文章编号: 1004-0609(2006)05-0835-06

含钪与不含钪铝镁钪合金焊接接头的组织与性能

陈苏里1, 姜 锋1, 尹志民1, 雷学锋1, 2, 聂 波1, 3

(1. 中南大学 材料科学与工程学院, 长沙 410083;

2. 航天材料及工艺研究所, 北京100076;

3. 东北轻合金有限责任公司, 哈尔滨 150060)

摘 要: 分别采用Al-Mg-Zr和Al-Mg-Zr-Sc合金焊丝为填充材料, 对2mm厚的Al-Mg-Sc合金薄板进行惰性气体保护焊接, 然后对两种焊接接头的显微组织和力学性能进行对比研究。 结果表明: 采用两种焊丝焊接的Al-Mg-Sc合金薄板的焊接接头强度系数均大于0.9。 但采用Al-Mg-Zr-Sc合金焊丝为填充材料时, 焊缝晶粒组织明显细化, 熔合区形成的细小等轴晶层提高了基材与焊缝填充材料的结合力, 焊接接头的屈服强度比采用Al-Mg-Zr合金焊丝为填充材料时提高了100MPa, 显著提高了Al-Mg-Sc合金焊接构件的许用强度, 因此焊接Al-Mg-Sc板材更宜采用Al-Mg-Sc-Zr焊丝。

关键词: 铝镁钪合金焊接; 焊丝; 熔合区; 焊接接头; 组织与性能 中图分类号: TG146

文献标识码: A

Microstructure and properties of Al-Mg-Sc alloy weld joints filled with Al-Mg-Zr and Al-Mg-Zr-Sc weld wires

CHEN Su-li1, JIANG Feng1, YIN Zhi-min1, LEI Xue-feng1, 2, NIE Bo1, 3

(1. School of Materials Science and Engineering, Central South University,

Changsha 410083, China;

2. Institute of Spaceflight Material and Technology, Beijing 100076, China;

3. Northeast Light Alloy Co. Ltd., Harbin 150060, China)

Abstract: The Al-Mg-Sc alloy sheets with 2mm thickness were welded by manual labor inert-gas arc welding method, the mechanical properties and microstructures of Al-Mg-Sc alloy weld joints filled with Al-Mg-Zr or Al-Mg-Zr-Sc welding wires were studied comparatively. When the Al-Mg-Zr-Sc welding wire was used as filling material, the grains of welding seam were refined obviously, and the weld joint was greatly strengthened by forming of fine equiaxial grains layer in fusion zone. The results show that, the coefficients of welded joints are both greater than 0.9, but the yield strength of weld joint filled with Al-Mg-Zr-Sc welding wire is greater 100MPa than that of filled with Al-Mg-Zr welding wire. It indicates that the Al-Mg-Zr-Sc welding wire is the best alteration of filling materials to weld of Al-Mg-Sc alloy.

Key words: weld of Al-Mg-Sc alloy; weld wire; fusion zone; weld joint; microstructure and properties

自从前苏联学者提出以来, Sc对Al合金的变质作用已经引起国内外研究者的关注与深入研究。 到目前为止, Sc为最有效的优化铝合金性能的合金元素, 在铝合金中添加微量钪能显著提高铝合金的综合性能[1], 特别是在钪与其他过渡金属元素(如Zr, Ti)复合添加时, 效果更佳[2]。 Sc在铝合金中主要起显著的铸态组织细化作用, 与Al基体共格的L12型Al3Sc粒子的沉淀强化作用, 弥散分布的Al3Sc质点强烈钉扎位错能有效地抑制合金再结晶的作用[3-5]。

Sc能显著改善铝合金的焊接性能, 焊接时不易出现液化裂纹, 能有效降低焊接热裂纹的敏感系数, 焊后热处理能保持完整的非再结晶结构, 且强度更高[6-9]。 在传统的不可热处理强化的Al-Mg合金中添加微量钪, 使这种耐蚀性最好的铝合金同时具有更好的强度和焊接性, 大大提高了这类合金的应用范围, Al-Mg-Sc合金已在俄罗斯被应用于航天航空等领域[10]。

本文作者分别采用Al-Mg-Zr和Al-Mg-Zr-Sc合金焊丝为填充材料对Al-Mg-Sc合金薄板进行惰性气体保护焊接, 然后对两种焊接接头的显微组织和力学性能进行了对比研究, 旨在从微观组织角度研究Sc对其焊接性能的影响, 为铝镁钪合金焊接构件的设计提供实验依据。

