DOI: 10.11817/j.issn.1672-7207.2017.06.009

变形过程中铸轧铝合金中元素分布的演化行为

朱远志1,沈卫东2,张帆2,赵超奇1,蒙毅1,林宇龙2

(1. 北方工业大学 机械与材料工程学院,北京 100144;

2. 国网冀北电力有限公司 经济技术研究院,北京 100041)

摘要:采用层状溶解法,利用等离子发射光谱研究不同轧制变形量对铸轧1235铝合金板材厚度方向上铁、硅元素分布的影响。研究结果表明:铸轧坯料中铁的偏析非常严重,硅在铸轧板中存在比较轻微的偏析。经较小的变形量(49.3%)变形后,铁、硅元素的偏析规律与铸轧坯料中基本相似,这些元素在板料中的流动符合层状流动规律;当变形量较大时(83.6%),合金元素在金属中的流动变得复杂。

关键词:1235铝合金;铸轧;偏析;轧制

中图分类号:TG290 文献标志码:A 文章编号:1672-7207(2017)06-1473-08

Alloy elements distribution in twin roller cast aluminum billet affected by deformation

ZHU Yuanzhi1, SHEN Weidong2, ZHANG Fan2, ZHAO Chaoqi1, MENG Yi1, LIN Yulong2

(1. College of Mechanical and Materials Engineering,North China University of Technology, Beijing 100144, China;

2. State Grid Jibei Electric Economic Research Institute, Beijing 100041, China)

Abstract: The effect of deformation on the distribution of Fe and Si in the twin roller cast billet was evaluated using a layer by layer dissolution method. ICP-AES was used to measure the chemical compositions in the dissolved solution. The results show that severe macro-segregation of Fe and slight macro-segregation of Si are of presence in the twin roller cast 1235 aluminum billet. A slight deformation (49.3%) cannot change the distribution of Fe and Si in the rolled twin roller cast strip. However, the distribution of Fe and Si in the twin roller cast strip is dramatically changed when the billet is deformed with a strain higher than 83.6%.

Key words: 1235 aluminum alloy; twin roller casting; macro-segregation; rolling

铝箔坯料的生产方式主要有热轧和铸轧。热轧是采用半连续铸锭,并经过热轧和冷轧后制成具有一定厚度的板材,而铸轧是指熔体在2个旋转冷却的辊子中间,边凝固边变形,然后经过适当后续变形至一定厚度的板材。传统的热轧工艺流程为熔炼—铸造—铣面—均匀化—热轧开坯—冷轧[1-2],而铸轧的工艺流程为熔炼—铸轧—冷轧[3-5]。热轧法由于具有热轧开坯环节。这一过程中的变形量非常大,有利于成分和组织的均匀性,因而生产的铝箔毛料更利于轧制高质量的铝箔。然而,铸轧法生产的铝箔毛料由于前面道次变形量相对比较小,板料中的偏析、夹杂难以完成破碎,因而要用铸轧法生产的铝箔毛料进一步生产出合格的铝箔难度比热轧法更大。但是与热轧相比,铸轧投资小、流程短、能耗低,因此,在铝板带材的生产上得到了更广泛的应用。在连续散热和凝固的过程中,铸轧坯料还要受到轧制力的影响,因此,与热轧坯料相比,铸轧坯料的质量更加难以控制。1235工业纯铝为生产铝箔的最常用合金,目前国内生产的铝箔90%采用1235铝合金[6-8]。1235铝合金在铸轧过程中可能形成特有的元素偏析[9],如果元素偏析遗传到后续加工工序,就会对铝箔表面质量产生重要影响。人们对铸轧1235铝合金坯料厚度方向的宏观偏析进行了一些研究,初步了解其分布规律[9]。这种铝合金坯料经过轧制后,第二相可能破碎,产生流动或纵横向运动,形成特殊的分布规律[10-11]。轧制后, 第二相元素的分布规律对其后续退火会产生重要影响[ 12-14]。目前,关于轧制对铸轧铝合金第二相元素分布的影响的研究较少,为了提高铝箔表面质量,本文作者以1235铝合金为研究对象,研究铸轧板坯经过后续轧制后,第二相元素的分布规律。

