热循环对锅炉管热喷涂Ni-Cr基纳米涂层的影响

来源期刊:中国有色金属学报(英文版)2015年第5期

论文作者:V. SENTHILKUMAR B. THIYAGARAJAN M. DURAISELVAM K. KARTHICK

文章页码:1533 - 1542

关键词:纳米结构;涂层;原料粉;热喷涂;锅炉管;超音速火焰喷涂

Key words:nanostructure; coating; feedstock powder; thermal spray; boiler tubes; high velocity oxygen fuel

摘 要:采用机械球磨法制备Ni-Cr基纳米原料粉末。粉末颗粒在行星球磨机中反复经历焊合、碎裂和重焊合过程。采用超音速火焰喷涂工艺(HVOF)在碳钢管上喷涂球磨纳米粉末。利用金相显微镜、XRD、扫描电子显微镜(SEM),高分辨透射电子显微镜(HR-TEM)、能谱(EDS)和显微硬度测试对原料粉和HVOF喷涂涂层进行表征。对喷涂和未喷涂试样进行热循环分析,研究相、冶金性能和显微硬度的变化。与传统喷涂试样相比,Ni-Cr纳米涂层试样具有更高的力学和冶金性能。与传统涂层相比,纳米涂层的显微组织更均匀和紧密。

Abstract: Ni-Cr based nanostructured feedstock powder was prepared by mechanical milling technique involving repeated welding, fracturing, and re-welding of powder particles in a planetary ball mill. The milled nanocrystalline powders were used to coat carbon steel tubes using high velocity oxygen fuel (HVOF) thermal spraying process. The characterization of the feedstock powder and HVOF coated substrates was performed using optical microscope, X-ray diffractometer (XRD), scanning electron microscope (SEM), high resolution transmission electron microscope (HR-TEM), energy dispersive spectrometer (EDS) and microhardness tests. The coated and uncoated samples were subjected to different thermal cycles and characterized for their phase changes, metallurgical changes and microhardness variations. Ni-Cr nanostructured coated samples exhibited higher mechanical and metallurgical properties compared to their conventionally coated counter parts. The results showed that the nanostructured coating possessed a more uniform and denser microstructure than the conventional coating.

Trans. Nonferrous Met. Soc. China 25(2015) 1533-1542

V. SENTHILKUMAR1, B. THIYAGARAJAN1, M. DURAISELVAM1, K. KARTHICK2

1. Department of Production Engineering, National Institute of Technology, Tiruchriappalli, India;

2. Bharath Heavy Electricals Limited, Tiruchirappalli, India

Received 11 April 2014; accepted 3 February 2015

Abstract: Ni-Cr based nanostructured feedstock powder was prepared by mechanical milling technique involving repeated welding, fracturing, and re-welding of powder particles in a planetary ball mill. The milled nanocrystalline powders were used to coat carbon steel tubes using high velocity oxygen fuel (HVOF) thermal spraying process. The characterization of the feedstock powder and HVOF coated substrates was performed using optical microscope, X-ray diffractometer (XRD), scanning electron microscope (SEM), high resolution transmission electron microscope (HR-TEM), energy dispersive spectrometer (EDS) and microhardness tests. The coated and uncoated samples were subjected to different thermal cycles and characterized for their phase changes, metallurgical changes and microhardness variations. Ni-Cr nanostructured coated samples exhibited higher mechanical and metallurgical properties compared to their conventionally coated counter parts. The results showed that the nanostructured coating possessed a more uniform and denser microstructure than the conventional coating.

