Al-7.8Zn-1.6Mg-1.8Cu合金铸锭及其均匀化的微结构研究

熊创贤1, 2,万里1, 3,邓运来1, 3,张新明1, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 湖南城市学院 土木工程学院,湖南 益阳,413000;

3. 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410012)

摘 要:采用光学金相(OM)、扫描电镜(SEM)、透射电镜(TEM)、X线衍射(XRD)、差示扫描量热(DSC)等技术研究Al-7.8Zn-1.6Mg-1.8Cu(7085型)合金铸锭及其均匀化的微结构。研究结果表明:该铝合金铸锭中主要结晶相为分布在晶界的网状Mg(Zn, Al, Cu)2相,晶内有少量微米量级球状和纳米量级条状的Al2Cu结晶相,此外,还有纳米量级Al2Cu和Fe-rich析出相;在均匀化过程中,Al3Zr粒子析出,Mg(Zn, Al, Cu)2相溶解消失,且部分转化成Al2CuMg相;当均匀化温度升高到470 ℃时,除Fe-rich相和Al3Zr粒子外,其他第二相都溶入基体;于400 ℃/12 h+ 470 ℃/12 h双级均匀化比于470 ℃/12 h单级均匀化更有利于提高Al3Zr粒子析出的数量和改善其分布均匀性。

关键词:Al-Zn-Mg-Cu合金;均匀化;微结构;溶解;析出

中图分类号:TG249.9 文献标志码:A 文章编号:1672-7207(2010)02-0465-07

Investigation of microstructures in as-cast and homogenized Al-7.8Zn-1.6Mg-1.8Cu aluminum alloy

XIONG Chuang-xian1, 2, WAN Li1, 3, DENG Yun-lai1, 3, ZHANG Xin-ming1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Civil Engineering, Hunan City University, Yiyang 413000, China;

3. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education, Changsha 410012, China)

Abstract: Microstructures in the as-cast and homogenized Al-7.8Zn-1.6Mg-1.8Cu aluminum alloy (7085 type) were investigated using optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscope (TEM), X-ray diffraction(XRD) and differential scanning calorimetry (DSC). The results show that the second solidifying phases in the ingot include a large mount of skeletal Mg(Zn, Al, Cu)2 phase, which are distributed on boundaries, and there are a little of micrometer-scale spherical and nanometer-scale club-shaped Al2Cu particles within grain. Precipitating Al2Cu and Fe-rich particles are in the ingot. During homogenization, Al3Zr particle precipitates, dissolution and transformation into Al2CuMg of the Mg(Zn, Al, Cu)2 phase occur in the mean time. Except Al3Zr and Fe-rich particles, other second phases dissolve into the matrix completely while homogenized at 470 ℃. The number density of the Al3Zr precipitation particles is larger, and the distribution of the Al3Zr precipitation particles is more homogeneous comparing the two-stage homogenization of 400 ℃/12 h + 470 ℃/12 h with that of 470 ℃/12 h.

Key words: Al-Zn-Mg-Cu aluminum alloy; homogenization; microstructure; dissolution; precipitation

7000系铝合金的铸锭中存在大量的非平衡共晶组织,其中Cu,Zn和Mg元素的偏聚和均匀化后残留的粗大第二相会严重降低其使役性能[1-9]。铝合金均匀化处理的主要目的是使非平衡共晶组织完全溶入基体,消除枝晶偏析。在均匀化处理时,温度和时间的选择对整个均匀化过程至关重要。在7000系铝合金中添加微量元素Zr可以在基体中形成亚稳Al3Zr粒子,该粒子阻止基体在后续热加工与热处理过程中发生再结晶。亚稳Al3Zr粒子阻碍再结晶的效果与其粒径、间距和分布有关[10-11]。Robson等[11-12]研究了均匀化温度和Zr元素的添加量对Al3Zr粒子析出行为的影响,认为7000系铝合金均匀化不仅需要消除粗大的结晶相,而且需控制Al3Zr粒子的析出行为,其均匀化状态与工艺控制十分复杂。由于7085铝合金具有高断裂韧性和低淬透性[13-14],其在航天等领域得到广泛应 用[15-17],已成为新一代超高强铝合金的代表,但对于其铸态微结构及其在均匀化过程中的演变研究较少。本文作者以合金成分为Al-7.8Zn-1.6Mg-1.8Cu的7085[13]铝合金为对象,研究该合金铸锭微结构及其在均匀化过程中的演变规律,探讨在该合金均匀化后获得的非平衡共晶组织完全溶解和Al3Zr粒子弥散析出的方法,以便为类似7085铝合金材料制备提供依据。