1 实验

1.1 实验材料

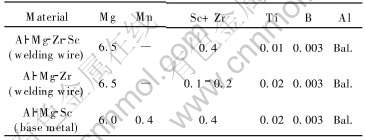

焊接用基材为2mm厚的Al-Mg-Sc合金薄板, 分别采用Al-Mg-Zr和Al-Mg-Zr-Sc合金焊丝(中南大学研制)为填充材料进行惰性气体保护焊接。 焊丝及基材的化学成分如表1所列。

表1 基材和焊丝合金的化学成分

Table 1 Chemical composition of base metal and welding wire (mass faction, %)

1.2 焊丝制备工艺

焊丝的制备工艺为合金焊丝成分设计→配料→熔化→熔剂精炼→熔体过滤→半连续急冷铸造→挤压→拉拨与中间退火→组合模拉拨→表面精刮→盘卷→真空包装。 Sc采用Al-2Sc中间合金(中南大学制备)的形式加入, Zr采用Al-10Zr中间合金的形式加入, 特别设计的组合模拉伸工艺顺序完成焊丝的减径、 表面刮削、 定径工序, 刮削工艺可以彻底清理焊丝表面的油污、 吸湿及疏松的氧化层。

1.3 焊接接头组织性能测试方法

在焊接好的Al-Mg-Sc板材上沿垂直焊缝方向截取拉伸试样, 采用Instron8019 电子拉伸机进行拉伸力学性能测试以确定焊接接头的强度系数。 采用低负荷硬度计(载荷为29.4N)沿焊接接头垂直焊道方向进行硬度测试, 观察焊接接头不同部位硬度的变化。 通过电解抛光以及阳极覆膜来制备焊接接头的金相样品, 用光学显微镜(POLTAR-MET)进行偏光观察。 为了观察和分析焊接接头上焊缝和热影响区的显微组织及其变化, 在焊接接头不同区域取样制成电镜薄膜样品, 在透射电镜(Tecnai G220 S-TWIN)上观察其显微组织。

2 结果及分析

2.1 焊接接头拉伸力学性能

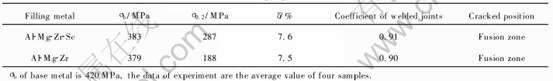

采用Al-Mg-Zr及Al-Mg-Zr-Sc合金焊丝为填充材料时, Al-Mg-Sc合金板材焊接接头的拉伸性能如表2所列。 一般焊接接头的拉伸性能不测其屈服强度, 但有文献报告微量钪能显著提高Al-Mg合金的强度(特别是屈服强度), 为了研究微量钪对焊缝组织和性能的影响, 本研究同时对焊接接头的屈服强度进行了测试。

由表2可看出, 两种焊丝的焊接接头强度系数均大于0.9, 采用Al-Mg-Zr-Sc合金焊丝时焊接接头抗拉强度较高。 应当注意的是, 采用Al-Mg-Zr合金焊丝时焊接接头屈服强度为188MPa, 但采用Al-Mg-Zr-Sc合金焊丝时焊接接头屈服强度高达287MPa(约提高了100MPa), 由此可看出, 这可显著提高焊接构件的许用强度。

表2 焊接接头的拉伸性能

Table 2 Mechanical properties of welded joint

2.2 焊接接头显微硬度分布及微观组织

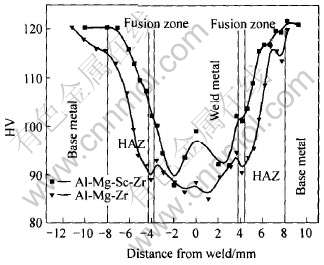

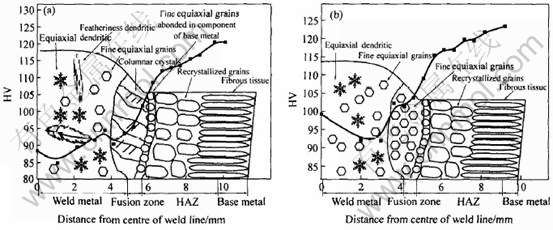

对采用Al-Mg-Zr合金焊丝及Al-Mg-Zr-Sc合金焊丝为填充材料的焊接接头焊缝区和热影响区(heat affected zone, HAZ)进行了显微硬度测试, 距焊缝中心不同距离处的显微硬度分布如图1所示。 由图1可看出, 以Al-Mg-Zr及Al-Mg-Zr-Sc合金焊丝为填充材料时, 焊接接头的显微硬度分布规律是一致的, 即焊缝中心区域的硬度较低, 离开焊缝中心向基材过渡时, 硬度逐渐升高。 从显微硬度值可以确定热影响区范围约为4mm, 采用Al-Mg-Zr-Sc合金焊丝为填充材料时, 焊缝中心的显微硬度比用Al-Mg-Zr合金焊丝时高。

