铜基体上渗铝层的高温抗氧化性能和组织变化

来源期刊:中国有色金属学报(英文版)2015年第1期

论文作者:王红星 张 炎 成家林 李玉山

文章页码:184 - 190

关键词:铜;Ni2Al3相渗层;高温抗氧化性能;NiAl相;包渗铅法

Key words:copper; Ni2Al3 coating; high temperature oxidation resistance; NiAl phase; pack aluminizing

摘 要:以铜为基体,采用电镀镍和浆料包渗铝法,在800 °C渗铝12 h制备出组织为Ni2Al3的单相渗层。采用SEM、XRD和光学显微镜,研究在1000 °C下空气中氧化25~250 h,Ni2Al3渗层的高温抗氧化性能与组织转变行为。结果表明:Ni2Al3渗层在1000 °C氧化250 h后,氧化增重分别为纯铜和镍镀层的1/15和1/2。氧化时间在25 h内时,渗层表面仍有Ni2Al3相;氧化50 h后,出现NiAl相;当氧化时间增加到100 h时,Ni2Al3相完全转变为NiAl相。当氧化到250 h时,渗层仍具有良好的抗高温氧化性能。

Abstract: The outermost coating with single phase Ni2Al3 was obtained on copper surface by electrodepositing nickel followed by slurry pack aluminizing at 800 °C for 12 h. The oxidation resistance and microstructure of the coating oxidized in ambient air at 1000 °C for 25-250 h were investigated using SEM, X-ray diffraction and optical microscope methods. The results show that the copper with single phase Ni2Al3 coating possesses the best high temperature oxidation resistance, and the mass gain of the coating is 1/15 that of pure copper and 1/2 that of nickel coating, respectively. The specimen surface after being oxidized for 25 h still comprises Ni2Al3 phase. However, when the time of oxidizing treatment increases to 50 h, the NiAl phase is formed. It is also found that the Ni2Al3 phase completely turns into NiAl phase after oxidizing treatment for 100 h and above. The NiAl coating shows excellent high temperature oxidation resistance when oxidation time is 250 h.

Trans. Nonferrous Met. Soc. China 25(2015) 184-190

Hong-xing WANG, Yan ZHANG, Jia-lin CHENG, Yu-shan LI

School of Materials Engineering, Nanjing Institute of Technology, Nanjing 211167, China

Received 13 January 2014; accepted 28 May 2014

Abstract: The outermost coating with single phase Ni2Al3 was obtained on copper surface by electrodepositing nickel followed by slurry pack aluminizing at 800 °C for 12 h. The oxidation resistance and microstructure of the coating oxidized in ambient air at 1000 °C for 25-250 h were investigated using SEM, X-ray diffraction and optical microscope methods. The results show that the copper with single phase Ni2Al3 coating possesses the best high temperature oxidation resistance, and the mass gain of the coating is 1/15 that of pure copper and 1/2 that of nickel coating, respectively. The specimen surface after being oxidized for 25 h still comprises Ni2Al3 phase. However, when the time of oxidizing treatment increases to 50 h, the NiAl phase is formed. It is also found that the Ni2Al3 phase completely turns into NiAl phase after oxidizing treatment for 100 h and above. The NiAl coating shows excellent high temperature oxidation resistance when oxidation time is 250 h.

Key words: copper; Ni2Al3 coating; high temperature oxidation resistance; NiAl phase; pack aluminizing

1 Introduction

Due to the excellent electrical and thermal conductivity, copper is widely used as crystallizer in continuous casting and rolling. However, the poor resistance oxidation and wear resistance at high operating temperature limit its application [1,2].