Key words: nanostructure; coating; feedstock powder; thermal spray; boiler tubes; high velocity oxygen fuel

1 Introduction

In most of the thermal power station, coal is burnt to convert water into steam which has been expanded through a turbine for the generation of electricity. Coal is a complex fuel that contains varying amount of sulphur and a substantial fraction of non-combustible mineral constituents, commonly called ash [1]. The coal used in Indian power stations contains ash (about 50%), consisting of abrasive mineral species (hard quartz up to 15%) which cause erosion of tubes [1]. During the combustion of coal, the mineral matter is transformed into fly ash, which is deposited on heat transfer surfaces of boilers. Accumulation of these deposits on the boiler tubes inhibits the heat transfer which is known as slagging or fouling. The heat transfer tubes of the boilers used in thermal power plants are subjected to intolerable levels of surface degradation by means of the combined cause of erosion–corrosion mechanism, ensuing in the tube wall thinning and untimely failure [2]. High temperature surface oxidation and erosion by the impact of fly ash and unburnt carbon particles are the main problems in coal fired boilers. Therefore, the development of erosion resistant and high temperature oxidation protection systems in industrial boilers is a very important topic from both engineering and economic point of view [3]. Thermal spray coating of heat transfer tubes which are exposed to fireside of the coal fired boiler is one of the possible methods to reduce tube thinning. Numerous types of thermal spray coatings are commonly used in boilers including nickel-chrome, TAFA 95MXC, iron-chrome, and Inconel 625 [4]. In thermal spray industry, a considerable attempt has been taken towards the development of nanostructured coatings, although none of these materials have been developed to the level where they can be economically used in boilers. Two approaches have been commonly used to produce nanostructured coating: the first approach is to start with a heavily deformed mechanically milled micron-sized powder that has a nanoscale-structure and the second approach relies on direct spraying of nano-powder precursors on the substrate [4]. Preparation of nanostructured feedstock powders is the initial step for the synthesis of nanostructured coatings. A number of routes that are capable of producing nanostructured materials include mechanical alloying/milling, gas condensation, thermo-chemical technique, spray conversion processing, vapour deposition, sputtering, electro-deposition, crystallization of amorphous alloys and sol–gel processing techniques [5]. Of these methods, only mechanical milling and thermo-chemical techniques have been used to produce huge quantities of nanostructured materials for possible commercial applications [6]. Thermal spraying of mechanically milled feedstock powders has been used as a means to produce nanocrystalline coatings having superior properties compared to conventional coatings [7-15]. WU et al [16] studied the cycle oxidation resistance of high velocity oxy-fuel (HVOF) sprayed nanostructured Ni60-TiB2 composite coating at 800 °C with static air sprayed by high velocity oxygen fuel spray method. In the earlier study [16], the nanostructured composite coating exhibited better cycle oxidation resistance than the conventional composite coating.

In the present work, mechanical milling was chosen as the most viable technique for producing nanostructured feedstock powders. The nanostructured Ni-Cr feedstock powders were prepared using ball milling. The feedstock powders were coated on carbon steel tubes by HVOF technique. The coated samples were mechanically and metallurgically characterized for their stability against cyclic oxidation resistance and erosion resistance.

2 Experimental

2.1 Synthesis of nanostructured feedstock powder

The nanostructured feedstock powder was prepared by milling of commercially available pre-alloyed 73.9Ni14.5Cr4.3Fe4.3Si3B HVOF feedstock powders with average particle size of 53 μm. The powder was immersed in hexane and milling was carried out in a two station planetary ball mill with a stainless steel vial and stainless steel balls (with ball diameter of 16 mm) at a rotation rate of 180 r/min. Hexane (H3C (CH2)4CH3) was used as process control agent to avoid contamination during ball milling process. The ball-to-powder mass ratio was taken as 10:1. After 20 h of milling, the milled powder was removed from the vial and used as feedstock powder for the HVOF coating process. The powder samples were analysed before and after milling, using various characterization techniques, such as X-ray diffraction (XRD) for structural analysis, scanning electron microscopy (SEM) for morphological analysis and high resolution transmission electron microscopy (JEOL JEM 2100 high resolution transmission electron microscope coupled with EDS) for structural and morphological characterization. X-ray diffraction analysis was carried out using an automated D/MAX Ultima III (Rigaku Corporation, Japan) diffractometer. The samples were exposed continuously to Cu Kα radiation (λ=1.5406  ) operated at 40 kV/30 mA and at a scanning speed of 2 (°)/min for a scanning range of 2θ=20°-80° in the step of 0.02°.

