铝电磁铸轧原理及其复合磁场电源控制系统

凌玉华,李海娜,杨欣荣,廖力清,谢焱彬

(中南大学 信息科学与工程学院,湖南 长沙,410083)

摘 要:针对目前铝电磁铸轧过程中存在的电磁场控制不稳定、铸轧带坯产品晶粒粗大等问题,分析铝电磁铸轧的工作原理和电磁力主要参数对铝板质量的影响;基于电磁力的特性主要取决于控制系统电流的特性,采用模糊自适应PID算法和在线查表的方法,设计一个适用于控制对象的特殊波形发生器,构建复合磁场电源控制系统,以便对智能变频器的电流进行控制。研究结果表明:此磁场电源控制系统能很好地控制电磁力的主要参数,使电流频率的作用范围为10~15 Hz,电流为10~24 A,换相周期数为1~5,谐波分量可以按实际要求进行调整;生产出的铝板组织均匀,晶粒度达到1级水平,系统运行稳定,控制精度高,动态性能好。

关键词:铝电磁铸轧;复合磁场;变频电源;模糊自适应PID控制

中图分类号:TG335.15 文献标识码:A 文章编号:1672-7207(2009)03-0725-06

Principle of aluminum electromagnetic roll-casting and its complex magnetic field power control system

LING Yu-hua, LI Hai-na, YANG Xin-rong, LIAO Li-qing, XIE Yan-bin

(School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: To solve the problems such as unsteadiness of the electro-magnetic field control system and grain coarse in roll-casting sheet, the working principle of aluminum electromagnetic roll-casting was analyzed. Based on the fact that product quality of the electromagnetic parameters was designed by the control system’s current, a specific waveform generator for the control object was designed on the foundation of fuzzy adaptive PID algorithm, and a complex magnetic field power supply control system was also built to control the current of variable frequency power. The results show that the main electromagnetic parameters can be controlled perfectly by this magnetic field power control system, make the action sphere of the frequency in 10-15 Hz, current in 10-24 A, the number of commutation cycle in 1-5, and harmonic component can be adjusted according to the reality needs. The aluminum plate has homogeneous microstructure and grain size reaches the first-class level. The system is stable with high control precision and good dynamic performance.

Key words: aluminum electromagnetic roll-casting; complex magnetic field; variable frequency power; fuzzy adaptive PID control

铝合金是重要的民用、战略金属材料,其力学性能与合金的晶粒粒径和形态密切相关。目前,采用连续铸轧工艺生产的未经细化处理的铸轧带坯晶粒粗大,柱状晶发达,深拉性能差,严重影响铸轧板的质量。国际上普遍采用添加铝钛硼细化剂来获得细晶粒组织,但是,这不仅增加了生产成本,同时,给某些高纯铝产品带来合金化污染,且不利于对铸轧板深拉性能的提高[1]。为了提高产品生产效率和质量,扩大使用铸轧法生产的合金品种范围,中南大学于20世纪90年代开始研究开发铝电磁场快速铸轧技术,这是一项集机械、电子、铸轧和加工工艺等多学科和新技术于一体的探索性研究课题,经过多年探索,铝电磁铸轧技术相继在西北铝加工分公司、兰州铝厂等生产现场成功应用。由于在电磁铸轧生产过程中,有时会出现电磁场系统控制不稳定,生产的铝板质量起伏较大等问题而导致无法正常生产,因此,使电磁感应装置产生符合工艺要求的复合电磁场是提高电磁铸轧产品质量的关键。在此,本文作者研究一种具有特殊波形发生器的电源控制系统,以满足特殊复合电磁场的技术要求。

1 电磁感应器的工作原理

铝电磁铸轧技术是通过在连续铸轧区施加特殊的交变电磁场,使铸轧区中产生几个方向、频率和强度都不同的电磁力,改变铸轧区中的结晶与变形条件,将金属的凝固-塑性流变置于电磁感应力的作用下。而旋转电磁力能够改变晶体成长的线速度,并使正在成长中的枝晶受到振动冲击而破碎,使晶核数量大量增加,从而改变在自然或强冷条件下的凝固结晶过程,使其组织及成分均匀,晶粒细化[2-3]。

