DOI: 10.11817/j.issn.1672-7207.2017.07.037

基于高炉渣的土壤重金属稳定/固化剂

何哲祥1, 2,肖威1,李翔1

(1. 中南大学 冶金与环境学院 环境工程研究所,湖南 长沙,410083;

2. 中南大学 国家重金属污染防治工程技术研究中心,湖南 长沙,410083)

摘要:通过测定土壤中重金属有效态降低量、正交实验法和扫描电镜方法,研制一种以高炉渣为主要原料的土壤重金属稳定/固化剂。研究结果表明:随着基础配方稳定/固化剂HMS-1的添加量的增加,修复土壤有效态重金属质量分数均降低越多,当HMS-1与土壤的质量比为1:4,液固比为0.28:1 L/kg,室温下养护7 d,有效态锌、镉和铅的质量分数分别降低40.23%,56.68%和48.33%。在HMS-1的基础上,采用正交实验,优化了HMS-1各组分配比,优化后的固化剂命名为HMS-2,即高炉渣、添加剂、石灰石和激发剂的质量分数比等于65:15:2:15。用HMS-2修复土壤,在添加量、液固比、养护温度不变的条件下养护90 d,修复土壤的pH接近原土壤,有水化产物低钙硅质量比的C—S—H凝胶生成,土壤内部结构致密,有利于吸附或共沉淀、包裹和固化重金属,有效态锌、镉和铅的质量分数分别降低了64.08%,66.37%和57.15%。

关键词:重金属;稳定/固化剂;高炉渣

中图分类号:X756 文献标志码:A 文章编号:1672-7207(2017)07-1957-07

Soil heavy metal solidification/stabilization agent based on blast furnace slag

HE Zhexiang1, 2, XIAO Wei1, LI Xiang1

(1. Institute of Environment Engineering, School of Metallurgy and Environment,

Central South University, Changsha 410083, China;

2. Chinese National Engineering Research Center for Control & Treatment of Heavy Metal Pollution,

Central South University, Changsha 410083, China)

Abstract: By means of measuring the reduced amount of available heavy metals in soil, orthogonal test and scanning electron microscope, a new type of soil heavy metal solidification/stabilization agent based on blast furnace slag was developed. The results show that the contents of available heavy metals in soil are lower with the increase of the addition amount of solidification/stabilization HMS-1 and the contents of available Zn, Cd and Pb respectively decrease by 40.23%, 56.68% and 48.33% when the mass ratio of HMS-1 to soil is 1:4, ratio of liquid to solid is 0.28:1 L/kg, temperature is 25 ℃ and curing time is 7 d. The component ratio of HMS-1 is optimized through orthogonal experiment and the optimized curing agent is named as HMS-2, that is to say, the mass fraction rate of blast furnace slag, additive, limestone and activator is equal to 65:15:2:15. When the addition quantity, ratio of liquid to solid and curing temperature is kept unchanged and curing time is 90 d, the pH value of soil treated by HMS-2 is close to that of the original soil, the hydration product of CSH gel with low mass ratio Ca to Si is formed, which makes the internal structure dense and is beneficial to the adsorption or coprecipitation, encapsulation and solidification of heavy metals, and the contents of available Zn, Cd and Pb in soil decrease by 64.08%, 66.37% and 57.15% respectively.

Key words: heavy metal; solidification/stabilization agent; blast furnace slag

高炉渣是冶炼生铁时的一种副产品,自高炉中流出后经水淬冷却得到的主要化学成分为CaO,SiO2,Al2O3和MgO的细小颗粒, 我国每年排放达数千万t,有一大部分仍放置在渣场,占用土地,污染环境[1-5]。高炉渣水淬后,呈中空的海绵状结构,结构疏松,主要为玻璃体结构,玻璃体主要以四配位体SiO44-作为其主要结构单元,部分由Al3+替代Si4+而形成的活性更高的AlO45-铝氧四面体,这种玻璃体是聚合度很低的不完整的网络体,具有较高的潜在活性[6-8]。矿业活动的排放、农药和化肥的不合理施用、污水灌溉和污泥滥用等导致的土壤环境重金属污染,往往不是单一污染,而是多种重金属组成复合污染,具有隐藏性、不可降解性和长期性,能通过食物链在人体内富集,危害人体健康,治理难度较大[9-13]。高炉矿渣在碱激发剂的作用下,发生水化反应形成C—S—H凝胶,反应产物具有网状结构,能有效固封重金属离子,具有良好的耐腐蚀性、耐久性、耐高温性。在修复土壤的固化/稳定化技术中,常用的重金属固化材料有石灰、磷酸盐、水泥、粉煤灰、沸石、碳酸钙、磷石灰和生物炭等,但将高炉渣应用于土壤重金属修复方面的公开报道较少。本文作者以高炉渣为主要原料在激发剂的作用下制备的土壤重金属固化剂,对湖南郴州某矿区污染土地中重金属Pb,Zn和Cd的稳定/固化效果进行了实验研究,研究土壤重金属稳定/固化剂HMS-1的添加量对降低土壤中有效态重金属质量分数的影响,在HMS-1的基础上进行正交实验,确定各组分最佳配比的稳定/固化剂HMS-2,研究养护时间对HMS-2降低土壤中有效态重金属质量分数的影响,并对HMS-2不同龄期的修复土壤进行SME电镜分析,以期为土壤中重金属的稳定/固化提供参考。