) operated at 40 kV/30 mA and at a scanning speed of 2 (°)/min for a scanning range of 2θ=20°-80° in the step of 0.02°.

2.2 Development of nanostructured HVOF coating

The as-received and milled feedstock powders were used to fabricate the conventional and nanostructured coatings, respectively. The high velocity oxygen fuel (HVOF) process was employed to fabricate the above coating on carbon steel grade SA210GrC substrates which were used for boiler water wall tubes. Steel samples of 50 mm × 50 mm × 5 mm were prepared from the above material. These specimens were grit blasted prior to the coating process in order to get good adhesive strength between the coating and the substrate. The substrates were grit blasted to improve the surface roughness to a Ra value of 10 μm. The spraying was carried out with DJ2600 HVOF system. The standard parameters used to fabricate the HVOF coating were given in Table 1. The conventional and nanostructured composite coatings were characterized using XRD, SEM and HRTEM/EDS. For HRTEM analysis, the disc shape sample of 3 mm in diameter was punched from the thermal spray coating of thickness 100 μm using disc punch tool followed by the dimple grinding process to reduce the thickness to 20 μm. The dimpled discs were then ion milled for obtaining electron transparent regions. The microhardness of the HVOF coated specimens was measured using Zwick Manufacture Technologies (Germany) Vickers hardness tester at a load of 500 g and the indenter was maintained in that position for 20 s. All the tests were repeated for five times randomly and the average data were reported. The porosity and microstructure of the conventional and nanostructured coatings were investigated in this work. Thermal cycle analysis was carried out at 650 °C, in order to examine the thermal stability of coating for high temperature service conditions between 550 °C and 650 °C. Thermal stability of the HVOF coated substrate material was investigated by heating the samples to a temperature of 650 °C and maintained at that temperature for different soaking time to explore the potential of applying nanostructured coatings for boiler tubes protection during high-temperature service.