1.1 电磁感应器的基本结构

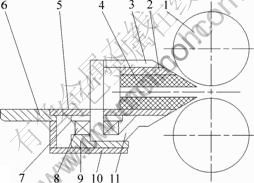

电磁感应装置由多个均匀分布的磁引导装置组成,在每个磁引导装置上都绕制线圈。将电磁感应装置安装在铸轧机操作侧的一定位置,使得供液嘴置于电磁感应装置的上、下磁引导装置的气隙中,磁力线穿过铸轧区中的铝熔体形成闭合的磁路[4]。

受设备结构的约束,将产生旋转电磁场的电磁感应器做成类似1台气隙很大的直线电动机向铸轧区中引入电磁场[5]。将供料嘴安装在电磁感应器的上、下铁芯气隙中,在线圈中通入交流电,在铝熔体中通入直流电,形成如图1所示的电磁铸轧系统。在沿轧辊轴线方向上均匀排列多个磁路引导装置,将其线圈连接成多相系统,并在线圈中通入交流电流,使整个铸轧区内的熔体都置入电磁场的作用范围内,通过多个由这样的磁路导引装置所组成的电磁感应装置向铸轧区输入电磁能量。

1—上轧辊;2—压板;3—上铁芯;4—供料嘴;5—隔磁板;6—底板;7—冷却水箱;8—感应线圈;9—支撑箱;10—滑动座;11—下铁芯

图1 电磁感应装置的基本结构示意图

Fig.1 Basic structure of electromagnetic inductor

1.2 影响电磁力的主要参数

不同的电磁参数对带坯的晶粒细化效果有不同的影响。实验结果表明,影响电磁力的主要参数有电流频率、电流、换相周期和谐波分量。

1.2.1 电流频率

频率对晶粒的细化效果起重要作用。当电磁场频率过高或过低时,其细化晶粒的作用均减弱,频率为10~15 Hz时可获得非常显著的细化效果[6-7]。

1.2.2 电 流

当铝熔体结晶前沿的磁感应强度低于0.020 T时,对晶粒细化的作用很小;磁感应强度增加时,晶粒细化作用增强;当磁感应强度达到0.048 T时,晶粒细化效果最佳。电流直接决定磁感应强度,因此,电流的作用可等同于磁场强度的作用[8]。但当电流增加到一定程度时,晶粒细化程度逐渐趋于平缓。而且过高的磁感应强度易使铸轧带坯表面产生波纹状的氧化膜折叠或浅表面裂纹,还会引起铸轧区震动,影响生产的平稳运行。因此,电流不宜太小也不能太大,一般取10~24 A。

1.2.3 换相周期

所谓换相,就是保持其中一相电流不变,其他两相电流变换,使其“正反转”。换相周期和电磁场的频率则决定了行波频率。要获得显著的晶粒细化效果,换相周期应为1~5[9],这样,有利于晶粒的等轴细化。

1.2.4 谐波分量

谐波分量产生的上下方向的脉振与左右方向的行波同时作用在铸轧区,使得因振荡而碎化的枝晶块被迫向左右和上下方向均匀扩散,使整个铝板的组织细化、等轴化,消除组织不均匀现象。但是,脉振强度过大会使铸轧带坯表面产生横纹,还会引起铸轧区的震动加剧,影响生产的平稳运行。因此,谐波分量也不宜过大。

2 特殊复合磁场电源控制系统设计

电磁铸轧的复合磁场发生系统由电磁感应装置及其控制系统2部分组成。在电磁感应装置的线圈中通入频率、幅值和相序按一定规律变化的交流电流,就会在铸轧区产生交变的脉振磁场和交变的行波磁场,同时,在铝熔体中通入直流电流,这样,就形成了铝电磁连续铸轧的复合磁场系统。

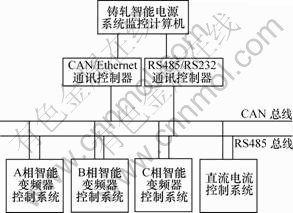

2.1 系统总体方案

电磁铸轧特殊复合磁场电源控制系统采用2级计算机控制系统。现场设备由3套智能变频器和1套直流电源控制系统构成,分别给电磁感应装置和铝熔体供电。车间监控级由工控机运行监控软件实现系统监控。控制系统采用CAN总线和RS-485总线并存的双总线结构,构成铸轧特种电源网络控制系统[10]。图2所示为铝电磁铸轧特殊复合磁场电源控制系统的网络结构示意图。

