网络首发时间: 2013-12-27 09:53

稀有金属 2014,38(06),1017-1021 DOI:10.13373/j.cnki.cjrm.2014.06.013

高剩磁钐钴合金等温退火过程的组织演化和磁性能的关联

孙威 朱明刚 方以坤 郭朝晖 陈红升 李卫

钢铁研究总院功能材料研究所

摘 要:

研究了在800℃等温退火不同时间的名义成分为Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, 原子分数) 的永磁体的磁性能和微观结构。研究显示, 在剩磁Br (~1.15 T) 基本不发生改变的情况下, 磁体的内禀矫顽力Hcj随着等温退火时间从10~40 h的增加呈现逐渐增加的趋势。但是, 其最大磁能积 (BH) max却显示了先增后减的变化规律, 这是因为磁体的方形度Hk/Hcj呈现了先增后减的变化。TEM分析显示等温退火时间为10和20 h的磁体的内部微结构有如下区别:10 h的磁体内部有微小 (<1 nm) 的沉淀相析出;较10 h的磁体的胞状结构而言, 20 h的磁体的胞状结构清晰且完整;相较10 h的磁体, 20 h的磁体的胞内2∶17R主相和胞壁1∶5H相之间的对比度小, 这就表明两相之间的错配度小, 而错配度与钉扎作用呈相反的变化趋势。在上述观察到的3个区别之中, 20 h的样品中的2∶17相对较纯净且不像10 h处理的磁体那样出现微小的沉淀相, 这应该是性能较优异的主要原因。

关键词:

等温退火时间;永磁体;内禀矫顽力;

中图分类号: TM274

作者简介:孙威 (1989-) , 男, 安徽人, 博士研究生, 研究方向:稀土永磁材料;E-mail:sunwei0314@163.com;;朱明刚, 教授;电话:13161977791;E-mail:mgzhu@126.com;

收稿日期:2013-11-26

基金:国家科技部重点基础研究发展 (973) 计划项目 (2014CB643701);国家自然科学基金项目 (51171048, 51371054) 资助;

Relevance Between Structural Evolution and Magnetic Properties in High Remanence Sm ( CobalFe0.245Cu0.07Zr0.02) 7.8 Alloy during Isothermal Annealing Process

Sun Wei Zhu Minggang Fang Yikun Guo Zhaohui Chen Hongsheng Li Wei

Division of Functional Materials, Central Iron & Steel Research Institute

Abstract:

Magnetic properties and microstructures of alloys with nominal composition of Sm ( CobalFe0. 245Cu0. 07Zr0. 02) 7. 8 ( %, atom fraction) isothermally annealed at 800 ℃ with different annealing time were investigated. The results showed that under the case that the remanence Brof different magnets with different annealing time was basically the same ( ~ 1. 15 T) , the intrinsic coercivity Hcjof different magnets presented the tendency of gradual increase with the isothermal annealing time increasing from 10 to 40 h. But the maximum energy product ( BH) maxfirst increased directly and then decreased, which accorded with the changing rule of rectangularity Hk/ Hcj. TEM images indicated that there were three differences between the microstructures of magnet isothermally annealed for 20 and10 h: firstly, there were precipitated dispersion phases with very small size ( less than 1 nm) in the magnet with the isothermal annealing time of 10 h, which could not be found in the magnet annealed for 20 h; secondly, compared with the cellular structure, the cellular structure of magnet with the isothermal annealing time of 20 h was not only distinct but also intact; thirdly, the contrast between the intracellular matrix 2∶ 17 R phase and the cell wall 1∶ 5H phase of magnet with the isothermal annealing time of 20 h was smaller than that of 10 h annealed one, which manifested that the misfit degree of the two coherent phases was smaller, and the pinning strength of1∶ 5H phase was stronger accordingly. Among the three differences above, it was considered that the first difference was the main reason which made the properties of the magnet annealed for 20 h better than those of 10 h annealed one.