1 材料制备与实验方法

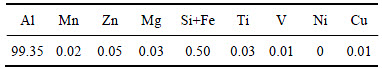

实验原材料厚度为7.3 mm的铸轧铝产品,其化学成分如表1所示。

表1 1235铝合金化学成分(质量分数)

Table 1 Chemical composition of 1235 aluminum alloys %

采用单机架双辊轧机,将原始铸轧铝板直接进行冷轧,冷轧变形量分别为49.3%和83.6%,冷轧后的厚度为3.7 mm和1.2 mm。

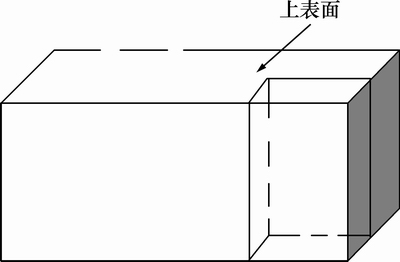

实验样品分别取自原始铸轧铝板和轧制后铝板,尽量保证在铝板相邻的位置取样,并对铸轧铝板的上下表面做好记号以便区分,取样方式如图1所示。

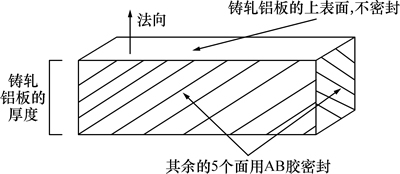

在进行成分测试时,需对实验样品进行溶解,为了测得沿厚度方向上元素的含量,对试验样品进行如图2所示的密封处理:将样品除轧制面外其余5个面均用AB胶(成分为C4H6O2)将其密封。成分测试在ICP-AES上完成。

图1 试验样品的取样方式

Fig. 1 Location of sample preparation

图2 试验样品的密封方法

Fig. 2 Sealing method of sample

2 结果分析与讨论

2.1 铸轧铝板中杂质元素分布特点

以上表面为厚度起点,反应时间为h,样品溶解的质量为m,腐蚀速度为v,样品密度ρ为2.7 g/cm3,反应面积为x,则m可表示为

(1)

(1)

由于铝的密度和反应面积s为已知常数,因而ρ×s用常数k表示,由式(1)可得

(2)

(2)

将式(2)两边同时乘以Fe的质量分数wFe,即可得每次溶解的Fe的质量mFe,

(3)

(3)

同理,也可以得出Si的质量关系式为

(4)

(4)

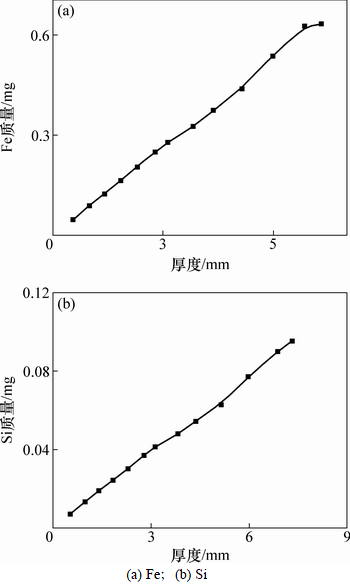

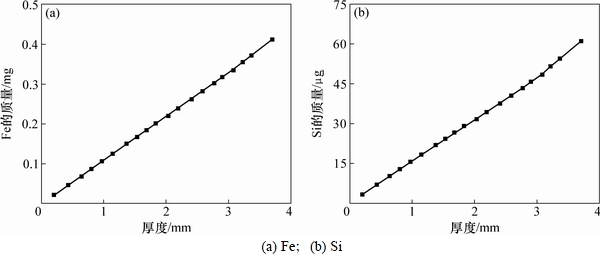

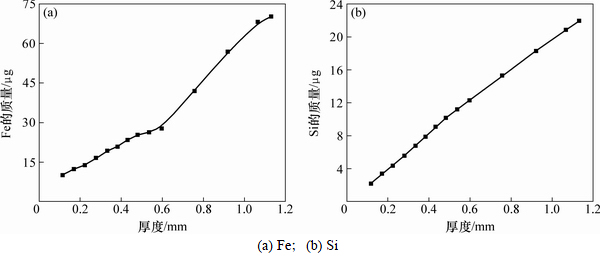

根据式(3)和式(4),可作出Fe和Si元素沿厚度方向上的质量分布图,如图3所示。

由图3可以看出:铸轧铝板中Fe和Si元素质量沿厚度方向上的分布并不是严格按照线性分布的,在厚度方向上存在一定的偏差,因此,可以判断Fe和Si沿厚度方向上质量分布不均匀,即发生了偏析,但是由于在工业纯铝中,Fe和Si元素的质量分数较小,因此,要得出准确的结果,应从Fe和Si元素沿厚度方向上的质量分数进行进一步分析。

