文章编号:1004-0609(2013)S1-s0287-05

高纯净度钛合金锭坯制备技术

杨文甲1,张文琦1,邢 义2,赵 军3,刘鸿羽3

(1. 沈阳卓越钛业有限公司,沈阳 110102;

2. 沈阳和世泰通用钛业有限公司,沈阳 110206;

3. 沈阳铸造研究所,沈阳 110022)

摘 要:采用(VAR)技术熔炼制备钛合金铸锭,为了提高铸锭质量,对原料纯净度、电极制备技术、熔炼工艺参数等方面进行控制与改进,减少了O、N、C、H、Si等杂质含量,保证了钛合金铸锭成分与组织的均匀性。经工业化生产试验最终使得(VAR)炉能够制备出符合标准要求的高纯度钛合金铸锭。

关键词:高纯净度;(VAR)炉;钛合金;电极;熔炼技术

中图分类号:TF062 文献标志码:A

Preparation technology of titanium alloy ingot and billet with high purity

YANG Wen-jia1, ZHANG Wen-qi1, XING Yi2, ZHAO Jun3, LIU Hong-yu3

(1. Shenyang Zhuoyue Titanium Industrial Co., Ltd., Shenyang 110102, China;

2. Shenyang HST General Titanium Co., Ltd., Shenyang 110206, China;

3. Shenyang Research Institute of Foundry, Shenyang 110022, China)

Abstract: The vacuum arc remelting technology is used for preparing the titanium ingot. In order to improve the ingot quality, the purity of raw material, the preparative technique of electrode and the melting process parameters were strictly controlled and improved. The contents of impurity elements such as O, N, C, H and Si are reduced and the titanium ingots have a good homogeneity on chemical composition and microstructure. After having a industrial test, it is found that the VAR preparative technique can meet the standard requirement of high purity titanium ingot.

Key words: high purity; (VAR) furnace; titanium alloy; electrode; smelting technology

钛合金具有耐腐蚀、比强度高、耐高温、化学相容性好等优异特性,在航空、航天、化工、冶金、能源等领域已得到了广泛应用[1-2]。而随着科技进步以及国防事业的发展,航空、航天等高新技术领域对钛合金结构件的性能提出了更高的要求,不断向大尺寸、薄壁、复杂结构以及高质量的方向发展[3-6],要求产品具有良好的一致性,这就首先要求熔炼时采用的钛合金铸锭在成分上具有较高的纯净度和良好的均匀性。采用高纯净度并且成分均匀的钛合金铸锭生产出来的钛合金铸件具有良好的综合性能,保证了批量生产过程中铸件质量的稳定性,提高了产品的安全性。

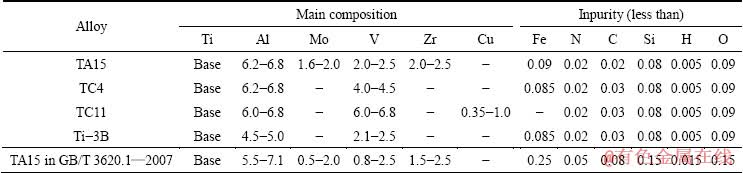

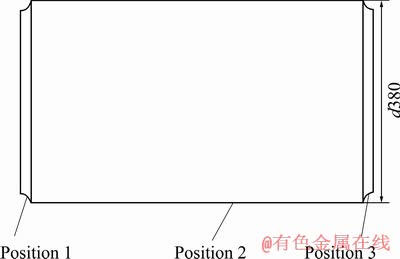

国内某航空、航天用钛合金铸件生产厂家提出的钛合金铸锭的成分标准要求如表1所示,取样标准如图1所示,要求各个测试位置的检测结果均达到成分要求。该用户的要求比现行 GB/T 3620.1—2007标准中的规定更为严格,在制备钛铸锭过程中,成分控制较为困难,生产难度较高,降低了铸锭的成品率。目前,制备钛合金铸锭最为常用的方法为真空自耗电极电弧熔炼(Vacuum arc remelting, VAR)技术,即在真空或惰性气体中,自耗钛电极在直流电弧的高温作用下,熔化在水冷铜坩埚中冷凝成为铸锭[7-8]。VAR技术的设备投资及运行成本较低,操作方便,适用于批量生产。常规的VAR技术难以生产出符合上述要求的钛合金铸锭,需要对工艺流程进行改进和创新。

表1 铸锭成分标准

Table 1 Standards of ingot component (mass fraction, %)

图1 取样部位示意图

Fig.1 Schematic diagram of sampling location (unit: mm)

本文作者采用VAR技术制备钛合金铸锭,通过对原料纯净度、电极制备技术、熔炼工艺参数及熔炼操作方法等方面加以控制及调整,进而减少杂质的混入,同时,调整电场、磁场的相关参数,提高成分的均匀性,保证了铸锭的质量,制备出了符合客户要求的高纯度钛合金铸锭。