1 实验材料与方法

采用高纯铝、纯锌、纯镁和铝-铜、铝-锆中间合金配料,Al-5Ti-B为晶粒细化剂,C2Cl6为除气剂。熔炼炉选用石墨坩埚电阻炉,熔炼温度为750~780 ℃,精炼温度为730~750 ℃,铸造温度为710~720 ℃。将熔体浇铸于铁模中获得长×宽×高为30 mm×80 mm×120 mm的7085型铝合金方锭,其化学成分如表1所示。通过差示扫描量热(DSC)检测发现该铝合金铸态微观组织中非平衡共晶熔化温度为475 ℃,采用的均匀化制度如表2所示。

将试样置于XJP-6A型金相显微镜上进行光学金相观察,金相试样的腐蚀试剂为1 mL HF+16 mL HNO3+3 g CrO3+83 mL蒸馏水(Graff Sargent试剂),扫描电子显微(SEM)用JSM-6360LV扫描电镜及其能谱仪(EDS)附件进行观察与分析;用TECNAIG220型透射电镜进行透射电子显微(TEM)分析,加速电压为200 kV;采用Rigaku D/Max 2500型18 kW转靶X线衍射仪进行 X-ray衍射(XRD)物相分析。差示扫描量热(DSC)分析采用NET2SCH-200 F3热分析仪,升温速度为10 ℃/min。

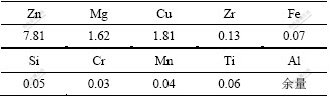

表1 试验所用Al-Zn-Mg-Cu合金的化学成分

Table 1 Chemical composition of investigated

Al-Zn-Mg-Cu alloy w/%

表2 均匀化制度

Table 2 Schemes of homogenizations

2 实验结果与讨论

2.1 DSC与XRD测试结果

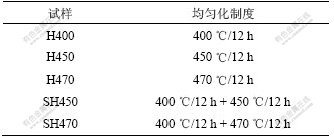

Al-7.8Zn-1.6Mg-1.8Cu合金(7085型)铸态及其经不同均匀化制度处理后试样的DSC曲线如图1所示。可以看出:该合金铸态样品测试曲线上在475 ℃有 1个明锐的吸热效应(A点),此效应为铸态基体中非平衡共晶组织熔化所形成;而试样H400的测试曲线上出现2个明锐的吸热效应(如图1中B点和C点)。B点的峰值温度为477 ℃,C点峰值温度为483 ℃,也就是说,在DSC升温过程中,H400试样中有2个第二相发生了溶解或熔化。比铸锭样品高2 ℃的吸热效应(B点)是非平衡共晶熔化产生的,因为在均匀化过程中,随着非平衡共晶的逐渐溶解,其熔点会逐渐增大。H470样品的DSC曲线上没有发现明锐的吸热或放热效应。此外,经过均匀化处理的试样在进行DSC加热时出现放热效应(D点和E点),并且均匀化温度越高,此类放热效应发生的温度也越高,而铸锭样品的DSC曲线上没有发现此类放热效应。此类放热效应发生的温度范围较宽,容易被忽略。

