采用氧化焙烧-酸浸法从高碳石煤中提钒试验研究

汪平1,冯雅丽1,李浩然2,张萍1,刘欣伟1

(1. 北京科技大学 土木与环境工程学院, 北京,100083;

2. 中国科学院过程工程研究所 生化工程国家重点实验室, 北京,100080)

摘要:针对广西某难浸高碳石煤,比较相同焙烧和酸浸条件下静态焙烧矿和流态化焙烧矿钒的浸出率,优化流态化焙烧矿的酸浸条件。研究结果表明:流态化焙烧矿酸浸钒的浸出率比静态焙烧矿酸浸钒的浸出率平均高24%,所以,在相同焙烧温度、时间下流态化焙烧较静态焙烧更利于钒的浸出;在液固质量比为0.8:1.0,二氧化锰添加量为3%和氢氟酸添加量为2%的条件下,得最佳酸浸条件,即酸矿质量比为0.4:1.0,浸出温度为150 ℃,浸出时间为6 h,在此最佳酸浸条件下,钒浸出率可达88.26%。

关键词:钒;高碳石煤;氧化焙烧;酸浸

中图分类号:TF803.21 文献标志码:A 文章编号:1672-7207(2011)10-2917-05

Extracting vanadium from high-carbon stone coal by oxidizing roasting-acid leaching method

WANG Ping1, FENG Ya-li1, LI Hao-ran2, ZHANG Ping1, LIU Xin-wei1

(1. School of Civil and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. National Key Laboratory of Biochemical Engineering, Institute of Process Engineering,

Chinese Academy of Science, Beijing 100080, China)

Abstract: Based on refractory high-carbon stone coal of Guangxi, the leaching rate of vanadium of static roasting and fluidized roasting in the same roasting and acid leaching condition was compared. The results show that the leaching rate of vanadium of fluidized roasting-acid leaching method is averagely 24% higher than that of static roasting-acid leaching method. Therefore, fluidized roasting is more favorable to leach vanadium. The optimal acid leaching condition for vanadium extraction is as follows: acid-mine ratio 0.4:1.0, leaching temperature 150 ℃, leaching time 6 h at liquid-solid mass ratio 0.8:1.0, addition of manganese dioxide 3% and addition of hydrofluoric acid 2%. Under the optimal acid leaching conditions, the rate of leaching vanadium can reach 88.26%.

Key words: vanadium; high-carbon stone coal; oxidizing roasting; acid leaching

钒是重要的战略物资,它具有许多优良的理化特性和机械特性,因而广泛应用于近代工业技术中[1-3]。我国钒资源主要赋存在石煤中,从石煤中提钒是我国钒资源利用的一个重要发展方向。目前,人们对难浸高碳石煤的研究较少,这类石煤钒矿因含碳量高,矿物结构复杂,存在石煤综合利用率不高、钒总回收率低、成本高等问题[4]。高碳石煤提钒现有的工艺主要有直接酸浸、加压酸浸、浮选脱碳-酸浸、氧化焙烧-酸浸、钙化焙烧-碱浸、一段焙烧脱碳-二段低钠钙化焙烧-碱浸等[5-8]。其中氧化焙烧-酸浸工艺在焙烧过程中直接利用空气中的氧气氧化石煤中的低价钒,不产生污染气体,废水、废渣稍加治理即可达排放标准,是一项清洁的生产工艺[9]。本研究采用氧化焙烧-酸浸工艺对广西某难浸高碳石煤在相同焙烧和酸浸条件下静态焙烧矿和流态化焙烧矿钒浸出率进行比较,重点考察流态化焙烧矿的酸浸条件试验。采用该方法不仅可以得到较高浸出率,而且大大减少了对环境的污染,为工业生产提供可靠的参数控制,应用前景广阔。