1 材料与方法

1.1 原材料

土壤重金属稳定/固化剂HMS-1由高炉渣、石灰石、添加剂和碱激发剂组成,其粒度不大于0.074 mm,前三者的化学成分见表1,碱激发剂的荧光分析见表2。

高炉渣活性的高低通常用矿渣质量系数K表示[14]:

K=w(MgO+CaO+Al2O3)/w(MnO+SiO2+TiO2) (1)

式中:w(MgO+CaO+Al2O3)为在矿渣中MgO,CaO和Al2O3质量分数之和;w(MnO+SiO2+TiO2)为在矿渣中MnO,SiO2和TiO2质量分数之和。矿渣的质量系数K越大,说明矿渣活性越高,实验所用矿渣的质量系数K=1.910>1.2,满足活性要求。

实验所用的土壤取自湖南郴州(112°13′E—114°14′E,24°53′N—26°50′N),采集土壤表层0~15 cm的土样,在干净的纸上,平摊成2~3 cm的薄层,于室内通风处阴干,过2 mm筛后,充分混合均匀,装入干净的土样袋中备用。实验所用的土壤其pH=8.40,根据土壤酸碱度分级,属于碱性土壤,土壤中重金属主要为Pb,Zn和Cd,其有效态质量分数分别为172.69,176.10和6.81 mg/kg。

表1 原料的化学成分(质量分数)

Table 1 Chemical composition of raw materials %

表2 碱激发剂X-射线荧光分析结果(质量分数)

Table 2 X-ray fluorescence analysis results of alkali activator %

1.2 实验方法与过程

1) 取土样200 g,土壤重金属稳定/固化剂HMS-1与土壤的质量比分别为1:4,1:5,1:6和1:7搅拌混合均匀,加水,制成样品,各样品的液固比为0.28(L/kg),覆盖保湿材料,置于室温下,养护7 d,其中HMS-1中各组分为:w(高炉渣):w(石灰石):w(添加剂):w(碱激发剂)=75:5:10:10;

2) 在HMS-1的基础上,以高炉渣、石灰石、添加剂和碱激发剂为影响因数,采用正交表L9(34),进行3水平4因数的正交实验,对HMS-1的配方进行优化,即将各组分不同配比的稳定/固化剂与污染土壤按质量比为1:4搅拌混合均匀,各样品的液固比为0.28(L/kg),覆盖保湿材料置于室温下养护,以有效态Zn,Cd和Pb质量分数为评价指标,采取多指标实验综合平衡法,分析养护28 d后的混合土壤的有效态重金属Zn,Cd和Pb质量分数,先对各个单指标进行分析,找出各个指标的最佳条件,然后对各指标的最佳条件进行综合平衡分析,选出兼顾每个指标都尽可能有利的条件,因数与水平见表3,表3中因数的数字表示占稳定/固化剂的质量分数,正交实验方案见表4;

3) 优化后的产品命名为HMS-2,用 HMS-2修复重金属污染土壤,在添加量为1:4,液固比为0.28 L/kg条件下,分别养护7,14,28和90 d,检测龄期的不同对降低土壤中有效态重金属质量分数的影响;