图2 特殊复合磁场电源控制系统网络结构图

Fig.2 Control system network structure of specific complex magnetic field power

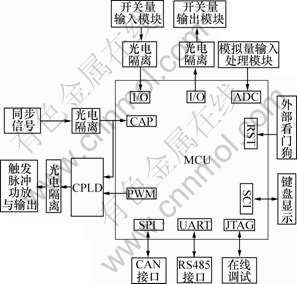

2.2 智能变频器硬件结构

智能变频器是产生特殊交变磁场的基础。硬件设计采取模块化的设计思想,将整个电路分为同步信号采集模块、反馈模拟量采集模块、触发脉冲产生模块、通讯模块、键盘与显示模块以及开关量输入输出模块等来设计[11-12]。控制电路采用“MCU+CPLD”的结构方式,主控芯片采用MSP430F1611芯片,它是一款16位具有超低功耗特性的单片机,具有丰富的片内外围模块和强大的处理能力。图3所示为智能变频器硬件电路基本结构图。

图3 智能变频器硬件电路基本结构图

Fig.3 Hardware circuit basal structure of intelligent variable frequency power

智能变频器的主要工作是产生触发脉冲控制晶闸管的通断实现变流。首先,控制器的模拟量输入模块采样反馈电流,然后,通过A/D转换进入MCU,经过运算处理得出脉冲触发角,同步信号经光电隔离,由MCU的I/O口捕获后启动定时器,定时到所需触发角时发出单窄脉冲,单窄脉冲和同步信号同时进入CPLD,完成逻辑运算后形成双窄脉冲,双窄脉冲通过光电隔离和功率放大与电磁隔离后触发晶闸管导通,完成对电流的控制。

2.3 智能变频器软件结构

智能变频器控制软件的设计也采用模块化的设计方法,分为控制程序模块、人机接口程序模块、通讯程序模块。主程序包括初始化、键盘扫描与处理、LCD显示处理等。中断服务程序主要包括:用于全数字触发的定时器B中断,采样转换完成的ADC中断,控制周期定时的定时器A中断,RS-485数据接收处理的UART1中断和CAN数据接收处理的P2口中断。

3 优化系统性能的控制策略

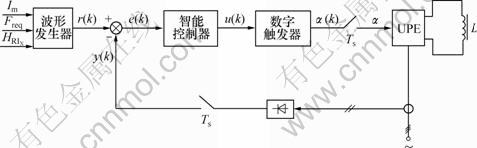

3.1 模糊自适应PID控制器

由于电磁感应器的数学模型是1个高阶次、非线性、强耦合的多变量系统,很难建立1个精确的数学模型,因此,4个电控参数也很难确定1组精确值,只能将它们限制在一定的范围内。另一方面,由于不同产品的特性不同,在生产不同合金铝板时,要求的磁场特性也不一样。因此,采用传统PID控制器进行调节时,采用1组固定的PID参数难以获得满意的电流波形,控制效果下降,从而,导致铸轧系统不稳定,难以正常生产。

模糊控制系统不依赖于系统精确的数学模型,特别适用于复杂系统与模糊性对象。在铸轧特种电源控制系统中,以电磁感应线圈为被控对象,以流过电磁感应线圈中的电流为被控变量。采用模糊自适应PID控制器作为电流调节器,以e(k)和?e(k)为输入量,通过模糊控制实现PID参数KP,KI和KD的在线自整定,以获得更满意的控制效果。基于模糊自适应PID控制器的智能电源控制系统原理如图4所示,其中:Im为给定铸轧特殊电流波的基波电流;Freq为基波电流频率;HRix为各次谐波含有率;r(k)为波形发生器的输出电流;y(k)为霍尔电流传感器测得的实际电流;e(k)为偏差;u(k)为模糊自适应控制器的输出量; 为晶闸管的导通角;UPE为电力电子变换器,这里为晶闸管正反桥整流组。通过导通角的变化来控制电流使其按给定基准电流变化。

为晶闸管的导通角;UPE为电力电子变换器,这里为晶闸管正反桥整流组。通过导通角的变化来控制电流使其按给定基准电流变化。

图4 基于模糊自适应PID控制器的智能电源控制系统原理图

Fig.4 Principle graph of intelligent power control system based on fuzzy adaptive PID controller

模糊自适应PID控制器设计的核心是建立合适的模糊控制规则,得到针对KP,KI和KD 3个参数分别整定的模糊控制表[13-14]。为满足实时控制的要求,模糊自适应PID控制算法的软件设计思想是离线计算和在线查表。首先,通过addmf命令建立隶属度函数,再利用addrule命令建立KP,KI和KD的模糊规则表,通过evalfis函数执行模糊推理运算,最后得到针对KP,KI和KD 3个参数分别进行整定的模糊控制表。实际控制时,将模糊控制表以二维数组的形式存放在计算机内存中,根据偏差和偏差变化的量化值E和EC查询该二维数组,用查询结果来修正KP,KI和KD,以修正后的KP,KI和KD进行增量式PID运算。