1 材料与方法

1.1 试验原料

含钒石煤矿样取自广西壮族自治区某石煤矿区,化学成分分析结果见表1。该石煤主要含二氧化硅、碳和三氧化二铝,碳质量分数为17.75%,属于高碳石煤[10]。

表1 高碳石煤主要化学成分(质量分数)

Table 1 Main chemical compositions of high-carbon stone coal %

1.2 试验试剂及装置

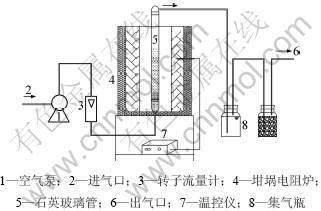

所用硫酸、二氧化锰和氢氟酸试剂均为分析纯,水为去离子水。所用装置主要有马弗炉(静态焙烧)、自制流态化焙烧反应装置(流态化焙烧)(图1)和KH-50高压反应釜。

图1 流态化焙烧反应装置示意图

Fig.1 Schematic diagram of fluidized roasting reactor

图1所示为自制流态化焙烧反应装置,主要由空气泵、转子流量计、坩埚电阻炉及石英玻璃管组成。核心部件为坩埚电阻炉内的石英玻璃管5,其上长为66 cm,下长为25 cm;上为出气口,下为进气口;放焙烧料管内径为3 cm。

1.3 试验方法

将粒径为0.20~0.71 mm的石煤矿样分别放入马弗炉和自制流态化焙烧反应装置于700 ℃焙烧2 h,转子转速为0.2 m3/h(换成流态化焙烧的条件)。自然冷却,将焙烧矿研磨至粒度小于0.074 mm(质量分数为70%),放入KH-50高压反应釜,加入40%(质量分数,下同)硫酸、3%二氧化锰和2%氢氟酸,添加去离子水使液固质量比为0.8:1.0(硫酸用量为100%时液固质量比为1:1),搅拌均匀后置于烘箱中,于150 ℃浸出6 h。反应后,在室温下磁力搅拌1 h,真空过滤,分析钒含量,按下式计算钒浸出率[11]。

(1)

(1)

式中:η为钒的浸出率,%;m为浸出试样质量,g;w1为试样中钒的质量分数,%;ρ为浸出液质量浓度,g/mL;V为浸出液体积,mL;w2为浸出液中钒的质量分数,%。

2 试验结果及讨论

2.1 静态焙烧矿酸浸和流态化焙烧矿酸浸对比试验

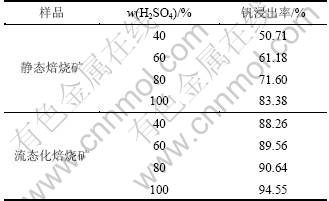

在马弗炉和自制流态化焙烧反应装置中得到焙烧矿,在同样的酸浸条件下钒浸出率见表2。由表2可知:静态焙烧矿酸浸钒的浸出率和流态化焙烧矿酸浸钒的浸出率随硫酸用量(质量分数)的增加而提高,而当硫酸用量相同时,流态化焙烧矿酸浸钒的浸出率比静态焙烧矿酸浸钒的浸出率平均高24%。

表2 H2SO4质量分数不同时对比试验结果

Table 2 Leaching rate of contrast test of vanadium under different mass fractions of H2SO4