4) 对原土壤、HMS-2与污染土样按质量比为1:4分别养护14,28和90 d的修复土壤进行SME电镜扫描分析,对它们的微观结构进行观察。

表3 因数与水平

Table 3 Factors and levels %

表4 正交实验方案

Table 4 Scheme of orthogonal experiment

1.3 分析方法

1.3.1 重金属有效态测定实验

土壤中有效态Pb,Cd和Zn的浸提测定根据GB/T 23739—2009,称取5.00 g粒径小于2 mm的风干土壤样品,置于100 mL具塞形瓶中,用移液管移取25.00 mLDTPA提取剂,在室温(25±2) ℃下,放入水平式往复振荡器,提取2 h,离心过滤,滤液上机测定[15]。

1.3.2 测试与分析方法

用原子吸收分光光度计(TAS-990)测定滤液中重金属Pb,Cd和Zn的质量分数;用320型pH计(METTLER TOLEDO公司)测定土壤pH;用JSM-6360LV型扫描电镜(日本电子公司)对土壤的微观结构进行分析,应用统计软件SPSS对结果进行统计分析。

2 结果与讨论

2.1 稳定/固化剂HMS-1添加量对土壤中有效态重金属质量分数的影响

不同稳定/固化剂HMS-1添加量的修复土壤中有效态重金属Pb,Cd和Zn的质量分数,如表5所示。

表5 不同稳定/固化剂HMS-1添加量下土壤中有效态重金属质量分数

Table 5 Available heavy metals content in soil under different addition amount of solidification/stabilization HMS-1

由表5和图1可知:当稳定/固化剂HMS-1添入土样后,土样中的重金属被吸附或共沉淀到矿渣胶凝材料中,使土样中的有效态重金属Pb,Cd和Zn的质量分数降低,对比原土壤中有效态重金属Pb,Cd和Zn的质量分数,分别为172.69,6.81和176.10 mg/kg,修复土壤中有效态Pb降低量从低到高依次为29.53%,29.75%,40.14%和48.33%,有效态Cd降低量从低到高依次为43.03%,45.23%,50.51%和56.68%,有效态Zn降低量从低到高依次为26.96%,32.50%,35.05%和40.23%。当HMS-1与土样质量比分别为1:6和1:7时,前者的修复效果好于后者的修复效果,但有效态Pb和Cd质量分数的降低不是很显著,随着HMS-1添加量的增加,各重金属有效态的质量分数均降低越多,当HMS-1与土壤的质量比为1:4时,为HMS-1的最佳添加量,土壤中有效态Zn,Cd和Pb的质量分数分别降低了40.23%,56.68%和48.33%。

图1 不同HMS-1添加量下土壤中有效态重金属降低量

Fig. 1 Reduced amount of available heavy metals in soil under different addition amount of HMS-1

图2 不同养护时间下土壤中有效态重金属降低量

Fig. 2 Reduced amount of available heavy metals in soil with different curing time

2.2 稳定/固化剂各组分最佳配比的正交实验

正交实验结果如表6所示,正交实验直观分析如表7所示。

表6 正交实验结果

Table 6 Orthogonal experiment results

由表7可知:

1) 当高炉渣的添加量取A1时,评价指标有效态Zn和Pb的质量分数都处于最低水平,当添加量取A1和A3时,评价指标有效态Cd的质量分数分别2.98和2.87 mg/kg,取A3时最好,但两者区别不大,又因数A对其处于最后的第三次要因数,且考虑到混合土壤的增容比,综合比较取A1为最佳水平。

2) 当添加剂的添加量为B3时,有效态Zn和Pb的质量分数均最低,有效态Cd的质量分数取B2为最佳,B2和B3对应的值分别为2.89和2.91 mg/kg,差异不明显,与A同处于最后的次要因数,而因数B对有效态Zn和Pb质量分数都同处于第二次要因数,综合考虑取B3。

3) 当石灰石的添加量为C1(2%)时,有效态Cd和Pb的质量分数均最低,对于有效态Zn质量分数来说,C1和C2对应的指标均值为110.50 mg/kg和110.33 mg/kg,故取C1和C2两者差别也不大,且因数C对有效态Zn的质量分数指标处于第三位的次要因数,综合考虑取C1为最佳水平。

4) 当激发剂的添加量为D3(15%)时,3种重金属的有效态质量分数均为最低值,且因数D对各指标处于第一位的主要因数,说明在本实验中其他组分给定的条件下,激发剂的添加量的增加有利于重金属有效态的降低,且影响显著,对3个评价指标而言,以D3为最佳水平。综合平衡以上的分析结果,得到的最佳组分方案为A1B3C1D3,稳定/固化剂HMS-2,即高炉渣、添加剂和石灰石、激发剂的质量比为65:15:2:15。