图3 厚度为7.30 mm样品的Fe和Si质量沿厚度方向的分布

Fig. 3 Mass distribution of Fe and Si in samples with thickness of 7.3 mm along thickness direction

2.2 铸轧铝板中Fe和Si元素的质量分数沿厚度方向的分布

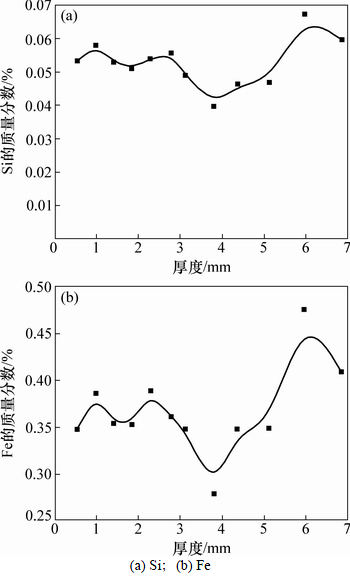

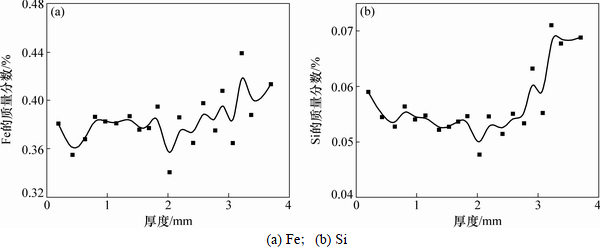

样品腐蚀完全后,采用ICP-AES对Fe和Si元素进行分析并测量其质量分数,可以得到Fe和Si元素的质量分数沿厚度方向的分布图,如图4所示。

由图4可以看出:在上表层样品中Si质量分数(图4(a))分布较均匀,过渡到中间层时出现下降趋势,在4 mm左右时,Si质量分数达到最低,随后又继续上升,并在下表层时达到最高,而且下表层的平均含量比上表层的高。由图4(b)所示,Fe质量分数的分布和Si质量分数的分布趋势相似,同样均为沿着上下表面层向中心层有所下降。因为在工业纯铝中,与其他元素相比较,Fe和Si元素质量分数较高,且对产品的性能影响最大,因此,重点讨论Fe和Si元素的分布规律和特点。

图4 样品Fe和Si元素质量分数沿厚度方向的分布

Fig. 4 Mass fractions of Fe and Si in samples along thickness direction

由宏观偏析方程可知[10]

(5)

(5)

其中:fL为液相体积分数;CL为溶质浓度;β为凝固收缩率;k为有效溶质分配系数;v为液相流动速度;R为凝固速度。由宏观偏析方程可知,由于固液两相区内凝固导致的收缩、铸轧过程中产生的几何变形及重力影响导致的枝晶间富集溶质液相的流动,Fe和Si元素质量分数在厚度方向的分布会存在差异,形成宏观偏析,又由于铸轧铝板中的Fe和Si元素的有效溶质分配系数不同、浓度和溶解度不同等原因,偏析情况会存在一定差异。

以Fe和Si含量的标准偏差来表征它们的宏观偏析程度,即

(6)

(6)

式中:Vdev为标准偏差;Xi为第i次测得的Fe和Si元素质量分数; 为Fe和Si质量分数平均值;n为腐蚀完全所用的次数。计算结果得Fe和Si元素的标准偏差分别为0.046和0.007,即Fe的偏析程度大于Si的偏析程度。

