文章编号: 1004-0609(2005)08-1167-06

热变形温度对TC18钛合金显微组织和力学性能的影响

沙爱学, 李兴无, 王庆如, 鲍如强

(北京航空材料研究院, 北京 100095)

摘 要: 研究了热变形温度从(tβ-25℃)~(tβ+20℃)变化时, 对TC18钛合金模锻件显微组织和拉伸、 冲击、 断裂韧度等主要力学性能的影响。 结果表明: 合金强度随变形温度升高变化不大, 均在1200MPa左右; 而塑性、 冲击韧性以及断裂韧度等性能指标对热变形温度变化反应敏感; 两相区变形时获得双态组织, 合金的塑性和冲击韧性较高, Ψ≥40%, aKU≥40J/cm2; 但断裂韧度偏低, KIC〈50MPa·m1/2。 β区变形时获得片状组织, 合金具有较高的断裂韧度, KIC>50MPa·m1/2; 但塑性和冲击韧性较低, Ψ≥20%, aKU≥25J/cm2。 在相变点附近变形时容易导致合金组织和性能出现不均匀性。

关键词: TC18钛合金; 热变形温度; 显微组织; 力学性能 中图分类号: TG146.23

文献标识码: A

Influence of hot deformation temperature on microstructure

and mechanical properties of TC18 alloy

SHA Ai-xue, LI Xing-wu, WANG Qing-ru, PAO Ru-qiang

(Beijing Institute of Aeronautical Materials, Beijng 100095, China)

Abstract: The influence of die forging temperature (changing from tβ-25℃ to tβ+20℃) on microstructure and mechanical properties such as tensile, impact and fracture toughness are studied when the other parameters kept consistent. The results show that ultimate strength of TC18(Ti-5Al-5Mo-5V-1Cr-1Fe) alloy remains at about 1200MPa when the die forging temperature increases. The ductility, impact property and fracture toughness are sensitive with the variety of die forging temperature. When deforming in α-β field, bimodel structure can be obtained. Ductility and impact toughness of the alloy are relatively high, but the fracture toughness is relatively low. Under this condition, the value of reduction of area and aKU are over 40% and 40J/cm2, respectively; KIC is lower than 50MPa·m1/2. When deforming in β field, lamellar structure can be obtained. The fracture toughness is relatively high, but ductility and impact toughness are lower than α-β field deforming. Under this condition, KIC is over 50MPa·m1/2, the value of reduction of area and aKU are over 20% and 25J/cm2, respectively. When deforming near beta transition point, it may lead to the uncertainty of microstructure and properties of TC18 alloy.

Key words: TC18 alloy; hot deformation temperature; microstructure; mechanical properties

与钢、 铝等合金不同, 钛合金的高低倍组织和力学性能对热变形温度十分敏感[1-5]。 对不同类型的钛合金, 变形温度对合金性能的影响程度不同[6-8]。 TC18钛合金是一种高合金化的α-β型两相合金, 其名义成分为Ti-5Al-5Mo-5V-1Cr-1Fe。 该合金退火后的强度与TC4、 TC6等合金固溶时效状态下的强度相当, 在1080MPa以上, 是退火状态下强度最高的钛合金[9]。 TC18钛合金的突出优点是最大淬透截面厚度可达250mm[9, 10], 而强度水平与其相当的Ti-1023淬透截面仅为100mm[11], Ti-17为150mm[12], 因此该合金在制造飞机大型承力结构件方面更具优势, 是一种很有前途的高强度铁合金。 目前欧美许多国家都开始对该合金的成分设计和性能水平展开研究[13-16], 但关于TC18钛合金热变形工艺的研究报道尚不多见, 已有的工艺参数实验都是在自由锻件上进行的, 得出的实验结果规律性不强[16, 17]。 这是由于在自由锻件上进行实验时受较多人为因素影响[18], 对道次变形量、 变形速率的控制很难作到前后一致, 因此得出的实验结果对模锻件生产的指导意义不大。 鉴于上述情况, 本文作者选择模锻件进行工艺实验, 实验中选择了4个温度, 即tβ-25℃、 tβ-10℃、 tβ+5℃和tβ+20℃, 考察了热变形温度对合金显微组织、 拉伸性能、 冲击韧性及断裂韧度的影响。 通过对组织和力学性能的综合评估, 可以根据设计要求优选出TC18钛合金合理的热变形温度范围。