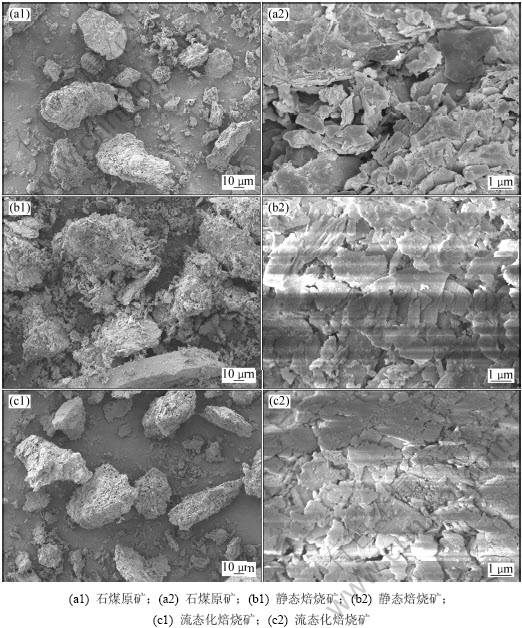

已有研究表明钒的浸出效果与钒是否被氧化以及钒是否被“包裹”有关[12]。图2所示为石煤原矿、静态焙烧矿和流态化焙烧矿破碎后的SEM像。从图2(a2),(b2)和(c2)可以看到静态焙烧矿和流态化焙烧矿相比石煤原矿部分颗粒相互黏结在一起,有轻度烧结现象发生,但矿物晶体结构基本骨架未被破坏,没有玻璃体结构形成,钒没有被“包裹”[13]。从图2(a1),(b1)和(c1)可以看到静态焙烧矿的“球团”流态化焙烧矿更加松散,颗粒比表面积更大。但试验结果表明钒浸出率反而更小。这可能在钒不被“包裹”的前提下,流态化焙烧矿颗粒均匀,松装密度大,钒氧化成高价的含量较高,利于浸出剂的浸入和钒的浸出,钒浸出率高。静态焙烧矿颗粒均匀性较差,松装密度较小,钒氧化成高价的含量较低,钒浸出耗酸多,是导致相同焙烧温度和焙烧时间下流态化焙烧矿酸浸钒浸出率比静态焙烧矿酸浸钒浸出率高的可能原因,可见流态化焙烧更利于钒的浸出。下面重点考察流态化焙烧矿的酸浸条件试验。

图2 石煤原矿和焙烧矿的SEM像

Fig.2 SEM images of raw ore and roasted residue

2.2 流态化焙烧矿酸浸条件试验

采用单因素试验法考察流态化焙烧矿酸浸中硫酸用量、浸出温度和浸出时间对钒浸出率的影响。

2.2.1 硫酸用量对钒浸出率的影响

硫酸用量对钒浸出率的影响如图3所示。从图3可见:钒的浸出率随硫酸用量的增加而提高。从宏观上讲,硫酸用量越大,则H+浓度就越大,进入矿物晶格中的概率就越大,有利于破坏晶体结构,从而钒浸出率就越高。但随着硫酸用量的增加,进入酸浸液的杂质金属离子和阴离子也随之增加,会加重后面的除杂工作,使碱消耗量增加[14]。经综合考虑,选定浸出酸用量为焙烧矿用量的40%。

图3 硫酸用量对钒浸出率的影响

Fig.3 Effect of dosage of sulfuric acid on leaching rate of vanadium

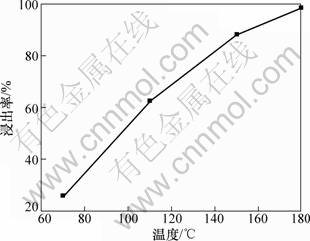

2.2.2 温度对钒浸出率的影响

不同温度对钒浸出率的影响如图4所示。从图4可见:温度对钒的浸出率影响较大,随着温度的升高,浸出率也逐渐提高。这是因为在一定浸出时间下,当温度升高时,钒的溶解速度增加,溶液黏度降低,黏度降低可以加快分子、离子的扩散速度,使浸出剂进入矿物晶格和产物扩散出来进入溶液更加容易和迅速,钒的浸出率得到提高[15]。考虑到高温浸出时的能源消耗及对浸出设备的要求,选定浸出温度为150 ℃。