3.2 特殊波形发生器设计

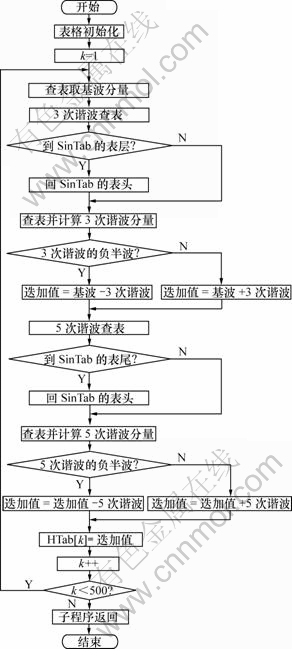

设计1个输出频率可调、幅值可调并能任意迭加高次谐波特殊波形发生器是实现铝电磁铸轧性能优化的关键环节,也是实现控制方案的关键。设计中采用软件实现该特殊波形发生器。由于所需电流波形是由多个不同的正弦波电流迭加而成,所以,根据幅值给定、频率给定和高次谐波含有率给定在线实时求解给定波形时,需要计算正弦函数,并且高次谐波越多,计算正弦函数的次数也相应增多。为了达到实时控制的要求,节省CPU资源,采用查表法来设计铸轧系统特殊电流波形发生器。其设计思想是:将波形离散化后进行离线计算,以表格形式存放在CPU内存中,取给定时访问表格,从表格中获取所需要的数据。图5所示为通过查表建立基波与3次谐波、5次谐波的迭加表的程序流程图。

图5 通过查表建立基波与谐波迭加表格的程序流程图

Fig.5 Program flow chart of establishing the fundamental and harmonic superposition forms through table lookup

3.3 应用结果

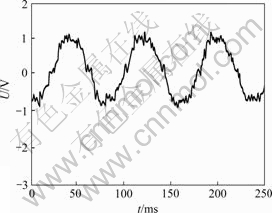

本系统已投入试生产,生产时设备运行稳定,控制效果良好。图6所示是试生产时频率为13 Hz,电流为13 A,三次谐波分量为10%时霍尔传感器反馈的B相电压波形,它正比于B相电流波形,电压波形较理想。采用这组参数在试生产中取到了良好的效 果,在撤掉铝钛硼添加剂后,轧机运行平稳,生产出来的铝板质量与添加铝钛硼时的铝板质量相当甚至更好。

图6 试生产时B相电压波形

Fig.6 Voltage waveform of phase B in test production

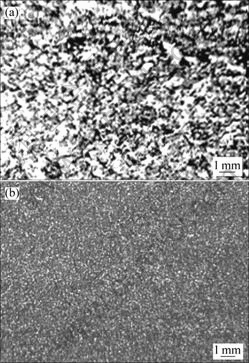

图7所示为铝铸轧过程中未加电磁场和引入电磁场后的铝带坯金相组织。可见,未加电磁场时,铝板组织起伏较大,晶粒粗大,通过与标准金相组织相对比得知,其晶粒度只有3~4级,而加电磁场的组织明显比不加电磁场的组织均匀,晶粒细小而均匀,主要是细等轴晶组织,其晶粒度达到1级。

(a) 未加入电磁场;(b) 加入电磁场

图7 电磁场对铝板组织结构的影响

Fig.7 Influence of electromagnetic field on aluminum strip organizational structure

4 结 论

a. 通过模糊PID算法和软件编程实现了一个特殊的电流波形发生器,能产生所需的特殊复合电磁场,使电源控制系统频率为10~15 Hz,电流为10~24 A,换相周期为1~5,谐波分量按实际需要进行调整,系统运行稳定。

b. 未加电磁场时,铝板组织具有强烈定向结晶的特点,晶体成长方向性强,柱状晶发达。而加电磁场以后,其组织明显比不加磁场的铝板组织均匀,晶粒细小而均匀,晶粒度达到1级,晶粒线性尺寸低于117 μm,在添加铝钛硼时晶粒线性尺寸为271 μm左右。可见,引入电磁场后,铝板质量比添加铝钛硼时的铝板质量更好。

参考文献:

[1] 李晓谦, 周伟华. 铝电磁铸轧发展现状[J]. 轻合金加工技术, 2002, 30(12): 12-13.