Table 1 Spraying parameter used for HVOF coating

Fig. 1 SEM images of feedstock powder

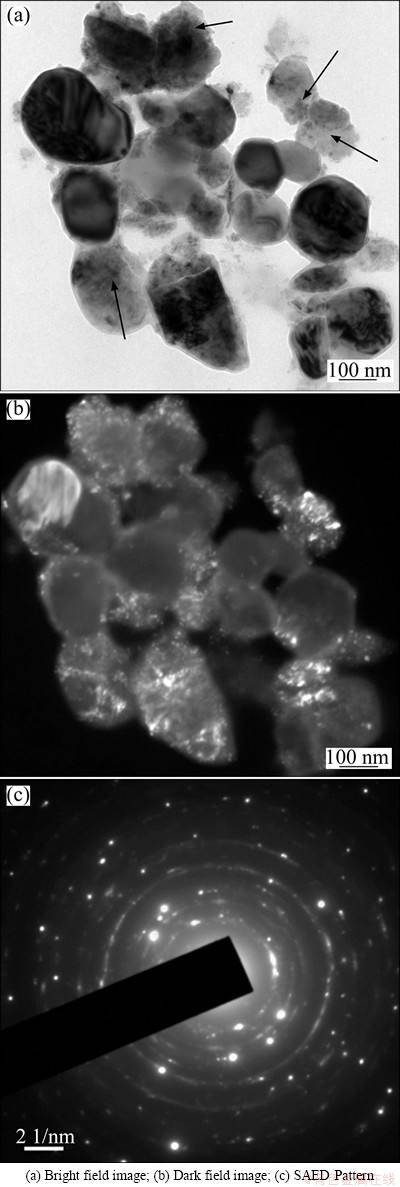

Fig. 2 HRTEM micrographs of nanostructured feedstock powder

3 Results and discussion

3.1 Microstructural characterization of feedstock powder

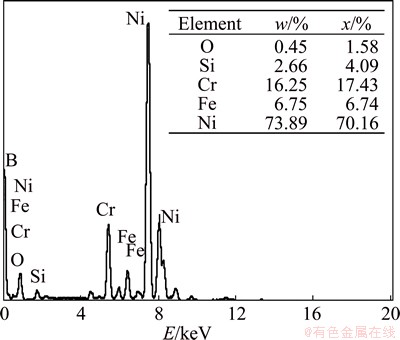

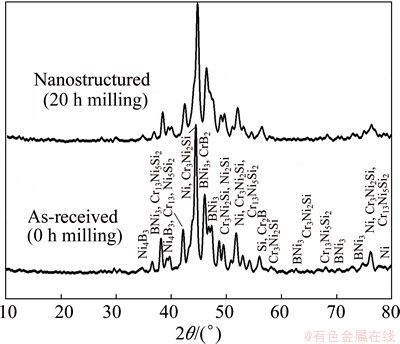

The morphology of HVOF feedstock powder particles was analysed by SEM. The as-received gas atomised powder particle with spherical shape is shown in Fig. 1(a). The mean particle size of the feedstock powder used in the present work was 53 μm. The irregular and flake shaped particles formed due to continuous fracture and welding as shown in Fig. 1(b). The irregular morphology was observed in Refs. [17-20]. The samples for the TEM were prepared by ultrasonically dispersing the feedstock powder in acetone, and then droplets were placed on copper coated grid for analysis. The bright field HRTEM image, dark field image and the corresponding selected area electron diffraction (SAED) pattern of the nanostructured HVOF feedstock powders are shown in Figs. 2(a), (b) and (c), respectively. The presence of sharp rings in the SAED pattern (Fig. 2(c)) confirms the ultrafine-grained structure and the bright spots coinciding with the rings confirm the presence of nanoparticles in the HVOF feedstock powder. The grain size of nanocrystalline powder particles measured using HRTEM images with Image-J software was found to be in the range of 10-91 nm, and the average value was found to be 42.73 nm for a sample size of 75 milled powder particles. Powder particles with nanocrystalline grains are indicated by arrows in Fig. 2(a). The EDS results of the nanostructrured powder shown in Fig. 3, confirmed the presence of definite composition of elements in the nanostructured feedstock powder. Contamination was unavoidable during the milling process. However, the absence of new peaks in the X-ray pattern of the milled powder (as shown in Figs. 4(a) and 4(b)) leads to the conclusion that the milled powder has negligible amount of contamination or relatively very minimal amount of contamination (<2%) which the X-ray can not detect.

Fig. 3 EDS pattern of nanostructured feedstock powder

Fig. 4 XRD patterns of as-received and nanostructured powder

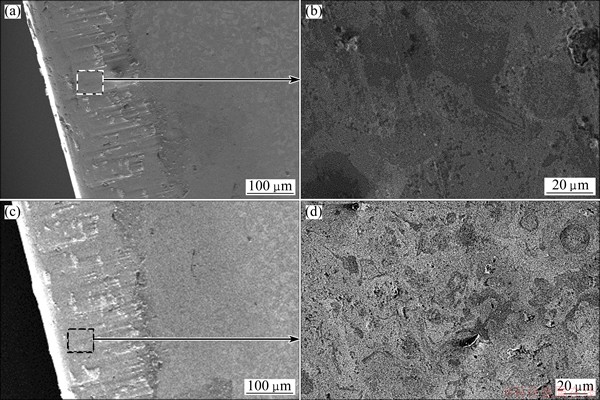

Fig. 5 SEM cross sectional morphologies of conventional coating (a, b) and nanostructured coating (c, d)