图4 温度对钒浸出率的影响

Fig.4 Effect of leaching temperature on leaching rate of vanadium

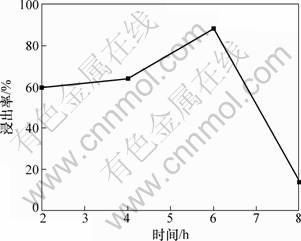

2.2.3 浸出时间对钒浸出率的影响

不同浸出时间对钒浸出率的影响如图5所示。从图5可见:随着浸出时间的延长,浸出剂能充分接触矿物,破坏矿物结构;浸出4 h时,浸出率就达到63.88%;而当浸出时间超过6 h时,浸出率反而下降。这是因为过长的浸出时间增大了杂质浸出的可能性,被溶出来的钒又与某种化合物结合而滞留在渣中,致使钒的浸出率急剧下降[16]。焙烧矿酸浸最佳浸出时间选为6 h。

图5 时间对钒浸出率的影响

Fig.5 Effect of leaching time on leaching rate of vanadium

3 结论

(1) 静态焙烧矿酸浸钒的浸出率和流态化焙烧矿酸浸钒的浸出率随硫酸用量的增加而提高;而当硫酸用量相同时,流态化焙烧矿酸浸钒的浸出率比静态焙烧矿酸浸钒的浸出率高。与静态焙烧矿相比,流态焙烧矿颗粒均匀,松装密度大,钒氧化成高价的含量较高,钒浸出耗酸少,有利于钒的浸出。

(2) 与硫酸用量和浸出温度相比,浸出时间对钒浸出率影响较显著,钒浸出率随硫酸用量和浸出温度增加而提高,随浸出时间延长钒浸出率先提高后下降。流态化焙烧矿在液固质量比为0.8:1.0、二氧化锰添加量为3%和氢氟酸添加量为2%的条件下进行浸出试验,最佳酸浸条件如下:酸矿质量比为0.4:1.0,浸出温度为150 ℃,浸出时间为6 h。在此最佳酸浸条件下,钒浸出率可达88.26%。

参考文献:

[1] 漆明鉴. 从石煤中提钒现状及前景[J]. 湿法冶金, 1999(4): 1-10.

QI Ming-jian. Current situation and prospect about extracting vanadium from stone coal[J]. Hydrometallurgy of China, 1999(4): 1-10.

[2] Smith D L, Chung H M, Matsui H, et al. Progress in vanadium alloy development for fusion applications[J]. Fusion Engineering and Design, 1998, 41: 7-14.

[3] 任学佑. 稀有金属钒的应用现状及市场前景[J]. 稀有金属, 2003, 27(6): 809-812.

REN Xue-you. Application status and market prospects of rare metal vanadium[J]. Chinese Journal of Rare Metals, 2003, 27(6): 809-812.

[4] 李静, 李朝建, 吴雪文, 等. 石煤提钒焙烧工艺及机理探讨[J]. 湖南有色金属, 2007, 23(6): 7-10.

LI Jing, LI Zhao-jian, WU Xue-wen, et al. Technology of roasting process on extraction of vanadium from stone coal and mechanism discussion[J]. Hunan Nonferrous Metals, 2007, 23(6): 7-10.

[5] 屈启龙, 谢建宏, 王冠甫. 高碳钒矿综合回收石墨试验研究[J]. 矿业快报,2007(4): 35-37.

QU Qi-long, XIE Jian-hong, WANG Guan-fu. Study of comprehensive recovery of graphite from high carbon vanadium ore[J]. Express Information of Mining Industry, 2007(4): 35-37.

[6] 朱保仓. 高碳石煤提钒新工艺研究[D]. 西安: 西安建筑科技大学冶金工程学院, 2007: 41-49.

ZHU Bao-cang. Study on a new technology of extracting vanadium from high-carbon stone-coal[D]. Xi’an: Xi’an University of Architecture and Technology. Metallurgy Engineering College, 2007: 41-49.

[7] 吴惠玲, 赵伟, 邓志敢, 等. 高碳石煤优先选煤富集钒新工艺研究[J]. 中国稀土学报, 2008, 26(Special Issue): 530-533.