In order to enhance the surface properties of pure copper, it is often needed to coat Ti, Si and Al on the copper surface. This may be achieved by diffusion of particular elements into the surface layers of copper in order to develop intermetallic type coatings. Therefore, lots of techniques have been studied to develop an efficient process to deposit coatings on copper or modify the chemical composition of its surface [3-5]. However, they are mainly focused on producing and characterizing the wear resistance of coatings. For instance, with the introduction of a nickel intermediate layer, a 0.13 mm thick Mo/Ni layer was obtained on copper by a two-step laser cladding of preplaced Ni and Mo layers. In this way, the wear resistance of copper could be largely improved [6]. A 1.5 mm nickel based alloy coating was deposited onto pure copper surface by laser cladding with coaxial powder feeding by ZHANG et al [7]. The results indicated that the average hardness of the coating was about HV 360, and the wear resistance of copper was significantly improved after cladding. Recently, Al and N have been introduced into copper by plasma immersion ion implantation and beam-line ion implantation by AN et al [8].

Among various coating processes used to improve the oxidation resistance, pack cementation is a relatively simple process to produce coatings on the substrate of complex geometry, which is widely used to deposit high temperature oxidation and corrosion resistance coatings on nickel-based superalloys and low-alloyed steels [9-14]. In recent years, several intermetallic compound coatings have been developed and successfully employed to copper surface with minimal wear in sliding and good oxidation properties [4].

To the best our knowledge, few information is available in literature concerning the oxidation resistance properties of copper after surface modification above 900 °C. The coating with the single phase Ni2Al3 was obtained on copper surface by electrodepositing nickel followed by slurry pack aluminizing at 800 °C for 12 h [15]. The aim of this work was to analyze the oxidation behavior and the structure of aluminized coating in ambient air at 1000 °C for 25, 50, 100, 150 and 250 h.

2 Experimental

2 Experimental

2.1 Materials and process

The plating electrolyte was a nickel sulfamate solution whose compositions are listed in Table 1 and the experimental process parameters are listed in Table 2. A commercial nickel plate with the size of 120 mm×80 mm×10 mm was used as the anode, and a copper plate with size of 12 mm×10 mm×2 mm was used as the cathode. The temperature of the electrolyte was maintained at room temperature. Cathode surface was ground with a series of Al2O3 paper up to 800-grit. They were ultrasonically cleaned in water bath, and then dipped in a water solution of 5% H2SO4 for 3 min, followed by cleaning in water and drying in air.

Table 1 Composition of electrolyte (g·L-1)

Table 2 Plating conditions

After electroplating, copper coated with nickel plating was firstly rinsed by water, and then cleaned ultrasonically in acetone. The slurry pack cementation powder mixtures mainly consisted of pure Al powder (70% as aluminzing source), NH4Cl (5% as activator), albumen (egg white, as cohesive agent), and Al2O3 powder (20%) as an anti-sintering reagent which was inert and did not take place in the process reactions but only was used for balancing heat transfer and temperature distribution. After weighting and mixing, the slurry pack powder mixture was ground by hand using an alumina mortar and pestle thoroughly, then mixed with the cohesive agent albumen into slurry. The slurry was spread on the nickel coating thoroughly by hand, and then dried in a vacuum airer at 80 °C for 1 h. The samples were placed into an alumina crucible filled with alumina powder, then the crucible was put into the vacuum firing furnace which was washed by argon for three times, and then was full of argon with 1.25 MPa pressure to avoid oxidation. The furnace temperature was raised to a final depositing temperature of 800 °C at a rate of 10 °C/min and the holding time was 12 h. The furnace was then cooled to room temperature at its natural rate by switching off its power supply while maintaining the argon pressure. To remove the pack powder remaining on the surface of specimens after the pack aluminizing process, ultra-sonicated cleaning was conducted in acetone for 20 min, and then in deionized water for 20 min.

2.2 Oxidation tests

In order to assess the oxidation resistance of coating prepared by pack aluminizing at 800 °C for 12 h, isothermal oxidation tests were heat-treated in ambient air at 1000 °C for 25, 50, 100, 150 and 250 h, respectively. Each specimen was placed in a corundum crucible. Prior to the tests, the crucibles were heat treated at 1000 °C for 24 h. The crucibles were cooled down to room temperature in furnace and measured using an electronic balance with a resolution of 0.1 mg. The masses of the specimen and the crucible were recorded together, which means that the spalled scale, if any, was included in the kinetics curves.