为Fe和Si质量分数平均值;n为腐蚀完全所用的次数。计算结果得Fe和Si元素的标准偏差分别为0.046和0.007,即Fe的偏析程度大于Si的偏析程度。

这里值得说明的是:铸轧板表面铁和硅的平均质量分数比中心位置的高,这与中心含有较大的偏析元素相反。这种反常的分布规律可能与铸轧特有的凝固规律有关。在铸轧板中心,由于高温停留时间长,第二相容易长大,但其平均数量并不一定比近表面位置的高。另外,垂直于板面的枝晶的形成可能给第二相元素的浓度扩散提高通道,导致这种反常的分布[15]。

2.3 轧制后铸轧铝板中Fe和Si元素质量沿厚度方向的分布

根据式(3)和式(4),Fe和Si元素质量沿厚度方向的分布如图5和图6所示。

由图5和图6可见:经过轧制变形后,金属发生流动,铸轧铝板中Fe和Si元素质量沿厚度方向的分布更均匀,但是轧制变形量过大时,铸轧铝板中Fe质量沿厚度方向的分布发生了明显的变化。因为Fe和Si元素的质量分数较小,无法准确反映轧制后Fe和Si元素质量分数的分布情况,因此,从Fe和Si元素沿厚度方向的质量分数进行进一步分析。

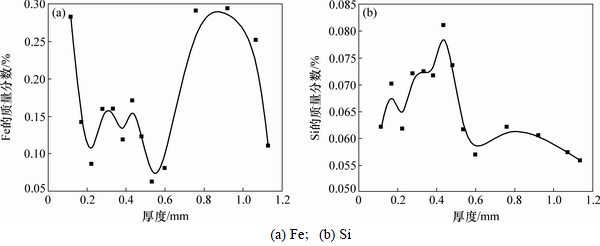

2.4 轧制后铸轧铝板中Fe和Si元素质量分数沿厚度方向的分布

厚度为3.70 mm样品的Fe和Si元素质量分数沿厚度方向的分布如图7所示。由图7可知:与轧制前样品比较,轧制后,Fe的质量分数分布更加均匀,而Si则没有明显的变化;样品的Fe质量分数在上表层分布较均匀,过渡到中间层时出现了非常明显的波谷,从中心层到下表层,Fe的质量分数逐渐上升,并在到达下表层时达到最高;样品的Si质量分数由上表层逐渐下降,在中心层时达到最低,继而又持续升高,在下表层底部时达到最高,形成1个“V”形,而且下表层中Si的质量分数明显比上表层的大。因此,Fe和Si在中心层的质量分数均达到最低。

而经过大变形量的轧制后,厚度为1.20 mm样品的Fe和Si元素质量分数沿厚度方向的分布如图8所示。可见:Fe和Si元素的质量分数分布规律不明显,在上表层Fe的质量分数有波动,但峰值较小,总体分布较为均匀;在中心层,Fe的质量分数达到最低,中心层到下表面Fe的质量分数又逐渐上升,并出现了很明显的峰值;而Si的质量分数逐渐上升,在距离最上表层0.5 mm左右处达到最高,随后又急剧下降,波动较大,在中心层,Si的质量分数达到最低,随后又在下表层时逐渐上升,在距离上表层0.8 mm处出现1个小峰值。

总的来说,小变形量(49.3%)后,板材中铁和硅元素沿厚度方向的分布形状与铸轧坯料中Fe和Si元素质量分数沿厚度方向的分布基本相似。其主要原因是当变形量较小时,金属的流动主要呈现为层状流动。这一点通过计算机模拟可以得出。

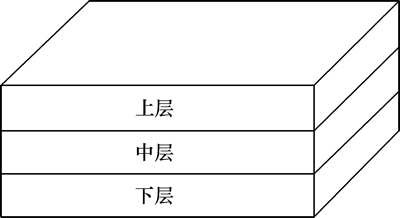

由于偏析相的尺寸为几微米到十几微米[16-17],因此,在几何模型构建时,只根据第二相元素的宏观浓度不同将板材大体分为3层:上表层、中心层和下表层。假设上表层、中心层和下表层之间浓度存在较大差异,而各层内部的浓度为均质。构建的几何模型如图9所示。