1 改进措施

1.1 自耗电极制备

1) 确认压制物料

本工序首先要对海绵钛进行破碎及筛分,以去除不合格料块,其次要对中间合金进行杂质的初算,避免海绵钛带入的杂质引起最终铸锭的杂质超标,预估杂质的可控余量。

2) 压制电极

将海绵钛与合金元素均匀合理搭配,按照公司的工艺规程和操作规程,采用立式横压法整体压制棒状电极,压制过程中须保证块料之间的结合强度,避免产生穿透性裂纹。为了保证电极的导电性,熔炼时产生足够大的电弧,压制的电极应具备足够的密度,电极密度越大,电阻值越小,导电性越好,结合实际的压制能力,将电极的密度控制在3.0~3.3 g/cm3。电极直径与坩埚直径的比值在0.6~0.7之间,电极直径过大,熔化时易起侧弧,电极直径过小,所形成的弧柱小,对熔池的覆盖面小,温度相对较低,会导致钛合金液成分不均匀,凝壳增厚,合金液流动性变差。压制成的电极表面要求光洁平整,无大尺寸缺陷,避免熔炼时电弧不稳产生边弧。

3) 焊接电极

采用等离子氩气保护焊技术焊接电极,氩气纯度不小于99.99%。焊接前需清理工作平台,电极块表面不得有油污、灰尘等污物。对照挤压电极传卡,检查来料牌号、批号及电极节数。焊接过程中,要保证有足够的焊接面积,使其具有一定的强度以承受自质量,每焊好一侧,应随即去除电极上的挥发物。焊接后的焊点应为银白色,不得氧化发蓝,焊接的电极须平直,避免在通过强大电流时局部产生过热。

1.2 熔炼技术

根据现有的铸锭生产条件,本文统计了大量质量达1 t、直径达370 mm的钛合金铸锭的成分分布情况。结果表明:主要元素Al、V往往偏低,而气体杂质元素N、O往往偏高,并且铸锭两端的成分及杂质偏差较大,虽然均符合GB/T3620.1—2007标准中的要求,但如果按照双方协议要求取样,合格率仅为75%。本文作者通过改进熔炼设备和调整工艺参数两个方面解决铸锭的均匀性问题。

1) 熔炼设备改进

为了使电弧工作稳定,通常在坩埚外层加稳弧线圈。稳弧线圈通入电流时会产生纵向磁场,减少边弧,稳定电弧,同时,纵向磁场会使熔池中的钛液旋转产生搅拌作用。在本实验中,对现有的稳弧线圈在坩埚底部和顶部位置加密,不仅使电弧更加稳定,更重要的是使得坩埚上下部位的搅拌能力得到增强,并使得熔炼炉的电磁场强度对熔化速度的调整处于可控的范围。

2) 熔炼工艺参数调整

熔炼过程中,电弧的控制对熔炼的质量和效率影响很大。电弧过短,会使得电极与熔池之间发生短路,阻碍正常熔炼,并使得熔池温度发生变化,电弧过长,会使得熔化速度过快,熔化温度过高。以上两种情况都会影响钛液的过热度和流动性,进而影响钛液的均匀性和充填性,会导致铸锭成分偏差,并出现深孔、“疤痕”、“冷隔”等缺陷。熔化速度是电弧热效率主要标志,在其他条件不变的情况下,熔炼的熔化速度仅与弧长有关。实践表明,电流不变时,随着磁场强度的增加,熔化速度出现极大值时,磁场下电弧的热效率最高,熔化速度最快。磁场强度过大时,电弧出现收敛现象,导致熔化温度较高,辐射热损失及金属挥发热损失大,磁场强度过小,电流出现发散现象,并出现辉光。只有磁场强度处于最佳值时,对应着某一特定的几何形状的电弧,该时电弧热效率最高,此时相应的熔化速度也达到极大值。

熔炼过程中,起主要作用的熔炼参数包括电流、电压和磁场[9],在操作过程中需要合理的控制电压、电流以及磁场,使弧长保持稳定状态,看弧人员与主操作人员互相配合,使弧长达到最佳值,保证铸锭质量和电弧热效率。各参数之间的关系较为复杂,对以往熔炼参数进行总结,得出熔炼二次经验电流是8 300~8 800 A。二次熔化速度降低到一次熔化速度的80%~90%。

钛合金作为活泼金属,在熔炼过程中很容易发生吸气现象,与O2,N2,CO2等气体发生化学反应,影响铸锭的化学成分,导致N,H和O等元素超标,因此需要对熔炼过程中的真空度加以控制。实践表明,首次熔炼时,真空度需达到0.7~10 Pa,二次熔炼时需要更高的真空度,但实际熔炼过程中,由于炉子结构不同,真空计指示值与弧压真空压力值的差值很大,即弧压力在70~4000 Pa之间电弧呈现“空间移动”,熔炼时指示压力控制在1 Pa左右。