2.3 Characterization of oxidized coating

Metallographic cross-sections of the oxidized coatings were prepared using standard procedures and etched using the etchant of HCl and HNO3 in volume ratio of 3:1. The surface morphology and the distribution of elements in cross-sections of the oxidized specimens were analyzed using field-emission scanning electron microscopy (SIRON) associated with energy dispersive spectroscopy (EDS). Phase was identified by XD-3A X-ray diffractometer with Cu Kα radiation, λ=1.5804 and scan speed of 5 (°)/min. The microstructure of the cross-sections was observed by OLYMPUS-B202.

3 Results and discussion

3.1 Microstructure and concentration profiles of as- prepared coating

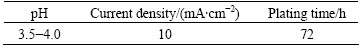

Figure 1(a) shows the structure of the cross-section of the coating formed by slurry pack cementation aluminizing process at 800 °C for 12 h. It can be seen that the surface copper consists of two layers: the outer layer is approximately 240 μm thick aluminized coating without obvious pores and the inner layer is about 300 μm thick Ni plating.

Figure 1(b) shows the SEM-EDS line-scanning profiles of element nickel and aluminum distribution across the aluminizing coating on the copper matrix. Figure 1(c) shows the optical micrograph of the etched cross-section of the aluminized coating. As shown in Fig. 1(b), the content of Al in the coating near the interface between Ni plating and aluminized coating decreases abruptly and that of Ni increases. EDS results show that the contents of Al at the surface and at the interface between Ni plating and aluminized coating are 62.3% and 64.4%, respectively, which indicates that there is a content gradient of Al from the surface layer to the inner layer of the aluminized coating. According to the binary phase diagram, Ni2Al3 phase can be formed after heating to 800 °C with the content of Al in the range of 59%-65% (mole fraction). During furnace cooling from 800 °C, the Ni2Al3 phase does not transform. The XRD results indicate that the outmost layer of coating is a single phase Ni2Al3 intermetallic compound, as shown in Fig. 1(d), which is in agreement with the EDS results.

Fig. 1 Cross-sectional morphology (a), content profiles of Ni and Al (b), optical image of Ni2Al3(c), and XRD pattern (d) of coating prepared by slurry pack cementation at 800 °C for 12 h

In the slurry pack cementation process, the Al metal powders at the treatment temperature react with the HCl vapors produced from dissociation of the activator (NH4Cl), resulting in the formation of precursor vapors of aluminium chlorides, which would pass through the porous pack and reach the Ni plating layer surface. The aluminium chlorides are absorbed and decomposed and release the active atoms on the Ni plating surface, and during the subsequent solid-state diffusion, the active atoms react with the Ni plating, which results in the formation of the aluminium-containing coating on the sample surface. According to Refs. [12-14], the mechanism of the deposition of aluminium was mainly transferred by the disproportionate amount of lower valence chlorides at the substrate surface, followed by the subsequent solid-state inward diffusion of aluminium and outward diffusion of Ni.

