文章编号: 1004-0609(2005)02-0205-05

Al-TiO2系XD合成铝基复合材料的反应机理

朱和国1, 王恒志1, 熊党生1, 孙强金1, 吴申庆2

(1. 南京理工大学 材料科学与工程系, 南京 210094; 2. 东南大学 材料科学与工程系, 南京 210096)

摘 要: 分析了Al-TiO2系XD合成铝基复合材料的反应机理。 研究表明: Al与TiO2之间可自发进行强放热反应, 燃烧温度随增强相体积分数的增加而增加, 在增强相体积分数为50%时, 燃烧温度已达1960K, 远高于Merzhanov 的经验判据值1800K; 反应产物Al2O3是由液态Al与固态TiO2直接反应产生的, 呈细小颗粒状, 偏聚于基体颗粒的界面; Al3Ti是活性Ti原子扩散穿过反应层进入铝液与液态Al结合生成的, 呈短棒状, 分布相对均匀; 影响反应速率的主要因素有: TiO2颗粒尺寸、 燃烧温度、 反应活化能、 反应界面面积等。

关键词: 复合材料; 活化能; 加热速率; 热扩散反应 中图分类号: TB332

文献标识码: A

Reactive mechanism of composites synthesized by XD method in Al-TiO2 system

ZHU He-guo1, WANG Heng-zhi1, XIONG Dang-sheng1, SUN Qiang-jin1, WU Shen-qing2

(1. Department of Materials Science and Engineering,

Nanjing University of Sciences and Technology, Nangjing 210094, China;

2. Department of Materials Science and Engineering,

Southeast University, Nangjing 210096, China)

Abstract: The reactive mechanism of the composites synthesized by XD method in the Al-TiO2 system was analyzed. The thermodynamic results indicate that the reactions between TiO2 and Al carry through spontaneously with high quantity of exothermic heat. The combustion temperature increases with promoting the volume fraction and exceed Merzhanov experience criterion which is about 1800K when the reinforcement volume fraction is higher than 50%. The combusted products consist of particulate Al2O3 and stick Al3Ti. The Al2O3 particulates are formed directly by the reaction between Al and TiO2 and accumulated at grain interfaces of the matrix. The stick Al3Ti is formed by the reaction between Al atoms and active titanium diffused from the reaction region of Al-TiO2 and distributes uniformly in the matrix. The main factors influencing the reaction velocity of Al-TiO2 system are the size of TiO2 powders, combustion temperature, reaction activation energy, area of the reaction interface etc.

Key words: composites; active energy; heating rate; exothermic dispersion reaction

内生型复合材料的增强相是通过原位反应在基体中直接产生的, 具有表面干净无污染, 与基体的相容性好, 热力学稳定, 界面结合强度高, 并可充分利用化学反应能, 节约能耗。 原位合成技术已成为一种新型的复合材料制备技术[1-5]。

通常, 由于反应条件如反应物尺寸、 压力、 温度等的不同, 同一反应产物在不同的反应体系中表现出来的反应机理是不同的, 即使在同一反应体系中而采用不同制备方法时, 其反应机理也可能不同。 任何动力学因数的改变, 均直接影响反应路径及其反应产物。 文献[6, 7]中作者通过对Al-Ti-C系反应动力学的研究表明, TiC是Ti原子穿过围裹在C周围的富钛层与C原子结合形成的, 形成后的TiC原子从熔液中析出并向外扩散。 Tong等[8]通过Al-K2TiF6-C反应系的动力学研究结果发现, TiC的形成是在铝熔体中石墨周围的Al首先与盐K2TiF6发生剧烈的化学反应, 放出大量的热, 在铝基体中形成大量的局部高温微区, 此时, 晶体中的Ti或Al3Ti才满足形成TiC的热力学条件, 从而在石墨颗粒周围反应生成TiC的。 赵玉涛等[9, 10]采用Al-ZrOCl2反应系熔体反应合成Al3Zr和Al2O3复合增强的铝基复合材料, 并分析了反应机理, 认为Al-ZrOCl2反应系为气-液和固-液反应的复合过程。 Peng等[11]利用Al-TiO2系XD(exothermic dispersion synthesis )合成了体积分数为30%的Al2O3增强金属间化合物Al3Ti为基体的复合材料, 并分析了微观结构和反应机理。

作者曾采用Al-TiO2系制备了Al2O3和Al3Ti复合增强的铝基复合材料[12], 并分析了增强相的体积分数对反应过程的影响。 对Al-TiO2系的深入研究直接影响到Al-TiO2-X反应系的开发和研究, 为此, 本文作者对Al-TiO2系的反应机理展开讨论。