在实际熔炼过程中,铸锭底部主要合金元素的含量往往达不到要求,为了解决此问题,在二次熔炼过程中,在坩埚底部采用合金料进行引弧,补充了铸锭底部的合金元素含量,使得浇铸出的铸锭两端的成分趋于一致。

2 结果分析

通过在以上几方面不断进行技术改进与攻关,经过近一年90多t钛合金铸锭的生产实验,铸锭质量最终得到了稳定,其中TA15合金铸锭坯约占85%,因此对TA15合金铸锭质量进行了分析,采用等离子发射光谱仪对铸锭上切取的试样进行合金元素的检测,采用光学金相显微镜对试样进行显微组织的观察,其中腐蚀液采用10%HF+20%HNO3+70%H2O(体积分数),采用电子拉伸测定仪进行力学性能的测试。

2.1 成分均匀性

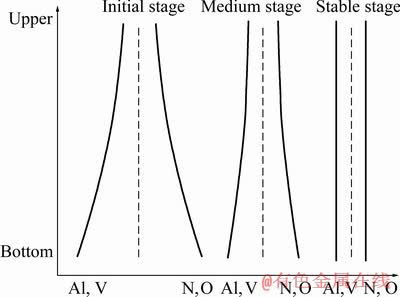

铸锭质量的稳定过程大致分为3个阶段,针对铸锭中含量波动较大的元素,将不同阶段铸锭的检测结果与内控标准上、下限范围进行比较,主要成分元素:Al和V;气体杂质元素:N和O,各元素含量与标准要求的分布走势如图2所示,表明了各阶段质量改进情况。

图2 铸锭质量改进过程中各阶段情况

Fig.2 All stages of ingots quality improvement

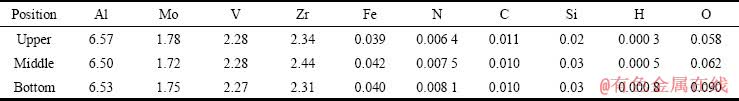

从生产出的TA15钛锭的成分上下限含量走势示意图可以看出:由于Al、V元素易烧损,N、O元素会发生扩散,熔炼初期存在元素烧损与含量波动等问题,随着工艺技术改进,铸锭的Al、V、N、O波动范围越来越小,含量也越来越接近配料的成分含量。最终获得了成分均匀的钛铸锭。对于Zr、Mo等元素,分析结果表明与配料中的含量几乎相等或相近,因此在配料过程中,Zr、Mo等元素的含量无需进行调整,这两种合金元素在整个熔炼过程中稳定,无烧损。在最终制备的TA15合金铸锭上、中、下3个部位取样,化学成分检测结果如表2所示,可见其化学成分已较为均匀。

表2 TA15铸锭各部位化学成分

Table 2 Chemical component of TA15 ingot on different positions (mass fraction, %)

铸锭整体成分均匀度得到了提高,最主要在于磁场的作用[10],在电流轴向外加磁场,使电弧旋转起来并收敛,使得在熔炼过程中熔池也会同时旋转起来,从而达到均匀加热熔池,稳定电弧搅拌金属的作用,同时,搅拌作用还兼破碎柱状晶的功效。

2.2 组织均匀性

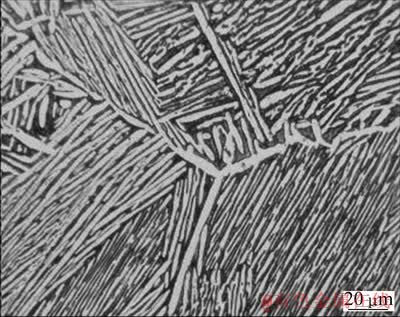

在TA15合金铸锭内部切取试块制成金相试样,经过腐蚀后,首先在低倍条件下观察整体晶粒组织,如图3所示,可以看到整个试样的晶粒尺寸较小,大小均匀,没有出现明显的夹杂和偏析。将试样在金相显微镜下观察,如图4所示,呈现层片状的a+b组织形貌,组织细小均匀,能使合金具有良好的强度和塑形。

图3 TA15铸锭试样低倍组织

Fig.3 Macrostructure of TA15 ingot

图4 TA15铸锭试样微观组织

Fig.4 Microstructure of TA15 ingot

2.3 力学性能

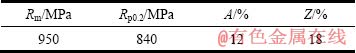

在铸锭上切取试样制成拉伸试棒进行力学性能的检验,结果如表3所示,其强度和塑性完全满足使用要求和国家标准(GJB 2896—2007)。

表3 TA15铸锭力学性能

Table 3 Mechanical property of TA15 ingot

3 结论

1) 通过控制原材料质量,规范生产中的操作规程,采用VAR熔炼技术可以制备出高纯净度的钛合金铸锭。

2) 通过改进稳弧线圈,合理控制熔炼过程中的真空度、电流、电压、磁场等参数,并采用合金料作为引弧料,保证了铸锭的成分与组织均匀性。

REFERENCES

[1] 李 梁, 孙健科, 孟祥军. 钛合金的应用现状及发展前景[J]. 钛工业进展, 2004, 21(5): 19-24.