1 实验

实验用料为TC18钛合金d220mm棒材, 其主要化学成分(质量分数, %)为: Al 5.86, Mo 4.72, V 5.00, Fe 1.00, 杂质总含量〈0.3, 其余为Ti。 选择某飞机零件(对应模锻件外形尺寸为440mm×225mm×98mm)作为本次工艺实验件。 模锻前先对原材料进行了预变形, 模锻采用的加热温度见表1。 锻后按统一的双重退火制度对模锻件进行热处理。 在Instron-4507万能实验机上测定拉伸性能, 试样d0= 5mm。 采用U型试样(10mm×10mm×50mm)在JB30B摆锤式冲击实验机上测定冲击性能。 采用紧凑拉伸试样(20mm×48mm×50mm)在MTS810-500KN实验机上测定KIC。 采用JSM-5800型扫描电镜进行微观组织及断口分析。

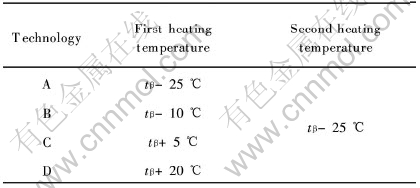

表1 模锻采用的加热温度

Table 1 Heating temperature of die forging

2 结果与分析

2.1 显微组织

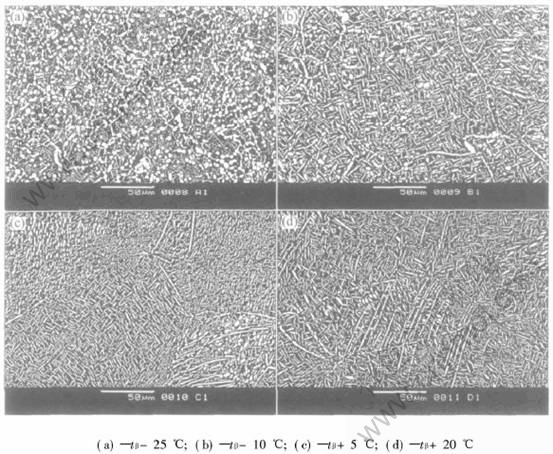

图1所示为合金不同模锻温度下退火态的显微组织照片。 由图1(a)可见, 按工艺A(tβ-25℃)变形时得到的是较典型的双态组织, 在β基体上分布着大量球状初生α相(αp), 约占40%左右。 由图1(b)可见, 按工艺B(tβ-10℃)变形时初生α相含量明显减少, αp≤5%, 并且可以看到少量未完全破碎的原始β晶界。 由图1(c)可见, 按工艺C(tβ+5℃)变形时, α相形态全部由等轴转变成片状, 晶界α相断续分布, 晶内α相编织良好。 由图1(d)可见, 按工艺D(tβ+20℃)变形时, 部分晶粒内可以看到较多取向一致的平直α相, 这种组织的出现往往会对合金的塑性造成不利影响。

图1 不同模锻温度下TC18钛合金的显微组织

Fig.1 Microstructures of TC18 alloy at different die forging temperatures

2.2 力学性能

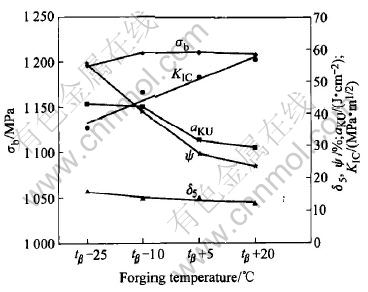

图2所示为不同热变形温度下TC18钛合金力学性能的变化趋势。 由图2可见, 合金的抗拉强度(L向)随变形温度升高变化不大, 均在1200MPa左右, 表明合金强度对宏观组织类型变化不敏感。 合金的塑性, 特别是断面收缩率对变形温度有明显的依赖关系, 随变形温度升高面缩明显降低。 但随着变形温度继续升高面缩的下降幅度趋于缓和, 在相变点以上20℃锻造时仍保持Ψ≥20%。 冲击韧性(L向)随变形温度升高呈阶段性变化: tβ-25℃~tβ-10℃温度区间冲击值保持在较高水平, aKU≥40J/cm2; tβ-10℃~tβ+5℃温度区间冲击值急剧下降; tβ+5℃~tβ+20℃温度区间冲击值变化不大, aKU在30J/cm2左右。 断裂韧度(T-L向)对锻造温度变化反映敏感, KIC值随锻造温度升高呈线性升高: 锻造温度每升高10℃, KIC约提高7MPa·m1/2。 这是因为随锻造温度升高, 组织中大量的片状α相能够有效改变裂纹扩展路径, 使裂纹扩展时所吸收的能量明显增加。