Fig. 6 HRTEM micrographs of nanostructured HVOF coating

Fig. 7 EDS pattern of nanostructured coating

3.2 Metallurgical characterization of HVOF coating

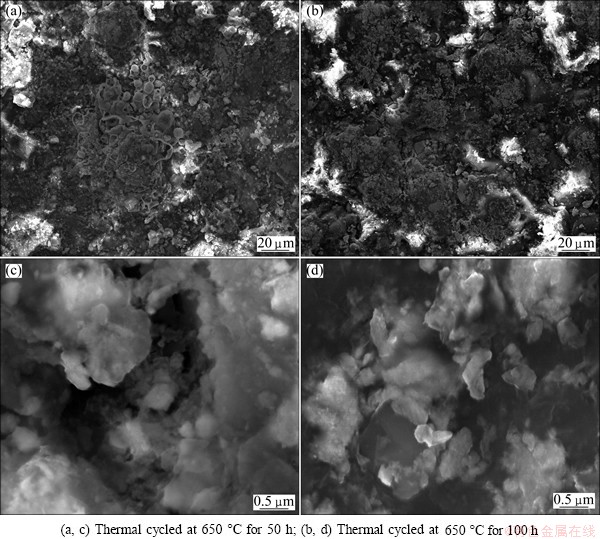

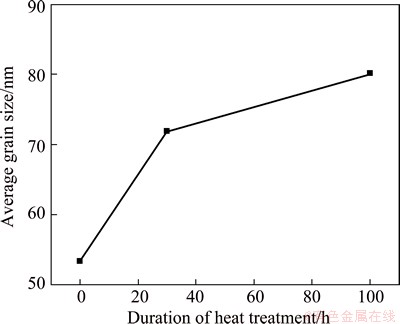

The cross sectional morphology of the conventional and nanostructured coatings was examined using SEM and is shown in Figs. 5(a) and (c), respectively. The magnified SEM morphology for the conventional and nanostructured coatings is shown in Figs. 5(b) and (d). The dense and uniform microstructure was observed in the nanostructured coatings, compared to the conventional coating. The disc-shaped specimen of the coating was prepared by mechanical polishing, dimpling and ion-beam milling of a flake-shape coating material, which was cut-off from the coated substrate for HRTEM analysis. HRTEM bright field image, dark field image and the corresponding selected area electron diffraction pattern of the nanostructured HVOF coatings are shown in Figs. 6(a), (b) and (c), respectively. As shown in Fig. 6(a), the TEM image reveals the presence of ultra- fine grained or nanostructured grains with equi-axed shape. The grain size measured from the HRTEM images showed that it is in the range of 17-95 nm using Image-J software, and the average value obtained for 50 grains was found to be 53.45 nm. The definite composition of elements in the nanostructured coating was conformed from the EDS result as shown in Fig. 7. The porosity percentage of the coatings was determined in terms of the area fraction of pores [21]. The porosity was measured using the Image-J software from the average of ten optical microscope images of the HVOF coating and is listed in Table 2. The porosity is an important coating feature that strongly influences coating properties. The XRD patterns of the conventional and nanostructured HVOF coatings are shown in Fig. 8. Ni, Cr, Cr3Ni2, Ni3C and Cr2Ni3 peaks were indexed using JCPDS file numbers 897128, 894055, 260430, 721467 and 655559, respectively. The surface of the coating also showed that the presence of weak intensity peaks correspond to Ni3C phase. Generally, the formation of Ni3C phase was regarded as a product of decarburization in the thermal spraying. During HVOF spraying, the flame temperature was usually less than 3000 °C, and the particle speed could attain up to 800-1000 m/s. Therefore, the duration of powder exposed to air was so short that the decomposition and decarburization were not serious issue. The XRD analysis was carried out for the thermal cycled samples of the nanostructured HVOF coatings to evaluate the thermal stability of the coatings to serve in the boiler service environment. The results of XRD analysis (Fig. 9) revealed that there was no appreciable change in the nanostructured HVOF coatings due to thermal cycle. The XRD results of the thermal cycled samples confirm the formation of oxide phase on the nanostructured coating. The oxide phase SiO2 was noticed on the XRD pattern of the 10 h and 20 h thermal cycled nanostructured coatings, which disappeared after the second thermal cycle due to the consumption of Si content in the outer layer of the nanostructed coating during oxidation reaction. The protective Cr2O3 oxide phase was observed on XRD patterns of the thermal cycled samples, which protect the nanostructured coating from further oxidation. The surface morphologies of the 50 h and 100 h thermal cycled nanostructured coatings are shown in Fig. 10, respectively, with different magnifications. No cracks were observed on the surface micrograph of the thermal cycled nanostructured coating. The grain size measured using Image-J software for the 30 h thermal cycled sample from the HRTEM images (Fig. 11) was found to be in the range of 26-230 nm, and the average value obtained by a mean of 50 grains was found to be 71.98 nm for the 30 h thermal cycled sample and the corresponding EDS pattern is shown in Fig. 12. The grain size measured for the 100 h thermal cycled sample from the HRTEM image (Fig. 13) was found to be in the range of 47-240 nm, and the average value obtained for a mean of 50 grains was 80.12 nm and the corresponding EDS spectrum is shown in Fig. 14. It was found that grain growth was comparatively low during the thermal cycle as shown in Fig. 15.