Keyword:

isothermally annealed time; permanent magnet; intrinsic coercivity;

Received: 2013-11-26

2∶17型Sm (Co, Fe, Cu, Zr) z烧结永磁体因其卓越的高温表现能力 (较之1∶5型Sm-Co永磁体和2∶14∶1型Nd-Fe-B永磁体) 而备受科研工作者青睐[1,2,3,4,5,6,7]。其拥有优越的高温表现能力的原因是拥有高的居里温度Tc (2∶17型Sm-Co永磁体的居里温度Tc约850℃, 而1∶5型Sm-Co永磁体和2∶14∶1型Nd-Fe-B永磁体的居里温度分别约为720和320℃) [8,9,10,11,12,13,14]。大量的文献[15-18]表明在制备2∶17型Sm (Co, Fe, Cu, Zr) z烧结永磁体诸多的热处理制度当中, 等温退火热处理过程对于最终态磁体的胞状微结构和片状富Zr相的形成是至关重要的, 后续的无论是缓慢冷却过程还是分级回火冷却过程只是Fe和Cu元素的扩散和重新分布过程。文献[3]认为2∶17R主相和1∶5H胞壁相之间的晶格错配形成锥体状的面, 且产生层错界。Feng等[5]的研究结果表明2∶17R主相和1∶5 H胞壁相之间的晶格错配度的增加会恶化1∶5 H相对2∶17 R主相的钉扎作用, 从而降低磁体的性能。

鉴于如上所述的等温退火热处理过程的重要作用, 本文试着讨论在800℃不同等温退火时间的名义成分为Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, 原子分数) 的永磁体的组织演化和磁性能的关联, 并尝试分析等温退火20 h的磁体磁性能优于退火处理10 h的磁体磁性能的原因。

1 实验

按照制得名义成分为Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, 原子分数) 的所需质量配备各金属元素的质量 (考虑到稀土元素Sm的易挥发特性, 特多加入1.5% (质量分数) 以补偿其在熔炼过程中的烧损) , 然后使用ZG-0.03G微正压感应熔炼炉炼制合金铸锭。合金依次经过机械粗破碎和细破碎后成为约300μm的颗粒, 把该颗粒放入以汽油作为介质保护的滚动球磨机中研磨30~90 min, 从而得到面积平均粒径 (SMD) 为4~5μm的粉末, 在约1500 k A·m-1的磁场下把上述所得磁性粉末取向成型而制得Φ30 mm×30 mm的毛坯, 经冷等静压进一步压制后, 在1200~1230℃烧结0.5~2.0h, 然后在1150~1180℃固溶处理2~6 h。把所得样品在800℃分别等温退火10, 15, 20和40 h, 伴随其后的是分级回火工艺, 从而最终制得磁体。用NIM-2000H型磁性测量仪测量机械加工后的Φ10 mm×10 mm的磁体磁性能, 采用JEM-2010型透射电子显微镜 (TEM) 对磁体的微观结构和形貌分别进行分析和观察。