图1 Al-Mg-Sc合金板材焊接接头显微硬度分布

Fig.1 Vickers-microhardness distribution of

Al-Mg-Sc alloy welded joint

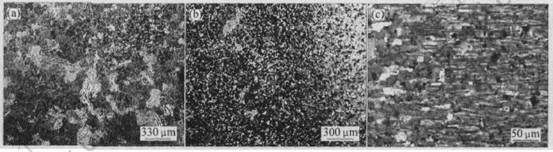

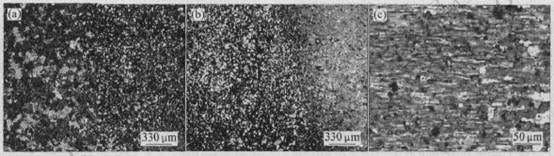

图2所示为采用Al-Mg-Zr合金焊丝为填充材料时焊接接头焊缝中心、 熔合区及热影响区显微组织。 由图2可看出, 焊缝中心区域晶粒较大, 甚至出现了羽毛状的枝晶(图2(a)); 而在熔合区内可观察到沿散热相反方向生长的柱状晶组织(图2(b)), 这是联生结晶的典型显微组织。 而图2(c)所示为基材部分的热影响区, 只有很小范围的晶粒发生了再结晶。

图3所示为采用Al-Mg-Zr-Sc焊丝焊接的接头焊缝中心、 熔合区以及热影响区的显微组织。 焊缝中心是大小不同等轴晶并存的铸态组织(图3(a)), 焊缝靠近熔合区的组织没有见到这个区域通常会出现的联生结晶的柱状晶, 而是非常细小的等轴晶(图3(b))。 靠近半熔化区的热影响区局部发生了再结晶(图3(c))。

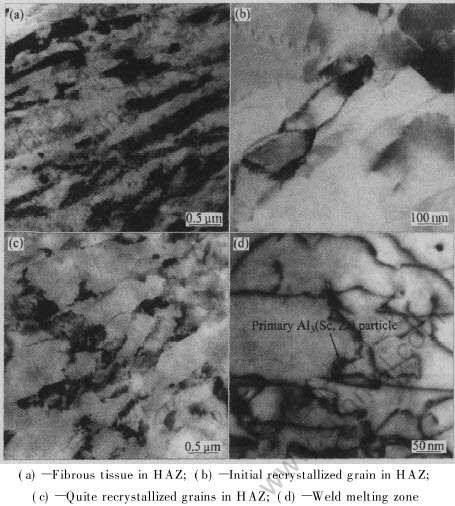

图4所示为以Al-Mg-Zr-Sc为焊丝时焊接接头热影响区及焊缝区的TEM像。 从图4(a), (b)和(c)中可以分别观察到未再结晶的冷变形纤维组织、 开始再结晶晶粒以及完全再结晶的晶粒。 从图4(d)可以看到冷却时焊缝中析出的一次Al3(Sc, Zr)复合粒子, 这种粒子呈马蹄状, 表明它们与基体共格。

图2 采用Al-Mg-Zr合金焊丝为填充材料时焊接接头焊缝区、 熔合区及热影响区的显微组织

Fig.2 Microstructures of welding zone(a), fusion zone(b) and soft zone in HAZ(c) of welded joint using Al-Mg-Zr welding wire as filling material

图3 采用Al-Mg-Zr-Sc合金焊丝为填充材料时焊接接头的显微组织

Fig.3 Microstructures of welding zone(a), fusion zone(b) and soft zone in HAZ(c) of welded joint using Al-Mg-Zr-Sc welding wire as filling material

图4 采用Al-Mg-Zr-Sc合金焊丝为填充材料的焊接接头的TEM像

Fig.4 TEM images of welded joint using Al-Mg-Zr-Sc welding wire as filling material

3 讨论

3.1 用Al-Mg-Zr焊丝焊接的接头显微组织特征

根据焊接接头显微硬度分布及不同区域显微组织绘制了焊接接头的显微组织模型图(见图5)。

图5(a)所示为Al-Mg-Zr焊丝焊接接头显微组织模型图。 由图5(a)可看出, 焊缝区同时存在大量粗大枝晶与细小等轴晶, 甚至出现了大尺寸(100~200μm)的羽毛状枝晶。 这是由于焊接过程中熔池内各区域的冷却速度和溶质浓度不同以及温度与成分的不均匀性导致焊缝内粗晶和细晶交替出现。