表7 正交实验直观分析表

Table 7 Visual analysis table of orthogonal experiment

2.3 最佳配比下养护时间对土壤中有效态重金属质量分数的影响

用稳定/固化剂HMS-2修复土壤,分别养护7,14,28和90 d土壤中有效态重金属Zn,Cd和Pb的质量分数如表8所示。

表8 不同养护时间下土壤中有效态重金属的质量分数

Table 8 Available heavy metals content in soil with different curing time

由表8和图2可知:固化后土壤的pH随着养护时间的增加,呈递减趋势,当养护至龄期90 d时,修复土壤的pH为8.51,接近原土壤的pH(pH=8.40)。有效态Zn的质量分数,随着养护时间的增加,逐渐降低,养护28 d和90 d,有效态Zn的质量分数分别为94.88和63.25 mg/kg,其有效态质量分数分别降低了46.12%和64.08%,两者差别较大,说明在龄期28 d后,增加养护时间对有效态Zn的质量分数降低有比较显著的效果。有效态Cd的质量分数整体变化趋势也是随着养护时间的增加而降低,养护28 d时,有效态质量分数降低65.71%,养护至90 d时,有效态质量分数减低66.37%,两者差别不大,说明养护至28 d龄期,对Cd的固定已基本稳定。在养护7~14 d时,有效态Pb的质量分数从86.41降到74.03 mg/kg,养护至28 d时,有效态质量分数升高到80.71 mg/kg,其有效态降低量为53.26%,随着养护时间的增加,有效态质量分数又开始降低,养护至90 d时,有效态质量分数为73.99 mg/kg,有效态质量分数降低57.15%,其有效态质量分数呈先降低后升高又开始降低。这是因为各重金属与矿渣胶凝材料之间吸附或共沉降存在着竞争,且随着养护时间增加,吸附或共沉淀反应逐渐趋向于稳定。HMS-2能够稳定/固化多种有效重金属,对有效态Cd的固化作用最明显,有效态Zn次之,有效态Pb再次之。在一定龄期内,随着养护时间的增加,稳定/固化效果越好是因为修复后的混合土壤呈碱性,Pb,Zn和Cd可在碱性条件下形成氢氧化物沉淀, 且这些氢氧化物在C—S—H凝胶表面的溶度积要远小于水溶液中的溶度积[16],且C—S—H凝胶具有巨大的比表面积和比表面能,由于胶体的凝聚性,有利于同重金属化合物的吸附或共沉降;此外,随着HMS-2水化反应的进行,高炉渣玻璃体中的Si—O—Si,Si—O—Al和Al—O—Al等共价键断裂生成的SiO44-和AlO45-等在碱的作用下进一步聚合生成类似于天然矿物的碱铝硅酸盐网络状结构[17],且C—S—H凝胶的网络结构在成型过程中可以进一步包裹和固定重金属。