Table 2 Porosity of HVOF coating

Fig. 8 XRD patterns of conventional and nanostructured HVOF coatings

Fig. 9 XRD patterns of nanostructured coating after thermal cycle at 650 °C for different time

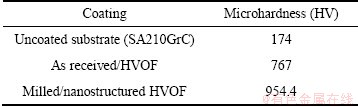

3.3 Mechanical characterization of HVOF coating

The Vickers microhardness using 500 g load was employed to evaluate the hardness of the uncoated and coated substrates. The results of hardness measurements revealed that the hardness of nanostructured coating was higher compared to the conventional coating with the same composition as provided in Table 3, taken for an average of five points selected randomly from different positions on the substrate surface. The variation of microhardness along the cross section for various HVOF coatings is shown in Fig. 16. The peak hardness values for all substrates were observed near the coating– substrate interface. The hardness of thermal sprayed coatings was affected by the coating process as well as characteristics of the feed stock powder [16]. In the HVOF technique, the particle velocity was high and the thermal energy was low, which resulted in high hardness [16]. In the present investigation, the hard ness of the nanostructured coating was higher than that of the coating prepared with as-received powders. The higher hardness of the nanostructured coatings can be attributed to the uniform microstructure produced in the mechanical milling process to obtain nanostructured material. Thermal stability of the HVOF coated substrate material was investigated by heating it to 650 °C and maintaining for different soaking time. The microhardness of the heat-treated samples was investigated at various time intervals as shown in Fig. 17. The results of hardness measurements revealed that the hardness value of all samples seems to be stable after some saturated time duration.

Fig. 10 SEM surface morphologies of thermal cycled samples

Fig. 11 HRTEM micrographs of nanostructured HVOF coating after 30 h thermal cycles at 650 °C

Fig. 12 EDS pattern of nanostructured coating after 30 h thermal cycles at 650 °C

Fig. 13 HRTEM micrographs of nanostructured HVOF coating after 100 h thermal cycled at 650 °C

Fig. 14 EDS pattern of nanostructured coating after 100 h thermal cycles at 650 °C

Fig. 15 Grain size variation during thermal cycle

Table 3 Vickers microhardness of HVOF coating

Fig. 16 Microhardness along cross section of coating

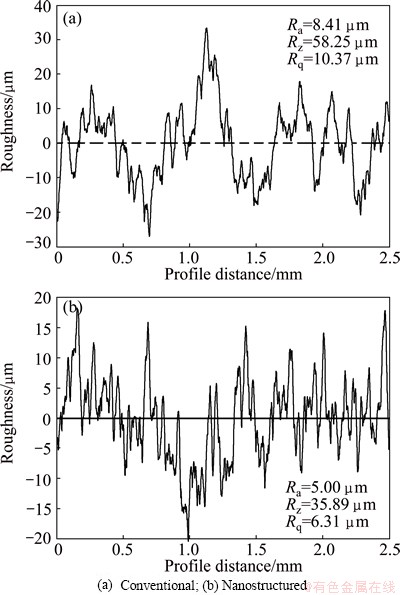

Surface height parameters of the HVOF coating were measured using the surface roughness tester to compare the surface roughness average (Ra), ten point height average (Rz—an average of the five highest peaks and the five lowest valleys measured in one cut-off length) and root mean square roughness (Rq) for all HVOF coating compositions. The surface profiles for all HVOF coatings are shown in Fig. 18. The results reveal that the surface height parameter of the nanostructured coating was comparatively low when compared to that of the conventional coating.