WU Hui-ling, ZHAO Wei, DENG Zhi-gan, et al. New craft study on enriching vanadium by means of priority coal flotation from high carbon stone-coal[J]. Journal of the Chinese Rare Earth Society, 2008, 26(Special Issue): 530-533.

[8] 魏昶, 吴惠玲, 李存兄, 等. 高碳石煤直接酸浸提钒探索性研究[J]. 中国稀土学报, 2008, 26(Special Issue): 534-536.

WEI Chang, WU Hui-ling, LI Cun-xiong, et al. Exploratory research on recovering vanadium from high carbon stone-coal by means of direct acid leaching[J]. Journal of the Chinese Rare Earth Society, 2008, 26(Special Issue): 534-536.

[9] 徐永新, 杨欢. 石煤提钒的最佳焙烧酸浸条件[J]. 有色金属, 2008, 60(3): 74-76.

XU Yong-xin, YANG Huan. Optimal roasting and leaching conditions for vanadium extraction from stone coal[J]. Nonferrous Metals, 2008, 60(3): 74-76.

[10] 魏昶, 吴惠玲, 樊刚, 等.酸浸法从高碳石煤中提钒[J]. 钢铁钒钛, 2009, 30(1): 7-11.

WEI Chang, WU Hui-ling, FAN Gang, et al. Recovering vanadium from high carbon stone coal by means of direct acid leaching[J]. Iron Steel Vanadium Titanium, 2009, 30(1): 7-11.

[11] 罗小兵, 冯雅丽, 李浩然, 等. 湿法浸出黏土钒矿中钒的研究[J]. 矿冶工程, 2007, 27(6): 48-53.

LUO Xiao-bing, FENG Ya-li, LI Hao-ran, et al. Investigation on extraction of V2O5 from clay containing vanadium by acid process[J]. Mining and Metallurgical Engineering, 2007, 27(6): 48-53.

[12] 何东升. 石煤型钒矿焙烧-浸出过程的理论研究[D]. 长沙: 中南大学资源加工与生物工程院, 2009: 74-77.

HE Dong-sheng. Theoretical investigation of roasting and leaching processes of stone coal-type vanadium ore[D]. Changsha: Central South University. College of Resource Processing & Bioengineering, 2009: 74-77.

[13] 何东升, 冯其明, 张国范, 等. 含钒石煤的氧化焙烧机理[J]. 中国有色金属学报, 2009, 19(1): 195-200.

HE Dong-sheng, FENG Qi-ming, ZHANG Guo-fan, et al. Mechanism of oxidizing roasting process of vanadium containing stone coal[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 195-200.

[14] LI Min-ting, WEI Chang, FAN Gang, et al. Extraction of vanadium from black shale using pressure acid leaching[J]. Hydrometallurgy, 2009, 98(3/4): 308-313.

[15] 向小艳, 王明玉, 肖连生, 等. 石煤酸浸提钒工艺研究[J]. 稀有金属与硬质合金,2007, 35(3): 10-13.

XIANG Xiao-yan, WANG Ming-yu, XIAO Lian-sheng, et al. Study on acid leaching of vanadium from stone coal[J]. Rare Metals and Cemented Carbides, 2007, 35(3): 10-13.

[16] 魏昶, 樊刚, 邓志敢, 等.含钒石煤氧压酸浸中影响钒浸出率的主要因素研究[J]. 稀有金属, 2007, 31(Special Issue): 98-101.

WEI Chang, FAN Gang, LI Zhi-gan, et al. Study on main factors effect of extracting vanadium from stone-coal containing vanadium by acid leaching with oxygen pressure[J]. Chinese Journal of Rare Metals, 2007, 31(Special Issue): 98-101.

(编辑 陈灿华)

收稿日期:2010-10-11;修回日期:2010-12-28

基金项目:国家自然科学基金资助项目(20876160)

通信作者:冯雅丽(1967-),女,北京人,博士,教授,从事矿物加工的研究;电话:010-62311181;E-mail:ylfeng126@126.com