控制不同的终温温度,并保温30 min,研究温度对废弃电路板热解的影响。由表3可看出,当热解终温较低时,废弃电路板的热解油产率也较低。在400 ℃开始热解油产率与气体产率之和与工业分析中挥发分含量基本接近,仅仅略微低于挥发分含量,其原因可能是废弃电路板中有机物并不能够完全裂解为气体或液体,挥发分中的一小部分有机物在热解过程中转化为焦炭或在焦炭上结积或积炭。故热解终温为400 ℃时热解基本完全。由表3可知,400~550 ℃时液体产率保持在35%左右,而200~300 ℃时为20%~30%,可知热解终温对热解产品产率的影响较大。在较低的温度下热解液体产率较低,有大量固体残余,这是因为低温下只发生了部分热解。而随着热解终温的提高,环氧树脂等高分子聚合物容易断裂为长链化合物,从而得到更多的液体产物,但如果温度过高,气体在抽出反应器之前会部分发生二次裂解反应,长链进一步裂解成短链,使得气体产物增多,液体产率则减少。因此,真空热解环氧树脂类型的废弃电路板终温为400~550 ℃比较合适。

表3 真空热解终温对热解产品产率的影响

Table 3 Effect of vacuum pyrolysis temperature on production

2.2 升温速率的影响

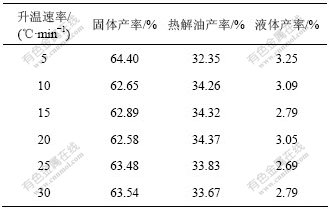

在控制热解终温为400 ℃,保温时间为30 min,压力为15 kPa的实验条件下,控制不同的升温速率,考查各状态产物产率变化。表4所示为不同升温速率对真空热解油的影响。由表4可以看出,在真空条件下,随着升温速率的提高,热解油的产率先升高后下降,升温速率为20 ℃/min时热解油产率最高,为34.37%。

表4 不同升温速率下的热解油产率

Table 4 Production distribution under different heating rate

在相同的热解终温下,升温速率越低,反应过程中二次反应的发生几率大,挥发分析出量越多。这是因为当升温速率较低时,样品在某一特定温度下的停留时间增加,有机物中较弱的氧桥键和苯环上的侧链断裂发生几率增加,形成自由基,使得液体产品产率减少。而随着升温速率的提高,样品开始分解的温度略有增加,这是因为随着升温速率的增加,热量传递延时,使样品在某一温度下的停留时间减少,导致样品在某一温度下的分解量减少。故提高升温速率可提高热解液体产品产率。但若升温速率持续升高,反应器内在很短时间内可达较高的温度,可能会导致热解出的短链热解油有机物重新聚合为长链聚合物,成为焦炭,使固体产率提高,也有可能因为短时间内达到较高的温度,使环氧树脂的Br对高分子碳链进行加成和脱HBr反应,从而促进缩合和环化反应的发生,有利于形成牢固的碳骨架结构,导致固体产率提高。因此,真空热解废弃电路板也应该选择适中的升温速率。

2.3 真空度的影响

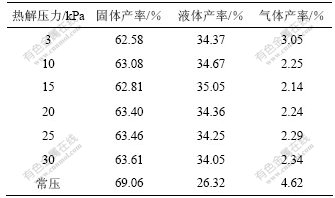

在加热速率为20 ℃/min,热解终温为400 ℃,保温时间为30 min不变的实验条件下,控制不同的真空度及在氮气作保护气的氛围下进行常压热解。真空热解废弃电路板时,合适的真空度对热解油产率是有利的,可提高热解油的产率,但并不是真空度越高越好。由表5可见,当真空度为15 kPa左右时,热解油产率最高。