1—铸态; 2—H400; 3—H470

均匀化制度:试样H400,400 ℃/12 h;试样H470,470 ℃/12 h

图1 铸态及其经不同均匀化处理后试样的DSC曲线

Fig.1 DSC plots of as-cast and homogenized samples

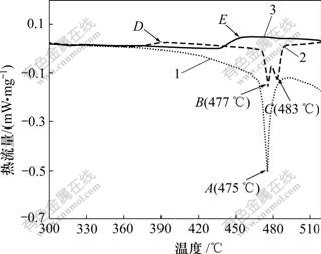

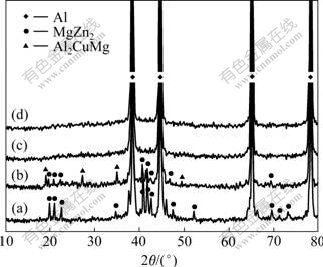

图2所示为该铝合金铸态及其经不同均匀化处理后的XRD扫描测试结果,图中可以识别的物相为α(Al) 和MgZn2相。经过不同均匀化制度处理后,H400在MgZn2相衍射峰的强度减弱的同时出现另外的衍射峰,对照PDF卡片可知其为Al2CuMg相的衍射峰。由此判断,H400样品DSC曲线上483 ℃(C点)的吸热效应应是Al2CuMg相熔化吸收热量所致。而在H450和SH450衍射图上除α(Al)基体的衍射峰外,几乎识别不出其他第二相的衍射峰。这是由于随着均匀化时间延长、温度升高,第二相粒子逐渐溶解到基体中,使其含量减小,小于XRD衍射仪所能检测的范围。

(a) 铸态; (b) 试样H400; (c) 试样H450; (d) 试样SH450

均匀化制度:试样H400,400 ℃/12 h; 试样H450,

450 ℃/12 h; 试样SH450,400 ℃/12 h+450 ℃/12 h

图2 铸锭及其不同均匀化处理后试样的XRD图谱

Fig.2 X-ray diffraction patterns of as-cast and

homogenized samples

2.2 Al-7.8Zn-1.6Mg-1.8Cu合金铸锭的微结构

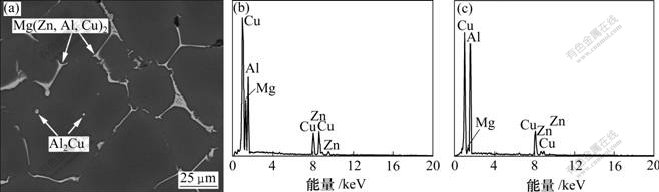

图3(a)所示为该合金铸锭样品的背散射图。图中黑色区域为α(Al)基体,大量分布于晶界处的白色区域为网格状的非平衡共晶组织。由于在该合金中w(Zn)/w(Mg)为4.9(>2.2),非平衡共晶组织的结晶相主要是MgZn2结构,同时在晶粒内部也发现一些灰色球状第二相粒子(如图3(a)中箭头所示)。对非平衡共晶组织进行EDS分析,结果如图3(b)所示,共晶组织中含有Al,Zn,Mg和Cu元素(摩尔分数分别为39.08%,18.98%,26.98%和14.96%)。综合图2所示的XRD分析结果可知:这些非平衡共晶组织的形成是MgZn2型结构粒子中固溶了大量的Al和Cu的缘故,这与Mondal等[2, 5]报道的Al-10Zn-2.5Mg-2.5Cu和7055合金铸锭中MgZn2型结构粒子的成分十分相似。对图3(a)箭头所示的灰色球状第二相粒子进行EDS分析,结果如图3(c)所示,可见:其与非平衡共晶组织的成分不同,主要含有Al和Cu元素(摩尔分数分别为67.66%和23.13%),其合金成分非常接近于平衡态的Al2Cu相成分,但是,由于其在基体中的含量很少,所以,并没有被XRD和DSC检测到。

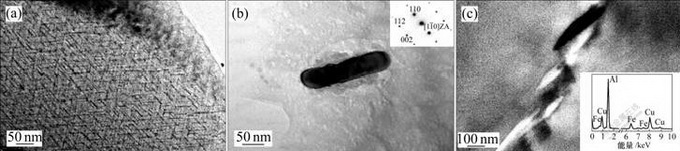

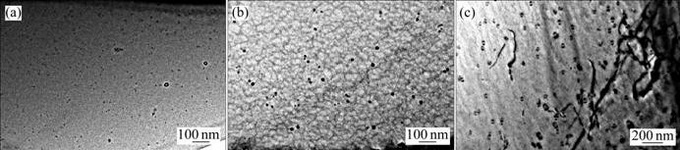

图4所示为该铝合金铸态组织的透射电镜照。从图4(a)可见:铸锭基体组织中有大量与基体呈共格状态,排列整齐的纳米级第二相,这是在凝固冷却过程中析出的非平衡态Al2Cu。此外,还发现游离的纳米级棒状粒子,如图4(b)所示。对其衍射特征花样标定(图4(b)中右上角),发现其为Al2Cu粒子,与扫描电镜下发现的微米量级Al2Cu粒子联系起来考虑,它们与基体没有晶体学位向关系,可以判定都是凝固结晶相。图4(b)中Al2Cu粒子尺寸小,还没长大成球状粒子。