Fig. 17 Effect of thermal cycle on microhardness

Fig. 18 Measured surface profile of HVOF coating

4 Conclusions

1) The presence of sharp rings in the SAED pattern confirms the ultrafine-grained structure and the bright spots coinciding with the rings confirm the presence of nano particles in the HVOF feedstock powder.

2) The absence of new peaks in the XRD patterns of the milled powder indicates neglible amount of contamination present in the powder after milling.

3) The results of hardness measurements reveal that the hardness of the nanostructured coating is higher compared to the conventional coating of same composition.

4) The grain size of as-milled nanocrystalline powders, nanocoated substrate and coated samples subjected to thermal analysis was evaluated. Ultrafine- grained nature of coating was maintained after 100 h of thermal cycle.

5) No phase change and very little amount of grain growth were found to occur in the nanostructured coating samples after various thermal cycles. This confirms the attainment of thermal stability of the coating.

6) The results of hardness measurements after thermal cycle reveal the attainment of stable state with regard to microhardness after some saturated time duration.

7) The surface roughness results reveal that the surface height parameter of the nanostructured coating is comparatively lower compared to that of conventional coating.

Acknowledgment

This work was supported and funded from consultancy project of Bharath Heavy Electricals Limited, Tiruchirappalli, India. Authors would like to thank for the financial support.

References

[1] VALERO A, CORTES C. Ash fouling in coal-fired utility boilers: Monitoring and optimization of on-load cleaning [J]. Prog Energy Combust Sci, 1996, 22: 189-200.

[2] SIDHU T S, PRAKASH S, AGRAWAL R D, RAMESH B. Erosion–corrosion behaviour of Ni-based superalloy Superni-75 in the real service environment of the boiler [J]. Sadhana, 2009, 34(2): 299-307.

[3] HIGUERA HIDALGO V, BELZUNCE VERELA J, CARRILES MENENDEZ A, POVEDA MARTINEZ S. High temperature erosion wear of flame and plasma-sprayed nickel-chromium coatings under simulated coal-fired boiler atmospheres [J]. Wear, 2001, 247: 214-222.

[4] BRANAGAN D J, BREITSAMETER M, MEACHAM B E, BELASHCHENKO V. High-performance nanoscale composite coatings for boiler applications [J]. Journal of Thermal Spray Technology, 2005, 14(2): 196-204.

[5] SURYANARAYANA C. Nanocrystalline materials [J]. International Materials Reviews, 1995, 40: 41-64.

[6] NAVAS C,  R, de DAMBORENEA J, VILAR R. Abrasive wear behaviour of laser clad and flame sprayed-melted NiCrBSi coatings [J]. Surface and Coatings Technology, 2006, 200: 6854-6862.

R, de DAMBORENEA J, VILAR R. Abrasive wear behaviour of laser clad and flame sprayed-melted NiCrBSi coatings [J]. Surface and Coatings Technology, 2006, 200: 6854-6862.

[7] HE J H, ICE M, LAVERNIA E J. Synthesis of nanostructured Cr3C2-25(Ni20Cr) coatings [J]. Metallurgical and Materials Transactions A, 2000, 31: 555-564.

[8] TELLKAMP V L, LAU M L, FABEL A, LAVERNIA E J. Thermal spraying of nanocrystalline Inconel 718 [J]. Nanostructured Materials, 1997, 9: 489-492.

[9] LAU M L, JIANG H G, NUCHTER W, LAVERNIA E J. Thermal spraying nanocrystaline Ni coatings [J]. Phys Status Solidi A, 1998, 166: 257-268.

[10] LAU M L, STROCK E, FABEL A, LAVERNIA C J, LAVERNIA E J. Synthesis and characterization of nanocrystalline Co-Cr coatings by plasma spraying [J]. Nanostructured Materials, 1998, 10: 723-730.

[11] HE J H, ICE M, DALLEK S, LAVERNIA E J. Synthesis of nanostructured WC-12pct Co coating using mechanical milling and high velocity oxygen fuel thermal spraying [J]. Metallurgical and Materials Transactions A, 2000, 31: 541-553.

