固液混合铸造Al-10Mn合金坯料的挤压

何建军, 陈振华, 严红革

(湖南大学 材料科学与工程学院, 长沙 410082)

摘 要: 采用固液混合铸造技术制备了Al-10Mn合金坯料, 将坯料进行热挤压加工, 研究了加热温度对挤压加工的影响及传统铸造、 固液混合铸造以及固液混合铸造坯料的热挤压加工制备的Al-10Mn合金的显微组织和力学性能。 结果表明: 固液混合铸造合金的析出相细小、 均匀、 圆整, 抗拉强度提高到130MPa, 热挤压后合金的抗拉强度增加到181MPa; 当坯料加热温度为600℃时, 挤压加工的合金具有最好的力学性能和较为均匀的显微组织; 当坯料加热温度为570℃时, 坯料则不能顺利挤出; 而当坯料加热温度高于610℃时, 合金力学性能大幅降低。

关键词: Al-Mn合金; 铸造; 固液混合铸造; 挤压 中图分类号: TG292

文献标识码: A

Al-10Mn alloys prepared by solid-liquid mixed casting and subsequent extruding process

HE Jian-jun, CHEN Zhen-hua, YAN Hong-ge

(College of Materials Science and Engineering,Hunan University, Changsha 410082, China)

Abstract: The Al-10Mn alloys were prepared by the solid-liquid mixed casting process and subsequent hot extrusion process, and the microstructures and mechanical properties were investigated. The influence of heating temperature on the extruding process was also studied. The results show that the precipitated phases of solid-liquid mixed casting billets are fine, uniformity and near spherical shape, and its tensile strength is improved to 130MPa. The tensile strength of the billets after subsequent hot extrusion process is greatly improved to 181MPa. When the heating temperature of billets is 600℃, the alloys produced by hot extrusion process have the best mechanical properties and microstructures. They can not be extruded successfully at below 570℃, while their mechanical properties decrease greatly at above 610℃.

Key words: Al-Mn alloy; casting; solid-liquid mixed casting; extrusion

固液混合铸造是一项新型的材料制备技术[1, 2], 将大量同种成分或润湿性好的异种合金粉末加入到过热的合金熔体中强烈搅拌, 当合金熔体处于某一半固态时, 迅速将浆料转移压铸成形或进行其它热加工的一种材料制备技术。 固液混合铸造能有效细化合金晶粒, 提高材料性能[3], 是一种有效的微晶材料制备技术。 采用这项技术制备的Al-Cr和Al-Si等高合金含量的合金组织中, 基体和析出相都被有效地细化, 析出相均匀圆整, 消除了铸态组织中粗大的网状枝晶结构, 提高了其力学性能[4, 5]。 同常规的半固态加工[6]一样, 固液混合铸造也可以先制备合金坯料, 再进行后续的各种热加工, 或者重新加热到半熔融状态后进行触变成形。 固液混合铸造的触变成形包括触变压铸、 触变挤压、 触变轧制和触变锻造等, 这些加工工艺更具有实际生产应用价值。 热挤压是一项改善合金组织和提高合金性能的重要塑性加工方法。 然而许多铸造高合金化材料, 由于析出相十分粗大, 塑性几乎为零, 其热加工性能很差, 不能进行挤压加工。 这些材料如果先通过固液混合铸造细晶技术细化晶粒和析出相、 改善显微组织后, 再进行挤压等热加工, 将有可能获得较好的加工性能和力学性能, 由此也可能探索一条拓展可应用合金成份范围的重要途径。

选用Mn含量较高(Al-10%Mn, 质量分数)的Al-Mn合金进行研究, Al-Mn合金有具很好的范性、 良好的抗蚀性和可焊性, 且Al-Mn合金的强度随Mn含量的增加而提高。 工业用Al-Mn合金只含有1.0%~1.6%的锰, 当Mn含量较高时, 传统铸造会形成粗大、 硬脆的Al6Mn化合物, 其力学性能极差, 塑性几乎为零, 不能进行后续的热加工, 限制了其应用。 Mn在Al中的共晶温度为658℃, 溶解度为1.82 %, 其热处理强化能力有限。 目前, Mn含量较高的Al-Mn合金研究较少, 合金成分的应用范围受到传统制备技术的限制。 为了提高Al-Mn高合金的力学性能, 本文作者采用固液混合铸造工艺制备显微组织和成形性能改善的Al-10Mn合金坯料, 然后对其进行热挤压加工的工艺路线。