(a) Al-7.8Zn-1.6Mg-1.8Cu合金铸锭的背散射图; (b) 非平衡共晶组织EDS分析图; (c) 灰色球状第二相粒子EDS分析图

图3 铸态样品微结构的背散射图及其能谱分析结果

Fig.3 Backscattered electron images of microstructures and EDS results in as-cast samples

(a) Al2Cu沉淀粒子; (b) 平衡态Al2Cu粒子; (c) Fe-rich粒子

图4 铸态样品中不同第二相粒子的TEM分析

Fig.4 Different second phase particles in as-cast sample determined by TEM

值得注意的是:图4(c)所示的Fe-rich相粒子(其EDS分析的成分结果如图中右下角图谱所示,由于测试粒子的尺寸较小,测试过程中会吸收基体的信号)与基体呈一定的位向关系,应属析出相。

2.3 粗大第二相粒子在均匀化过程中的演变

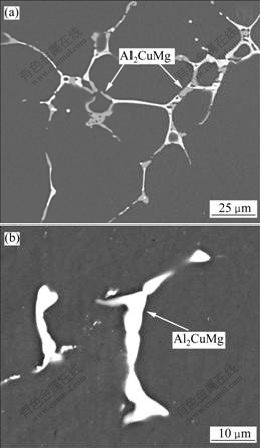

采用扫描电镜(SEM)研究不同均匀化制度处理后样品的微结构,其典型结果如图5所示。在H400样品中可以清晰地看到紧挨着Mg(Zn, Al, Cu)2相形成的新相(如图5(a)箭头所示),其占据原来Mg(Zn, Al, Cu)2相的位置,EDS分析表明新相中Al,Cu,Zn和Mg的摩尔分数分别为57.40%,17.33%,1.88%和23.39%,这与图1中的DSC曲线和图2中XRD谱检测到的Al2CuMg相成分含量相吻合。SH450样品的背散射图如图5(b)所示,从图中可以发现基体中仅剩下小部分的第二相粒子,EDS分析表明,其均为没有完全固溶到基体中的Al2CuMg相,此时已很难找出Al2Cu粒子。上述结果表明:由于Al基体中Cu和Mg原子的扩散速度比Zn原子扩散速度低,导致Mg(Zn, Al, Cu)2相溶解的同时也有一部分会转变为Al2CuMg相。

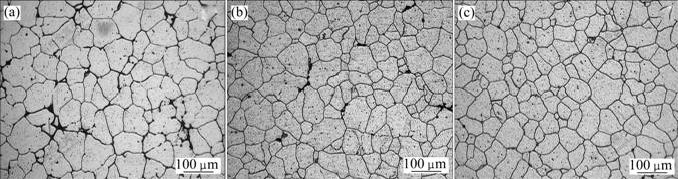

图6所示为经过不同均匀化处理后的金相(OM)图。从图6(a)可以看出,在H400样品的金相图中,虽然枝晶已大部分消除,但是,仍然可以清晰地看出晶界有一定宽度,且在部分三叉晶界交合处存在第二相。结合图2和图5(a)可判定晶界上及晶界交合处的第二相分别为铸造时形成的Mg(Zn, Al, Cu)2结晶相和均匀化过程中形成的Al2CuMg相。SH450(图6(b))样品中晶粒均匀,但部分晶界上仍存在部分黑色粒子,结合图5(b)可知其为Al2CuMg相。SH470样品(图6(c))晶粒均匀,晶界细小清晰,在其中很难找到第二相粒子。由此可见:随着均匀化温度升高到470 ℃,由Mg(Zn, Al, Cu)2结晶相转变而来的Al2CuMg相溶入基体。

(a) 试样H400,400 ℃/12 h;