LI Liang, SUN Jian-ke, MENG Xiang-jun. Application state and prospects for titanium alloys[J]. Titanium Industry Progress, 2004, 21(5): 19-24.

[2] 吴海峰, 张治民, 李保成. 钛合金及其成形技术在民品中的应用前景[J]. 锻压技术, 2003(4): 44-46.

WU Hai-feng, ZHANG Zhi-min, LI Bao-cheng. Application of titanium alloys and its forming technology in commodity[J]. Forging & Stamping Technology, 2003(4): 44-46.

[3] 肖树龙, 陈玉勇, 朱洪艳, 田 竟, 吴宝昌. 大型复杂薄壁钛合金铸件熔模精密铸造研究现状及发展[J]. 稀有金属材料与工程, 2006, 35(5): 678-681.

XIAO Shu-long, CHEN Yu-yong, ZHU Hong-yan, TIAN Jing, WU Bao-chang. Recent advances on precision casting of large thin wall complex castings of titanium alloys[J]. Rare Metal Materials and Engineering, 2006, 35(5): 678-681.

[4] 曹春晓. 航空用钛合金的发展概况[J]. 航空科学技术, 2005(4): 3-6.

CAO Chun-xiao. General development situation of titanium alloys for aviation[J]. Aeronautical Science and Technology, 2005(4): 3-6.

[5] 付艳艳, 宋月清, 惠松骁, 米绪军. 航空用钛合金的研究与应用进展[J]. 稀有金属, 2006, 30(6): 850-856.

FU Yan-yan, SONG Yue-qing, HUI Song-xiao, MI Xu-jun. Research and application of typical aerospace titanium alloys[J]. Chinese Journal of Rare Metals, 2006, 30(6): 850-856.

[6] 黄晓艳, 刘 波, 李 雪. 钛合金在军事上的应用[J]. 轻金属, 2005(9): 51-53.

HUANG Xiao-yan, LIU Bo, LI Xue. The application of titanium alloy in military[J]. Light Metals, 2006, 30(6): 850-856.

[7] 舒 群, 郭永良, 陈子勇, 孔凡涛, 陈玉勇. 铸造钛合金及其熔炼技术的发展现状[J]. 材料科学与工艺, 2004, 12(3): 332-336.

SHU Qun, GUO Yong-liang, CHEN Zi-yong, KONG Fan-tao, CHEN Yu-yong. Development of casting and melting technology of titanium alloys[J]. Materials Science & Technology, 2004, 12(3): 332-336.

[8] 张金林, 陈 红, 郭培军, 曲玉福, 周 跃. 真空自耗凝壳炉直接熔配和铸造钛合金件的工艺研究[J]. 铸造, 2006, 55(5): 452-455.

ZHANG Jin-lin, CHEN Hong, GUO Pei-jun, QU Yu-fu, ZHOU Yue. Research on technique of single melting and casting titanium alloy by var[J]. Foundry, 2006, 55(5): 452-455.

[9] 赵小花, 李金山, 常 辉, 杨治军, 寇宏超, 胡 锐, 周 廉. 真空自耗电弧熔炼过程中电磁场的数值模拟[J]. 中国有色金属学报, 2010, 20: 538-543.

ZHAO Xiao-hua, LI Jin-shan, CHANG Hui, YANG Zhi-jun, KOU Hong-chao, HU Rui, ZHOU Lian. Numerical simulation of electromagnetic field in vacuum arc remelting process[J]. The Chinese Journal of Nonferrous Metals, 2010, 20: 538-543.

[10] 杨治军, 寇宏超, 常 辉, 李金山, 胡 锐, 周 廉. VAR工艺参数对Ti-10V-2Fe-3Al 铸锭凝固行为的影响[J]. 特种铸造及有色合金, 2010, 30(4): 295-298.

YANG Zhi-jun, KOU Hong-chao, CHANG Hui, LI Jin-shan, HU Rui, ZHOU Li-an. Effects of VAR( vacuum consumable arc remelting) processing parameters on solidification behavior of Ti-10V-2Fe-3Al alloy ingot[J]. Special Casting & Nonferrous Alloys, 2010, 30(4): 295-298.

(编辑 杨幼平)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:杨文甲,工程师;电话:024-31486604; E-mail: 1442023682@qq.com