1 实验方法

采用纯Al和TiO2粉末为反应物, 纯度分别为99.6%和99.0%, 粒度尺寸分别为50~100μm和20~30μm。 以一定的化学计量比进行配粉、 球磨, 再以不同的压力冷挤成直径为30mm、 高度为10mm左右的压坯, 将之置于真空反应炉中, 抽真空、 充氩, 反复两次, 再以一定的升温速率预热, 在1000K左右时压坯发生化学反应, 保温一段时间后冷至室温, 制样后进行SEM电镜观察(型号: QUANTA200)、 X射线衍射和能谱分析。

2 实验结果

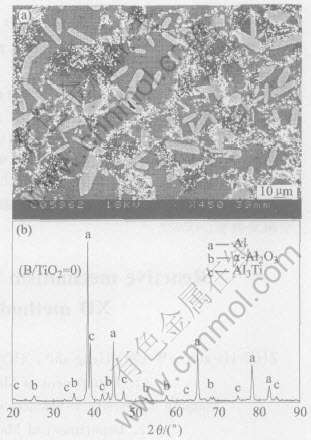

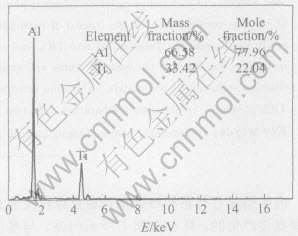

图1所示为Al-TiO2反应系的反应产物的SEM照片及其X射线衍射谱。 从图1(a)可以看出反应产物由棒状物、 偏聚的细小颗粒以及基体3部分组成。 由X射线衍射谱(图1(b))可知3种组织为Al、 Al2O3和Al3Ti, 棒状物由其能谱分析(图2)可知为Al3Ti, 则细小颗粒为Al2O3, 暗色为铝基体。

图1 Al-TiO2系反应产物的SEM显微组织及其X射线衍射谱

Fig.1 SEM microstructure(a) and XRD spectrum(b)

of reacted products of Al-TiO2 system

图2 棒状物的能谱图

Fig.2 EDS of stick-shape phase

3 反应机理

3.1 反应热力学

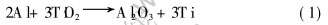

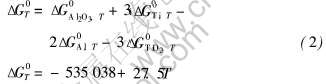

Al-TiO2系有如下的反应:

由文献[13, 14]及相关数据得:

令ΔG0T=0 则T0=19455K。 T>T0时, 反应式ΔG0T>0。 通常温度均远低于19455K, 因此从热力学角度来讲, ΔG0T远小于0, 式(1)是可以自发进行的。

反应产生的活性Ti原子与Al原子有多种结合形式, 即:

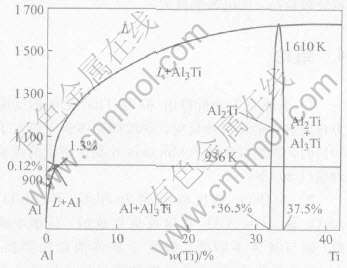

从Al-Ti二元相图(图3)可知, 在Al含量较高(大于63.5%)时, AlxTiy以Al3Ti的形式存在, 本研究所涉及的铝含量均高于此值, 因此Al与Ti的结合产物应为Al3Ti。

图3 Al-Ti二元相图

Fig.3 Al-Ti binary phase diagram

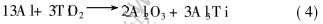

Al-TiO2系的总反应式为

此时

令式(5)等于0, 则T=3760K。

因此, 正常条件下ΔG0T〈0, 即反应式(5)能自发进行。

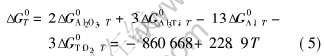

由文献[13, 14]得:

∑x=∑nix生成物-∑nix反应物(ni为反应式中的计量数)(8)

再由文献[13, 14]的相关数据得:

ΔH0298=2ΔH0Al2O3+3ΔH0Al3Ti-

13ΔH0Al-3ΔH0TiO2=-936530J

∑a=-82.26; ∑b=121.47;

∑c=123.72; ∑d=0

Δcp, T=-86.26+121.47 10-3T+

123.72 105T-2

则(4)式的热效应为

ΔH0T=-936530-86.26T-6.07 10-1T2-

123.72 105T-1(9)

通过线性插值法计算得Al-TiO2系的燃烧温度为2966K。

当增强相体积分数小于100%时, 反应过程中有过量铝存在, 并吸收反应热, 导致燃烧温度下降。 在增强相体积分数分别为20%、 30%、 40%、 50%、 100%时, 通过计算燃烧温度分别为1320、 1507、 1736、 1982、 2996K。 由Merzhanov经验判据[15]: T>1800K时, SHS燃烧反应可稳定进行。 在Al-TiO2系中只有增强相体积分数高于50%时燃烧反应方可稳定进行, 因此在增强相体积分数低于50%时, 不宜采用SHS法, 而XD法可通过预热和调整升温速率等工艺参数弥补其放热不足, 仍可制得体积分数相对较低的金属基复合材料。