2.4 最佳配比下修复土壤的SEM电镜分析

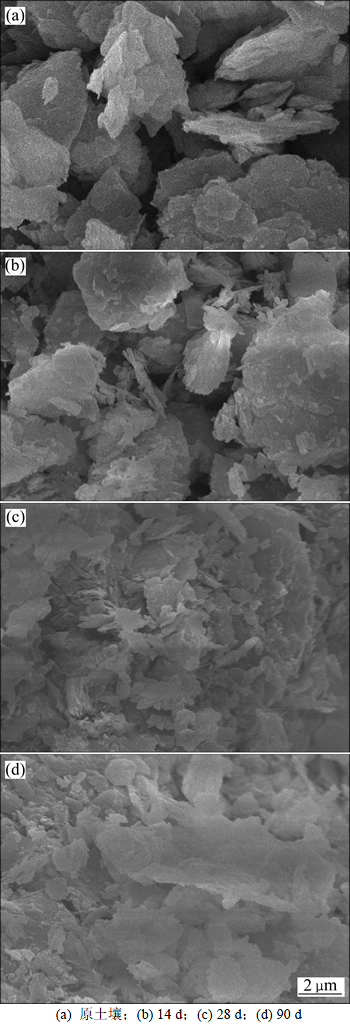

原土壤以及不同龄期的HMS-2修复土壤的SME电镜扫描如图3所示。

图3 不同养护时间样品的SEM像

Fig. 3 SEM images of samples with different curing time

从图3(a)可以看出:原土壤结构较疏松,土壤颗粒之间存在间隙。图3(b)所示为添加稳定/固化剂养护14 d的修复土壤,结构比原土壤要致密,有针状物水化产物生成,即为矿渣中的活性成分Al2O3和CaO等在石灰石以及碱激发剂的作用下生成的钙矾石晶体[18]。图3(c)所示为养护28 d的修复土壤,与图3(b)相比,钙矾石晶体减少,土壤颗粒物的空隙小,被填充的更加细密,这是由于随着养护时间延长,水化产物进一步增加的缘故;养护至90 d时,有结合在一起的团状物质生成,激发剂可以打断矿渣玻璃体中的Si—O,Ca—O和Al—O共价健,产生的Si4+,Ca2+,Al3+和Ca(OH)+等与H3SiO4-反应形成C—S—H凝胶[17, 19-20],这些团状物质即为水化产物低钙硅质量比的C—S—H凝胶,水化硅酸钙的生成,使内部结构更加致密,有利于吸附或共沉淀、包裹和固化重金属。

3 结论

1) 稳定/固化剂HMS-1的添加,能够使土样中有效态重金属Zn,Cd和Pb的质量分数降低,且随着添加量的增加,其有效态质量分数均降低越多,修复效果越显著,当HMS-1与土壤的质量比为1:4时,有效态Zn,Cd和Pb的质量分数分别降低40.23%,56.68%和48.33%。

2) 以矿渣、添加剂、石灰石和激发剂的添加量为影响因数,以有效态重金属Zn,Cd和Pb的质量分数为评价指标,用正交表L9(34)进行3水平4因数的正交实验,实验结果确定了各组分最佳配比的稳定/固化剂HMS-2,即矿渣、添加剂、石灰石、激发剂的质量分数比为65:15:2:15。

3) 稳定/固化剂HMS-2与污染土壤按质量比为1:4,搅拌混合均匀,液固比为0.28(L/kg),养护至90 d龄期,修复土壤的pH接近原土壤,有水化产物水化硅酸钙凝胶生成,土壤内部结构致密,有利于吸附或共沉淀、包裹和固化重金属,有效态Zn,Cd和Pb的质量分数分别降低64.08%,66.37%和57.15%。

参考文献:

[1] KUMAR R, KUMAR S, BADJENA S, et al. Hydration of mechanically activated granulated blast furnace slag[J]. Metallurgical and Materials Transactions B, 2005, 36(6): 873-883.

[2] 易耀林, 李晨, 孙川, 等. 碱激发矿粉固化连云港软土试验研究[J]. 岩石力学与工程学报, 2013, 32(9): 1820-1826.

YI Yaolin, LI Chen, SUN Chuan, et al. Test on alkali-activated ground granulated blast-furnace slag (GGBS) for Lianyungang soft soil stabilization[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(9): 1820-1826.

[3] 孙鹏, 车玉满, 郭天永, 等. 高炉渣综合利用现状与展望[J]. 鞍钢技术, 2008(3): 6-9.

SUN Peng, CHE Yuman, GUO Tianyong, et al. Present situation and forecast of blast furnace slag comprehensive utilization[J]. Angang Technology, 2008(3): 6-9.

[4] 易耀林, 卿学文, 庄严, 等. 粒化高炉矿渣微粉在软土固化中的应用及其加固机理[J]. 岩土工程学报, 2013, 35(增刊2): 829-833.

YI Yaolin, QING Xuewen, ZHUANG Yan, et al. Utilization of GGBS in stabilization of soft soils and its mechanism[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(Suppl 2): 829-833.

[5] 卢红霞, 于霖, 任向前, 等. 利用炼铁高炉渣制备胶凝材料的研究[J]. 郑州大学学报(工学版), 2009, 30(4): 81-84.

LU Hongxia, YU lin, REN Xiangqian, et al. Preparation of cementitious materials from blast furnace slag[J]. Journal of Zhengzhou University (Engineering Science), 2009, 30(4): 81-84.

[6] 朱宏伟, 夏举佩, 周新涛, 等. 矿渣基胶凝材料固化硫砷渣的研究[J]. 硅酸盐通报, 2014, 33(4): 874-879.

ZHU Hongwei, XIA Jupei, ZHOU Xintao, et al. Study on solidifying arsenic sulfide residue by slag cementitious material[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(4): 874-879.