3.2 Oxidation behavior of aluminized coating

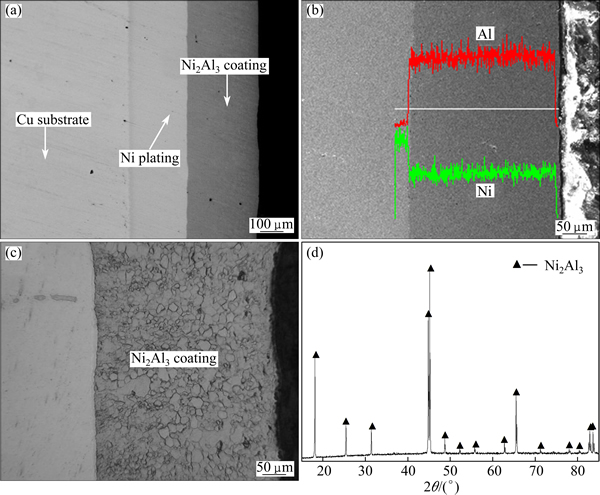

Figure 2 shows the variations of mass gain vs time of the aluminized coating, copper and nickel coating during oxidation at 1000 °C for 25, 50, 100, 150 and 250 h, respectively. The results indicate that the mass gains of the aluminized coating and nickel coating are much lower than that of the copper matrix. The comparison of the oxidation behavior of nickel and aluminized coatings shows a lower mass gain for the latter. Scale growth on the pure copper follows parabolic law for the first 150 h. Since then, the oxidation rates become faster because the spallation of oxide scales exposes fresh surfaces of the metal. The oxidation of the aluminized coating and nickel coating does not obey the parabolic growth law, they also show a similar trend during oxidation as shown in Fig. 2. After 250 h oxidation, the mass gain of pure copper is 148.313 mg/cm2, whereas for Ni plating and aluminized coating it is 25.526 mg/cm2 and 10.108 mg/cm2, respectively.

Fig. 2 Oxidation kinetics of Ni2Al3 coating, pure copper and nickel plating at 1000 °C for different time

3.3 Morphology and phases on surface of aluminized coatings after oxidation

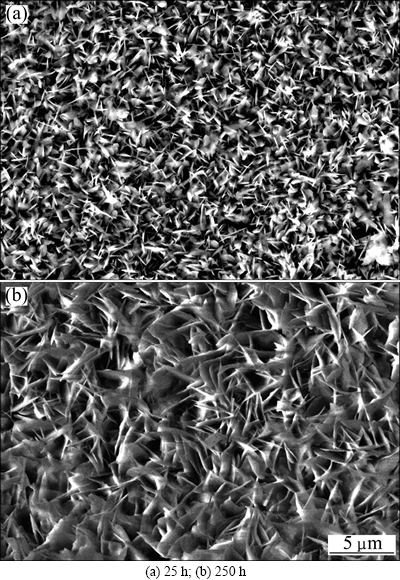

Figure 3 shows the surface morphologies of the aluminized coating oxidized in ambient air at 1000 °C for 25 h and 250 h, respectively. It is found that a needle-like oxide is formed on the surface after oxidation of 25 h, as shown in Fig. 3(a). The size of oxides increases with the increase of the oxidation time, and no cracks and voids are observed, as shown in Fig. 3(b), which can effectively lower the diffusion ratio of O and Al atom through the oxides scale to form the oxides. This provides a good oxidation resistance for the substrate materials.