2 结果与讨论

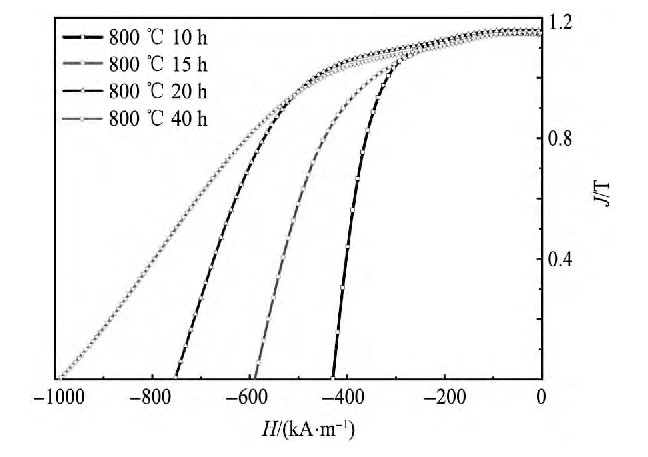

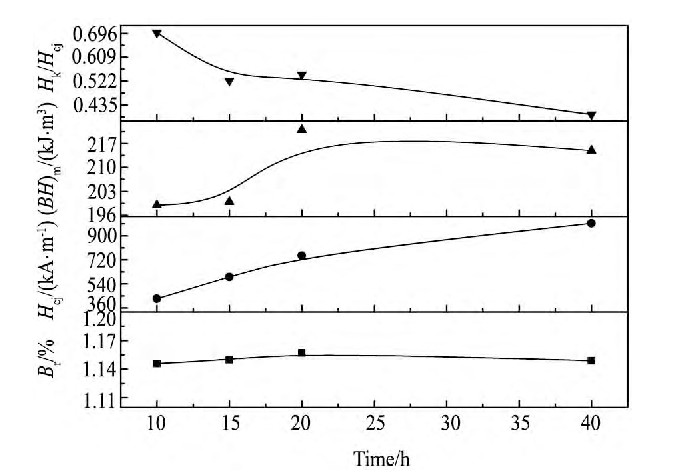

对于名义成分为Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, 原子分数) 的合金铸锭, 探究了等温退火热处理温度为800℃的时间对最终态磁体磁性能的影响。图1是样品经10, 15, 20和40 h等温退火热处理并伴随相同分级回火工艺所得磁体的J-H曲线。其磁性能随着退火时间从10~40 h递增变化曲线示于图2。在图2中, 可以观察到磁体的剩磁Br基本保持在1.15 T, 内禀矫顽力Hcj呈现从429~9949 k A·m-1逐渐增加的变化趋势。但是, 磁体的最大磁能积 (BH) max却显示了先增后减的变化规律, 在等温退火时间为20 h时, 该物理量达到极大值221 k J·m-3。这个规律同样表现在磁体的方形度Hk/Hcj变化上 (除了等温退火时间为10 h的磁体方形度Hk/Hcj之外) 。这是因为磁体的最大磁能积 (BH) max属于结构敏感磁参量, 其值不仅与剩磁Br、内禀矫顽力Hcj相关联, 还与磁体的退磁曲线方形度Hk/Hcj紧密相关。所以, 综合来看, 名义成分为Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, 原子分数) 的磁体在等温退火温度为800℃时的较佳处理时间是20 h。

图1 样品在800℃等温退火10, 15, 20和40 h并伴随相同分级回火工艺所得磁体的J-H曲线Fig.1 Demagnetization J-H curves of samples isothermally an-nealed at 800℃for 10, 15, 20 and 40 h

图2磁体的磁性能剩磁Br、内禀矫顽力Hcj、最大磁能积 (BH) max和方形度Hk/Hcj在800℃等温退火不同时间的变化曲线Fig.2 Magnetic properties including remanence Br, intrinsic coercivity Hcj, maximum energy product (BH) maxand rectangularity Hk/Hcjof samples isothermally annealed at 800℃for different annealing time