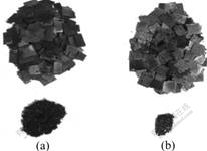

当真空度不够大时,不利于热解过程产生挥发分及时离开反应区,导致部分热解油发生二次裂解,由表5可知,在较低真空度下,随着真空度的提高,固体产率几乎不变,而气体产率下降。热解油产率的提高是通过减少不凝气体产物而实现的。在氮气气氛下,废弃电路板的常压热解所得液体产率明显低于真空条件下的液体产率,固体产率明显提高,这是由于常压下热解气不能及时离开反应管,致使热解气发生二次反应一方面重新结焦成焦炭,从而使热解残余固体产率增高。由图2可明显看出,在氮气条件下,所得固体残余物中,焦炭产量明显提高。另一方面,热解气发生二次裂解生成相对小分子质量气体,使得不凝气含量升高。当真空度过高时,热解油产率有所下降。其原因是在真空泵的作用下,热解过程中的挥发分过快离开冷凝管得不到充分冷凝,并且在高真空下产物的沸点降低,冷凝强度却没有提高,从而导致热解油产率有所下降。关于较高真空度对热解油产率的影响,需进一步进行实验研究。

表5 不同真空度下热解废弃电路板产率

Table 5 Effects of different pressures on production

图2 氮气条件(a)和真空条件(b)下的废弃电路板热解残余物

Fig.2 Pyrolytic residue of waste printed circuit boards in (a)nitrogen (b)vacuum

2.4 保温时间的影响

在控制加热速率为20 ℃/min,裂解终温为400 ℃,压力为5 kPa的实验条件下,控制不同的保温时间,考查各条件下所得产物产率的变化。

理论上,在一定裂解终温下保温时间越久,废弃电路板热解得越充分,在真空条件下,所得热解油产率越高,而实验情况并非如此。由表6可知,当保温时间为30 min时,热解油产率最大。随着保温时间的延长,热解油产率呈现下降趋势,且保温时间越长,产率下降越明显。其原因可能是:由于产生的热解油挥发性较强,而冷凝强度有限,致使二次挥发的热解油得不到冷凝。因此,随着保温时间的增长,挥发的热解油含量比因为保温时间延长而增加的热解油产率更多,从而导致总产率下降。

表6 不同保温时间时热解油产量

Table 6 Production distribution after different reaction times

3 热解油的红外光谱分析

对热解油进行FT-IR分析,不同条件下真空热解油的红外光谱如图3所示。

从图3可知,不同条件下的红外谱图基本相似,表明在不同条件下所得热解油中有机物的组成基本 相似,故官能团基本相似。在不同条件下所得热解油均在3 000~3 500 cm-1之间出现1个宽而强的吸收峰,为酚羟基的O—H伸缩振动峰,水分的O—H及N—H的伸缩振动吸收峰。2 850 cm-1和2 964 cm-1处的峰对应亚甲基和甲基的C—H伸缩振动,由谱图可知,该峰仅为2个小峰,表明热解油中长链烷烃的含量较少。1 710 cm-1处的峰为酯羰基吸收峰,表明酯羰基存在。同样,由于峰较小,可知热解油中酯类物质含量较少。1 470~1 600 cm-1之间4个吸收峰对应苯环的骨架C=C伸缩振动,1 220~1 370 cm-1之间2个吸收峰对应酚中O—H的弯曲振动,由于所处化学环境不同,导致吸收峰不同程度的向低波偏移。1 177 cm-1附近的峰对应双酚A分子中的(CH3—C—CH3)结构与对异丙基结构(CH3—C—CH3)的变角振动。990~1 100cm-1之间的小吸收峰对应脂肪C—N的伸缩振动,产生于环氧树脂交联剂的裂解产物。690~890 cm-1之间的吸收带为单烷芳烃C—H面外变形振动吸收峰,其中:690 cm-1处的峰为苯酚的吸收峰,754 cm-1处的峰主要对应邻位和邻对位取代酚的吸收信号,810~830 cm-1处的峰对应对位取代酚的吸收信号,此区间的吸收信号表明热解油中存在大量的苯酚及邻、对位取代酚。886 cm-1处的峰为间位二取代酚的弱吸收峰,说明热解油中邻位和对位3个位置都被取代的酚很少。

1—压力为5 kPa,热解终温为300 ℃;2—压力为5 kPa,热解终温为400 ℃;3—压力为5 kPa,热解终温为500 ℃;

4—压力为5 kPa,热解终温为600 ℃;5—压力为15 kPa,热解终温为500 ℃;6—压力为30 kPa,热解终温为500 ℃

图3 不同条件下热解所得热解油的红外谱图

Fig.3 Infrared spectra of liquid products obtained from WPCB pyrolysis under various conditions