(b) 试样SH450,400 ℃/12 h+450 ℃/12 h

图5 不同均匀化样品中粗大第二相粒子的SEM 分析

Fig.5 Residual coarse phases determined by SEM after homogenization

上述结果表明:所用的7085型铝合金铸锭中的Al2Cu相在均匀化温度达到450 ℃时已溶入基体,而Mg(Zn, Al, Cu)2结晶相在均匀化过程中发生溶解的同时,一部分转变为Al2CuMg粒子,随着均匀化温度升高到470 ℃,Al2CuMg粒子溶入基体。

(a) 试样H400,400 ℃/12 h; (b) 试样SH450,400 ℃/12 h+450 ℃/12 h; (c) 试样SH470,400 ℃/12 h+470 ℃/12 h

图6 不同均匀化处理后的金相图

Fig.6 Optical micrographs of homogenized samples

2.4 Al3Zr粒子的析出行为

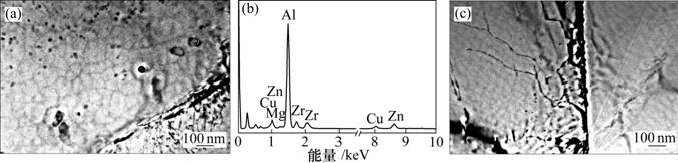

图7和图8所示分别为经过不同均匀化制度处理的样品中Al3Zr粒子在晶粒内部和晶界附近区域析出的透射电镜图。经检测,发现图7~8中的Al3Zr粒子均为共格态粒子,由于衍射方向不同而表现出不同的形貌状态。从图7(a)中可以看出:H400样品晶粒内部弥散析出大量细小(尺寸<10 nm)的Al3Zr粒子。图7(b)中H470试样晶粒内部Al3Zr粒子的数量远小于H400样品晶粒内部的数量。这主要是因为较低的均匀化温度增加了基体中Zr原子的过饱和固溶度,从而大大提高了形成Al3Zr粒子的驱动力。图7(c)中SH470试样晶粒内部的数量远高于H470试样晶粒内部的数量,且其尺寸较H400中Al3Zr粒子的尺寸大,这表明采用双级均匀化,细小的Al3Zr粒子能够在第一级低温段大量弥散析出,当温度升高到第二级时,Al3Zr粒子逐渐长大,即双级均匀化使Al3Zr粒子析出的含量大大增加。

从图8(a)可以看出:在SH450试样中,Al3Zr粒子在靠近晶界区域析出的数量少于晶粒内部析出的数量,且尺寸显著增大,但与H450(图8(c))相比,其晶界附近区域Al3Zr粒子析出量明显增多。由于Al和Zr元素熔点差距大,在合金铸锭凝固过程中,Zr元素的高熔点特性使Zr原子易成为结晶核心,从而导致Zr原子产生晶内偏析。Robson[11]报道了7050合金铸锭中Zr原子在枝晶臂中部聚集密度高于在晶界聚集的密度,经过均匀化处理后,Al3Zr粒子在晶粒不同区域的分布存在明显差异。研究所用的7085型铝合金的Zr含量与7050合金的Zr含量相似,采取两级均匀化处理(如SH450,SH470),在低温保温 (400 ℃/12 h)时,在靠近晶界处Al3Zr粒子可能会在未溶解的Mg(Zn, Al, Cu)2和转化的Al2CuMg粒子上异质形核析出、长大,于是,便出现了如图8(a)所示的Al3Zr粒子(其能谱图见图8(b))析出行为。而直接采用较高温度的单级均匀化处理(如H450试样),由于晶界处的Mg(Zn, Al, Cu)2相较快地溶入基体,减少了Al3Zr粒子可能异质形核的位置,所以,在晶界附近只有很少的Al3Zr粒子析出(如图8(c))。