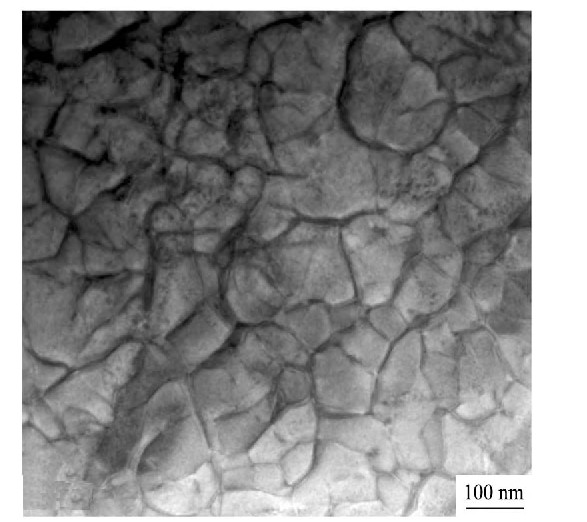

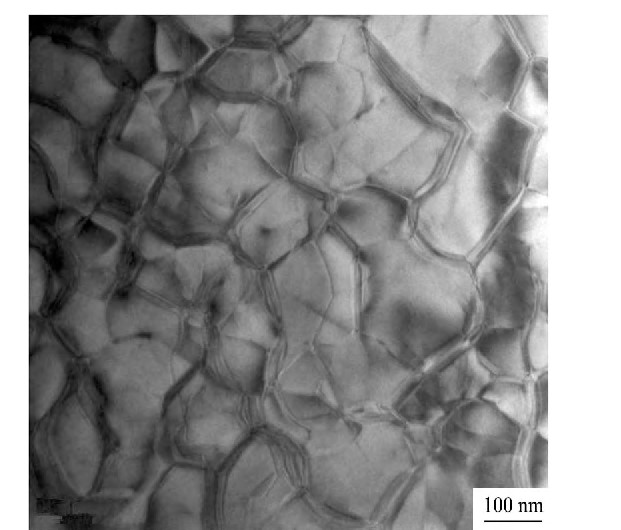

为了解释磁体的最大磁能积 (BH) max在800℃等温退火不同时间 (10~40 h) 先增后减的变化规律, 采用TEM观察退火10和20 h的磁体的微观形貌, 示于图3和4。从图3和4可以比较明显地观察到至少3个方面的区别: (1) 相较退火10 h的磁体的胞状结构而言, 等温退火热处理为20 h的磁体的胞状结构清晰且完整, 这对于磁体获得较高的内禀矫顽力Hcj是必要条件之一; (2) 相较退火10 h的磁体, 20 h的磁体的胞内2∶17R主相和胞壁1∶5H相之间的对比度小, 这就意味着两相之间的晶格错配度小, 而两相之间的晶格错配度与1∶5H相的钉扎强度呈相反的变化趋势[5,7], 换言之, 退火20 h的磁体的胞内2∶17R主相和胞壁1∶5H相之间的晶格错配度小于退火10 h的磁体的, 因此退火20 h的磁体的1∶5H相的钉扎场大于退火10 h的磁体的。此结论与使用NIM-2000H永磁测量仪所测得的数据是吻合的; (3) 退火10 h的磁体内部有微小 (<1 nm) 的沉淀相析出, 由于该沉淀析出相尺寸太小, 其成分和晶体结构尚需进一步地研究和确认。但是, 不难得出的结论是:此沉淀析出物必然会导致退火10 h的磁体的胞壁1∶5H钉扎相的成分不同于退火20 h的磁体的成分, 也就是说, 退火10 h的磁体的成分偏析严重, 这应该是退火10 h的磁体的内禀矫顽力Hcj小于退火20 h的磁体的内禀矫顽力的主要原因之一。

图3在800℃等温退火10 h的Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, 原子分数) 最终态磁体的沿[0001]2∶17R晶带轴的明场 (BF) 像Fig.3 BF image along[0001]2∶17R zone axis of ultimate Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, atom fraction) magnet annealed for 10 h at isothermal temperature of800℃

图4在800℃等温退火20 h的Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, 原子分数) 最终态磁体的沿[0001]2∶17R晶带轴的明场 (BF) 像Fig.4 BF image along[0001]2∶17R zone axis of ultimate Sm (CobalFe0.245Cu0.07Zr0.02) 7.8 (%, atom fraction) magnet annealed for 20 h at isothermal temperature of 800℃

3 结论

通过对在800℃等温退火不同时间的名义成分为Sm (CobalFe24.5Cu7Zr2) 7.8 (%, 原子分数) 的永磁体的磁性能和微观结构的研究, 可得到以下结论:在等温退火温度为800℃时, 磁体的最大磁能积 (BH) max随着退火时间从10~40 h的递增呈现出先增后减的变化规律, 其极大值出现在20 h左右, 此时的磁体的最大磁能积 (BH) max达到极大值221 k J·m-3。退火20 h的样品中的2∶17相对较纯净且不像10 h处理的磁体那样出现微小的沉淀相, 这应该是性能较优异的主要原因。另外, 相较退火10 h的磁体而言, 等温退火20 h的磁体的胞状结构清晰且完整, 且胞内2∶17R主相和胞壁1∶5H相之间的对比度小。

参考文献

[1] Strnat K, Hoffer G, Olson J, Ostertag W, Becker J J.A family of new cobalt-base permanent magnet materials[J]J.Appl.Phys., 1967, 38:1001.