熔合区主要由沿散热相反方向生长的柱状晶层及很薄的一层细等轴晶组成。 这是由于焊接时金属液过热度较高, 熔化了部分母材。 在靠近母材部分, 熔体温度相对较低, 母材中Al3Sc、 Al3(Sc, Zr)第二相粒子成为非均匀形核核心, 形成一层类似激冷层的细晶层; 在远离母材部分熔体温度较高, 熔体的大部分热量通过细晶层再经母材向外散失, 散热方向性增强。 由于垂直母材横截面方向散热最快, 细晶层中主轴与其垂直的枝晶就优先长大, 可能超越取向不利的相邻晶粒生长, 形成较粗大的的联生柱状晶。

3.2 用Al-Mg-Sc-Zr焊丝焊接的接头显微组织特征

图5(b)所示为Al-Mg-Zr-Sc焊丝焊接接头显微组织模型图。 由图5(b)可看出, 焊缝中心部分是由平均晶粒尺寸60μm的大小不同的等轴晶组成, 焊缝晶粒被明显细化。 这是由于复合添加Sc和Zr比单独添加Zr具有更好的晶粒细化效果。 单独添加Zr时, 凝固过程中析出的初生Al3Zr粒子为四方DO23型结构, a=0.4013nm, c=1.732nm, 与Al晶体结构相似程度不高, 不能达到最好的晶粒细化效果; 而复合添加Sc和Zr时析出的Al3(Sc, Zr)和Al3(Ti, Sc)复合粒子的晶格类型(LI2)及晶胞尺寸[ 11 ]与基体极为相似, 错配度非常小, 因此能得到最好的晶粒细化效果[ 12 ]。

图5 以Al-Mg-Zr(a)和Al-Mg-Zr-Sc(b)焊丝焊接的焊缝显微组织模型图

Fig.5 Microstructure models of weld line by Al-Mg-Zr(a) and Al-Mg-Zr-Sc(b) welding wire

熔合区也完全由细小的等轴晶组成(平均晶粒尺寸为20μm)。 靠近焊缝部分的熔合区内, 初生的Al3Sc、 Al3(Sc, Zr)粒子作为非均匀形核的核心质点, 同时由于金属液中高熔点的Al3Sc、 Al3(Sc, Zr)粒子阻碍凝固前沿的移动, 抑制了柱状晶的生长, 从而形成了熔合区内的等轴晶层。

在热影响区, 基材中的Al3(Sc, Zr)第二相粒子在焊接热循环短时高温作用下尚不会粗化和团聚, 仍然保留在基体中对位错和亚晶界起钉扎作用, 提高了板材的再结晶温度, 使发生再结晶的热影响区范围减小[13-15], 同时也降低了热影响区的软化程度。

3.3 Sc对Al-Mg-Sc合金焊接接头力学性能的影响

由于Al3(Sc, Zr)第二相粒子抑制再结晶的作用, 焊接接头热影响区仍保持较高的强度, 而焊缝中心经过余高补强后, 焊接接头拉伸实验时断裂发生在相对较弱的熔合区(从硬度图1中可以看出)。 采用不含钪的焊丝做填充材料时, 熔合区组织以粗大的联生柱状晶为主; 而采用含钪焊丝做填充材料时, 熔合区由细小等轴晶组成。 Hall-Petch公式中指出, 晶粒的细化能显著提高金属的屈服强度, 同时, Al3(Sc, Zr)等粒子对晶界和位错的钉扎作用也能使屈服屈服强度增加[16]。

焊接构件的强度设计是以屈服强度为参考的, 提高屈服强度即提高了材料的许用强度。 采用Al-Mg-Zr-Sc焊丝做填充材料时的屈服强度比用Al-Mg-Zr合金焊丝做填充材料时的高100MPa(提高了53%), 因此Al-Mg-Sc合金板材最好采用Al-Mg-Zr-Sc焊丝进行焊接。

4 结论

1) Al-Mg-Zr-Sc焊丝能明显改善焊接接头的显微组织, Sc能显著细化焊缝中心的组织、 消除粗大枝晶以及抑制熔合区内柱状晶的生长形成细晶层。

2) Al-Mg-Sc合金板材采用Al-Mg-Zr和Al-Mg-Zr-Sc焊丝焊接时, 焊接接头强度系数均大于0.9; 但采用Al-Mg-Zr-Sc焊丝焊接时, 焊接接头屈服强度比采用Al-Mg-Zr焊丝高100MPa, 提高了焊接构件的许用强度, 因此Al-Mg-Sc合金板材的焊接最好采用Al-Mg-Zr-Sc焊丝为填充材料。

3) Al3(Sc, Zr)粒子能有效地抑制焊接热影响引起的基材再结晶行为, 保留大量的冷变形组织, 提高了Al-Mg-Sc合金板材抗焊接软化的能力。

REFERENCES

[1]YIN Zhi-min, JIANG Feng, PAN Qing-lin, et al. Microstructures and mechanical properties of Al-Mg and Al-Zn-Mg based alloys containing minor scandium and zirconium[J]. Trans Nonferrous Met Soc China, 2003, 13(3): 515-520.