[12] STEWART D A, SHIPWAY P H, McCARTNEY D G. Microstructural evolution in thermally sprayed WC-Co coatings: Comparison between nanocomposite and conventional starting powders [J]. Acta Mater, 2000, 48: 1593-1604.

[13] GROSDIDIER T, TIDU A, LIAO H L. Nanocrystalline Fe40Al coating processed by thermal spraying of milled powder [J]. Scripta Mater, 2001, 44: 387-393.

[14] AJDELSZTAJN L, PICAS J A, KIM G E, BASTIAN F L, SCHOENUNG J, PROVENZANO V. Oxidation behaviour of HVOF sprayed nanocrystalline NiCrAlY powder [J]. Mater Sci Eng A, 2002, 338: 33-43.

[15] LAU M L, HE J, SCHWEINFEST R, RUHLE M, LEVI C G, LAVERNIA E J. Synthesis and characterization of nanocrystalline Cu-Al coatings [J]. Mater Sci Eng A, 2003, 347: 231-242.

[16] WU Y S, QIU W Q, YU H Y, ZHONG X C, LIU Z W, ZENG D C, LI S Z. Cycle oxidation behavior of nanostructured Ni60–TiB2 composite coating sprayed by HVOF technique [J]. Applied Surface Science, 2011, 257: 10224-10232.

[17] da CUNHA C A, de LIMA N B, MARTINELLI J R, de ALMEIDA BRESSIANI A H, FERNANDO PADIAL A G, RAMANATHAN L V. Microstructure and mechanical properties of thermal sprayed nanostructured Cr3C2-Ni20Cr coating [J]. Journal of Materials Research, 2008, 11(2): 137-143.

[18] RANA N, MAHAPATRA M M, JAYAGANTHAN R, PRAKASH S. Deposition of nanocrystalline coatings by modified LVOF thermal spray method [J]. Journal of Alloys and Compounds, 2014, 615: 779-783.

[19] YAGHTIN A H, JAVADPOUR S, SHARIAT M H. Hot corrosion of nanostructured CoNiCrAlYSi coatings deposited by high velocity oxy fuel process [J]. Journal of Alloys and Compounds, 2014, 584: 303-307

[20] MAZAHERI Y, KARIMZADEH F, ENAYATI M H. Development of Al356-Al2O3 nanocomposite coatings by high velocity oxy-fuel technique [J]. Journal of Mater Sci Technology, 2013, 29(9): 813-820.

[21] ENAYATI M H, KARIMZADEH F, JAFARI M, MARKAZI A, TAHVILIAN A. Microstructural and wear characteristics of HVOF-sprayed nanocrystalline NiAl coating [J]. Wear, 2014, 309: 192-199.

V. SENTHILKUMAR1, B. THIYAGARAJAN1, M. DURAISELVAM1, K. KARTHICK2

1. Department of Production Engineering, National Institute of Technology, Tiruchriappalli, India;

2. Bharath Heavy Electricals Limited, Tiruchirappalli, India

摘 要:采用机械球磨法制备Ni-Cr基纳米原料粉末。粉末颗粒在行星球磨机中反复经历焊合、碎裂和重焊合过程。采用超音速火焰喷涂工艺(HVOF)在碳钢管上喷涂球磨纳米粉末。利用金相显微镜、XRD、扫描电子显微镜(SEM),高分辨透射电子显微镜(HR-TEM)、能谱(EDS)和显微硬度测试对原料粉和HVOF喷涂涂层进行表征。对喷涂和未喷涂试样进行热循环分析,研究相、冶金性能和显微硬度的变化。与传统喷涂试样相比,Ni-Cr纳米涂层试样具有更高的力学和冶金性能。与传统涂层相比,纳米涂层的显微组织更均匀和紧密。

关键词:纳米结构;涂层;原料粉;热喷涂;锅炉管;超音速火焰喷涂

(Edited by Yun-bin HE)

Corresponding author: V. SENTHILKUMAR; Tel: +91-431-2503519; Fax: +91-431-2500133; E-mail: vskumar@nitt.edu

DOI: 10.1016/S1003-6326(15)63755-4