以上分析表明,在不同条件下所得热解油主要由酚及取代酚等芳香化合物构成,这是由于环氧树脂由双酚A和环氧氯丙烷耦联的结构中包含芳香族化合物。热解油中亚甲基的吸收信号(2 850 cm-1)很弱,说明热解产物中链烷烃数量较少,且不存在长链烷烃。

4 气相色谱—质谱分析

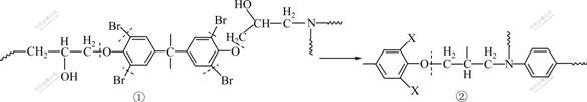

为了进一步了解热解油的组成,采用GC/MS对热解油进行定量分析。表7给出了升温速率为20 ℃/min、真空度为15 kPa、热解终温为500 ℃,保温时间30 min时所得热解油的主要组成成分及含量(在此条件下,热解废弃电路板得到的热解油产率最高)。总离子流色谱图如图4所示。由表7可知,热解油主要由苯酚、取代苯酚、双酚A及他们的溴化物组成,其生成途径可能如图5所示。其中:溴化环氧树脂第一分解过程是水分的释放和不饱和结构的形成,则由①产生②结构片段;②中伴随H的提取,导致苯酚的生成,同时伴随有2-溴苯酚及2,6-二溴苯酚的生成;当单体①结构两侧同时发生C—O及C—Br键断裂即产生双酚A。热解过程中,不同位置的断链导致生成不同的有机物质,环氧树脂的主要结构形式导致其热解生成主要化合物类型。在检测到的成分中,苯酚含量为28.42%,2, 3, 5-三甲基苯酚含量为13.14%,双酚A为13.71%,1, 1, 1-三对羟基苯基乙烷为7.77%,酚类物质总含量为 84.08%,主要来自环氧树脂中非溴化部分的热解。由表7可知,热解油中含有不少数量的同分异构物,其原因可能是,在热解过程中,外部环境差异导致断链位置不同而出现同分异构现象。而热解油中含溴化合物含量高达15.34%,分别为:3.6% 4-溴酚,3.31% 2, 4-2溴酚,1.86% 1-(3-溴-4-羟苯基)-乙酮,6.57% 4, 5-二溴苯基-9-氯-吖啶,是由阻燃剂溴化环氧树脂降解得到,没有检测出有HBr的存在,可能由于HBr含量太少不在检测范围内而没检测出。实验中只检测出2种含氮化合物,含氮成分来自电路板中含氮交联剂裂解产物。除酚类、含溴氮类化合物外,热解油中含有痕量的酮类、酯类有机物,其来源可能为环氧树脂中的醚片段裂解断裂而生成[16]。链烷烃类有机物几乎没有。

图4 热解终温为500 ℃时所得油的总离子流色谱图

Fig.4 Total ion chromatogram of pyrolysis products at 500 ℃

① 溴化环氧树脂单体;② X为H或Br

图5 环氧树脂单体的裂解

Fig.5 Decomposition pathway of epoxy resin

表7 500 ℃时废弃电路板热解油中主要化学成分及含量

Table 7 Main liquid products of thermolysis of sample at 500 ℃

5 结 论

a. 真空热解可提高废弃电路板树脂热解油产率,降低固体和气体产品的产率,降低热解的终温温度,体现了真空热解所具有的优势。

b. 热解温度、升温速率、真空度及保温时间对真空热解产品的产率有明显影响。其中,热解温度的影响最显著。较低的热解终温会使得热解不充分,而当热解终温较高时,易使热解气发生二次裂解,降低热解油产率,且大大提高设备投资成本。选择适当的热解温度(400~550 ℃)、升温速率(15~20 ℃/min)、真空度(压力15 kPa)及保温时间(30 min)有利于提高热解液体产品的产率,提高废弃电路板的综合回收利用率。

c. 热解油主要由苯酚、取代苯酚、双酚A及它们的溴取代酚组成,酚类物质总含量为 84.08%,含溴有机物含量高达15.34%。因此,开发合理方法提取分离热解油中有用的化工原料前景广阔,而如何有效除去热解油中溴有待于进一步研究。

参考文献:

[1] 李芝华, 任冬燕, 郑子樵, 等. 聚氨酯改性TDE-85/MeTHPA 环氧树脂体系的结构表征[J]. 中南大学学报:自然科学版, 2007, 38(3): 399-403.