[2] Nesbitt E A, Willens R H, Sherwood R C, Buehler E, Wernick J H.New permanent magnet materials[J].Appl.Phys.Lett., 1968, 12:361.

[3] Wang Q, Wang Y B, Li Y, Li P J, Zhang X, Li J T.Effects of Cu on domain structures and intrinsic coercivity of 2:17-type Sm Co permanent magnets[J].Chinese Journal of Rare Metals, 2013, 37 (6) :896. (王倩, 王燕波, 李扬, 李培佳, 张鑫, 李俊涛.Cu含量对2:17型Sm Co永磁体磁畴结构和矫顽力的影响[J].稀有金属, 2013, 37 (6) :896.)

[4] Guo Z H, Pan W, Li W.Sm (Co, Fe, Cu, Zr) zsintered magnets with a maximum operating temperature of500℃[J].J.Magn.Magn.Mater., 2006, 303 (2) :e396.

[5] Feng H B, Chen H S, Guo Z H, Pan W, Zhu M G, Li W.Investigation on microstructure and magnetic properties of Sm2Co17magnets aged at high temperature[J].J.Appl.Phys., 2011, 109:07A763.

[6] Fang Y K, Chang H W, Guo Z H, Liu T, Li X M, Li W, Chang W C, Han B S.Magnetic microstructures of phase-separated Sm-Co 2∶17-type sintered magnets[J].J.Alloy.Compd., 2008, 462 (1-2) :376.

[7] Rabenberg L, Mishra R K, Thomas G.Microstructures of precipitation-hardened Sm Co permanent magnets[J].J.Appl.Phys., 1982, 53:2389.

[8] Fang Y K, Yin X L, Zhao R, Valloppilly Shah, Li W, Zhu M G, Liou Sy Hwang.Magnetic micro-structural uniformity of die-upset Nd-Fe-B magnet[J].J.Appl.Phys., 2012, 111:07A734.

[9] Sun W, Zhu M G, Fang Y K, Pan W, Li J J, Li Y F, Li W.Microstructures and magnetic properties of Ce32.15Co49.36Cu9.84Fe9.65magnet sintered at different temperatures[J].Rare Metals, 2012, 31 (5) :470.

[10] Li W, Li A H, Wang H J, Pan W, Chang H W.Study on strengthening and toughening of sintered rare-earth permanent magnets[J].J.Appl.Phys., 2009, 105:07A703.

[11] Zhu M G, Fang Y K, Guo Y Q, Li W, Han B S.Study of magnetic microstructures of Nd-Fe-B casting strips by using magnetic force microscope[J].J.Magn.Magn.Mater., 2004, 282:180.

[12] Li A H, Li W, Dong S Z, Li X M.Sintered Nd-Fe-B magnets with high strength[J].J.Magn.Magn.Mater., 2003, 265 (3) :331.

[13] Li Z, Ding H, Zhang J, Wang H B, Wang H.Effects of annealing temperature and time on microstructure and magnetic properties of Pr-Co thin films[J].Rare Metals, 2012, 31 (2) :121.

[14] Wang H C, Zhou Q F, Teng J, Wang L J, Yu G H.Magnetic property and recording performance of chemical deposition Co P thin films[J].Rare Metals, 2012, 31 (3) :260.

[15] Kronmüller H, Goll D.Micromagnetic analysis of pinning-hardened nanostructured, nanocrystalline Sm2Co17based alloys[J].Scripta Mater., 2002, 47 (8) :545.

[16] Searle C W, Davis V, Hutchens R D.Magnetically determined particle alignment factors of sintered rareearth cobalt permanent magnets[J].J.Appl.Phys., 1982, 53:2395.

[17] Melton K N, Perkins R S.Magnetic properties of Sm: (Co, Cu) alloys.I.Electron microscopy[J].J.Appl.Phys., 1982, 47:2671.

[18] Kronmüller H, Goll D.Analysis of the temperature dependence of the coercive field of Sm2Co17based magnets[J].Scripta Mater, 2003, 48 (7) :833.