[2]YIN Zhi-min, PAN Qing-lin, ZHANG Yong-hong, et al. Effect of minor Sc and Zr on the microstructure and mechanical properties of Al-Mg based alloys[J]. Mater Sci and Eng, 2000, A280(1): 151-155.

[3]JIANG Feng, YIN Zhi-min, HUANG Bai-yun, et al. Homogenization and recrystallization of Al-6Mg alloys with and without Sc and Zr[J]. Journal of Rare Earths, 2004, 22(5): 600-603.

[4]Parker B A, Zhou Z F, Nolle P. The effect of small additions of scandium on the properties of aluminum alloys[J]. Journal of Materials Science, 1995, 30(2): 452-458.

[5]Daizen W, Chihiro W. Ostwald ripening of Al3Sc particles in an Al-Mg-Sc alloy[J]. Journal of Japan Institute of Light Metals, 2005, 55(4): 169-174.

[6]Malinkina T I, Markachev N A, Kovtun V A, et al. Welded structures of 01570 aluminium alloy[J]. Welding International, 1998, 12(7): 566-569.

[7]Lathabai S, Lloyd P G. The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al-Mg alloy[J]. Acta Materialia, 2002, 50(17): 4275-4292.

[8]Vilukin V I. Effect of alloying elements Sc, Mn and Zr on weldability of alloy of the Al-Mg-Sc-Mn-Zr system[J]. Welding International, 1996, 10(12): 987-989.

[9]Lapasset G, Girard Y. Investigation of the microstructure and properties of a friction stir welded Al-Mg-Sc alloy[J]. Materials Science Forum, 2003(426-432): 2987-2992.

[10]王月. 含钪铝合金的研究进展[J]. 上海金属, 2003, 25(1): 36-39.

WANG Yue. The research progress of aluminum alloy containing scandium[J]. Shanghai Metals, 2003, 25(1): 36-39.

[11]李绍禄, 潘青林, 陈显明. Sc 和Ti 复合微合金化对Al-Mg合金组织与性能的影响[J]. 兵器材料科学与工程, 2003, 26(1): 11-15.

LI Zhao-lu, PAN Qing-lin, CHEN Xian-ming. Effect of minor Sc and Ti on microstructures and mechanical properties of Al- Mg based alloys[J]. Material Science and Engineering of Weapon, 2003, 26(1): 11-15.

[12]Filatov Y A, Yelagin V I, Zakharov V V. New Al-Mg-Sc alloys[J] . Materials Science and Engineering, 2000, A280(1): 97-101.

[13]Riddle Y W, Hallem H, Ryum N. Highly recrystallization resistant Al-Mn-Mg alloys using Sc and Zr[J]. Materials Science Forum, 2002, 396(1): 563-568.

[14]尹志民, 朱大鹏, 姜锋. Al-Mg-Mn 和Al-Mg-Mn-Sc-Zr 合金的再结晶[J]. 材料工程, 2004, 6: 3-6.

YIN Zhi-min, ZHU Da-peng, JIANG Feng. Recrystallization of Al-Mg-Mn and Al-Mg-Mn-Sc-Zr alloys[J]. Material Engineering, 2004, 6: 3-6.

[15]Ocenasek V, Slamova M. Resistance to recrystallization due to Sc and Zr addition to Al-Mg alloys[J]. Materials Characterization, 2001, 47(2): 157- 162.

[16]唐仁政. 物理冶金基础[M]. 北京: 冶金工业出版社, 1997.

TANG Ren-zheng. Basis of Physical Metallurgy[M]. Beijing: Metallurgical Industry Press, 1997.

基金项目: 国际合作重点计划资助项目(2005DFA50550); 中国博士后科学基金资助项目(20040352031)

收稿日期: 2005-09-08; 修订日期: 2005-11-23

通讯作者: 姜 锋, 教授, 博士; 电话: 0731-8877682; E-mail: jfeng@mail.csut.edu.cn

(编辑李艳红)