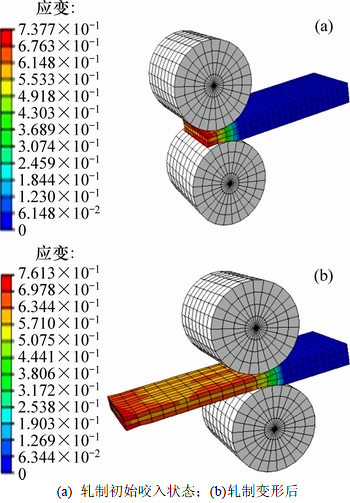

辊子的摩擦因数取0.3,压下量为49.3%。1235板坯经过轧辊轧制后结果如图10所示。

图5 厚度为3.70 mm样品的Fe和Si元素质量沿厚度方向的分布

Fig. 5 Mass of samples with thickness of 3.70 mm along thickness direction

图6 厚度为1.20 mm样品中Fe和Si元素质量沿厚度方向的分布

Fig. 6 Mass of Fe and Si of samples with thickness of 1.20 mm along thickness direction

图7 厚度为3.70 mm样品中Fe和Si元素质量分数沿厚度方向的分布

Fig. 7 Mass fracture of Fe and Si of samples with thickness of 3.70 mm along thickness direction

图8 厚度为1.20 mm样品中Fe和Si元素质量分数沿厚度方向的分布

Fig. 8 Mass fracture of Fe and Si of samples with thickness of 1.20 mm along thickness direction

图9 元素宏观分布几何模型

Fig. 9 Schematic diagram of alloy element distribution

图10 铸轧1235板坯轧制变形49.3%数值模拟

Fig. 10 Numerical simulation of 49.3% rolling deformation for twin roller cast 1235 aluminum alloy strip

由图10可见:与上层和下层相比,中间层的变形程度较小,而且铸轧铝板在轧制的过程中,金属的流动遵循轧制过程中金属的流动规律,Fe和Si元素随着金属流动而流动,而且铸轧铝板在上、中、下层中只发生分层流动,相邻层间只发生滑动而不发生混合,因此,对Fe和Si元素的分布没有产生太大的影响。

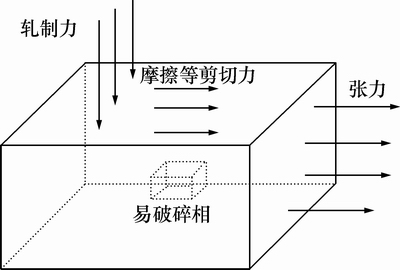

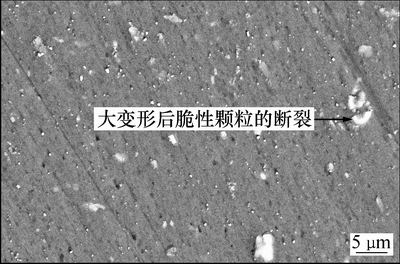

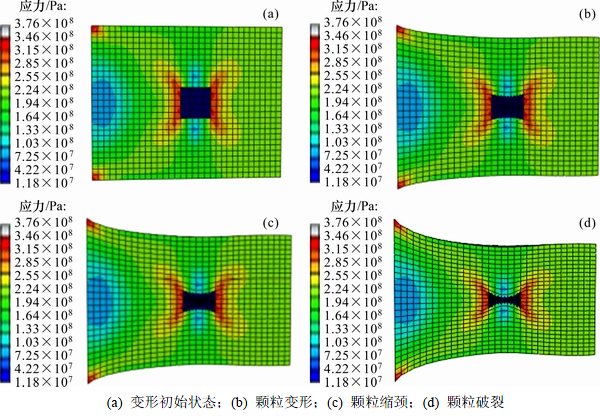

但是,随着变形量的增加,如变形量增加到83.6%,轧制后板料厚度变为1.2 mm,第二相含量高的中间层或者变形量较大的近表层硬化程度比较高, 随着变形的不断深入,第二相含量较低的部位可能更加易于发生变形,挤入第二相含量较多的中心层。第二相含量较高的中心层中的第二相颗粒也开始逐渐向表层靠拢。当压力达到一定程度后,比较脆的第二相颗粒还可能发生破裂。这一点从数值模拟过程可以看出。铸轧铝板中,存在容易发生破碎的α(AlFeSi)相[18],因此,假设在铸轧铝板中心含有一个易破碎的α(AlFeSi)相(如图11中所示小方块),将模型简化为在铸轧铝板上下表面受轧制压力、由摩擦产生的剪切力以及张力。大变形后脆性颗粒的断裂的扫描电镜照片如图12所示。经过ABAQUS模拟之后,易破碎相变化过程如图13所示。