图2 不同热变形温度下TC18钛合金的室温力学性能

Fig.2 Mechanical properties of TC18 alloy at different die forging temperatures

2.3 断口分析

2.3.1 拉伸断口

图3所示为不同模锻温度下的拉伸断口形貌。 由图3可见, 按工艺A(tβ-25℃)锻造的拉伸断口为典型的韧性断口, 断口表面分布着深浅一致的小韧窝, 反映出合金晶粒尺寸很细小。 按工艺B(tβ-10℃)锻造时的断口为韧脆混合形貌, 相对于工艺A而言, 该断口中的韧窝稍浅一些, 同时可以看到一部分裂纹沿晶界扩展留下的晶粒轮廓。 相变点以上锻造(工艺C和工艺D)的拉伸断口均属于延性沿晶断裂断口, 即断裂路径是沿晶界断裂, 断裂方式是延性的, 在断裂过程中沿晶界产生了一定的塑性变形。 其中按工艺C(tβ+5℃)锻造的拉伸断口表面韧窝比工艺D(tβ+20℃)更多一些。 断口形貌由韧到脆的变化很好地反映出合金断面收缩率不断降低的变化规律。

图3 不同模锻温度下TC18钛合金拉伸试样断口形貌

Fig.3 Tensile fractographies of TC18 alloy at different die forging temperatures

2.3.2 冲击断口

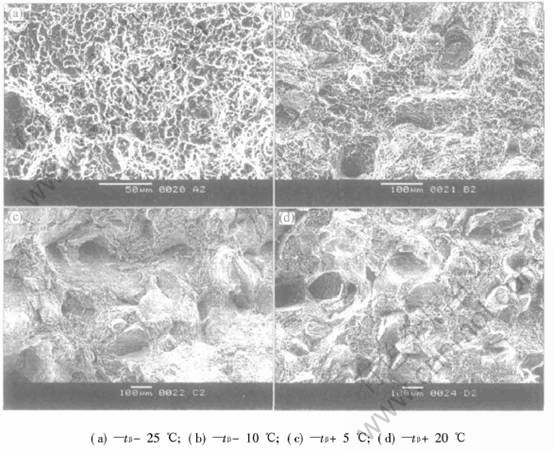

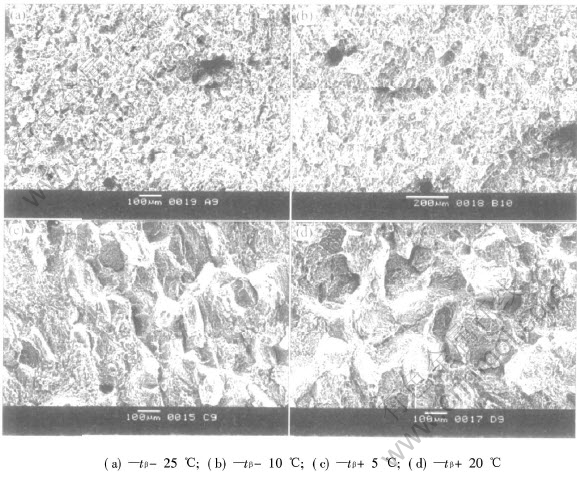

图4所示为不同锻造温度下的冲击断口SEM照片。 由图可见, 相变点以下锻造和相变点以上锻造时冲击试样的断口形貌有明显差异: 相变点以下锻造时(图4(a)和4(b))的冲击断口形貌相近, 均为韧性断口, 断口表面有均匀的韧窝; 相变点以上锻造时(图4(c)和4(d))均为韧性沿晶断口, 裂纹沿晶界扩展, 还可以看到少量二次沿晶裂纹。 断口形貌在跨相变点温度区间(tβ-10℃→tβ+5℃)的突变与合金冲击值的阶段性变化一致。

图4 不同模锻温度下TC18钛合金冲击试样断口的SEM照片

Fig.4 SEM fractographies of TC18 alloy impact specimens at different die forging temperatures

3 讨论

研究了热变形温度与TC18钛合金拉伸、 冲击及断裂性能的关系。 实验结果表明, 在统一的热处理制度下, 合金强度对变形温度和宏观组织类型的变化不敏感, 均在1200MPa左右。 早期研究工作表明, TC18合金抗拉强度主要取决于双重退火时的第二级退火温度。 随第二级退火温度上升, β相中的次生α相明显粗化, 导致强化效果减弱。 在570~650℃温度范围内, 退火温度每升高10℃, 强度降低20MPa左右[19]。 因此调整TC18钛合金的强度水平应通过改变热处理制度实现。