1 实验

1.1 固液混合铸造坯料的制备

图1所示为Al-Mn合金的固液混合铸造实验流程图。

将工业纯Al和纯Mn在中频感应炉中熔炼成Al-10Mn合金熔体, 一部分浇入石墨黏土坩埚中, 自然冷却凝固后用以研究传统铸造的组织和性能以及作为后面固液混合铸造的原始坯料; 另一部分用于雾化制粉。 Al-10Mn合金粉末采用自制的设备氮气雾化制粉, 然后经过烘干、 筛分而制得, 氮气压力为10MPa, 喷嘴直径为4mm。

固液混合铸造时, 将Al-10Mn合金置于自制的固液混合铸造机的搅拌室坩埚中加热熔化(900℃), 将粒径小于175μm的Al-Mn合金急冷粉末(粉末加入量为坯料质量的40%)加入合金熔体中并强烈搅拌, 同时关闭搅拌室加热电炉的电源, 熔体迅速达到半固态, 搅拌速度为100r/min, 搅拌时间为3min, 然后将浆料迅速转移至预热的压铸模中压铸成试棒, 压铸模预热温度为600℃。 将试样车去表层后制成d49×100mm坯料, 然后进行热挤压实验。

1.2 固液混合铸造坯料的热挤压

在将坯料重新加热至半固态然后进行挤压的实验过程中, 如果坯料加热温度过高, 保温时间太长, 坯料中液相量较大, 则容易出现坍塌变形或“流汤”现象, 不利于试样的夹持和转移。 且在试样转移、 挤压模具的装配过程中, 试样冷却较快, 导致温度测量误差较大。 本研究中试样虽然没有加热到半固态, 但由于试样较小, 出炉后降温很快, 试样温度过低以致无法挤出。 因此, 本研究对加热方式和挤压模具进行了改进, 采用H13 热作模具钢制作挤压模具, 先将挤压模具置于箱式炉加热到指定温度(如600℃), 然后将模具取出, 将试样和垫片快速和模具装配在一起, 再一起重新置于箱式电阻炉中加热, 到一定温度后保温30min, 将模具转移至立式四柱液压机上进行挤压。 Al-10Mn合金加热温度分别为580、 590、 600和610℃, 采用机油石墨润滑, 挤压压力为160MPa, 挤压速度为50mm/s, 挤压比为4∶1。

将固液混合铸造压铸试棒和后续热挤压试棒加工成圆棒形拉伸试样, 在济南试金集团生产的WDW-E200型拉伸机上测试力学性能, 再分别取样制得金相试样观测其显微组织并测试其硬度。 金相试样磨好抛光后用5 %的氢氟酸腐蚀, 显微组织照片采用德国Leixz MM6金相显微镜和PiexLINK capture图像摄制分析系统拍摄, 硬度测试在HBRVU-187.5型布洛维硬度计上进行, 压头钢球直径为2.5mm, 载荷613N。

图1 Al-Mn合金的固液混合铸造实验流程图

Fig.1 Experimental flow chart of solid-liquid mixed casting process

2 结果与分析

2.1 组织和力学性能

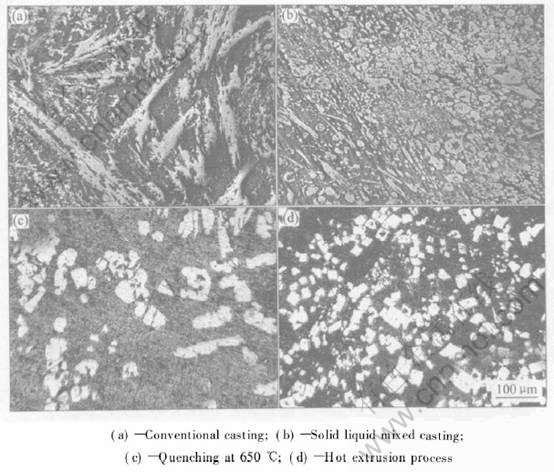

传统铸造Al-10Mn合金组织非常粗大, 其尺寸可达毫米级, 呈板条状和发射状(图2(a)), 这种组织的合金极脆, 塑性几乎为零, 其抗拉强度约为30~40MPa, 根本不能应用。 采用固液混合铸造工艺, 有效地细化了Al-10Mn合金的析出相, 绝大部分析出相呈近球状或等轴状(图2(b))。