综合上述实验结果,可以判定图1中的放热效应(D点和E点)应是由Al3Zr粒子在基体中析出放热所形成。由于DSC测试加热速度较快,铸锭试样在整个加热过程中伴随着非平衡共晶组织的溶解和熔化的剧烈放热效应,所以,不能从直接加热铸态试样的DSC曲线上看到Al3Zr粒子析出导致的放热效应。而经过均匀化处理的试样H400和H470,由于在此前的均匀化过程中已将大量的非平衡共晶溶入基体,所以,在DSC曲线的较低温度段(<470 ℃)不会发生明显的第二相溶解吸热效应,从而使Al3Zr粒子在加热过程中的析出放热效应得以显现。同时,还发现试样H400的DSC曲线上的效应(D点,390 ℃)比试样H470的DSC曲线上的效应(E点,450 ℃)提前约60 ℃出现。这可能是因为试样H400在DSC测试前晶粒内部已经析出均匀、弥散的Al3Zr粒子(图7(a)),晶界上又存在有大量Mg(Zn, Al, Cu)2和Al2CuMg粒子(如图5(a)),在一定程度上为Al3Zr粒子的析出提供了异质形核位置,降低了Al3Zr形核和激活能。而H470试样在DSC测试前晶粒内部析出的Al3Zr粒子较少,尺寸较大(图7(b)),且其晶界的Mg(Zn, Al, Cu)2和Al2CuMg粒子均已溶入基体,Al3Zr粒子析出缺少异质形核位置,从而增大了Al3Zr形核和激活能。此时,需要更高的温度以提高Zr原子的扩散速度,才能使Al3Zr粒子形核和长大。这就是图1中DSC曲线上反映Al3Zr粒子析出的放热效应(D点)比放热效应(E点)低60 ℃发生的 原因。

(a) 试样H400,400 ℃/12 h; (b) 试样H470,470 ℃/12 h; (c) 试样SH470,400 ℃/12 h+470 ℃/12 h

图7 不同均匀化制度样品的晶粒内部Al3Zr粒子的析出情况

Fig.7 Precipitations of Al3Zr particles within grains after homogenization

(a) 试样SH450,400 ℃/12 h+450 ℃/12 h; (b) SH450样品中Al3Zr粒子能谱图; (c) 试样H450,450 ℃/12 h

图8 不同均匀化样品晶界附近区域Al3Zr粒子的析出情况

Fig.8 Precipitations of Al3Zr particles in regions close to grain boundaries after homogenizations

综上所述,研究采用的7085型铝合金铸锭在均匀化处理时,晶粒内各区域Al3Zr粒子的析出行为不同。采用400 ℃/12 h+470 ℃/12 h的双级均匀化制度有利于提高Al3Zr粒子析出的数量,改善其分布均匀性。在第一级低温段(400 ℃/12 h),Al3Zr粒子在晶内高浓度区均匀形核,且不至于过快地长大,而在晶界附近区域又极有可能以缓慢溶解的Mg(Zn, Al, Cu)2相和新生成的Al2CuMg相为异质形核点进行形核、长大;在第二级高温段(470 ℃/12 h),Al3Zr粒子逐渐长大,粗大的Mg(Zn, Al, Cu)2相和Al2CuMg粒子均能溶入基体,从而较好地协同了不同种类第二相的溶解与析出行为,为后续加工过程中控制该合金基体组织的再结晶与性能提供较好的微结构条件。

3 结论

(1) Al-7.8Zn-1.6Mg-1.8Cu (7085型)合金铸锭及其微结构主要由α(Al)基体和分布在晶界的网状Mg(Zn, Al, Cu)2结晶相组成,晶内还有少量微米量级球状和纳米量级条状的Al2Cu结晶相,此外,还有纳米量级Al2Cu和Fe-rich析出相。

(2) 7085型铝合金铸锭中的Al2Cu相在均匀化温度达到450 ℃时已溶入基体,而Mg(Zn, Al, Cu)2结晶相在均匀化过程中发生溶解的同时,一部分转变为Al2CuMg相,随着均匀化温度升高到470 ℃,Al2CuMg粒子溶入基体,只剩下Fe-rich相和析出的Al3Zr粒子。

(3) 7085型铝合金铸锭均匀化处理时,晶粒内各区域Al3Zr粒子的析出行为不同;采用400 ℃/12 h+ 470 ℃/12 h双级均匀化比470 ℃/12 h单级均匀化更有利于提高Al3Zr粒子析出的数量,提高其分布均匀性。

参考文献:

[1] YAN Xia-li, PING Li, GANG Zhao, et al. The constituents in Al-10Zn-2.5Mg-2.5Cu aluminum alloy[J]. Materials Science and Engineering A, 2005, 397(1/2): 204-208.