合金的塑性、 冲击性能和断裂韧度对变形温度有明显的依赖关系。 常规两相区变形时, 合金具有很高的塑性, 拉伸断口颈缩明显。 塑性的降低主要 发生在tβ-25℃→tβ+5℃温度区间, 由于球状初生α相含量的迅速减少, 合金的断面收缩率呈线性下降。 随变形温度继续升高, 塑性的下降趋势得到缓解, 在相变点以上20℃变形时, 仍可保证合金的δ5≥10%, Ψ≥20。 这是因为TC18钛合金中具有较高的β稳定元素含量, 对相变点以上的晶粒快速长大具有抑制作用, 从而保证了合金的塑性水平。 冲击韧性的变化也主要是在跨相变点温度区间, 由于断裂方式由穿晶韧性断裂变为韧性沿晶断裂, 导致冲击值下降10J/cm2以上。 合金的断裂韧度对变形温度的变化最为敏感, 在本次实验条件下, 变形温度每升高10℃, KIC约提高7MPa·m1/2。 这是由于片状或条状的初生α相可以最大程度地改变裂纹扩展路径, 使裂纹扩展时消耗的能量大大增加。

总的来说, 合金的塑性与断裂韧度之间是一对矛盾关系。 要追求高的塑性和冲击值指标, 应选择相变点以下变形, 获得等轴或双态组织; 要想得到较高的断裂韧度, 则应选择相变点以上变形, 获得片状组织。 由此带来的塑性和冲击韧性损失可以通过调整热处理制度进行不同程度的补救。 在跨相变点温度区间, 由于组织类型的变化, 合金的塑性值和冲击值都会有较大波动, 对应的低倍组织均匀性也较差, 因此在该温度区间进行TC18钛合金热变形时应开展更多的研究工作。

4 结论

1) TC18钛合金的强度随模锻温度升高变化不大, 而塑性, 特别是断面收缩率、 冲击韧性以及断裂韧度等性能指标对模锻温度变化反应敏感。

2) 两相区锻造时获得双态组织, 合金的塑性和冲击韧性较高, 其中δ5≥13%, Ψ≥40%, aKU≥40J/cm2; 但断裂韧度偏低, KIC〈50MPa·m1/2。

3) β区锻造时获得片状组织, 合金具有较高的断裂韧度, KIC在50~60MPa·m1/2之间; 塑性和冲击韧性较低, 但仍能保证δ5≥10%, Ψ≥20%, aKU≥25J/cm2。

REFERENCES

[1] Semiatin S L, Seetharaman V, Weiss I. Hot working of titanium alloys-an overview[A]. Weiss I, Srinvasan R, Bania P J, et al. Advances in the Science and Technology of Titanium Alloy Processing[C]. Anaheim: TMS, 1997. 3-37.

[2] Howson T E, Broadwell R G. The design, production, and metallurgy of advanced, very large, titanium aerospace forgings[A]. Weiss I, Srinvasan R, Bania P J, et al. Advances in the Science and Technology of Titanium Alloy Processing[C]. Anaheim: TMS, 1997. 143-152.

[3] Brun M, Shachanova G. Principles of titanium alloys' structure control with the purpose of increasing their mechnanical properties[A]. Weiss I, Srinvasan R, Bania P J, et al. Advances in the Science and Technology of Titanium Alloy Processing[C]. Anaheim: TMS, 1997. 193-199.

[4] 王新平, 孟祥军, 刘茵琪. 热变形参数对亚稳定β型钛合金组织和性能的影响[J]. 金属学报, 1999, 35(S1): S456-S459.

WANG Xing-ping, MENG Xiang-jun, LIU Yin-qi. The effect of thermal deformation parameters on microstructure and properties of metastable beta titanium alloy[J]. Acta Metallurgica Sinica, 1999, 35(S1): S456-S459.

[5] 朱知寿, 王庆如, 郑永灵, 等. 损伤容限型钛合金新型β锻造工艺[J]. 中国有色金属有色学报, 2004, 14(S3): 13-16.

ZHU Zhi-shou, WANG Qing-ru, ZHENG Yong-ling, et al. A new β forging processing for damage tolerance titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S3): 13-16.

[6] 张庆玲, 李兴无, 储俊鹏, 等. 变形温度对TA15合金组织的影响[J]. 金属学报, 2002, 38(S1): S161-S163.