3.2 反应动力学

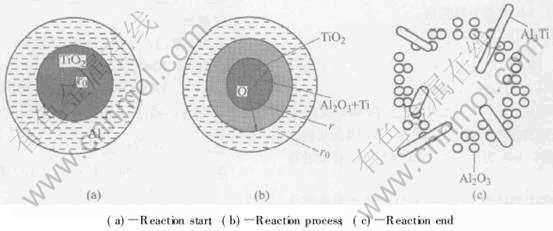

在1000K左右时, Al已液化, 并通过原子扩散和毛细吸附的作用包裹TiO2粉, 形成液固界面(如图4所示)。 反应过程剧烈, 持续时间仅数秒钟, 界面的瞬时温度达2000K左右[16], 在Al-TiO2反应界面产生Al2O3颗粒和活性Ti原子, 因ρAl2O3>ρTiO2, 这样反应产物层的体积减小, Al2O3不能完全致密分布在TiO2颗粒的表面, 这样铝液可通过毛细扩散穿过Al2O3反应层。 尽管Al2O3与Al液的润湿性差(润湿角为118°[17]), 影响了铝原子的扩散, 但反应界面温度高, 由粘温性可知, 高温时铝液的粘度降低, 毛细吸附能力增强, 扩散速率相应提高。 浓度梯度和高温促使各自反应区内的活性Ti原子向Al液中扩散, 同时也促使Al液向反应界面传输。 随着反应的进行, 原子的扩散路程和扩散阻力逐渐增加, 反应界面逐渐减小, 反应速率也随之降低。 因此, Al-TiO2之间的反应速率和扩散速率的变化基本同步。 为此, 以反应控制建立动力学反应模型, 同时作如下假设:

图4 Al-TiO2系反应过程的动力学模型

Fig.4 Kinetic model of Al-TiO2 reaction system

1)反应组元TiO2固体颗粒为球形, 反应时被铝液包裹, 原始半径为r0, 反应过程中的半径为r, 如图4所示;

2)反应过程为等温过程;

3)产物形核在瞬间完成。

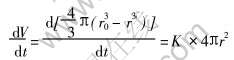

此时, 反应产物的体积用V表示, 则

由反应控制原理得

式中 S为反应界面面积; K为反应速率常数。

得

表明在反应过程中, 球形颗粒的半径减小的速率即为反应速率常数。

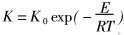

由定义得

式中 η为转化率; ; R为气体常数; E为反应活化能; K0为常数。

; R为气体常数; E为反应活化能; K0为常数。

由反应速率的定义得

因此, 反应速率φ与TiO2颗粒的粒径2r0、 反应温度T、 反应活化能E、 反应界面面积S等因素有关。 TiO2颗粒愈细, 混粉质量愈好, 增强体的体积分数愈高, 反应速率愈大。

4 结论

1) 从热力学分析得出Al与TiO2之间的反应为自发进行的强放热反应, 在增强相体积分数大于50%时, 燃烧温度高于Merzhanov稳定燃烧的经验判据(1800K)。

2) Al-TiO2系反应产物为Al2O3和Al3Ti。 Al2O3是Al与TiO2直接反应生成的, 呈细小颗粒, 因与基体不润湿, 偏聚于基体颗粒的界面; Al3Ti是活性Ti原子通过扩散穿过反应层进入铝液, 与铝原子结合生成的, 呈棒状, 分布相对均匀。

3) Al-TiO2系XD合成时, 反应和扩散基本同步, 影响反应速率的主要因素有TiO2颗粒的尺寸、 反应温度、 反应活化能、 反应界面面积等。

REFERENCES

[1]刘江, 彭晓东, 刘相果, 等. 原位合成铝基复合材料的研究现状[J]. 重庆大学学报, 2003, 26(10): 1-5.

LIU Jiang, PENG Xiao-dong, LIU Xiang-guo, et al. The studying status of in situ aluminum matrix composites[J]. Journal of Chongqing University, 2003, 26(10): 1-5.

[2]YANG B, WANG F, ZHANG J S. Microstructure characterization of in situ TiC/Al and TiC/Al-20Si-5Fe-3Cu-1Mg composites prepared by spray deposition[J]. Acta Materialia, 2003, 51: 4977-4989.

[3]Ranganath S. A review on particulate-reinforced titanium matrix composites[J]. Journal of Materials Science, 1997, 32: 1-16.