[7] 姚振亚, 郑娟荣, 刘丽娜. 碱激发胶凝材料化学收缩或膨胀的试验研究[J]. 郑州大学学报(工学版), 2008, 29(4): 69-72.

YAO Zhenya, ZHENG Juanrong, LIU Lina. Test investigation on the chemical shrinkage or expansion of alkali-activated cementing materials[J]. Journal of Zhengzhou University (Engineering Science), 2008, 29(4): 69-72.

[8] SHI Caijun, KRIVENKO P, ROY D. Alkali-activated cements and concretes[M]. London: Taylor & Francis, 2006: 90-124.

[9] BEGUM Z A, RAHMAN I M, TATE Y, et al. Remediation of toxic metal contaminated soil by washing with biodegradable aminopolycarboxylate chelants[J]. Chemosphere, 2012, 87(10): 1161-1170.

[10] REYNDERS H, BERVOETS L, GELDERS M, et al. Accumulation and effects of metals in caged carp and resident roach along a metal pollution gradient[J]. Science of the Total Environment, 2008, 391(1): 82-95.

[11] QIU Hao, GU Haihong, HE Erkai, et al. Attenuation of metal bioavailability in acidic multi-metal contaminated soil treated with fly ash and steel slag[J]. Pedosphere, 2012, 22(4): 544-553.

[12] LEE S H, LEE J S, CHOI Y J, et al. In situ stabilization of cadmium-, lead-, and zinc-contaminated soil using various amendments[J]. Chemosphere, 2009, 77(8): 1069-1075.

[13] MADRID F, ROMERO A S, MADRID L, et al. Reduction of availability of trace metals in urban soils using inorganic amendments[J]. Environmental Geochemistry and Health, 2006, 28(4): 365-373.

[14] GB/T 203—2008, 用于水泥中的粒化高炉矿渣[S].

GB/T 203—2008, Granulated blast furnace slag used for cement production[S].

[15] 易磊, 张增强, 沈峰, 等. 浸提条件和浸提剂类型对土壤重金属浸提效率的影响[J]. 西北农业学报, 2012, 21(1): 156-160.

YI Lei, ZHANG Zengqiang, SHEN Feng, et al. Impact of different extraction conditions and different extracts on heavy metals from several typical soils[J]. Acta Agriculturae Boreali-occidentalis Sinica, 2012, 21(1): 156-160.

[16] CHEN Q Y, TYRER M, HILLS C D, et al. Immobilisation of heavy metal in cement-based solidification/stabilization: a review[J]. Waste Manage, 2009, 29(1): 390-403.

[17] 杨立容, 王春梅, 封孝信, 等. 粉煤灰/矿渣基地聚合物的制备及固化机理研究[J]. 武汉理工大学学报, 2009, 31(7): 115-119.

YANG Lirong, WANG Chunmei, FENG Xiaoxin, et al. Preparation and consolidation mechanism of fly ash-based geopolymer incorporating slag[J]. Journal of Wuhan University of Technology, 2009, 31(7): 115-119.

[18] 高术杰, 倪文, 祝丽萍, 等. 脱硫石膏对赤泥-矿渣胶结充填料强度性能的影响[J]. 中南大学学报(自然科学版), 2013, 44(6): 2259-2266.

GAO Shujie, NI Wen, ZHU Liping, et al. Effect of gypsum on strength performance of cemented backfilling materials of red mud-slag system[J]. Journal of Central South University (Science and Technology), 2013, 44(6): 2259-2266.

[19] SHI Caijun, DAY R L. A calorimetric study of early hydration of alkali-slag cements[J]. Cement and Concrete Research, 1995, 25(6): 1333-1346.

[20] PALOMO A, GRUTZECK M W, BLANCO M T. Alkali- activated fly ashes: a cement for the future[J]. Cement and Concrete Research, 1999, 29(8): 1323-1329.

(编辑 杨幼平)

收稿日期:2016-07-09;修回日期:2016-10-11

基金项目(Foundation item):国家“十二五”科技支撑计划项目(2012BAC09B02) (Project(2012BAC09B02) supported by the National Science and Technology Pillar Program during the 12th “Five-Year” Plan Period)

通信作者:何哲祥,博士,教授,从事尾矿处理与利用、矿山充填及胶凝材料等研究;E-mail: hncsxy301@163.com