Fig. 3 Surface morphologies after different oxidation time at 1000 °C

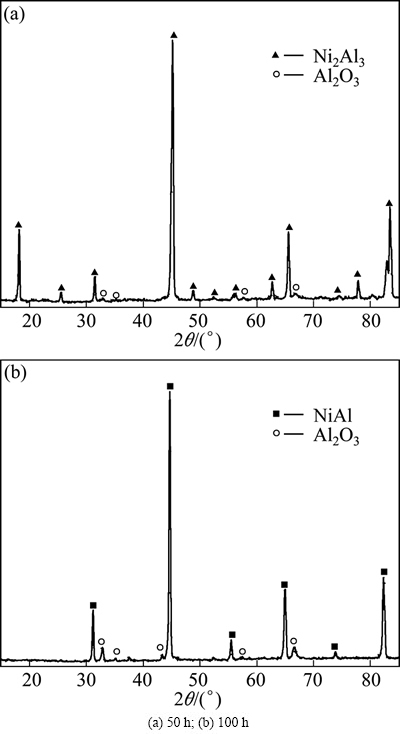

The XRD patterns for the surfaces of the coatings after 1000 °C oxidation for different time are shown in Fig. 4. The phase on the surface of aluminized coating is a single phase Ni2Al3 intermetallic compound after oxidation for 25 h. At the early stage of oxidation, a needle-like shape oxide on the surface of the aluminized coating is formed after oxidation for 25 h (as shown in Fig. 3(a)), but X-ray diffraction cannot detect any oxides. This may be due to the fact that the thickness is rather small, exceeding the capability of the X-ray diffraction. When the oxidation time is up to 50 h, the coating surface consists of two phases: Al2O3 and Ni2Al3, as shown in Fig. 4(a). Further extending oxidation time to 100 h, the peaks of Ni2Al3 phase disappear and the peaks of NiAl phase appear, as shown in Fig. 4(b). After oxidation time from 100 to 250 h, the phases of the aluminized coating surfaces are still composed of Al2O3 and NiAl as shown in Fig. 4(b). On the surface of coating, Al depletion occurs in the coating near the interface between oxide and coating due to Al anion outward diffusion to the surface and reaction with oxygen at the gas/scale interface, which could be the formation of Al2O3 described by the reaction 4Ni2Al3+3O2→8NiAl+ 2Al2O3. According to Ellingham-Richardson diagram, the free energies of formation of Al2O3 and NiO are -936 kJ/mol and -285 kJ/mol, respectively. From the thermodynamic point of view, the thermal stability of Al2O3 is much higher than that of NiO, which leads to selective oxidation to form Al2O3 scale at high temperature.

Fig. 4 XRD patterns of aluminized coatings after oxidation at 1000 °C

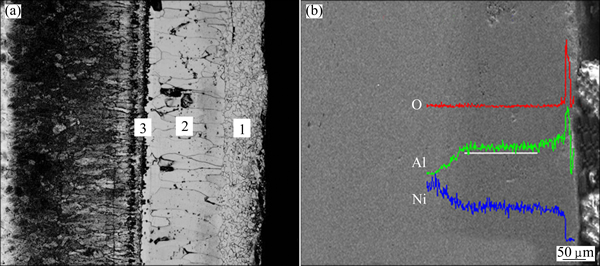

3.4 Constituent change in cross-sections of aluminized coatings after oxidation

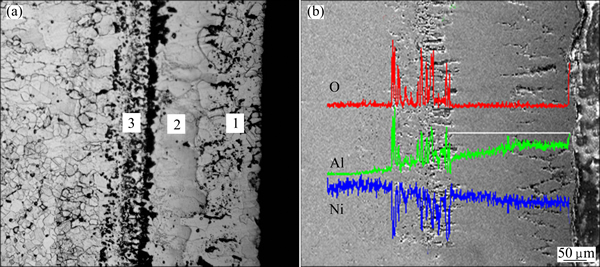

Figures 5(a) and (b) show the microstructure and distribution of Al, Ni and O in cross-section of aluminized coating oxidized for 25 h, respectively. It can be seen that the aluminized coating with a single phase Ni2Al3 (shown in Fig. 1(a)) has been changed into three-layer structure, which is composed of an outermost layer (1), an intermediate layer (2) and an inner layer (3). EDS patterns from the outermost layer and an intermediate layer show that the aluminized coating contains Al and Ni. The outermost layer contains 55.1%- 58.9% Al (mole fraction), and the intermediate layer contains 50.5%-55.1% Al. According to the Ni-Al binary phase diagram, the outermost layer is Ni2Al3 phase and the intermediate layer is NiAl phase, respectively. When the oxidation time is up to 50 h, the thickness of the outermost layer decreases, and Ni2Al3 phase with 15 μm thickness still appears, which contains 53.5%-56.7% Al. The intermediate layer with the Al content between 48.5% and 53.5% is still NiAl phase. The dentritic structure grows with increasing the oxidation time. The microstructure of the inner layer remains unchanged with Al content in the range of 8.3%-48.5%, but the thickness is larger than that after oxidation 25 h, as shown in Fig. 6. Further extending the oxidation time to 250 h, the outermost layer remains to be a NiAl phase with an Al content in the range of 44.5%-52.68%, but cracks already present in the coating. It is observed that there are no voids and cracks in the intermediate layer with an Al content of 40.5%-44.5%. In the inner layer with an Al content of ~40.5%, voids are found at the coating/substrate interface. These voids may have been formed by phase transformation from Ni2Al3 to NiAl, accompanied by a volume reduction. Using the molar volumes of Ni2Al3 (40.5 cm3/mol) and NiAl (15.9 cm3/mol), the volume reduction can be estimated to be about 21.5% theoretically. Accordingly, the relatively large reduction of volume due to the phase transformation could be the main cause of the void formation. In addition, many vacancies are left in the lattice of NiAl due to the Al anion outward diffusion. The vacancy congregates and grows with the increase of the oxidation time, and finally forms voids near the interface of NiAl/Al2O3 scale.