[4]WANG H Y, JIANG Q C, LI X L. Effect of Al content on the self-propagating high-temperature synthesis reaction of Al-Ti-C system in molten magnesium[J]. Journal of Alloys and Compounds, 2004, 366: L9-L12.

[5]FAN T X, ZHANG D, YANG G. Fabrication of in situ Al2O3/Al composites via remelting[J]. Journal of Materials Processing Technology, 2003, 142: 556-561.

[6]张作贵, 刘相法, 边秀房, 等. Al-Ti-C系中TiC形成的热力学与动力学研究[J]. 金属学报, 2000, 36: 1025-1029.

ZHANG Zuo-gui, LIU Xiang-fa, BIAN Xiu-fang, et al. Study on the thermodynamics and kinetics of the TiC formed in Al-Ti-C system[J]. Acta Metallurgica Sinica, 2000, 36: 1025-1029.

[7]ZHANG E L, ZENG S Y, YANG B, et al. A study on the kinetic process of reaction synthesis[J]. Metallurgical Transaction A, 1999, 30A: 1147-1157.

[8]TONG X C, FANG H S. Al-TiC composites in situ processed by ingot metallurgy and rapid solidification technology: part 1 microstructure evolution[J]. Metallurgical and Materials Transactions A, 1998, 29: 875-890.

[9]赵玉涛, 孙国雄. Al-ZrOCl2体系熔体反应生成Al3Zr(p), Al2O3(p)/Al复合材料的反应机制[J]. 中国有色金属学报, 2001, 11(3): 372-376.

ZHAO Yu-tao, SUN Guo-xiong. Reactive mechanism of Al3Zr(p), Al2O3(p)/Al composites formed by reaction between ZrOCl2 and liquid aluminum[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 372-376.

[10]赵玉涛, 孙国雄. Al-ZrOCl2体系反应制备Al3Zr(p)+Al2O3(p)Al复合材料[J]. 中国有色金属学报, 2001, 11(1): 41-46.

ZHAO Yu-tao, SUN Guo-xiong. Fabrication of the in situ composite Al3Zr(p), Al2O3(p)/Al in Al-ZrOCl2 system[J]. The Chinese Journal of Nonferrous Metals, 2001, 10: 41-44.

[11]PENG H X, FEN Z, WANG D Z. In situ Al3Ti-Al2O3 intermetallic matrix composites synthesis microstructure and compressive behavior[J]. J Materials Research, 2000, 15: 1943-1949.

[12]朱和国, 王恒志, 吴申庆. TiO2/Al摩尔比对Al-TiO2系XD反应合成铝基复合材料的影响[J]. 铸造, 2000, 49: 6-10.

ZHU He-guo, WANG Heng-zhi, WU Shen-qing. Influence of Al/TiO2 mole ratio on the XD synthesis of Al-TiO2 system[J]. Foundry, 2000, 49: 6-10.

[13]叶大伦, 胡建华. 实用无机物热力学数据手册[M]. 北京: 冶金工业出版社, 2002. 72-1059.

YE Da-lun, HU Jian-hua. Handbook of Thermodynamic Data for Inorganic Compound[M]. Beijing: Metallurgical Industry Press, 2002. 72-1059.

[14]梁英教, 车荫昌. 无机物热力学数据手册[M]. 沈阳: 东北大学出版社, 1993. 49-381.

LIANG Yin-jiao, CHE Ying-chang. Handbook of Thermodynamic Data for Inorganic Compound[M]. Shenyang: Northeastern University Press, 1993. 49-381.

[15]Merzhanov A G. Combustion processes that synthesis materials[J]. Journal of Materials Processing Technology, 1996, 56: 222-241.

[16]朱和国. Al-TiO2-X及Al-Fe2O3系原位反应合成复合材料研究[D]. 南京: 东南大学, 2003.

ZHU He-guo. Study on the Composites Fabricated by in situ Reactioin Method in Al-TiO2-X and Al-Fe2O3 Systems[D]. Nanjing: Southeast University, 2003.

[17]于化顺, 闵文辉, 陈熙琛. 固体粒子进入熔体的条件及影响因素[J]. 复合材料学报, 2000, 17 (3): 113-115.

YU Hua-shun, MIN Wen-hui, CHEN Xi-cheng. Conditions of the solid particles into melt and influence factors on it[J]. Acta Materiae Composites Sinica, 2000, 17 (3): 113-115.

基金项目: 南京理工大学发展基金资助项目(AB96056);国家高技术研究发展计划资助项目(2002AA331010)

收稿日期: 2004-07-06; 修订日期: 2004-11-08

作者简介: 朱和国(1963-),男,讲师,博士.

通讯作者: 朱和国, 博士; 电话: 025-84315979; E-mail:zhg1200@sina.com

(编辑袁赛前)