由于固液混合铸造是在过热的合金熔体中加入同种成分的合金粉末, 且粉末的添加量很大, 当室温的粉末加入到熔体中时, 一部分粉末熔解, 而另一部分和熔体同处某一半固态温度, 这样粉末会吸收大量的热量, 导致粉末周围的熔体快速凝固, 过冷度瞬间急剧增大。 过冷度越大, 晶核形成的临界半径越小, 晶核的形核功越小, 达到临界半径的晶坯数量就越多, 形核率越大, 晶粒就非常微细。 加入同种成分的粉末进行固液混合铸造, 由于结构相似, 粉末与金属熔体润湿, 因而两者在界面两边的原子具有良好的匹配关系。 两者匹配得愈好, 其间的界面张力愈低, 界面能也越小。 界面上晶核原子和同种粉末原子相互间位错度(或称不匹配度)δ值很小, 当δ值很小时, 过冷度ΔT与δ之间有如下关系[7]:

ΔT∝δ2

因此, 非均匀形核的过冷度很低, 有利于非均匀形核。 强烈的机械搅拌除了将加入的粉末均匀分散在合金熔体中外, 还能细化晶粒、 球化枝晶的作用。 强烈的搅拌引起金属液的强烈紊流, 晶粒处于基本等温的环境, 其形核在全面过冷的金属液中同时进行。 较大搅拌速度可以促使温度场、 浓度场的均匀, 从而降低负温度梯度和溶质富集, 直接抑制枝晶前端的进一步失稳生长并促使晶粒增殖; 搅拌使得粗化过程由长程扩散转变为界面短程控制, 进而缩短粗化时间; 一定的搅拌时间可使晶粒充分粗化而演变为近球形。

图2(c)所示为固液混合铸造坯料二次加热到650℃迅速淬火的组织。 由图2(c)可以看出, 经过重新加热、 保温后, 合金中Al6Mn析出相尺寸变大, 数目减少, 经过二次加热后, 晶粒球化明显, 第二相的数量、 尺寸有所减少(图2)。 其原因一方面是由于铸锭中的少部分枝晶组织, 当加热到合金的固相线温度以上时, 发生枝晶熔断, 即晶界处低熔点相首先熔化, 枝晶块游离于液体中。 根据DLA模型[8], 枝晶块上曲率大的地方, 熔点低, 优先熔化, 因此, 枝晶更易从曲率大的地方熔断, 而得到近球形组织; 另一方面是由于这种近球形组织与铸锭中大部分非枝晶组织在表面张力的作用下自发收缩成球形。

图2 不同工艺条件下Al-10Mn合金的显微组织

Fig.2 Microstructures of Al-10Mn alloy prepared by different processes

图2(d)所示为固液混合铸造坯料热挤压组织。 由图2(d)可看出, 析出相大多呈四方形, 棱角分明完全没有长柱状相且合金各部分组织均匀。 Al-10Mn合金在挤压过程中, 合金发生塑性变形和流动, 硬脆的Al6Mn相被破碎, 同时由于压铸过程中产生的气孔、 冷隔等缺陷得到有效减少, 使材料更加致密。 表1所列 为不同工艺条件制备Al-10Mn合金的力学性能。 由表1可看出, 传统铸造的Al-10Mn合金的抗拉强度很低, 由于固液混合铸造时加入的大量合金粉末, 熔体的快速凝固增大了α-Al的固溶度, 合金产生固溶强化, 同时消除了铸态的粗大枝晶和网状组织, 细化了析出相并使其均匀圆整, 由Hall-Petch公式:

d为合金平均晶粒度。

可知, 当合金的平均晶粒度d减小时, 固液混合铸造流变压铸后合金的强度得到一定的提高。 固液混合铸造合金再经过热挤压, 合金致密度提高, 固液混合铸造的加粉搅拌和转移压铸过程中产生的氧化物得到一定程度的破碎, 其中未熔聚团的合金粉末能较为均匀地分布于合金中, 力学性能也大幅度提高到了181MPa。

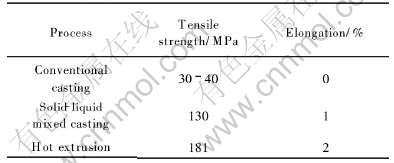

表1 不同工艺条件制备Al-10Mn合金的力学性能

Table 1 Mechanical properties of Al-10Mn alloys prepared by different processes

2.2 不同加热温度对挤压实验的影响

二次加热温度是合金挤压实验的重要工艺参数, 本研究分别采用加热温度为580、 590、 600和610℃, 其它工艺参数相同, 固液混合铸造坯料热挤压后的组织如图3所示。