由图13可以看到:在轧制过程中,随着变形量的逐渐增大,容易破碎的第二相的形状和大小逐渐发生变化,沿轧制方向被展宽或者拉长,垂直于轧制方向被压缩,如图13(b)和13(c)所示。随着变形量增大,第二相粒子的形状发生了明显变化,并逐渐形成了不规则的形状和长棒状,而且有逐渐被拉断而破碎的趋势,如图12(d)所示。随着基体的流动而分离,甚至离散在基体内。这一点从变形试验过程中易破碎相的断裂中也可以明显看到(图12)。

大变形后,伴随着颗粒的破碎,层与层之间颗粒和金属运动变得复杂起来,因而其元素沿着厚度方向的分布比原始铸轧态样品和较小变形量板料中的分布复杂(见图8)。

图11 易破碎相轧制示意图

Fig. 11 Stress on brittle precipitate in the rolling process

图12 大变形后脆性颗粒的断裂的扫描电镜照片

Fig. 12 SEM image of fracture of brittle particles after severe deformation of twin roller cast plate

图13 易破碎相轧制过程变化图

Fig. 13 Changes of brittle precipitates in rolling

3 结论

1) 铸轧板坯中铁元素存在比较严重的表面偏析,而铸轧板中硅元素的偏析比较轻微。

2) 当铸轧板在较小变形量下变形时,金属元素铁、硅在坯料中主要是层状流动,这时的变形难以改善偏析元素的分布。

3) 经较大变形量后,铸轧坯料中偏析元素铁和硅的流动变得复杂。

参考文献:

[1] CHROMINSKI W, OLEJNIK L, ROSOCHOWSKI A, et al. Grain refinement in technically pure aluminium plates using incremental ECAP processing[J]. Materials Science and Engineering A, 2015, 636(11): 172-180.

[2] AB RAHIM S N, LAJIS M A, ARIFFIN S. A review on recycling aluminum chips by hot extrusion process[J]. Procedia CIRP, 2015, 26: 761-766.

[3] 李建平, 肖琼, 毛大恒,等. AZ31B镁合金电磁超声铸轧板后续温轧的组织和织构演变[J]. 中南大学学报(自然科学版), 2013, 44(12): 4811-4818.

LI Jianping, XIAO Qiong, MAO Daheng, et al. Evolution of microstructure and texture of electromagnetic and ultrasonic energy-field cast-rolling AZ31B Mg alloy sheet during subsequent warm-rolling process[J]. Journal of Central South University (Science and Technology), 2013, 44(12): 4811-4818.

[4] 戴青松, 邓运来, 胥福顺, 等. 铸嘴结构对3004铝合金铸轧流热场的影响及其优化设计[J]. 中南大学学报(自然科学版), 2015, 46(5): 1602-1608.

DAI Qingsong, DENG Yunlai, XU Fushun, et al. Effect of nozzle structure on fluid-thermal field of 3004 aluminum alloy melt in cast-rolling and its optimum design[J]. Journal of Central South University (Science and Technology), 2015, 46(5): 1602-1608.

[5] 毛大恒, 赵苏琨, 扶宗礼, 等. 电磁/超声能场对1060铝合金铸轧板组织性能的影响[J]. 中南大学学报(自然科学版), 2014, 45(6): 1819-1826.

MAO Daheng, ZHAO Sukun, FU Zongli, et al. Effect of electromagnetic andultrasonic energy field on microstructure and properties of 1060 aluminum alloy casting and rolling plate[J]. Journal of Central South University (Science and Technology), 2014, 45(6): 1819-1826.

[6] 李亚红. 均匀化退火对铸轧1235铝合金双零箔坯料质量和箔材成品针孔的影响[J]. 轻合金加工技术, 2012, 40(4): 57-60.