LI Zhi-hua, REN Dong-yan, ZHENG Zi-qiao, et al. Structural identification of PU-modified TDE-85/MeTHPA epoxy resin[J]. Journal of Central South University: Science and Technology, 2007, 38(3): 399-403.

[2] Chien Y C, Wang H P, Lin K S, et al. Fate of bromine in pyrolysis of printed circuit board wastes[J]. Chemosphere, 2000, 40(4): 383-387.

[3] Luda M P, Euringer N, Moratti U, et al. WEEE recycling: Pyrolysis of fire retardant model polymers[J]. Waste Management, 2005, 25(2): 203-208.

[4] Blazsó M, Czégény Z S, Csoma C S. Pyrolysis and debromination of flame retarded polymers of electronic scrap studied by analytical pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2002, 64(2): 249-261.

[5] William J H, Williams P T. Separation and recovery of materials from scrap printed circuit boards[J]. Resources, Conservation and Recycling, 2007, 51(3): 691-709.

[6] WEI Rong-dang, Masatoshi K, Hideki S, et al. Chemical recycling of glass fiber reinforced epoxy resin cured with amine using nitric acid[J]. Polymer, 2005, 46(6): 1905-1912.

[7] 彭 科, 奚 波, 姚 强. 印刷电路板基材的热解实验研究[J]. 环境污染治理技术与设备, 2004, 5(5): 34-37.

PENG Ke, XI Bo, YAO Qiang. An experimental research on pyrolysis of printed circuit board backing[J]. Techniques and Environmental Pollution Control, 2004, 5(5): 34-37.

[8] Barontini F, Marsanich K, Petarca L, et al. Thermal degradation and decomposition products of electronic boards containing BFRs[J]. Ind Eng Chem Res, 2005, 44(12): 4186-4199.

[9] Chiang Hung-Lung, Lin Kuo-Hsiung, Lai Mei-Hsiu, et al. Pyrolysis characteristics of integrated circuit boards at various particle sizes and temperatures[J]. Journal of Hazardous Materials, 2007, 149(1): 151-159.

[10] WEI R D, Masatoshi K, Shurou Y, et al. An approach to chemical recycling of epoxy resin cured with amine using nitric acid[J]. Polymer, 2002, 43(10): 2953-2958.

[11] Mazzocchia C, Kaddouri A, Modica G, et al. Hardware components wastes pyrolysis: Energy recovery and liquid fraction valorization[J]. Journal of Analytical and Applied Pyrolysis, 2003, 70(2): 263-276.

[12] Chen K S, Yeh R Z. Pyrolysis kinetics of epoxy resin in a nitrogen atmosphere[J]. J Hazard Mater, 1996, 49(2/3): 105-113.

[13] 熊祖鸿, 李海滨, 吴创之, 等. 印刷线路板废弃物的热解与动力学实验研究[J]. 环境污染治理技术与设备, 2006, 7(10): 47-50.

XIONG Zu-hong, LI Hai-bin, WU Chuang-zhi, et al. A study on pyrolysis and kinetics of circuit boards wastes[J]. Techniques and Environmental Pollution Contron, 2006, 7(10): 47-50.

[14] Miranda R, Pakdel H, Roy C, et al. Vacuum pyrolysis of commingled plastics containing PVCII. Product analysis[J]. Polym Degrad Stabil, 2001, 73(1): 47-67.

[15] Roy C, Chaala A. Vacuum pyrolysis of automobile shredder residues[J]. Resources Conservation Recycling, 2001, 32(1): 1-27.

[16] Blazsó M. Studies on diol modified epoxy resins by analytical pyrolysis[J]. Polymer, 1991, 32(4): 590-596.

收稿日期:2008-10-25;修回日期:2009-03-10

基金项目:国家高技术研究发展计划(“863”计划)项目(2006AA06Z375)

通信作者:丘克强(1956-),男,广东梅县人,博士,教授,博士生导师,从事真空分离理论与工程、高纯材料加工和功能纳米材料制备技术及二次资源绿色循环化学与技术等研究;电话:0731-88877364;E-mail: qiuwhs@sohu.com