在进行挤压实验时发现, 当加热温度低于570℃时, 挤压抗拉急剧增大, 不能顺利挤出, 取出坯料可以观察到, 试样出现碎裂现象; 当加热温度为580℃时, 加热对析出相影响不大, 合金基体较硬, 挤压后硬脆的析出相破碎成大小不一的块状, 形状很不规则, 尺寸差别很大且分布不均匀(图3(a)); 当加热温度继续升高时, 合金在挤压实验时流动性较好, 析出相大致呈四方块形状, 尺寸大体一致且分布均匀, 析出相破碎均匀(图3(b)和(c)); 当加热温度达到610℃甚至更高时, 合金基体较软, 挤压抗力大大减小, 挤压对硬脆的Al6Mn析出相破碎作用有限, 析出相部分破碎但有团聚现象, 有的甚至呈絮状, 合金的致密度也不高(图3(d))。 图中仍然存在一些孔洞(A), 这是由于合金在挤压过程中的挤压比不大, 挤压抗力较小, 对材料的致密化效果不好, 且这些热挤压试棒相应的抗拉强度和硬度相差较大所致。

图3 固液混合铸造Al-10Mn合金不同加热温度挤压的微观组织

Fig.3 Microstructures of Al-10Mn alloys prepared by solid liquid mixed casting after extruding at different temperature(A is pole)

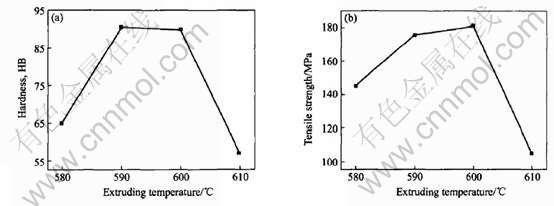

图4所示为挤压温度对Al-10Mn合金力学性能的影响。 由图4可看出, 加热温度对挤压合金的性能影响很大, 当加热温度为590~600℃时, 合金的硬度和抗拉强度最大; 继续升高温度, 当温度到达610℃时, 其硬度和抗拉强度则大幅下降。 在挤压实验中发现, 当坯料温度到达610℃时, Al-10Mn合金基体较软, 挤压抗拉显著减小, 挤压加工对析出相的破碎效果逐渐下降, 同时对合金的致密度效果也不明显。 在进一步的研究中发现, 当坯料加热温度低于570℃时, 挤压抗拉急剧增大, 不能顺利挤出, 取出坯料可以观察到, 试样出现碎裂现象。 因此, Al-10Mn合金在600℃挤压能获得较好的力学性能。

3 讨论

很多高合金化铸件如Al-Mn、 Al-Cr、 Al-Ni和Al-Co等, 由于在铸造过程中的冷速受到限制, 会产生晶粒和析出相粗大、 成分偏析严重等问题, 在挤压和锻造加工时的变形不均匀, 从而引起铸件开裂。 采用增大铸件冷却速度、 提高金属液流动性和对金属液进行变质处理等一系列方法可以解决显微组织粗大问题。 近年来, 半固态加工[9, 10]和喷射沉积[11-13]等一系列新技术制备细晶材料方面得到了广泛的应用。 固液混合铸造兼有半固态加工优点和喷射沉积中的快速凝固细晶的特点, 相比于在金属或合金熔体中加入Al-/Ti-/B等晶粒细化剂的化学细晶法[14]来说, 固液混合铸造加入的是大量同成分的快冷合金粉末, 粉末作为形核核心能与析出相和晶粒有较好的润湿性, 不会造成合成合金污染, 且合金粉末种类不受限制, 甚至还可以细化纯金属的组织。 高合金化材料在晶粒和析出相细化及组织均匀后, 力学性能提高, 有望提高其后续加工性能。 固液混合铸造制备的坯料与喷射沉积坯料组织相当, 但由于搅拌效果的影响和粉末在熔体中的均匀分散方面的问题, 制备的大尺寸合金的组织均匀性还不够。

在固液混合铸造过程中, 由于加入大量合金粉末, 使得合金熔体迅速降温并有一部分快速凝固成固相, 强烈的机械搅拌时间很短, 将粉末快速均匀分散在熔体中是固液混合铸造技术要解决的关键问[CM(22]题。 合金在加粉搅拌、 浆料转移压铸过程中可能造

图4 挤压温度对Al-10Mn合金力学性能的影响

Fig.4 Influence of heating temperature on mechanical properties of Al-10Mn alloys during extruding