Fig. 5 Cross-sectional microstructure (a) and element content profiles of Ni, Al, O (b) for aluminized coating oxidized at 1000 °C for 25 h

Fig. 6 Cross-sectional microstructure (a) and element content profiles of Ni, Al, O (b) for aluminized coating oxidized at 1000 °C for 50 h

Fig. 7 Cross-sectional microstructure (a) and element content profile of Ni, Al, O (b) for aluminized coating oxidized at 1000 °C for 250 h

From the Ni-Al binary diagram, the Ni2Al3 phase region is narrow enough to easily transform to NiAl phase because of Al depletion. Due to the low melting point (1133 °C) and extreme brittleness of Ni2Al3 phase, it is not desirable to form a protective phase for high temperature application. It is possible to transform this brittle and low melting point Ni2Al3 phase into high melting point NiAl phase. There is an abrupt content change of Al at the interface between Ni plating and Ni2Al3 coating (as shown in Fig. 7(b)), which results in a diffusion couple between the nickel plating and Ni2Al3 coating. During the process of oxidation, the Al atoms in Ni2Al3 coating diffuse inwardly and the Ni atoms in nickel plating diffuse outwardly through the interface between Ni plating and Ni2Al3 coating. The interdiffusion leads to the decrease of the Al atom content in Ni2Al3 phase, and the increase of Ni atom content. Ni2Al3 phase near the interface transforms into NiAl phase described by the reaction Ni2Al3+Ni→3NiAl. The good high temperature oxidation resistance of the Ni2Al3 coating is attributed to the high Al content in the coating layer that is beneficial in forming an Al2O3 scale. Furthermore, NiAl phase formed by Ni2Al3 phase by changes in the coating exhibits a better oxidation resistance at high temperature.

4 Conclusions

1) The coating formed on Ni plated copper substrate by the slurry pack cementation has a duplex layer structure (outermost Ni2Al3 and inner nickel plating). The outermost layer is a single Ni2Al3 phase with Al composition in the range of 59%-65%.

2) The coated copper is oxidized slowly without exfoliation of the protective Al2O3 scale, resulting in a mass gain of 10.108 mg/cm2 after oxidation for 250 h at 1000 °C. The coating exhibits a better oxidation resistance. After being oxidized at 1000 °C for 25 h, the coating structure is still mainly Ni2Al3 phase; NiAl phase is presented after oxidation for 50 h. Finally, Ni2Al3 phase changes into NiAl phase wholly after being treated for 100 h or a longer time. Among them, NiAl phase in the outermost layer is Al-rich while NiAl in inner layer is Ni-rich.

References

[1] SUZUKI S, SHIBUTANI N, MIMURA K, ISSHIKI M, WASEDA Y. Improvement in strength and electrical conductivity of Cu-Ni-Si alloys by aging and cold rolling [J]. Journal of Alloys and Compounds, 2006, 417(1-2): 116-120.

[2] LIU Fang, LIU Chang-sheng, TAO Xing-qi, CHEN Sui-yuan. Laser cladding of Ni-based alloy on copper substrate [J]. Journal of University of Science and Technology Beijing, 2006, 13(4): 329-332. (in Chinese)

[3] LIU H F, CHEN W X. Reactive oxide-dispersed Ni3Al intermetallic coatings by sediment co-deposition [J]. Intermetallics, 2005, 13(8): 805-817.

[4] FATHY A, SHEHATA F, ABEDLHAMEED M, ELMAHDY M. Compressive and wear resistance of nanometric alumina reinforced copper matrix composites [J]. Materials and Design, 2012, 36: 100-117.