LI Yahong. Homogenization effect of continuous cast stock on quality and pinhole of double rolled 1235 aluminum alloy foil[J]. Light Alloy Fabrication Technology, 2012, 40(4): 57-60.

[7] 毛宏亮, 王剑华, 杨钢, 等. 1235铝合金连续铸轧态微观组织的表征[J]. 中国有色金属学报, 2014, 24(4): 863-869.

MAO Hongliang, WANG Jianhua, YANGGang, et al. Characterization of microstructure of 1235 aluminum alloy sheet produced by twin roll casting[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 863-869.

[8] 蔡邦霞. 1235铝合金双零箔用铸轧坯料的生产工艺[J]. 甘肃冶金, 2015, 37(3): 33-35.

CAI Bangxia. Producing process of cast-rolling sheet stock for 1235 aluminium-alloy light gauge foil[J]. Gansu Metallurgy, 2015, 37(3): 33-35.

[9] ZHU Y Z. Comparative study on effects of microstructures of hot rolled and twin roll casting 1235 aluminium alloy on surface quality of aluminum foils produced[J]. Materials Science and Technology, 2011, 27(4): 761-766.

[10] 冯科, 徐楚韶, 陈登福, 等. 连铸坯微观及宏观偏析数学模型的研究进展[J]. 特殊钢, 2002, 23(4): 8-12.

FENG Ke, XU Chushao, CHEN Dengfu, et al. Review on mathematic models on micro- and macro- segregation in continuous cast billet[J]. Special Steel, 2002, 23(4): 8-12.

[11] MCCARTHY J F. Phase diagram effects in phase field models of dendritic growth in binary alloys[J]. Acta Materialia, 1997, 45(10): 4077-4091.

[12] DHAL A, PANIGRAHI S K, SHUNMUGAM M S. Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment[J]. Journal of Alloys and Compounds, 2015, 649(15): 229-238.

[13] HUANG K, ENGLER O, LI Y J, et al. Evolution in microstructure and properties during non-isothermal annealing of a cold-rolled Al-Mn-Fe-Si alloy with different microchemistry states[J]. Materials Science and Engineering A, 2015, 628(25): 216-229.

[14] WANG Ning, FLATOY J E, LI Yanjun, et al. Evolution in microstructure and mechanical properties during back-annealing of AlMnFeSi alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1878-1883.

[15] ZHU Y Z, ZHAO C Q, LI J C, et al. Macro-distribution of alloy elements along the thickness of the twin roll cast billet[J]. Materials Science Forum, 2014, 788: 262-266.

[16] 蒋海春, 叶凌英, 张新明, 等. 5059高镁铝合金均匀化热处理工艺[J]. 中南大学学报(自然科学版), 2014, 45(12): 4138-4144.

JIANG Haichun, YE Lingying, ZHANG Ximning, et al. Homogenization heat treatment process of 5059 high Mg containing aluminum alloy[J]. Journal of Central South University (Science and Technology), 2014, 45(12): 4138-4144.

[17] 黎正华, 李晓谦, 胡仕成, 等. 熔体超声处理对7050铝合金铸锭宏观偏析的影响[J]. 中南大学学报(自然科学版), 2011, 42(9): 2669-2675.

LI Zhenghua, LI Xiaoqian, HU Shicheng, et al. Effect of 7050 aluminum alloy melt treated by ultrasonic on macrosegregation in ingot[J]. Journal of Central South University (Science and Technology), 2011, 42(9): 2669-2675.

[18] ZHU Yuanzhi, WAN Qiang, LI Bingliang. Three-dimensional modeling of effect of surface intermetallic phase on surface defects of Al-Fe-Si aluminum foils during twin-roll casting[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 477-483.

(编辑 赵俊)

收稿日期:2016-06-05;修回日期:2016-09-09

基金项目(Foundation item):北京市长城学者资助项目(CIT&TCD20140301);国家自然科学基金资助项目(51675007)(Project(CIT&TCD20140301) supported by the Great Wall Scholar Foundation of Beijing; Project(51675007) supported by the National Natural Science Foundation of China)

通信作者:朱远志,教授,从事新材料加工及表征方法研究;E-mail:tozyz1@163.com