成氧化和吸气, 通过将固液混合铸造坯料进行加热挤压加工, 可以在一定程度上消除这些缺陷, 提高力学性能。 因此, 采用固液混合铸造制坯和后续热挤压加工的材料制备路线, 可以适当降低在制坯操作中的工艺要求, 同时也有利于实现批量生产。

4 结论

1) 对Al-10%Mn合金的传统铸造、 固液混合铸造以及固液混合铸造坯料的热挤压加工, 发现固液混合铸造能显著细化Al-10%Mn合金的析出相, 使其均匀、 圆整, 抗拉强度大幅提高到130MPa, 其后续加工性能得以改善。

2) 固液混合铸造坯料的热挤压加工, 使Al-10%Mn合金中析出相破碎为棱角分明的方形, 抗拉强度提高到181MPa。

3) 当坯料加热温度为600℃时, 挤压加工的合金具有最好的硬度和抗拉强度, 其显微组织也较为均匀; 当温度低于570℃时, 合金开裂, 不能顺利地挤出; 当坯料加热温度高于610℃时, 合金挤压抗力显著下降, 合金力学性能也大幅降低。

REFERENCES

[1]陈振华. Al-Si合金固液混合铸造[J]. 中国有色金属学报, 2000, 10(3): 349-352.

CHEN Zhen-hua. Solid-liquid mixing casting of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(3): 349-352.

[2]陈振华, 严红革, 陈刚, 等. 合金和复合材料的固液混合铸造技术[P]. CN ZL00113221. 2000-01-13.

CHEN Zhen-hua, YAN Hong-ge, CHEN Gang et al. Solid-liquid Mixed Casting Technology for Alloy and Composite Materials[P]. CN ZL00113221. 2000-01-13.

[3]陈振华, 严红革, 陈刚, 等. Al-8.7Fe-1.6V-1.3Si耐热铝合金的固液混合铸造[J]. 中国有色金属学报, 2002, 12(3): 422-425.

CHEN Zhen-hua, YAN Hong-ge, CHEN Gang, et al. Mixed solid liquid casting processing of Al-8.7 Fe-1.6V-1.3Si elevated temperature alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 422-425.

[4]程相飞, 严红革, 陈振华, 等. 固液混合铸造制备Al-10Cr合金的研究[J]. 特种铸造及有色合金, 2005, 25(2): 85-87.

CHENG Xiang-fei, YAN Hong-ge, CHEN Zhen-hua, et al. Preparation of Al-10Cr alloy by mixed liquid-solid casting[J]. Special Casting and Nonferrous Alloys, 2005, 25(2): 85-87.

[5]CHEN Zhen-hua, HE Jian-jun, YAN Hong-ge, et al. New technology for the preparation of fine-grained aluminum alloy[J]. Metal Casting Technologies, 2005, 12(12): 28-33.

[6]Fan Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 48-59.

[7]胡汉起. 金属凝固原理[M]. 第二版. 北京: 机械工业出版社, 2000.

HU Han-qi. Principle of Metal Solidification[M]. 2nd ed. Beijing: China Machine Press, 2000.

[8]Chen C P, Tsao C Y A. Response of spray deposited stirred cast and conventional cast Pb Sn alloys to deformation in semisolid state[J]. Journal of Materials Science, 1995, 30: 4019-4023.

[9]Flemings M C. Behavior of metal alloy in the semisolid state[J]. Metall Trans A, 1991, A22(4): 957-981.

[10]Flemings M C, Rleck R G, Young K P. Rheocasting[J]. Mater Sci Eng, 1976, 25(1-2): 103-117.

[11]Johnson S. Net-shape P/M applications[J]. Int J Powder Metall, 1990, 26(3): 27-30.

[12]康智涛, 张豪, 陈振华. 6066/SiCp喷射共沉积复合材料的半固态加工[J]. 中国有色金属学报, 1998, 8(4): 595-599.

KANG Zhi-tao, ZHANG Hao, CHEN Zhen-hua. Semi-solid processing of spray co-deposited 6066/SiCp composites[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(4): 595-599.

[13]Singer A R E. Recent developments in the spray forming of metals[J]. Inter J of Powder Metall and Powder Tech, 1985, 21(3): 219-225.

[14]Backerud L, Yidong S. Grain refining mechanisms in aluminum as a result of additions of titanium and boron[J]. Aluminum(Part Ⅰ & Ⅱ), 1991, 67: 780-785.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50274037)

收稿日期: 2005-11-09; 修订日期: 2006-01-12

通讯作者: 何建军; 电话: 0731-8821648; 传真: 0731-8821648; E-mail: hejianjun329@126.com