LI Xiao-qian, ZHOU Wei-hua. Development conditions of aluminum electromagnetic casting-rolling[J]. Light Alloy Fabrication Technology, 2002, 30(12): 12-13.

[2] MAO Da-heng, YAN Heng-zhi, ZHAO Xiao-ling, et al. The principle and technology of electromagnetic roll-casting[J]. Journal of Materials Processing Technology, 2003, 138(1/3): 605-609.

[3] 钟 掘. 铝合金的超常铸轧制备[J]. 中国有色金属学报, 2004, 14(1): 147-153.

ZHONG Jue. Transnormal roll casting processing of aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 147-153

[4] 赵啸林, 毛大恒, 易幼平. 铝电磁连续铸轧电控系统探讨[J]. 上海有色金属, 2000, 21(2): 57-63.

ZHAO Xiao-lin, MAO Da-heng, YI You-ping. Discussion about electronic control system for continuous roll casting of aluminum[J]. Shanghai Nonferrous Metals, 2000, 21(2): 57-63.

[5] YANG Jing, DANG Jing-zhi, PENG You-gen, et al. Design method of electromagnetic field applied to Al-alloy electromagnetic casting[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S3): 1437-1441.

[6] Li J C, Wang B F. Modeling and experimental research of four-strand low-frequency electromagnetic casting aluminum alloy[J]. Acta Metallurgica Sinica: English Letters, 2007, 20(3): 157-166.

[7] 赵啸林, 毛大恒, 李晓谦. 铝电磁铸轧中熔体的频率响应[J]. 中国有色金属学报, 2001, 11(1): 22-26.

ZHAO Xiao-lin, MAO Da-heng, LI Xiao-qian, Frequency response of melt in aluminum electromagnetically continuous cast-rolling process[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 22-26.

[8] WANG Hui, LI Ting-ju, JIN Jun-ze. Mathematical modeling of electromagnetic domensionless number for electromagnetic casting of metals and its application[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(3): 606-611.

[9] MAO Da-heng, YAN Hong-zhi, ZHAO Xiao-ling, et al. Crystallization in aluminum roll-casting process under electromagnetic disturbance and texture evolution of roll-casting strips[J]. International Journal of Materials and Product Technology, 2001, 2: 482-487.

[10] 章 林, 陈登顺, 廖力清, 等. 铝电磁场快速铸轧网络化控制系统的设计[J]. 工业控制计算机, 2006, 19(1): 26-27.

ZHANG Lin, CHEN Deng-shun, LIAO Li-qing, et al. Design of a electromagnetically fast cast-rolling of aluminum networked control system[J]. Industrial Control Computer, 2006, 19(1): 26-27.

[11] 胡崇岳. 现代交流调速技术[M]. 北京: 机械工业出版社, 1998: 148-151.

HU Cong-yue. Modern AC adjusting speed technology[M]. Beijing: China Machine Press, 1998: 148-151.

[12] 胡仕成, 杜 磊. 基于MCU+CPLD 技术的铝电磁场快速铸轧控制系统[J]. 工业仪表与自动化装置, 2007(3): 77-80.

HU Shi-cheng, DU Lei. A control system designed for aluminum electromagnetic rapid roll-casting[J]. Industrial Instrumentation & Automation, 2007(3): 77-80.

[13] 黄松林. PID参数模糊自整定非线性系统仿真研究[J]. 机械工程与自动化, 2007(2): 93-97.

HUANG Song-lin. Study on nonlinear control system based on PID controller with fuzzy self-adjusting[J]. Mechanical Engineering & Automation, 2007(2): 93-97.

[14] 许良琼, 陆新江, 李群明. 模糊PID控制在电磁悬浮平台中的应用[J]. 中南大学学报: 自然科学版, 2005, 36(4): 631-636.

XU Liang-qiong, LU Xin-jiang, LI Qun-ming. Application of fuzzy-PID control to electromagnetic suspension platform[J]. Journal of Central South University: Science and Technology, 2005, 36(4): 631-636.

收稿日期:2008-06-31;修回日期:2008-09-10

基金项目:国家“863”高技术研究发展计划项目(2001AA337070)

通信作者:凌玉华(1965-),女,湖南衡阳人,教授,从事测控技术研究;电话:0731-8879381(O);E-mail: yhling@mail.csu.edu.cn