[5] LI M Y, CHAO M Y, LIANG E J, YU J M, ZHANG J J, LI D C. Improving wear resistance of pure copper by laser surface modification [J]. Applied Surface Science, 2011, 258(4): 1599-1604.

[6] NG K W, MAN H C, CHENG F T, YUE T M. Laser cladding of copper with molybdenum for wear resistance enhancement in electrical contacts [J]. Applied Surface Science, 2007, 253(14): 6236-6241.

[7] ZHANG Y Z, TU Y, XI M Z, SHI L K. Characterization on laser clad nickel based alloy coating on pure copper [J]. Surface and Coatings Technology, 2008, 202(24): 5924-5928.

[8] AN Q Z, LI L H, HU T, XIN Y C, RICKY K Y F, KWOK D T K, CAI X, CHU PAUL K. Comparison of oxidation resistance of copper treated by beam-line ion implantation and plasma immersion ion implantation [J]. Materials Chemistry and Physics, 2009, 116(2-3): 519-522.

[9] QIAO M, ZHOU C G. Hot corrosion behavior of Co modified NiAl coating on nickel based superalloys [J]. Corrosion Science, 2012, 63: 239-245.

[10] GUO H B, LI D Q, PENG H, CUI Y J, GONG S K. High-temperature oxidation and hot-corrosion behaviour of EB-PVD β-NiAlDy coatings [J]. Corrosion Science, 2011, 53(3): 1050-1059.

[11] VENKATAKRISHNA K, CHITHARANJAN H A. Composition modulated multilayer Zn-Fe alloy coatings on mild steel for better corrosion resistance [J]. Materials and Manufacturing Processes, 2011, 26(2): 29-36.

[12] LUO Hong. Corrosion resistance of pack aluminized SUS304 stainless steel [J]. Journal of Chinese Society for Corrosion and Protection, 2009, 29(5): 344-348. (in Chinese)

[13] HUANG Min, WANG Yu. Effects of embedding time on the microstructure and properties of aluminized N80 casting steel [J]. Journal of Xi’an Shiyou University: Natural Science Edition, 2011, 26(4): 64-68. (in Chinese)

[14] CHALIAMPALIAS D, PAPAZOGLOU M, TSIPAS S,PAVLIDOU E, SKOLIANOS S, STERGIOUDIS G, VOURLIAS G. The effect of Al and Cr additions on pack cementation zinc coatings [J]. Applied Surface Science, 2010, 256(11): 3618-3623.

[15] WANG Hong-xing, SHENG Xiao-bo, CHU Cheng-lin, LIN Ping-hua. Aluminizing microstructure and its formation mechanism on electro-deposited nickel layer on copper matrix [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1616-1621. (in Chinese).

王红星,张 炎,成家林,李玉山

南京工程学院 材料工程学院,南京 211167

摘 要:以铜为基体,采用电镀镍和浆料包渗铝法,在800 °C渗铝12 h制备出组织为Ni2Al3的单相渗层。采用SEM、XRD和光学显微镜,研究在1000 °C下空气中氧化25~250 h,Ni2Al3渗层的高温抗氧化性能与组织转变行为。结果表明:Ni2Al3渗层在1000 °C氧化250 h后,氧化增重分别为纯铜和镍镀层的1/15和1/2。氧化时间在25 h内时,渗层表面仍有Ni2Al3相;氧化50 h后,出现NiAl相;当氧化时间增加到100 h时,Ni2Al3相完全转变为NiAl相。当氧化到250 h时,渗层仍具有良好的抗高温氧化性能。

关键词:铜;Ni2Al3相渗层;高温抗氧化性能;NiAl相;包渗铅法

(Edited by Yun-bin HE)

Foundation item: Projects (CKJB201205, QKJB201202, YJK201307) supported by the Nanjing Institute of Technology, China

Corresponding author: Hong-xing WANG; Tel: +86-25-86118274; E-mail: wangzhao2000922@163.com

DOI: 10.1016/S1003-6326(15)63594-4