[2] Mondal C, Mukhopadhyay A K. On the nature of T(Al2Mg3Zn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy[J]. Materials Science and Engineering A, 2005, 391(1/2): 367-376.

[3] 刘晓涛, 董杰, 崔建忠, 等. 高强铝合金均匀化热处理[J]. 中国有色金属学报, 2003, 13(4): 909-913.

LIU Xiao-tao, DONG Jie, CUI Jian-zhong, et al. Homogenizing treatment of high strength aluminium alloy cast under electric magnetic field[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 909-913.

[4] LI Hai, CAO Da-hu, WANG Zhi-xiu, et al. High-pressure homogenization treatment of Al-Zn-Mg-Cu aluminum alloy[J]. Journal of Materials Science, 2008, 43(5): 1583-1586.

[5] FAN Xi-gang, JIANG Da-ming, MENG Qing-chang, et al. The microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization[J]. Materials Letters, 2006, 60(12): 1475-1479.

[6] Toda H, Kobayashi T, Takahashi A. Mechanical analysis of toughness degradation due to premature fracture of course inclusions in wrought aluminium alloys[J]. Materials Science and Engineering A, 2000, 280(1): 69-75.

[7] 李国峰, 张新明, 朱航飞, 等. 7B50高强铝合金的均匀化[J]. 中国有色金属学报, 2008, 18(5): 764-770.

LI Guo-feng, ZHANG Xin-ming, ZHU Hang-fei, et al. Homogenizing treatment of 7B50 high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 764-770.

[8] XIE Fan-you, YAN Xin-yan, DING Ling, et al. A study of microstructure and microsegregation of aluminum 7050 alloy[J]. Materials Science and Engineering A, 2003, 355(1/2): 144-153.

[9] 贺永东, 张新明, 游江海. 7A55合金均匀化处理[J]. 中国有色金属学报, 2006, 16(4): 764-770.

HE Yong-dong, ZHANG Xin-ming, YOU Jiang-hai. Homogenizing treatment of 7A55 alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 764-770.

[10] Robson J D, Prangnel P B. Dispersoid precipitation and process modelling in zirconium containing commercial aluminium alloys[J]. Acta Materialia, 2001, 49(4): 599-613.

[11] Robson J D. Optimizing the homogenization of zirconium containing commercial aluminium alloys using a novel process model[J]. Materials Science and Engineering A, 2002, 338(1/2): 219-229.

[12] Zedalis M S, Fine M E. Precipitation and ostwald ripening in dilute Al Base-Zr-V alloys[J]. Metallurgical and Materials Transactions A, 1986, 17(12): 2187-2198.

[13] Chakrabarti D J, Liu J, Sawtell R R, et al. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity[J]. Materials Forum, 2004, 28: 969-974.

[14] Liu J. Advanced aluminum and hybrid aerostructures for future aircraft[J]. Materials Science Forum, 2006, 519/512: 1233-1238.

[15] Karabin M E, Barlat F, Schultz R W. Numerical and experimental study of the cold expansion process in 7085 plate using a modified split sleeve[J]. Journal of Materials Processing Technology, 2007, 189(1/3): 45-57.

[16] Luong H, Michael R. Hill. The effects of laser peening on high-cycle fatigue in 7085-T7651 aluminum alloy[J]. Materials Science and Engineering A, 2008, 477(1/2): 208-216.

[17] Shuey R T, Barlat F, Karabin M E, et al. Experimental and analytical investigations on plane strain toughness for 7085 aluminum alloy[J]. Metallurgical and Materials Transactions A, 2009, 40(2): 365-376.

收稿日期:2009-08-27;修回日期:2009-11-21

基金项目:国家重点基础研究发展计划(“973”计划)项目(2005CB623700)

通信作者:熊创贤(1973-),男,湖南益阳人,博士研究生,副教授,从事高强铝合金性能及加工研究;电话:0731-88876913;E-mail: xiongchuangxian@163.com

(编辑 刘华森)