ZHANG Qing-ling, LI Xing-wu, CHU Jun-peng, et al. The effect of upset deformation temperature on microstructure of TA15 alloy[J]. Acta Metallurgica Sinica, 2002, 38(S1): S161-S163.

[7] 徐 锋, 黄爱军, 李阁平, 等. 热工艺对TC6钛合金显微组织的影响[J]. 金属学报, 2002, 38(S1): S174-S177.

XU Feng, HUANG Ai-jun, LI Ge-ping, et al. Effect of heat treatment on microstructure of TC6 alloy[J]. Acta Metallurgica Sinica, 2002, 38(S1): S174-S177.

[8] 姚泽坤, 郭鸿镇, 杨 陈, 等. 热力参数对Ti-17合金等温锻件显微组织和力学性能的影响[J]. 金属学报, 2002, 38(S1): S164-S167.

YAO Ze-kun, GUO Hong-zhen, YANG Chen, et al. The effect of thermodynamic parameters on microstructure and mechanical properties of Ti-17 alloy[J]. Acta Metallurgica Sinica, 2002, 38(S1): S164-S167.

[9] 王金友, 葛志明, 周彦邦. 航空用钛合金[M]. 上海: 上海科学技术出版社, 1985. 161-163.

WANG Jin-you, GE Zhi-ming, ZHOU Yan-bang. Titanium for Aviation Usage[M]. Shanghai: Shanghai Science and Technology Press, 1985. 161-163.

[10] Polkin S, Rodionov V L, Stroshkov A N, et al. Structure and mechanical properties of VT22(α+β)high strength titanium alloy semiproducts[A] Froes I H, Caplan I. Titanium92: Science and Technology[C]. San Diego: TMS, 1992. 1569-1572.

[11] Chen C C, Boyer R R. Practical considerations for manufacturing high-strength Ti-10V-2Fe-3Al alloy forgings[J]. Journal of Metals, 1979, 31(7): 33-39.

[12] William F B Jr. Aerospace Structural Metals Handbook(Vol.4)[M]. West Lafayette: CINDAS/USAF CRDA Handbooks Operation, 1994. 3724.

[13] Lyasotskaya V S, Knyazeva S I, Fedorava L V. The selection of thermocycling treatment types applied to the welded joints of titanium alloys[A]. Lütjering G, Albrecht J. Ti-2003 Science and Technology[C]. Hamburg: DGM, 2004. 707-710.

[14] Kubiak K, Hadasik E, Sieniawski J, et al. Influence of Microstructure on hot plasticity of Ti-6Al-4V and Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloys[A]. Lütjering G, Albrecht J. Ti-2003 Science and Technology[C]. Hamburg: DGM, 2004. 371-376.

[15] Horwath W, Marketz W, Gach E. Take-off on titanium[A]. Lütjering G, Albrecht J. Ti-2003 Science and Technology[C]. Hamburg: DGM, 2004. 2713-2719.

[16] Fanning J C, Boyer R R. Properties of TIMETAL 555—a new near-beta titanium alloy for airframe components[A]. Lütjering G, Albrecht J. Ti-2003: Science and Technology[C]. Hamburg: DGM, 2004. 2643-2649.

[17] 盛险峰, 丁志文, 朱益藩. 变形量和热处理工艺对Ti-5Al-5Mo-5V-1Cr-1Fe钛合金组织和性能的影响[J]. 金属学报, 1999, 35(S1): S465-S468.

SHENG Xian-feng, DING Zhi-wen, ZHU Yi-fan. The effects of deformation and heat treatment on the microstructure and properties of Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloys[J]. Acta Metallurgica Sinica, 1999, 35(S1): S465-S468.

[18] Mitchell A. Melting, casting and forging problems in titanium alloys[J]. Mater Sci Eng A, 1998, A243: 257-262.

[19] 沙爱学, 李兴无. 热处理工艺参数对TC18钛合金显微组织和力学性能的影响[J]. 材料工程, 2002, 208(增刊): 23-26.

SHA Ai-xue, LI Xing-wu. Effect of heat-treatment parameter on the microstructure and mechanical properties of TC18 titanium alloy[J]. Journal of Materials Engineering, 2002, 208(S): 23-26.

收稿日期: 2005-01-15;

修订日期: 2005-04-01

作者简介: 沙爱学(1973-), 女, 高级工程师, 博士.

通讯作者: 沙爱学, 博士; 电话:010-62496630-82; 传真: 010-62496640; E-mail: aixue.sha@biam.ac.cn

(编辑 龙怀中)